LED LIGHT ENGINE APPLICATION PROGRAM

MANUAL FOR LED LIGHT ENGINE KIT INSTALLATION

Address: 12705 South Van Ness Ave., Hawthorne, CA 90250 · Telephone: 1-323-599-5000 · Fax: 1-323-754-9060 · E-mail: LEDretrofit@fulham.com · Website: www.fulham.com

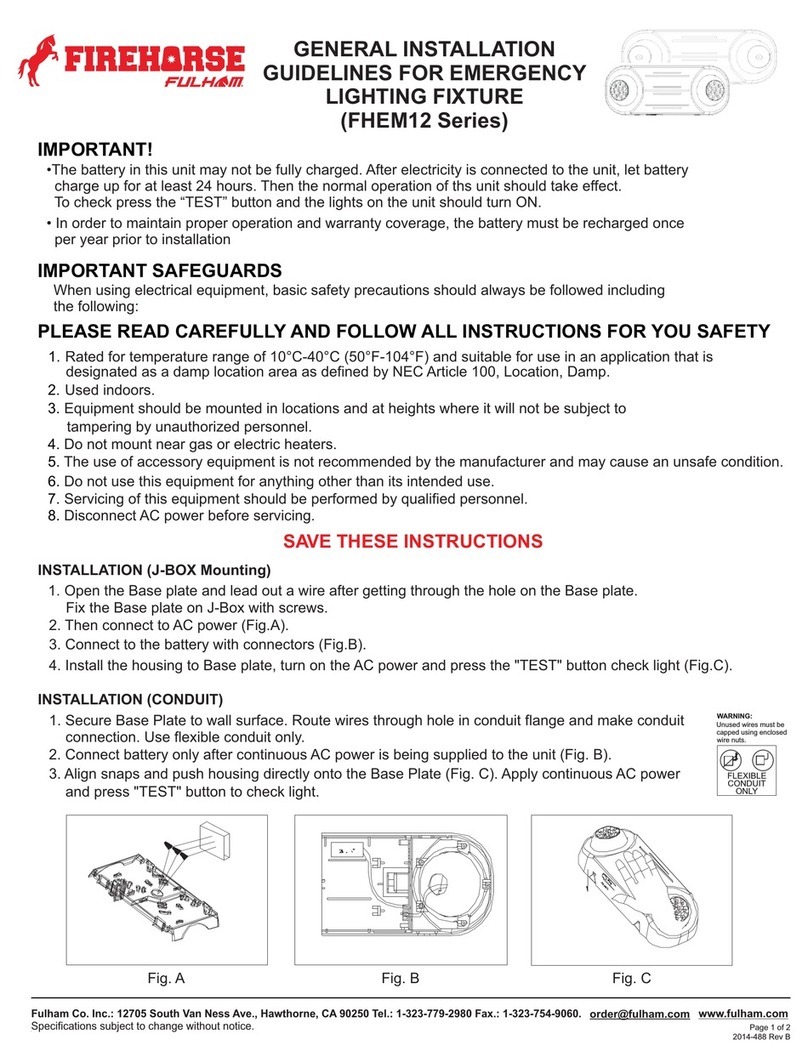

01/14/16 LED 7” Engine, Rev D Page 2

Tool # Description QTY

1 11/32” Nut Driver 1

2 3/16” Drill Bit 1

3 Power Drill 1

4 Phillips Drill Bit (P2) 1

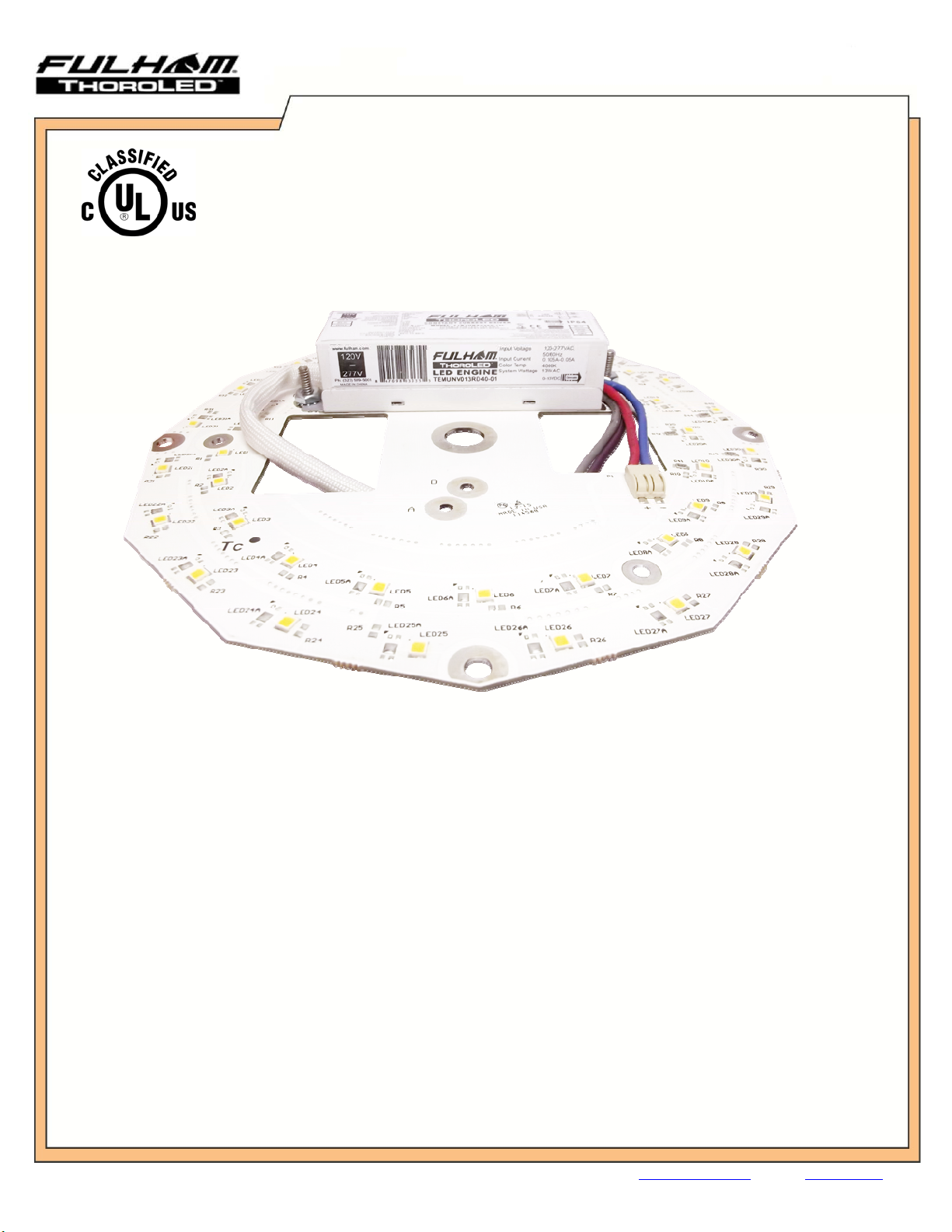

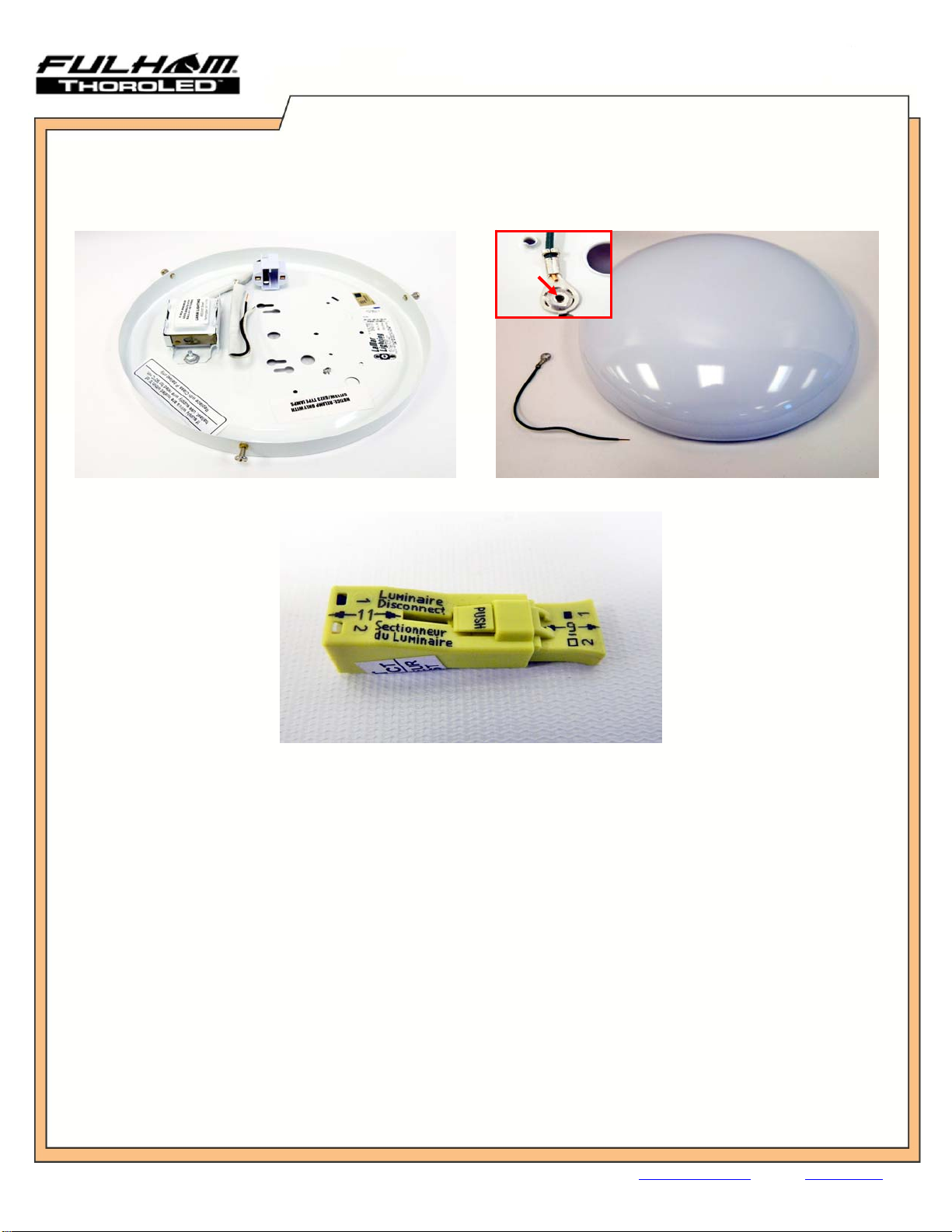

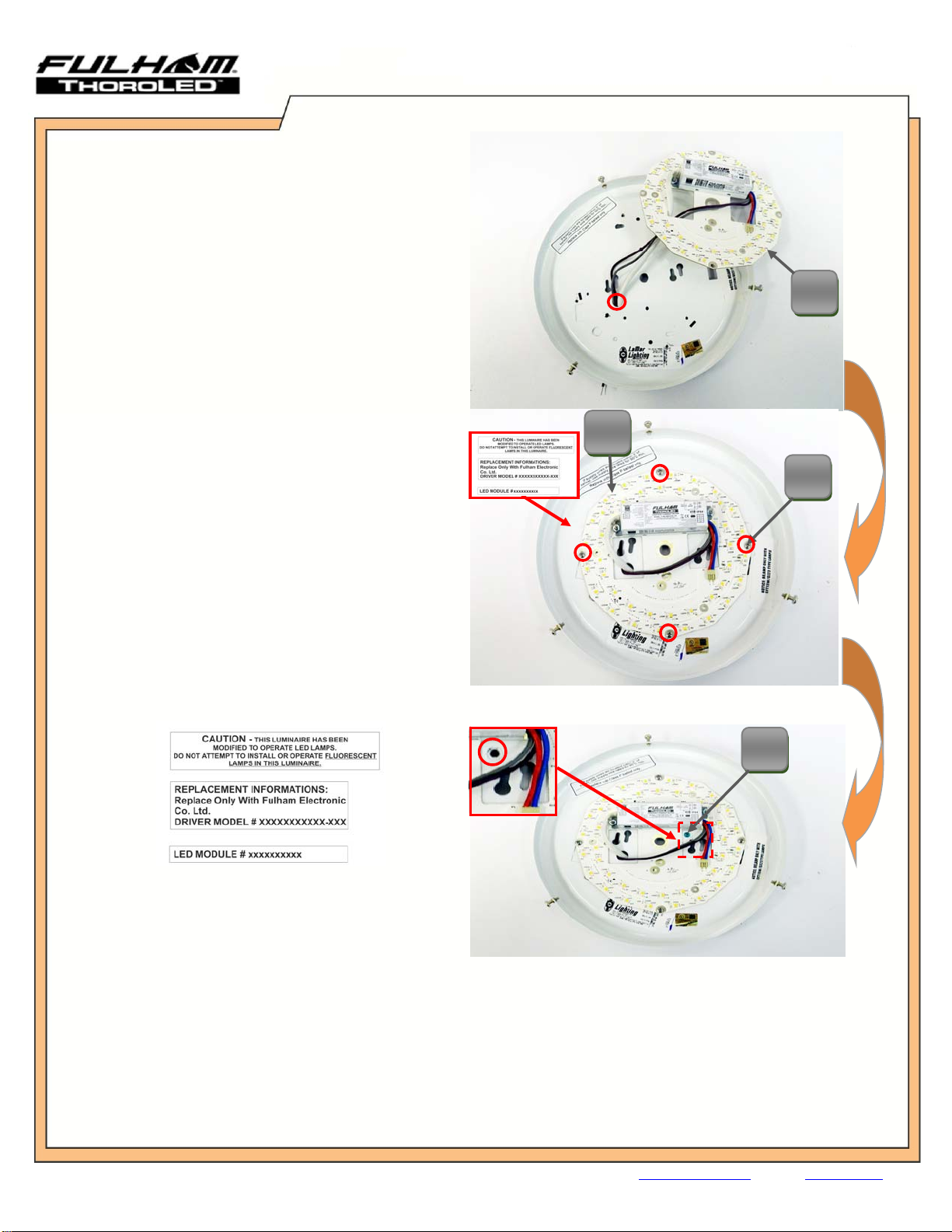

KeeptheOriginalDiffuser.

Removealltheremaining

originalfixtureparts,hardware,

andlampinordertobeginthe

retrofit.

Illustration 1: Minimum Original Luminaire Dimensions

Mfr: Lamar Li

htin

Model: CDW11311PN1SW

ThisLEDEngineKitcanretrofitanyluminairewithadiameter/heightgreaterorequaltotheminimum

dimensionsshownabove.

ThisLEDEngineKitcanbeusedwithluminairessimilartotheoneillustratedabove.

3.25”

Dia.=ø11”

Dia.=ø10”

1. “THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON

FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED.”

2. "WARNING - Risk of fire or electric shock. LED Retrofit kit installation requires knowledge of luminaires electrical systems. If not

qualified, do not attempt installation. Contact a qualified electrician.”

3. "WARNING - Risk of fire or electric shock. Install this kit only in the luminaries that has the construction features and dimensions shown in

the photographs and/or drawings."

4. "WARNING - To prevent wiring damage or abrasion, do not expose wiring to edges of sheet metal or other sharp objects."

5. "WARNING –Risk of fire or electric shock. Luminaire wiring and electrical parts may be damaged when drilling for installation of LED

retrofit kit. Check for enclosed wiring and components."

6. “Please make sure the grounding conductor of the luminaire is properly secured to the Branch Circuit Grounding conductor. “

7. “CAUTION – RISK OF FIRE. CONSULT A QUALIFIED ELECTRICIAN TO ENSURE CORRECT BRANCH CIRCUIT

CONDUCTOR.”

8. “The assembly of this LED retrofit should be performed by a licensed electrician or equivalent as State or Provincial Codes and Laws

dictate.”

9. “WARNING – RISK OF FIRE OR ELECTRIC SHOCK. DO NOT ALTER, RELOCATE, OR REMOVE WIRING, LAMPHOLDERS,

POWER SUPPLY, OR ANY OTHER ELECTRICAL COMPONENT.”

10. “THE RETROFIT KIT IS ACCEPTED AS A COMPONENT OF A LUMINAIRE WHERE THE SUITABILITY OF THE COMBINATION

SHALL BE DETERMINED BY CSA OR AUTHORITIES HAVING JURISDICTION."

1.0 INSTALLATION INSTRUCTION WARNINGS

Tool #1 Tool #2 Tool #3

4.0 Required Tools (Not Included)

2.0 Minimum Original Luminaire Dimensions

Tool #4

3.0 Intended Use