Service ManualforFNDX5

08/2009FR

WARNING:

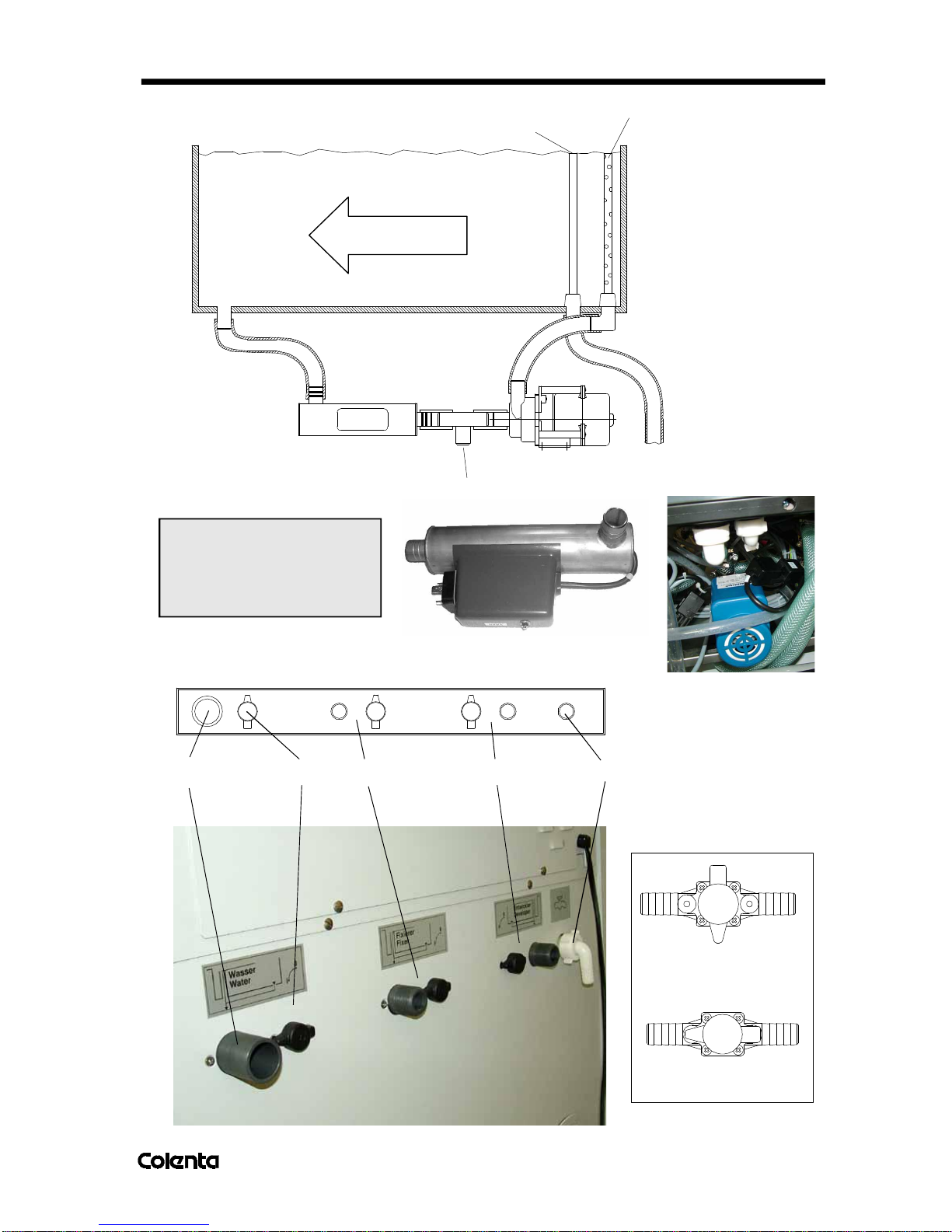

*) Do notusebrass orcopperinthe drainage system.

*) Chemistry disposalmustbe inaccordancewithlocal

environmentalregulations.

*) Toavoidbackpressureinthedrain,the hosesshould be

freeofbendsandwithaconstantdownwardgradient.

Cover

DEV FIX

FIX

USE FLOADINGLID

TOPROTECT

DEVELOPER

AGAINSTOXYDATION

DEV

Cover

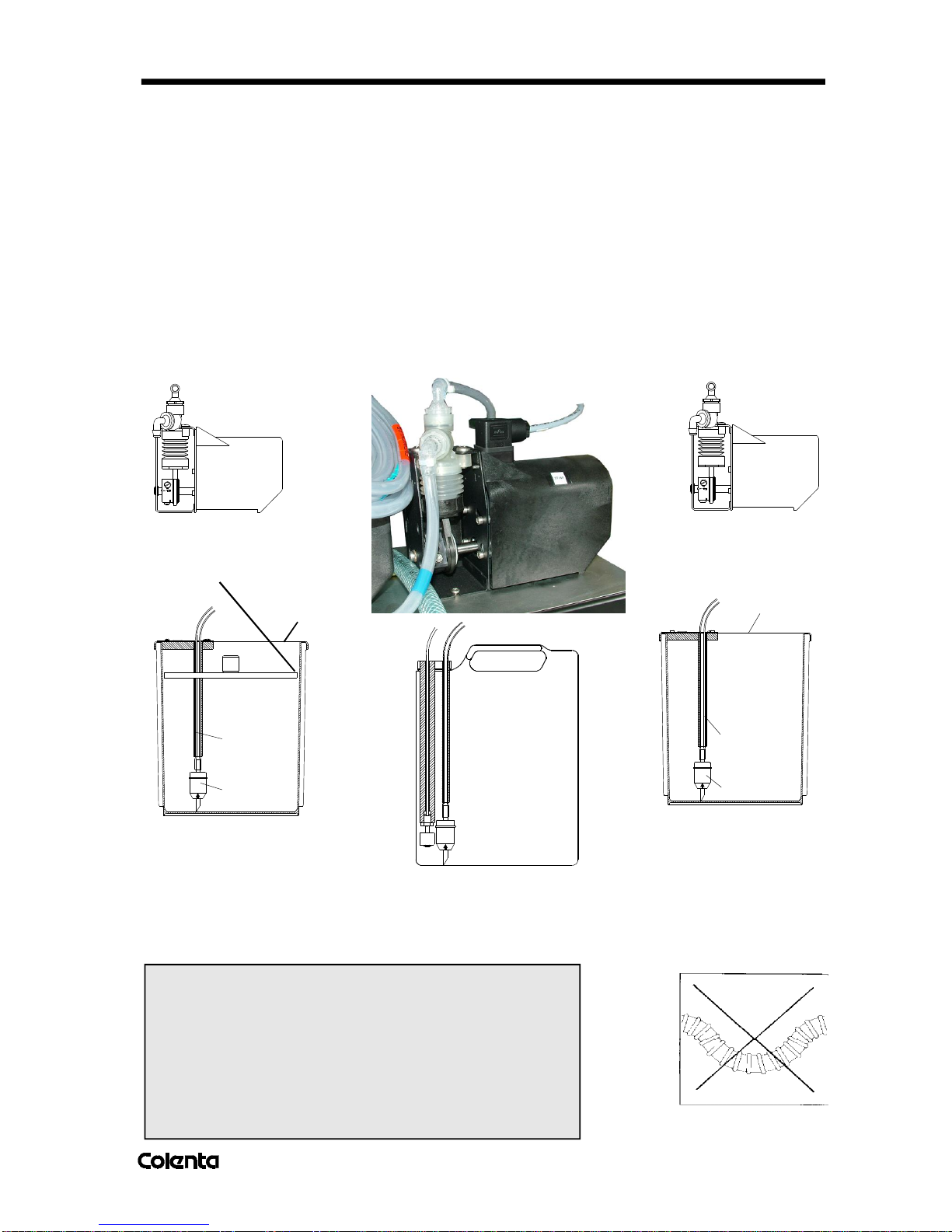

NOTE:

ALevelcontroldeviceforreplenishertankisoptionalavailableonrequest.

Standpipe

Filter

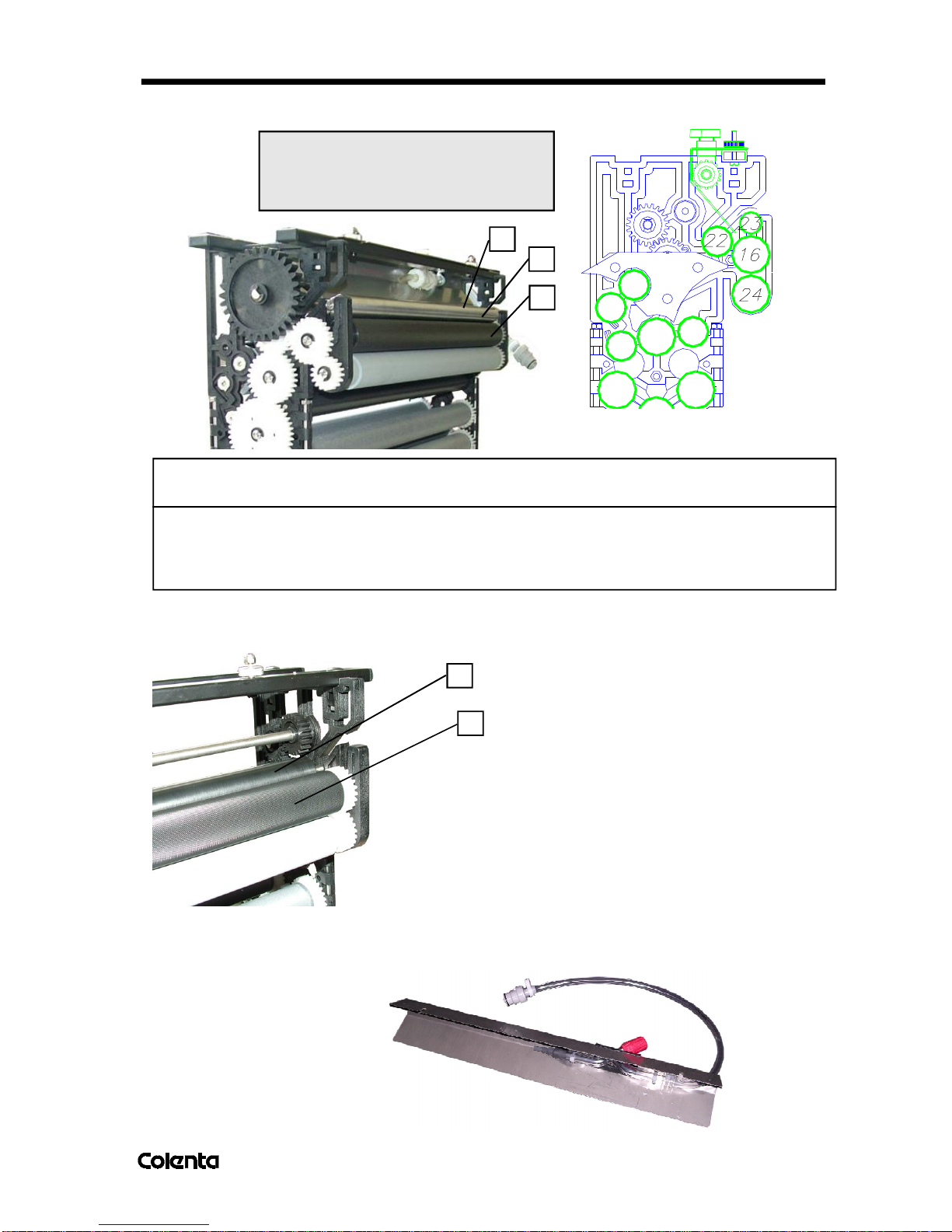

3.1.1 ChemicalReplenishmentSystem

Whenoperatingaprocessorwhichuseschemicalsforthecontinuousproductionofplate/filmitisvery

importantthatthe chemicalswithinthe machine arekeepingood working ordersoastoprovide consistent

processingquality.

Toachievethisconsistencyweusereplenishmentsolutions,whichareformulated bythechemical

manufacturerandinjectedintotheprocessorpreciselyfortheareaofmaterialbeingproduced.

Replenishmentofthechemicaltanksisdone automaticallyusing infrared sensorslocatedatthe entrance

totheprocessor.Thesesensors accuratelymonitorthe widthofmaterialenteringthe processor,this

informationisinthenused bythe microprocessor(CPU)controlsoftwaretocalculatethesurfaceareafor

eachplateloaded intothe processor.

Eachsensor,whencovered,will generateapulse,whichisthenrecorded on adecoderand counted –

themoresensorsthatarecovered thenthefasterthe count.Whenthe countreachestheprogrammedvalue

ofpulsecountsittriggersthestartofareplenishmentcycle.

Duringeachreplenishmentcyclethereplenishmentpumpsinjectfreshsolution fromsmallstorage bottles/

tankand intothe corresponding"working"tanksolutionsforapre-settime.

DEV

Replenishment

(Canister)

ReplenishmentPump

tothepump

Standpipe

Filter

Page4