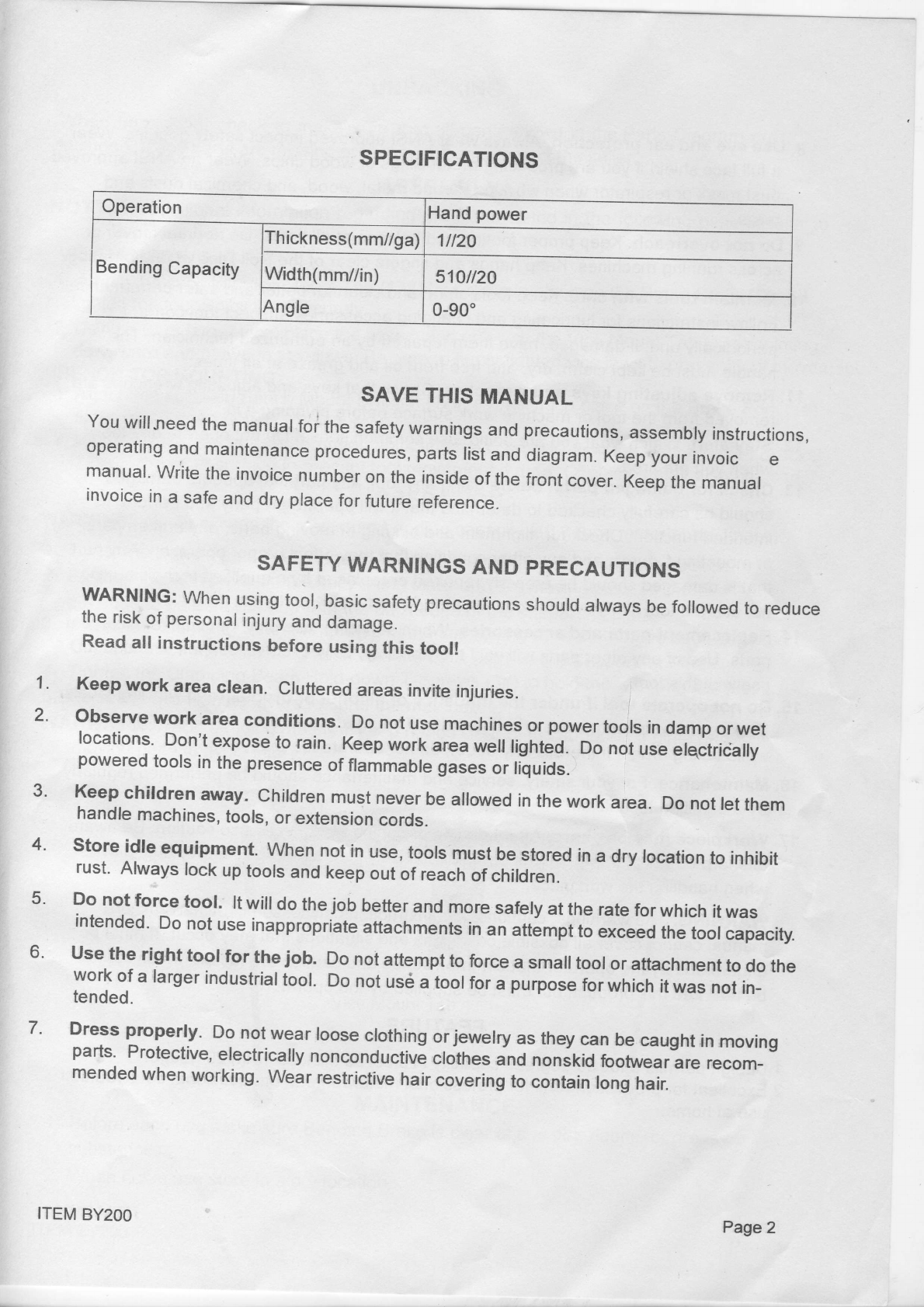

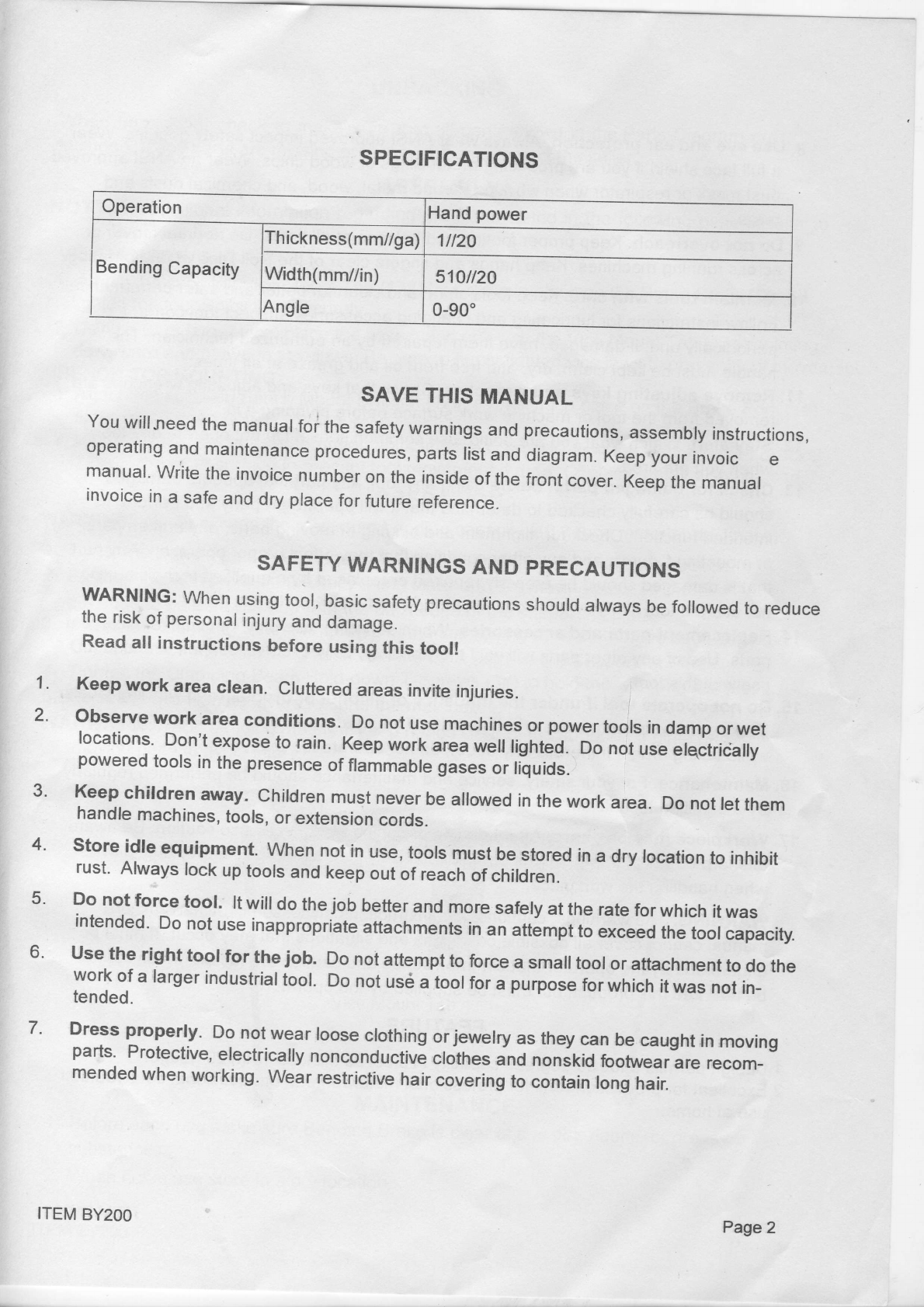

SPECIFICATIONS

Operation Hand

power

Bending

Capacity Thickness(mm//ga)

1il20

Width(mm//in) 510il20

Angle 0-90'

SAVE

THIS

MANUAL

You

willneed

the

manual

toi

the

safety

warnings

and

precautions,

assembly

instructions,

operating

and

maintenance

procedures,

parts

list

and

diagram.

Keep

your

invoic e

manual'

wiitethe

invoice

number

on

theinside

of

the

front

cover.

Keep

the

manual

invoice

in

asafe

and

dry

place

for

future

reference.

SAFETY

WARNINGS

ANDPRECAUTIONS

WARNING:

When

using

tool,

basic

safety

precautions

should

always

befollowed

toreduce

therisk

of

personal

injury

and

damage.

Read

allinstructions

before

using

this

tool!

Keep

work area

clean. Cluttered

areas

invite

injuries.

observework area

conditions. Do

not

use

machines

orpower

tools

in

damp

or

wet

locations'

Don't

expose

torain. Keep

work

area

wetl

lighted.

Do

not

use

elqctrically

poweredtoo|sinthepresenceoff|ammab|egaseSor|iiuids.

Keep

children

away.Children

must

never

be

allowed

in

the

work

area.Do

not

let

them

handle

machines,

tools,

or

extension

cords.

Storeidle

equipment.When

not

in

use,

tools

must

be

stored

in

adrylocation

toinhibit

rust'Always

lock

up

toors

and

keep

out

ofreach

of

chirdren.

Donotforce

tool. lt

will

do

the

jobbetter

and

more

safety

at

the

rate

for

which

it

was

intended'

Do

not

use

inappropriate

attachments

in

anattempt

to

exceed

the

toolcapacity.

usetherighttoolfor the

job. Do

not

attempt

to

force

asmall

tool

or

attachment

todo

the

work

of

alarger

industrial

tool.

Do

not

us6

atool

for

apurpose

forwhich

it

was

not

in-

tended.

Dress

properly. Do

not

wear

loose

clothing

or

jewelry

as

they

can

becaught

in

moving

parts'Protective,

electrically

nonconductive

cloihes

and

nonskid

footwear

arerecom-

mended

when

working.

Wear

restrictive

hair

covering

tocontain

long

hair.

1.

2.

3.

4.

5.

6.

7.

ITEM

BY2OO Page2