1.1 Receiving, Storage and Transportation1.1 Receiving, Storage and Transportation

Chapter 1 IntroductionChapter 1 Introduction

AC drive. This chapter contains information on the AC drive. This chapter contains information on the

unpack installunpack install

1.1 Receiving, Transportation, and Storage1.1 Receiving, Transportation, and Storage

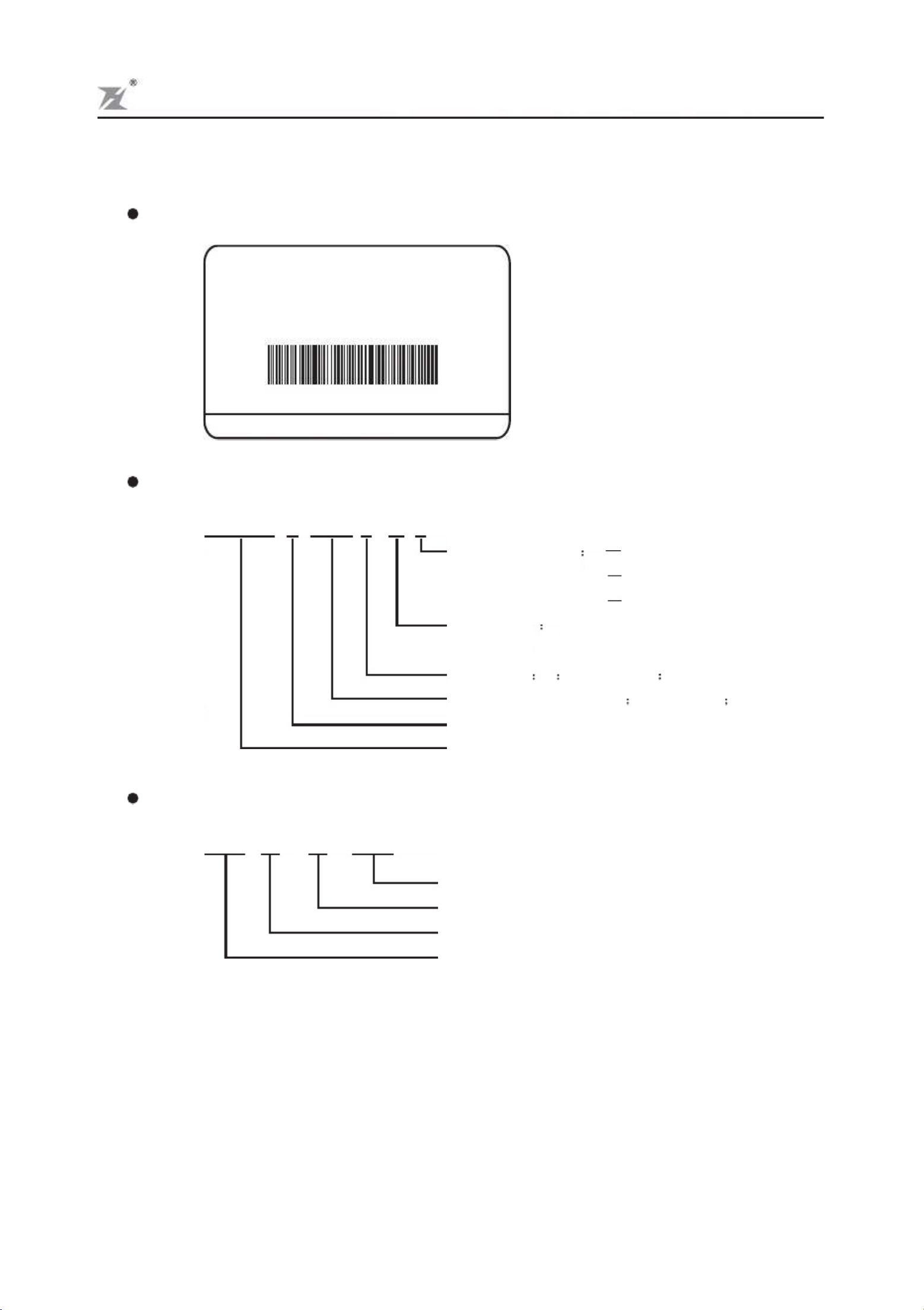

1.2 Nameplate Information1.2 Nameplate Information

AC motor drive has gone through rigorous quality control tests at the factory before shipment.AC motor drive has gone through rigorous quality control tests at the factory before shipment.

After receiving theAfter receiving the

AC drive, check for AC drive, check for

the following.the following.

1.Check to make sure that the 1.Check to make sure that the

package includes anpackage includes an

AC drive,the User AC drive,the User

Manual,dust covers andManual,dust covers and

rubber bushings.rubber bushings.

2.Inspect the unit to insure it was not damaged during shipment.2.Inspect the unit to insure it was not damaged during shipment.

3.Make sure that the part number indicated on the nameplate corresponds with the part number3.Make sure that the part number indicated on the nameplate corresponds with the part number

AC Drive should be kept in the shipping carton before installation. In order to retain theAC Drive should be kept in the shipping carton before installation. In order to retain the

warranty coverage, thewarranty coverage, the

AC drive should be AC drive should be

stored properly stored properly

when it is not when it is not

to be used for anto be used for an

extended period of time. Some storage suggestions are:extended period of time. Some storage suggestions are:

1.Store in a clean, dry location.1.Store in a clean, dry location.

3.If possible, store in 3.If possible, store in

an air-conditioned environment where the relative humidity an air-conditioned environment where the relative humidity

95%, non-condensing.95%, non-condensing.

4.Do not store the4.Do not store the

AC drive in places where it could be exposed to corrosive gases.AC drive in places where it could be exposed to corrosive gases.

5.Do not store the5.Do not store the

AC drive on a shelf or on an unstable surface.AC drive on a shelf or on an unstable surface.

TransportationTransportation

Air Pressure: 70kPa to 106kPa.Air Pressure: 70kPa to 106kPa.