8

SECTION 3: OPERATING YOUR UTILITY VEHICLE

Starting Utility Vehicle

• Inspect area around vehicle for any items which

may be in your path.

• Make sure battery disconnect switch under the seat

is in the ON position.

• Adjust seat to desired position.

• Insert the key into the ignition switch.

• Make sure wheels are turned to desired position.

• To drive forward, turn key from OFF position

clockwise to one of the forward speeds: H (High) or

L (Low).

• To drive in reverse, turn key counter-clockwise to R

(Reverse).

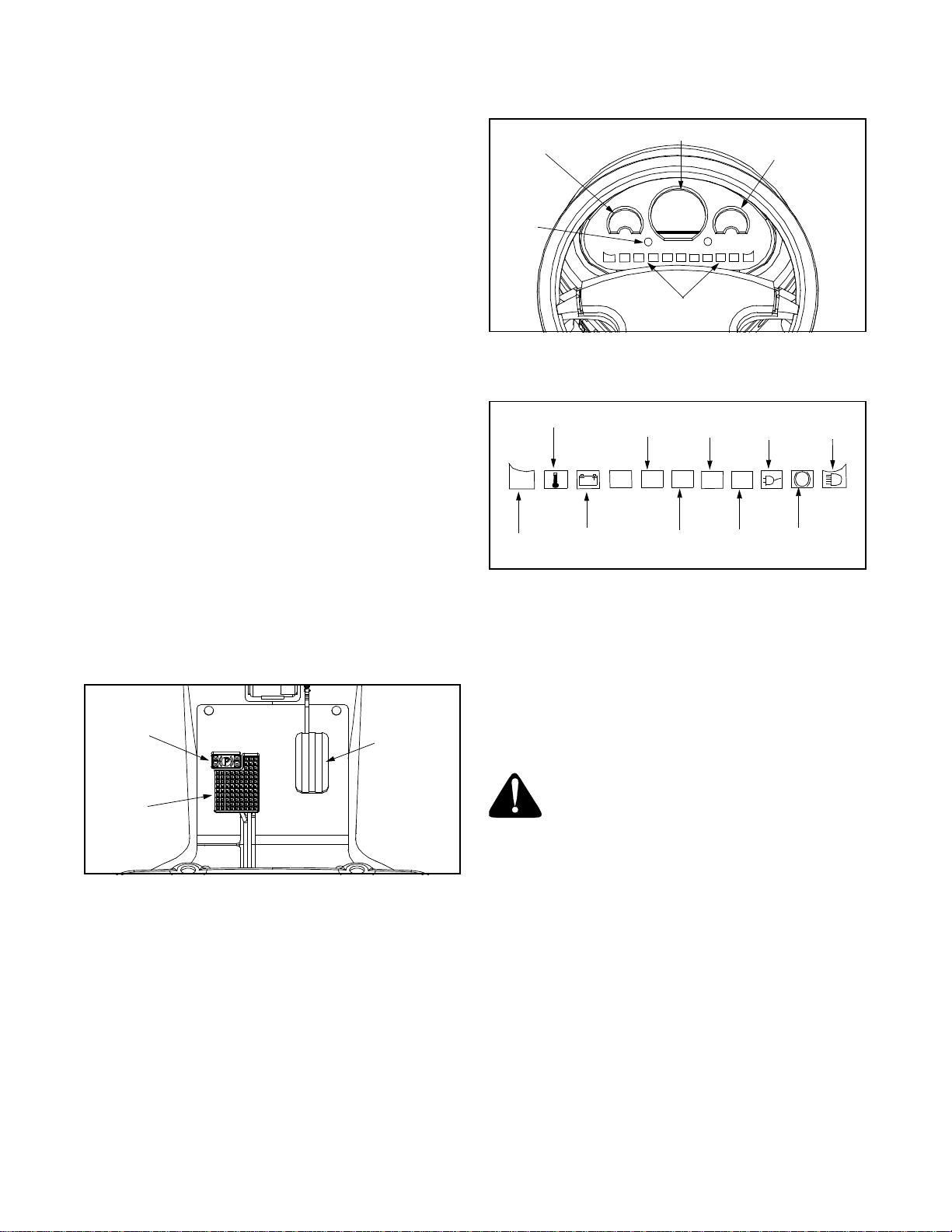

• Check instrument cluster for vehicle operating

conditions, i.e. battery or temperature.

a. If charging is needed proceed to Charging

Utility Vehicle in this section.

b. If temperature gauge shows to be high, park,

turn off vehicle and let cool.

• Release parking brake by depressing brake pedal

all the way to the floor and release.

• By turning key from the OFF position, an indicator

light will illuminate “ON”. After a couple of seconds

an indicator light will illuminate showing the speed

or direction, (H) High, (L) Low, (R) Reverse.

• After the speed or direction light is illuminated,

slowly depress accelerator pedal and the vehicle

will start to move until the maximum speed selected

is reached.

IMPORTANT:

If the accelerator is depressed before

the indicator light is illuminated showing the speed

or direction, the vehicle will not move, four “Beeps”

will sound, and the fault light on dash will flash four

times. The operator must remove their foot from the

accelerator, so the “Beeping” will stop and the

vehicle can be operated.

NOTE: If vehicle will not move and charging is not

needed, turn ignition key to OFF and then repeat

starting procedure.

• When driving in forward or reverse, the vehicle can

be switched to the opposite direction, by turning the

ignition switch QUICKLY to the other direction

WITHOUT STOPPING in the OFF position or stop-

ping the vehicle. This WILL NOT harm the vehicle.

Stopping in the OFF position when switching from

one direction to another while driving may cause a

“fault light” or system error to occur.

Stopping Utility Vehicle

• To stop utility vehicle, release accelerator pedal

and depress brake pedal until vehicle comes to a

complete stop.

• Just releasing accelerator pedal will also slow and

gradually stop the vehicle.

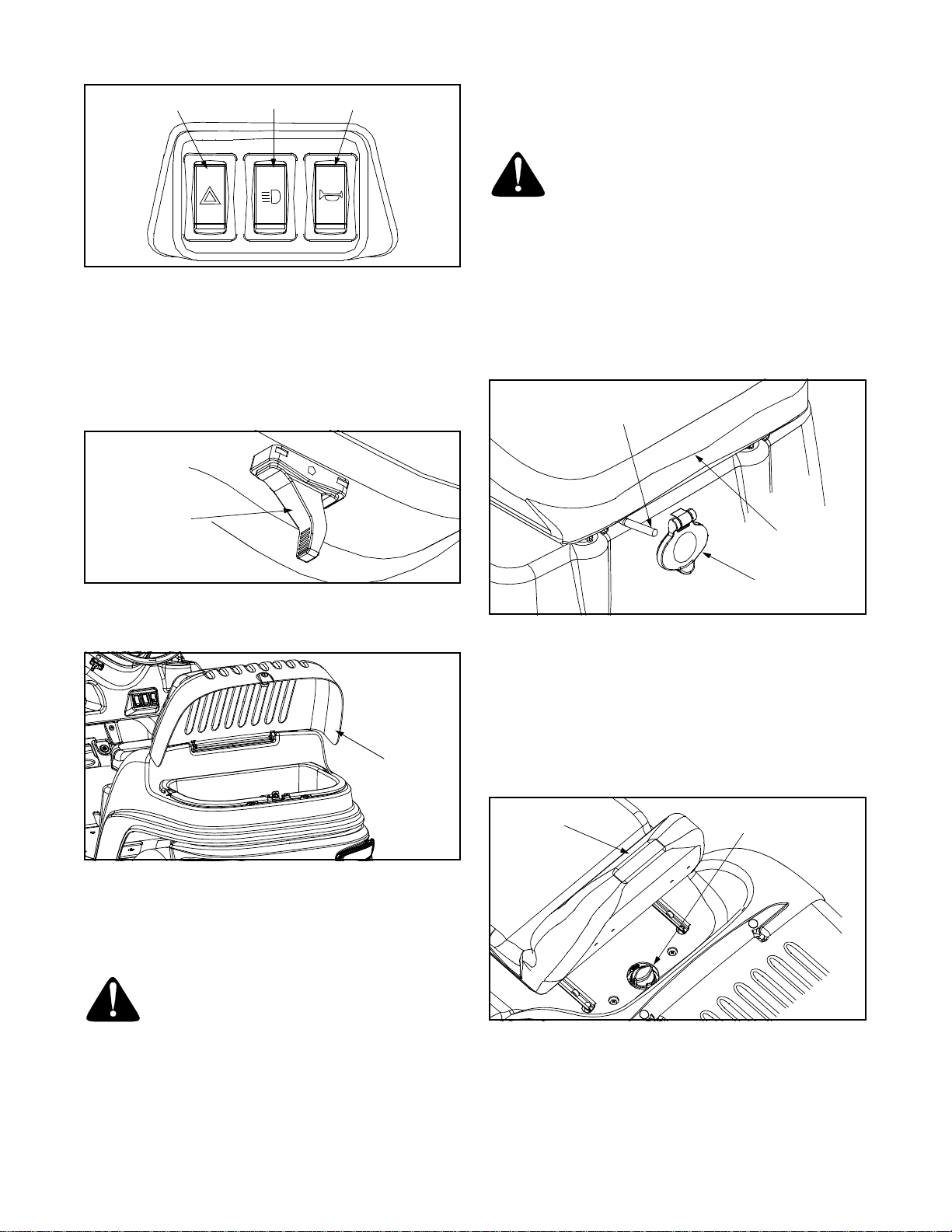

• After stopping the vehicle, firmly depress parking

brake pedal, top left of brake pedal, until it locks.

• Turn the ignition key to the OFF position and

remove the key when not in use.

IMPORTANT:

When stopped on a hill, use the brake

pedal to hold your position. Do not use the accelerator

pedal, this may cause damage to the electric drive

system.

Charging Utility Vehicle

The electric motor receives power from four batteries

stored under the seat. These batteries are sealed and

maintenance-free, so acid levels cannot be checked

and water cannot be added. When the accelerator

pedal is released the motor braking feature acts as a

power regenerator to the batteries.

Recharging the batteries is required when the battery

gauge on the instrument cluster indicates a low charge

when the vehicle is at rest or not under a heavy load.

The vehicle may also need charging if it has not been in

use for several days.

NOTE: When operating the vehicle under a heavy load

or an incline, the battery gauge may display a

temporary lower charge. This does not indicate

charging is needed.

WARNING: The electrical outlet for

charging your vehicle must be grounded

(GFCI protection) and accept a 3-prong

plug. The extension cord used for

charging must be a 3-wire grounding type

cord with a 3-prong plug. It must be a

minimum 16 AWG and be no longer than

50 feet. The use of an improper extension

cord could result in a fire or an electrical

shock. Always disconnect the extension

cord from the grounded ac outlet and

vehicle before driving vehicle.

• To recharge vehicle, plug a 3-prong 120V,ac

extension cord that is 16 gauge minimum and 50ft

maximum length (110-120V 60Hz) into a properly

grounded three-prong 120V, ac outlet (GFCI

protection).

• Insert the extension cord into the charging port on

the vehicle. Refer to Figure 8.

• It can take up to 7 to 8 hours to fully recharge the

batteries. Refer to the battery gauge on the

instrument cluster to determine level ofcharge.

• Before driving, disconnect the extension cord from

the grounded three-prong outlet first and then from

the charging porton the vehicle.