2-1 LTVP_ISP

IMPORTANT SAFETY PRECAUTIONS

Prior to shipment from the factory, our products are strictly inspected for recognized product safety and electrical

codes of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally

important to implement the following precautions when a set is being serviced.

Safety Precautions for LCD TV

Circuit

1. Before returning an instrument to the

customer, always make a safety check of the

entire instrument, including, but not limited to, the

following items:

a. Be sure that no built-in protective devices are

defective and have been defeated during

servicing. (1) Protective shields are provided

on this chassis to protect both the technician

and the customer. Correctly replace all missing

protective shields, including any removed for

servicing convenience. (2) When reinstalling

the chassis and/or other assembly in the

cabinet, be sure to put back in place all

protective devices, including but not limited to,

nonmetallic control knobs, insulating

fishpapers, adjustment and compartment

covers/shields, and isolation resistor/capacitor

networks. Do not operate this instrument or

permit it to be operated without all

protective devices correctly installed and

functioning. Servicers who defeat safety

features or fail to perform safety checks

may be liable for any resulting damage.

b. Be sure that there are no cabinet openings

through which an adult or child might be able to

insert their fingers and contact a hazardous

voltage. Such openings include, but are not

limited to, (1) spacing between the LCD module

and the cabinet mask, (2) excessively wide

cabinet ventilation slots, and (3) an improperly

fitted and/or incorrectly secured cabinet back

cover.

c. Antenna Cold Check - With the instrument AC

plug removed from any AC source, connect an

electrical jumper across the two AC plug

prongs. Place the instrument AC switch in the

on position. Connect one lead of an ohmmeter

to the AC plug prongs tied together and touch

the other ohmmeter lead in turn to each tuner

antenna input exposed terminal screw and, if

applicable, to the coaxial connector. If the

measured resistance is less than 1.0 megohm

or greater than 5.2 megohm, an abnormality

exists that must be corrected before the

instrument is returned to the customer. Repeat

this test with the instrument AC switch in the off

position.

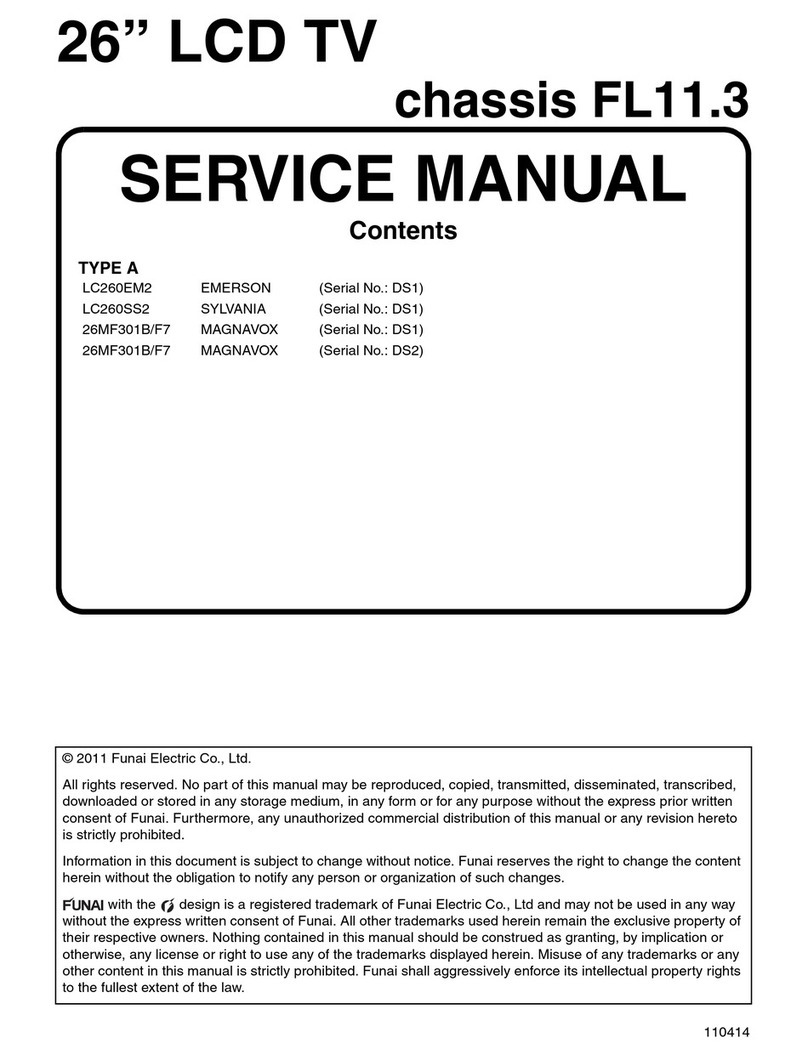

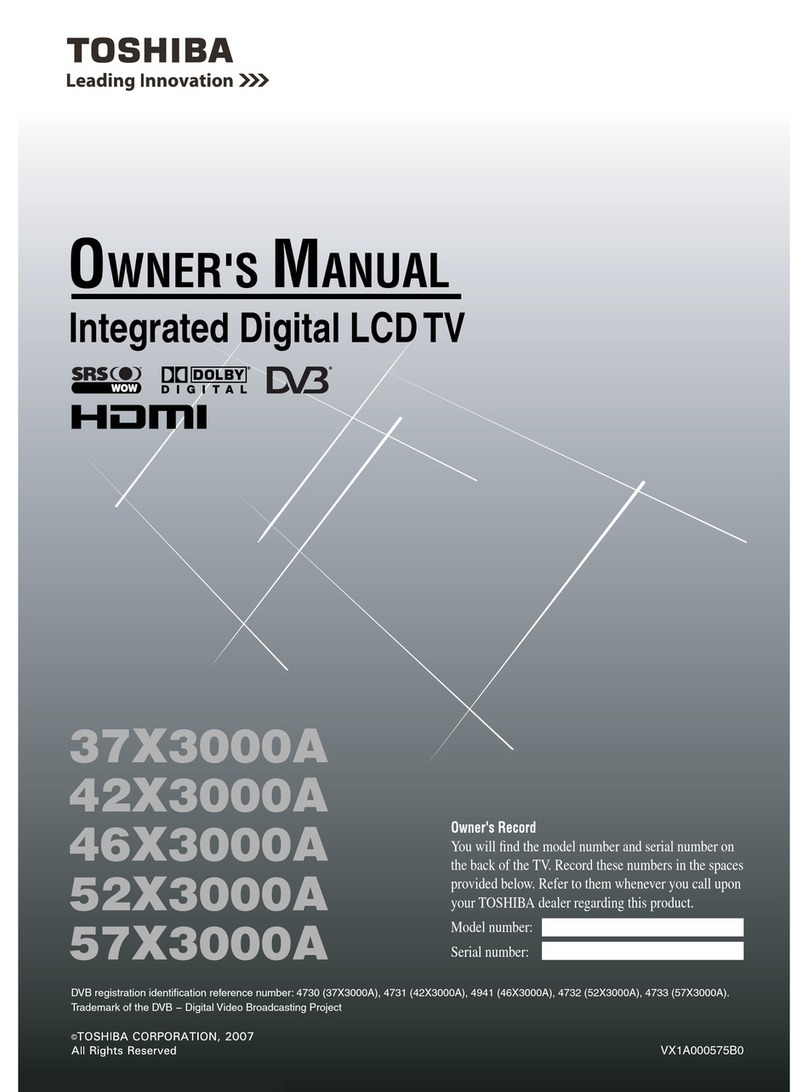

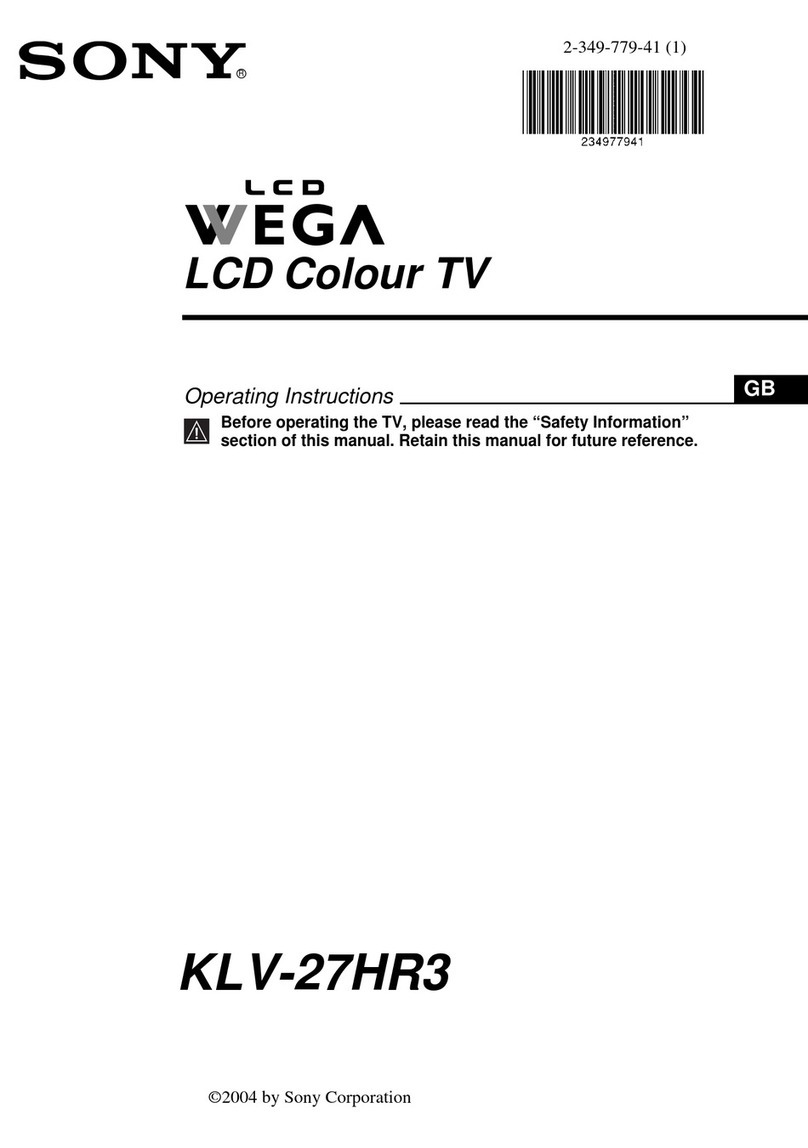

d. Leakage Current Hot Check - With the

instrument completely reassembled, plug the

AC line cord directly into a 230 V AC outlet. (Do

not use an isolation transformer during this

test.) Use a leakage current tester or a

metering system that complies with American

National Standards Institute (ANSI) C101.1

Leakage Current for Appliances and

Underwriters Laboratories (UL) 1410, (50.7).

With the instrument AC switch first in the on

position and then in the off position, measure

from a known earth ground (metal water pipe,

conduit, etc.) to all exposed metal parts of the

instrument (antennas, handle brackets, metal

cabinet, screw heads, metallic overlays, control

shafts, etc.), especially any exposed metal

parts that offer an electrical return path to the

chassis. Any current measured must not

exceed 0.5 milli-ampere. Reverse the

instrument power cord plug in the outlet and

repeat the test.

ANY MEASUREMENTS NOT WITHIN THE

LIMITS SPECIFIED HEREIN INDICATE A

POTENTIAL SHOCK HAZARD THAT MUST

BE ELIMINATED BEFORE RETURNING THE

INSTRUMENT TO THE CUSTOMER OR

BEFORE CONNECTING THE ANTENNA OR

ACCESSORIES.

2. Read and comply with all caution and safety-

related notes on or inside the receiver cabinet, on

the receiver chassis, or on the LCD module.

3. Design Alteration Warning - Do not alter or add

to the mechanical or electrical design of this LCD

TV receiver. Design alterations and additions,

including, but not limited to circuit modifications

and the addition of items such as auxiliary audio

and/or video output connections, might alter the

safety characteristics of this receiver and create a

hazard to the user. Any design alterations or

additions will void the manufacturer's warranty and

may make you, the servicer, responsible for

personal injury or property damage resulting

therefrom.

ALSO TEST WITH

PLUG REVERSED

USING AC

ADAPTER PLUG

AS REQUIRED

TEST ALL EXPOSED

METAL SURFACES

READING SHOULD

NOT BE ABOVE 0.5 mA

EARTH

GROUND

_

DEVICE

LEAKAGE

CURRENT

TESTER

+

BEING

TESTED