MHT258a (Engl.)

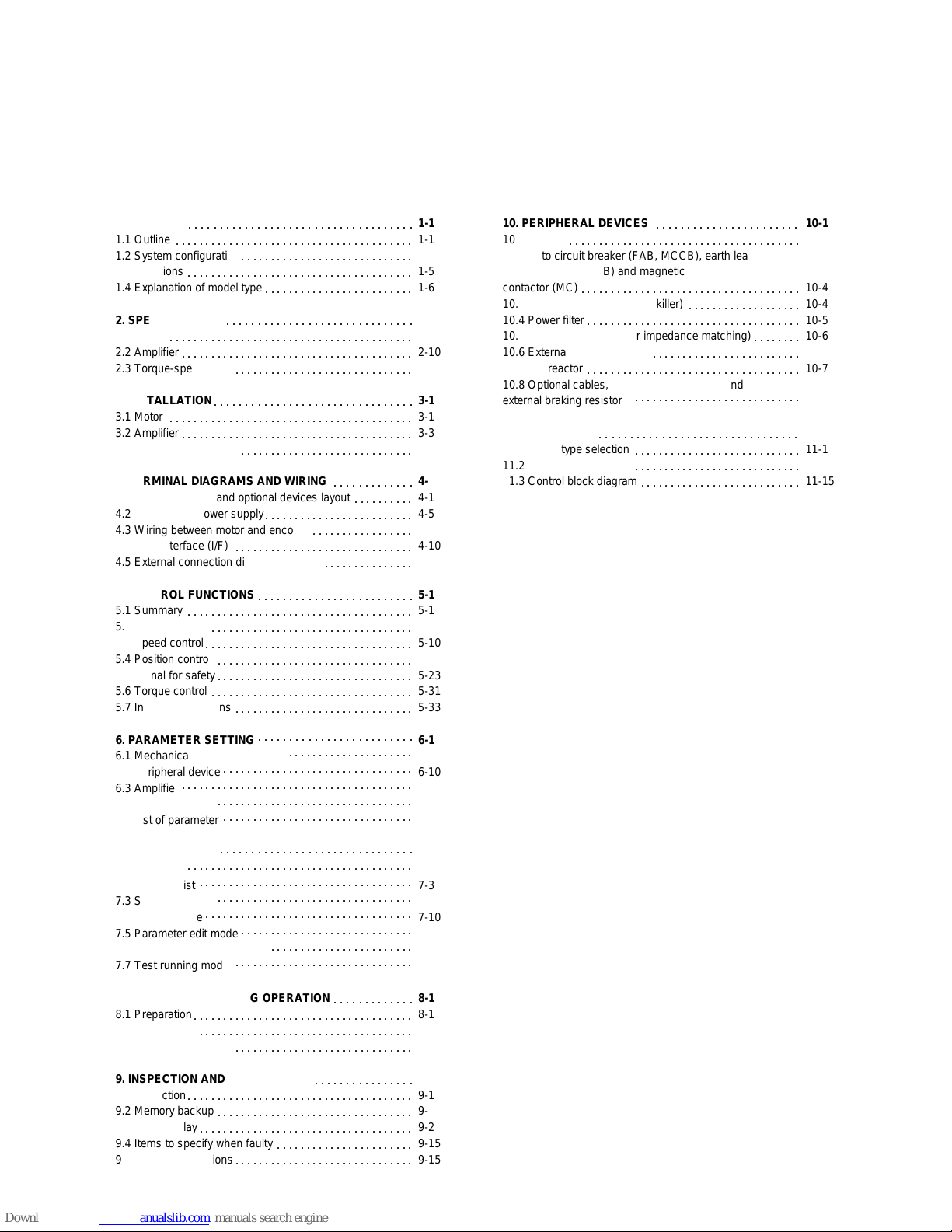

CONTENTS

SAFETY INSTRUCTION

1. GENERAL

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

1-1

1.1 Outline

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

1-1

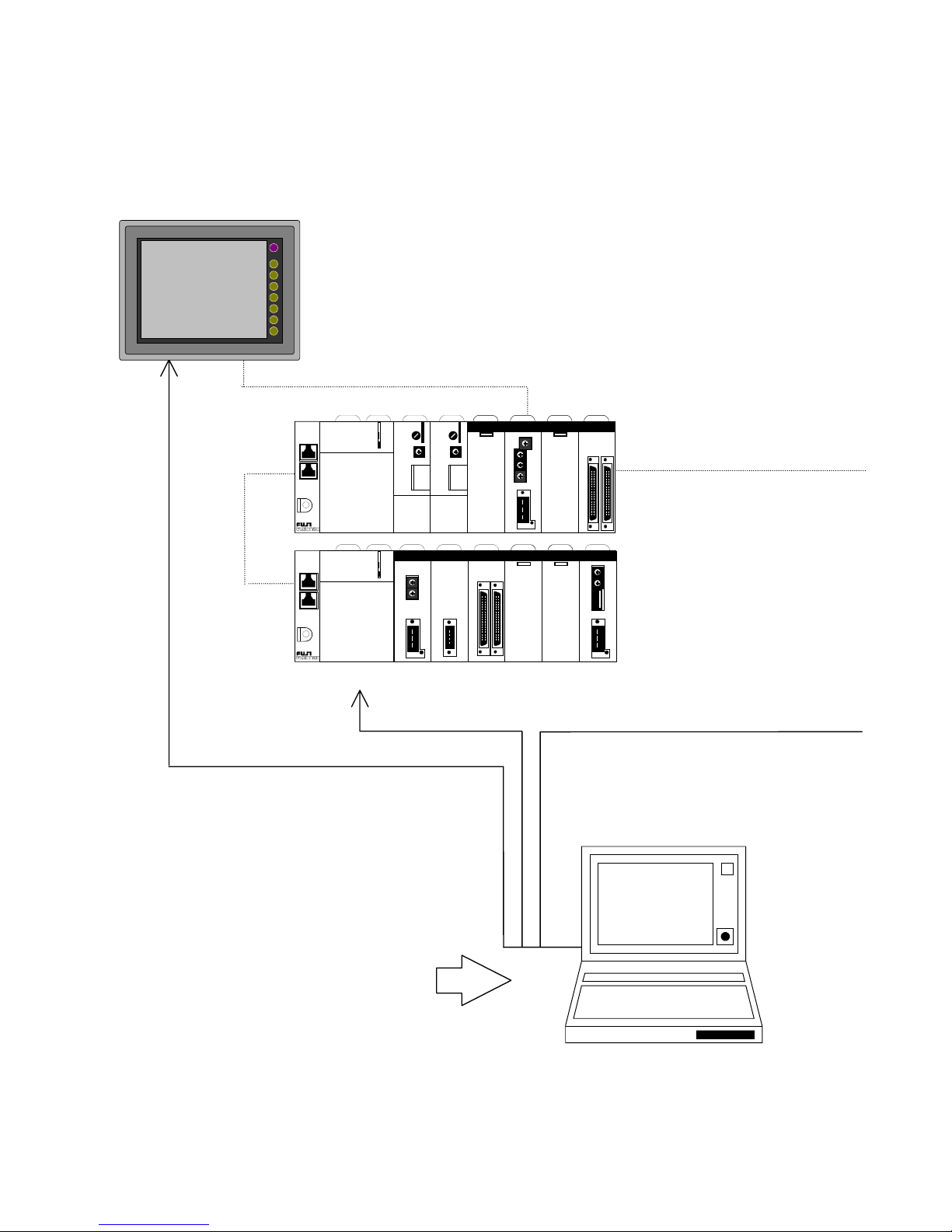

1.2 System configuration

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

1-3

1.3 Functions

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

1-5

1.4 Explanation of model type

ெெெெெெெெெெெெெெெெெெெெெெெெெ

1-6

2. SPECIFICATIONS

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

2-1

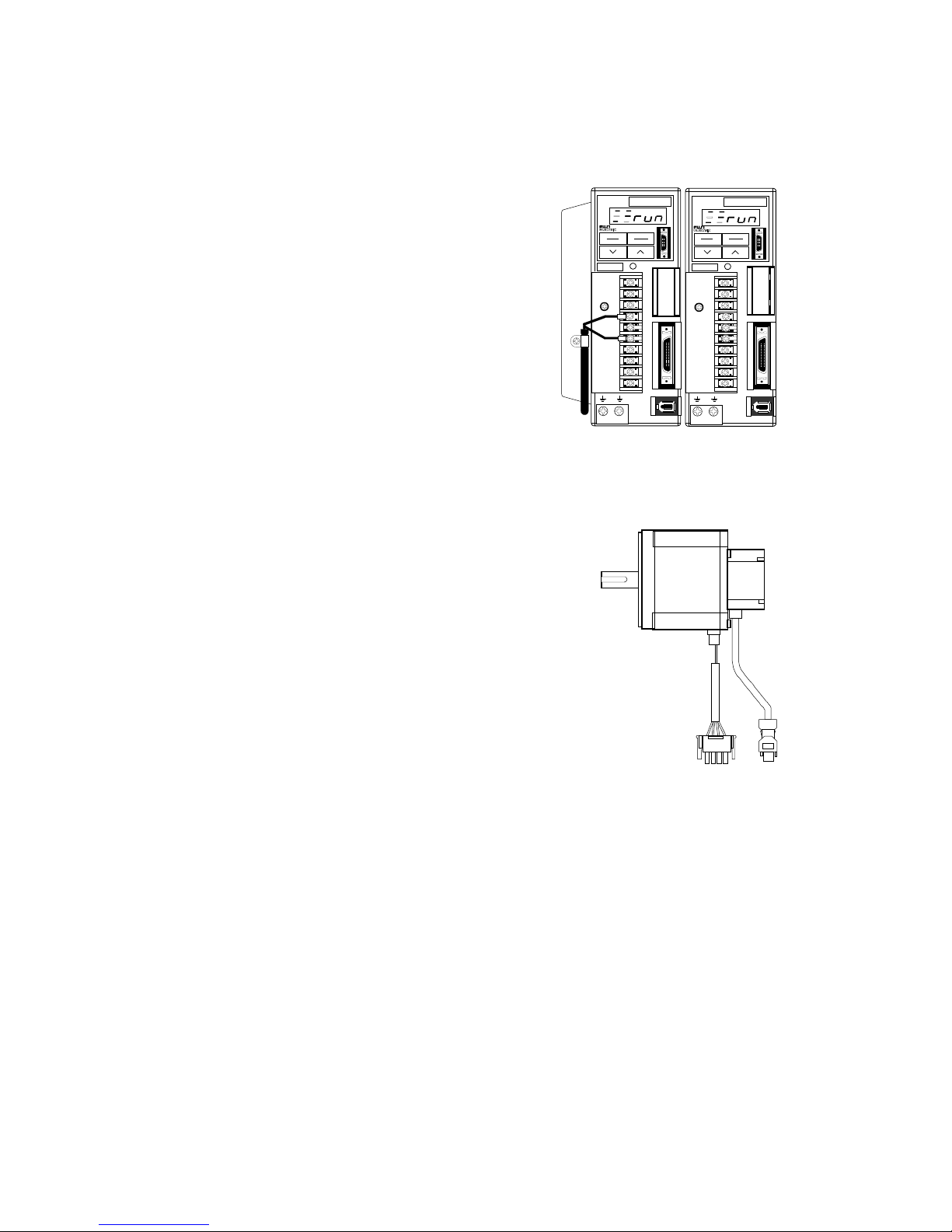

2.1 Motor

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

2-1

2.2 Amplifier

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

2-10

2.3 Torque-speed data

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

2-14

3. INSTALLATION

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

3-1

3.1 Motor

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

3-1

3.2 Amplifier

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

3-3

3.3 External dimensions

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

3-8

4. TERMINAL DIAGRAMS AND WIRING

ெெெெெெெெெெெெெ

4-1

4.1 Amplifier, motor and optional devices layout

ெெெெெெெெெெ

4-1

4.2 Commercial power supply

ெெெெெெெெெெெெெெெெெெெெெெெெெ

4-5

4.3 Wiring between motor and encoder

ெெெெெெெெெெெெெெெெெ

4-6

4.4 Host interface (I/F)

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

4-10

4.5 External connection diagrams (basic)

ெெெெெெெெெெெெெெெ

4-15

5. CONTROL FUNCTIONS

ெெெெெெெெெெெெெெெெெெெெெெெெெ

5-1

5.1 Summary

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

5-1

5.2 Run command

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

5-5

5.3 Speed control

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

5-10

5.4 Position control

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

5-15

5.5 Signal for safety

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

5-23

5.6 Torque control

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

5-31

5.7 Incidental functions

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

5-33

6. PARAMETER SETTING

ெெெெெெெெெெெெெெெெெெெெெெெெெ

6-1

6.1 Mechanical equipment system

ெெெெெெெெெெெெெெெெெெெெெ

6-1

6.2 Peripheral device

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

6-10

6.3 Amplifier

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

6-17

6.4 Communication

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

6-23

6.5 List of parameter

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

6-24

7. KEYPAD PANEL

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

7-1

7.1 Summary

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

7-1

7.2 Function list

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

7-3

7.3 Sequence mode

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

7-5

7.4 Monitor mode

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

7-10

7.5 Parameter edit mode

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

7-15

7.6 Positioning data edit mode

ெெெெெெெெெெெெெெெெெெெெெெெெ

7-19

7.7 Test running mode

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

7-19

8. TEST (TRIAL) RUNNING OPERATION

ெெெெெெெெெெெெெ

8-1

8.1 Preparation

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

8-1

8.2 Touch panel

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

8-4

8.3 Control input signal

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

8-6

9. INSPECTION AND MAINTENANCE

ெெெெெெெெெெெெெெெெ

9-1

9.1 Inspection

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

9-1

9.2 Memory backup

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

9-1

9.3 Fault display

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

9-2

9.4 Items to specify when faulty

ெெெெெெெெெெெெெெெெெெெெெெெ

9-15

9.5 Others informations

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

9-15

10. PERIPHERAL DEVICES

ெெெெெெெெெெெெெெெெெெெெெெெ

10-1

10.1 Cables

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

10-3

10.2 Auto circuit breaker (FAB, MCCB), earth leakage

circuit breaker (ELCB) and magnetic

contactor (MC)

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

10-4

10.3 Surge suppressor (surge killer)

ெெெெெெெெெெெெெெெெெெெ

10-4

10.4 Power filter

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

10-5

10.5 AC reactor (reactor for impedance matching)

ெெெெெெெெ

10-6

10.6 External braking resistor

ெெெெெெெெெெெெெெெெெெெெெெெெெ

10-6

10.7 DC reactor

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

10-7

10.8 Optional cables, connector kits, battery and

external braking resistors

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

10-8

11. APPENDIXES

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

11-1

11.1 Model type selection

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

11-1

11.2 Example of program

ெெெெெெெெெெெெெெெெெெெெெெெெெெெெ

11-10

11.3 Control block diagram

ெெெெெெெெெெெெெெெெெெெெெெெெெெெ

11-15