Technical Help

is available from:

Thomas & Betts Limited

Furse

Wilford Road

Nottingham

NG2 1EB

United Kingdom

Tel: +44 (0)115 964 3700

Fax: +44 (0)115 986 0538

www.furse.com

Installation Instructions

For in-line data-line protectors

ESP SL06, ESP SL15, ESP SL30,

ESP SL50, ESP SL110, ESP SL15X,

ESP SL30X, ESP SL TN, ESP SLR TD

Earthing (continued)

In extreme cases where even 4m of connecting

lead is not sufficient, the incoming line should be

re-routed to bring it within 4m of the earth.

If the line cannot be re-routed; the Lightning

Barrier can, as a last resort, be connected to

the electrical earth local to the equipment

being protected.

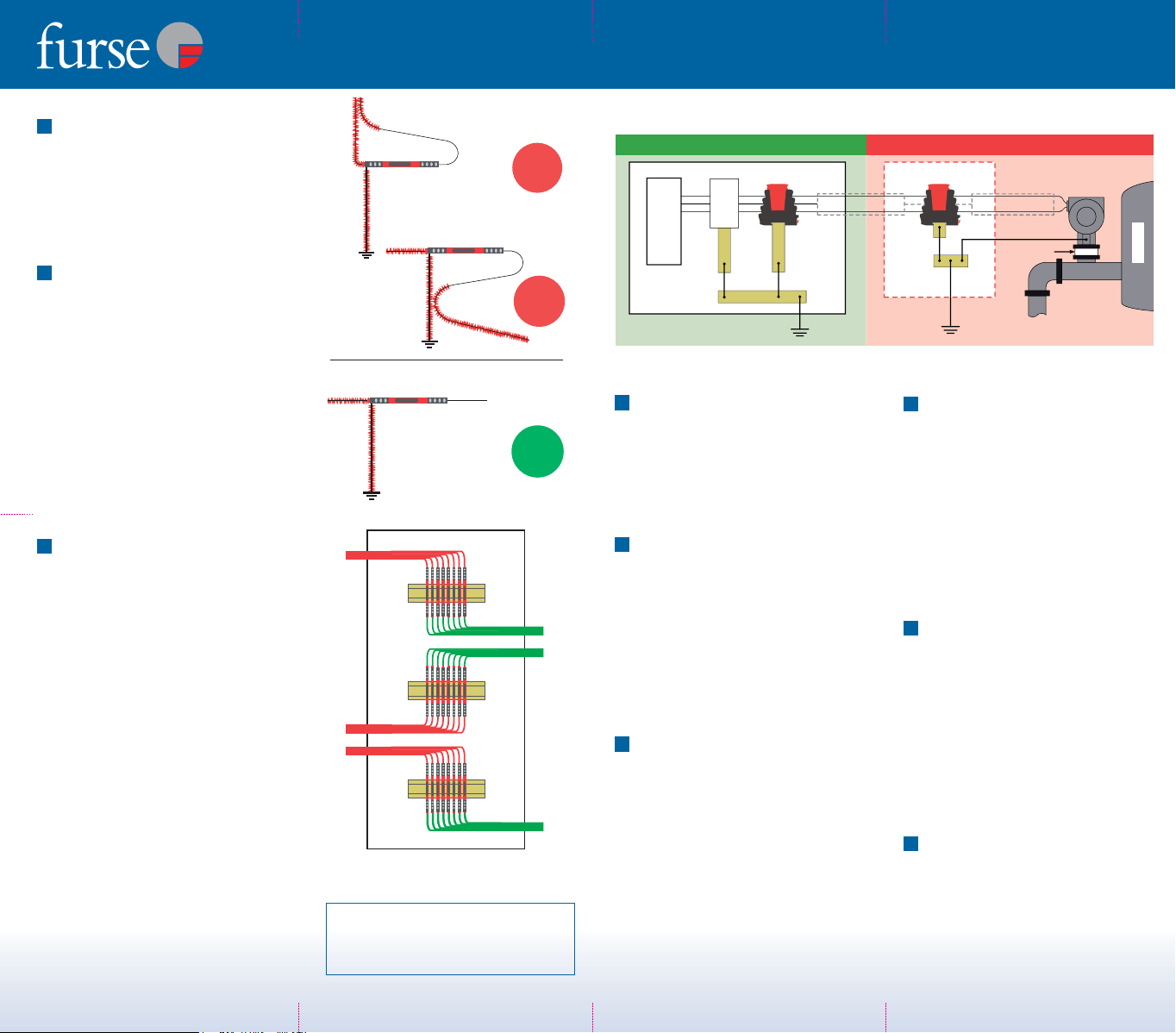

Keep clean lines away from dirty lines

Cables connected to the Lightning Barrier’s clean

end should never be routed next to dirty line

cables or dirty barrier earth bonds. See Figure 7.

If rows of Lightning Barriers are installed close to

each other, dirty (‘line’) lines and earth bonds

must be kept at least 5cm apart from ‘clean’ lines.

See Figure 8.

Note: When using the DIN rail foot to

provide the Earth to the Lightning Barrier in

conjunction with a base plate (i.e. DIN rail

not directly bonded onto cabinet chassis)

ensure the earth bond to the base plate (or

DIN rail itself) is kept clear of the ‘clean’

lines.

Maintenance/Spares

In the unlikely event of a failure, replacement

modules are available, contact sales on

+44 (0)115 964 3700.

If a replacement module is required please

quote part number with a suffix /M

e.g. a replacement module for an ESP SL30 barrier

would be ESP SL30/M.

ESP Lightning Barriers contain no user

serviceable parts and must be replaced with

equivalent genuine Furse modules.

The modules can easily be removed by pressing in

the release button and pulling the module away

from the base. The module is keyed to prevent it

being inserted the wrong way around.

Insulation/Flash testing

The ESP Lightning Barriers can be easily

disconnected from the system for insulation

testing. When the module is 1cm away from

being fully inserted there is a 2nd hold point.

Instead of completely removing the module and

having to record which point it is required to be

replaced in, this point allows the module to be

held in place within the base but disconnected

from the system’s wiring.

General information

In common with all other electrical apparatus

installed in hazardous areas, the Lightning Barriers

must only be installed, operated and maintained

by competent personnel. The ESP SL**X Series

have a group IIC T4 certification making it

acceptable for use with all gas/air mixtures.

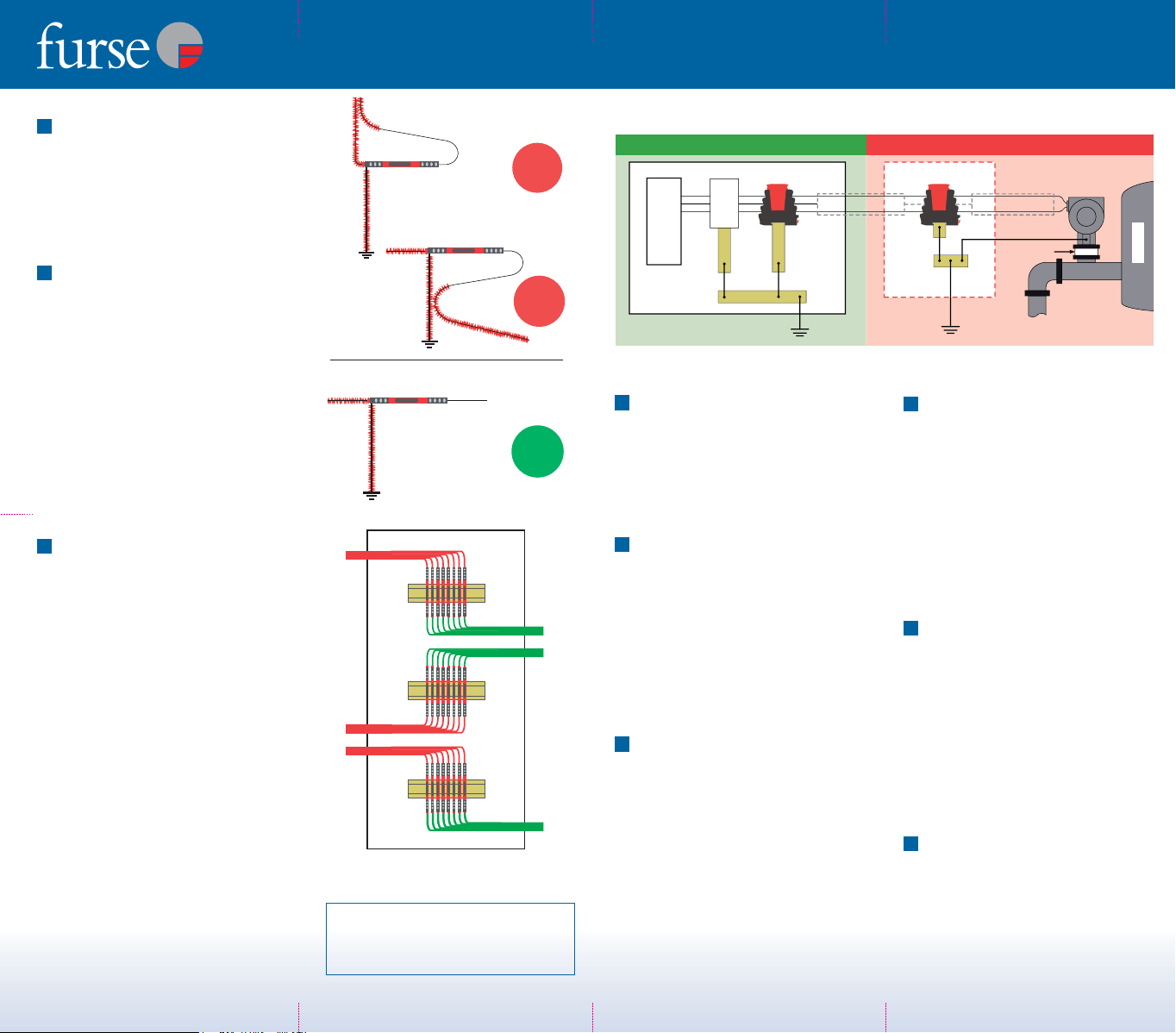

Location

Field instrument protection should take place in

Zone 1 and as close as practically possible to the

Zone 0 boundary, preferably within 1m to prevent

transient voltages from entering Zone 0. Ensure

the Lightning Barriers are mounted on a separate

DIN rail to the IS Barriers. See figure 9. Ideally, the

Lightning Barrier should be installed within the

housing of the field instrument, however due to

space restrictions it may be necessary to mount

the unit in a suitable enclosure available from

Furse.

Installation

The Lightning Barrier must not be subjected to

thermal and/or mechanical stresses in excess of

those permitted in the certification

documentation, see product datasheet. If

necessary the product must be protected by an

enclosure to prevent mechanical damage as the

Lightning Barrier requires additional protection for

use in dust environments.

The Lightning Barrier must not be installed in

a location where it may be attacked by

aggressive substances and must be protected from

excessive dust, moisture and other contaminants

by an enclosure.

Inspection and Maintenance

Inspection and maintenance should be carried out

in accordance with European, national and local

regulations which may refer to the IEC standard

IEC 60079-17. In addition specific industries or

end users may have specific requirements which

should also be met.

If the outer enclosure of the Lightning Barrier

needs to be cleaned, this should be done with a

cloth lightly moistened by a dilute mixture of

detergent in water.

Conditions for safe use

The plastic enclosure must not be rubbed in

service as it may present an electrostatic risk.

When the surge protection module is fitted, the

range of SL**X Series Surge Protection Devices

will not meet the 500V insulation requirements to

earth. Please refer to Installation - Section 8,

Insulation/Flash testing, for information of how to

disconnect the module for insulation testing.

ESP SL**X barriers provide surge protection

on the Intrinsically safe (IS) circuits only and

do not replace the IS barrier itself.

Marking

The specific ATEX certification and ratings are

clearly marked on the product label for each of

the ESP SL**X Lightning Barriers. In addition there

is a separate label on both the replaceable

module and base housing to indicate the

manufacturing date.

2

1

6

5

4

3

8

7

6

SAFETY NOTE:

1. Always handle cables by their insulation

2. Never work on Lightning Barriers or their

cables during a storm

© Copyright Thomas&Betts 2010

ESP SL06, ESP SL15, ESP SL30, ESP SL50, ESP SL110,

ESP SL15X, ESP SL30X, ESP SL TN, ESP SL RTD

L

I

N

E

C

L

E

A

N

L

I

N

E

C

L

E

A

N

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

ESPSL06S

Figure 7 - Cable routeing

Figure 8 - Positioning of adjacent rows of

Lightning Barriers

Figure 9 - The ESP SL**X Series can provide protection for the PLC or RTU I/O as well as providing protection

for the IS barrier. The isolated screen (ESP SL**X/I) version should be used in zone 1, 2.

Instrumentation

Instrument

Earth

ESP SL30X/I

ESP SL30X

Control cabinet

IP54

enclosure

Instrument

Earth

System

Earth

Field

earth

Open end cable screen

ZONE 0

Hazardous AreaZones 1,2Non-Hazardous Area

Isolated

coupling

IS

Barrier

Intrinsically safe barriers for Hazardous areas - ESP SL**X only

TNB 2059 ESP Instructions v2:Layout 1 25/2/10 16:51 Page 1