4

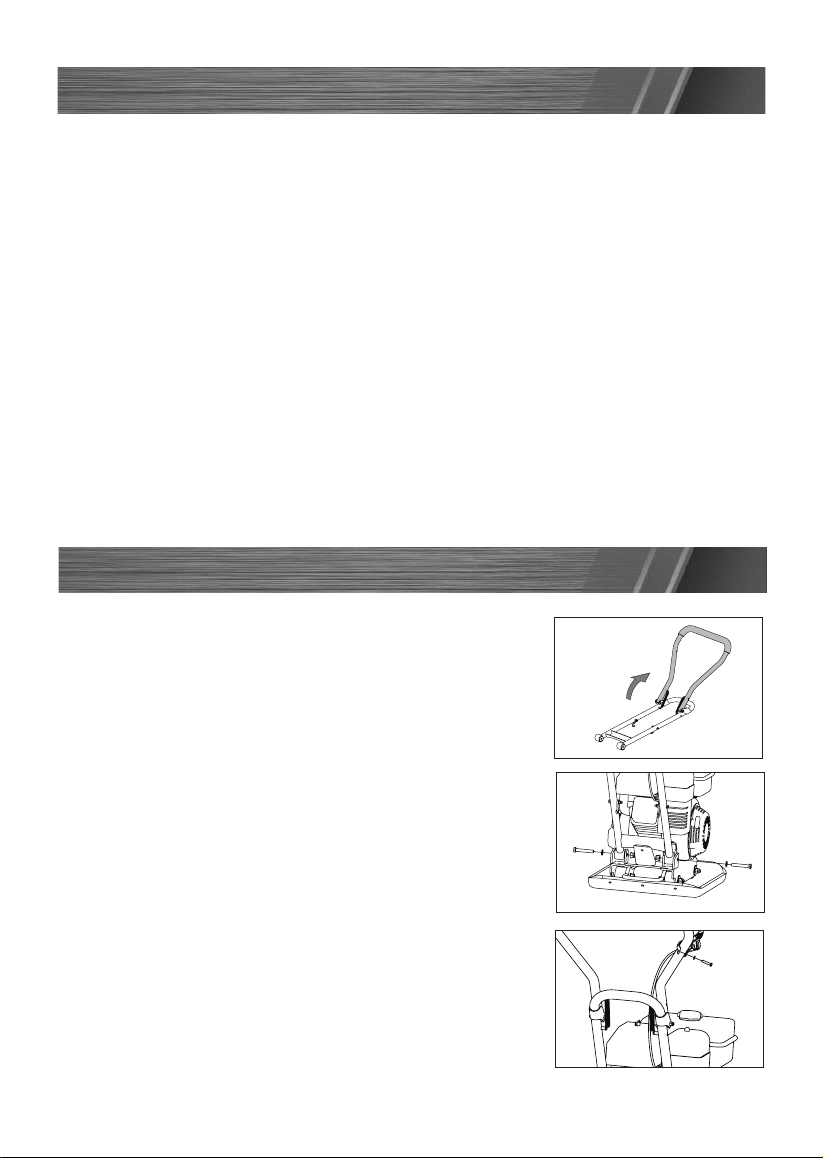

Congratulations on purchasing a Full Boar Plate Compactor.

Your Full Boar Plate Compactor FBT-5700 has been

designed for paving projects like driveways, landscaping

or preparing foundations for concreting.

1) WORK AREA

a) Do not operate plate compactor in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Engine may create sparks which

may ignite the dust or fumes.

b) ever run engine in an enclosed area. Exhaust gases contain deadly,

poisonous carbon monoxide, which has no odour or taste. Exposure may cause

loss of consciousness and may lead to death.

c) Keep by-standers, children and visitors away while setting up plate

compactor. Distractions can result in mistakes.

d) Keep the engine at least 1 metre (3 feet) away from buildings and other

equipment during operation. Do not place flammable objects close to the

engine. Procedure should be followed to prevent fire hazards and to provide

adequate ventilation.

2) PERSO AL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating

this plate compactor. Do not attempt to use plate compactor while tired or

under the influence of drugs, alcohol or medications. A moment of inattention

while operating power tools may result in serious personal injury.

b) Dress appropriately. Do not wear loose clothing or jewellery. Contain long

hair. Keep your hair, clothing and gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in moving parts.

c) Do not overreach. Keep proper footing and balance at all times. Proper

footing and balance enables better control of the plate compactor in unexpected

situations.

d) Use safety equipment. Always wear eye protection. Dust mask, non-skid safety

shoes and hard hat must be used for appropriate conditions.

3) PLATE COMPACTOR USE A D CARE

a) Store idle plate compactor out of reach of children and other untrained

persons. Plate compactor are dangerous in the hands of untrained users.

b) Maintain plate compactor. Keep the engine and muffler free of grass, leaves,

excessive grease or carbon build up to reduce the chance of a fire hazard. Properly

maintained plate compactors are less likely to malfunction and cause injury.

c) Check for misalignment or binding of moving parts, breakage of parts and

any other condition that may affect the plate compactor operation. If

damaged, have the plate compactor serviced before using. Accidents can be

caused by poorly maintained plate compactors.

INTRODUCTION

GENERAL SAFETY INSTRUCTIONS