Ensure the refuelling trailer and vehicle or power unit to

be refuelled are adjacent to each other and within the

10m reach of the dispensing hose. Apply all park brakes

and turn all engines off.

Reset the delivery meter prior to fuel dispensing if

required. Simply turn the handle located on the left of

the meter clockwise until the top dials all read zero. The

smaller bottom gauge cannot be reset.

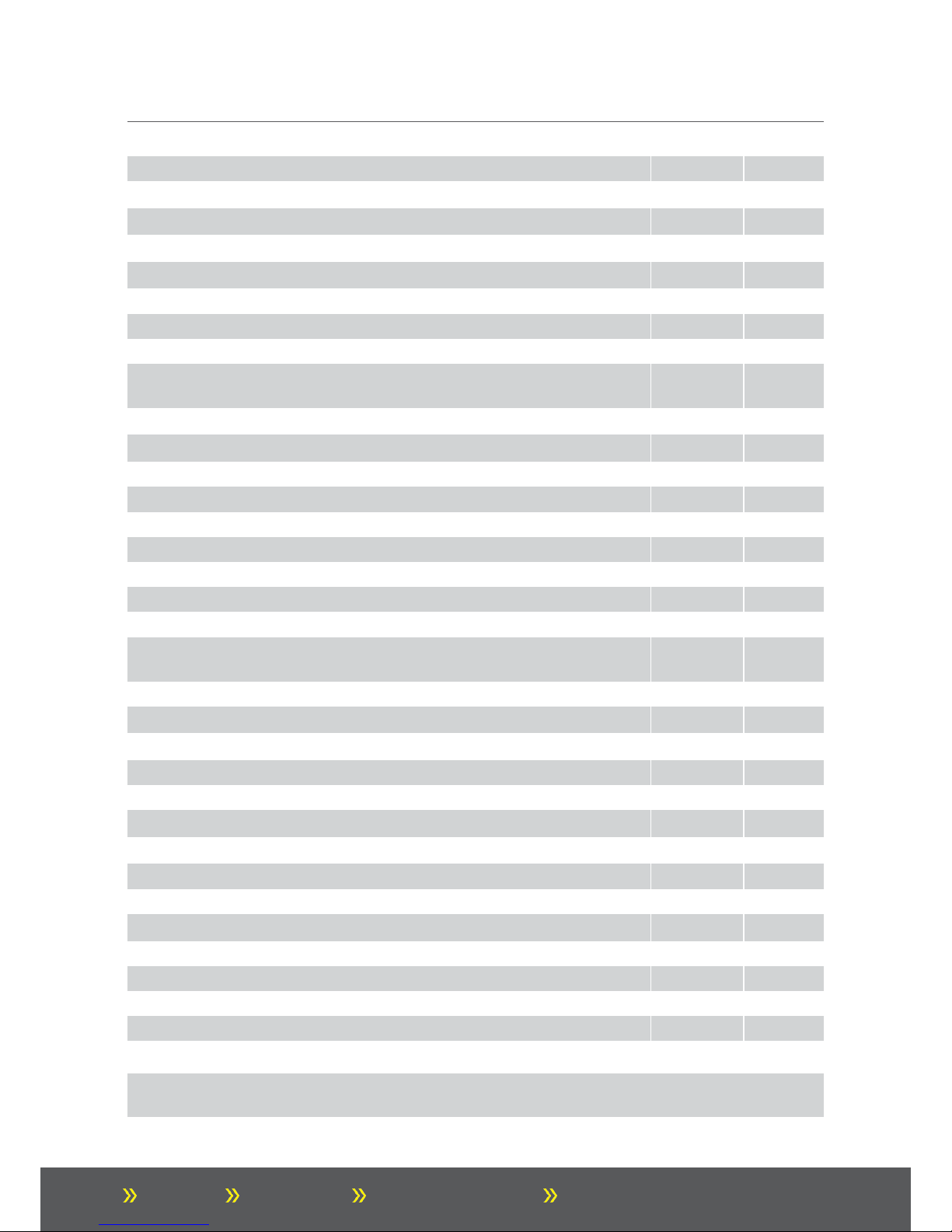

To prevent accidental spillage, dip the fuel tank before

and after fuel dispensing with the dip stick provided.

Ensure the fuel tank capacity of the unit to be refuelled is

known. The auto shut off nozzle should engage when the

vehicle tank is full. Nevertheless, care should be taken to

preventaccidentalspillageduringrefuelling.

Remove the fuel cap from the unit to be refuelled and

clean any dirt or dust to prevent contamination during

refuelling.

On diesel units, start the pump engine and open the

suction isolation valve. Solar powered pumps are self-

priming -fuel will commence to flow when the hand held

auto nozzle trigger is engaged on either unit. This has an

auto shut off mechanism but care should be taken when

refuellingtopreventaccidentalspillage.

Insert therefuelling nozzle and commencerefuelling.

When refuelling is complete replace all caps, and fully

retract the dispensing reel and house the dispensing

nozzle in the trailer housing.

Under nocircumstances leave the unit unattended whilst

refuelling.

On the diesel powered model, ensure the suction

isolation valve is opened and closed prior to and after

refuelling has taken place. The solar model does not

require one as the pump is designed to maintain

prime when not in use

Care should also betaken if the trailer is completely

emptied during refuelling. If this occurs, the pumping

unit must be shut off immediately to prevent irreparable

damage. Suction can also be lost on diesel powered units

requiring the unit to be re-primed. Simply follow the steps

in the Pumping section on page 14.

For safe and reliable service of diesel engine powered

trailers, ensure the separate engine operating guide is

referred to prior to operations. Failure to read and fully

understand the manual may result in incorrect operation

leading to equipment damage or personal injury.

For solar powered trailers, ensure the unit has sufficient

charge as the unit will fail to pump if this is not the case.

Refer to the LED charge indicators showing battery

voltage, this is located inside the lockable front cabinet

of the trailer. It is not advisable to operate the pump

when a voltage below 11v is displayed, doing so can

cause irreparable damage to the battery.

A standard 12v battery charger can be used if the battery

has insufficient charge. Only trained personnel should

attempt to recharge using jump leads connected to

another vehicle and pumping should only commence

after five minutes of charge being introduced via vehicle

jump leads.

Only when familiar with the safe operation ofeither

pumping mechanism, commence refuelling.

The hirer is liable if damage occurs to pumping units

which continue to run without fuel.