AUTOPILOT

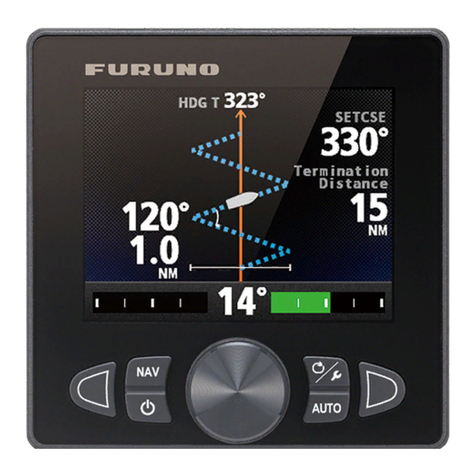

NAVpilot-700/711/720

Installation Manual

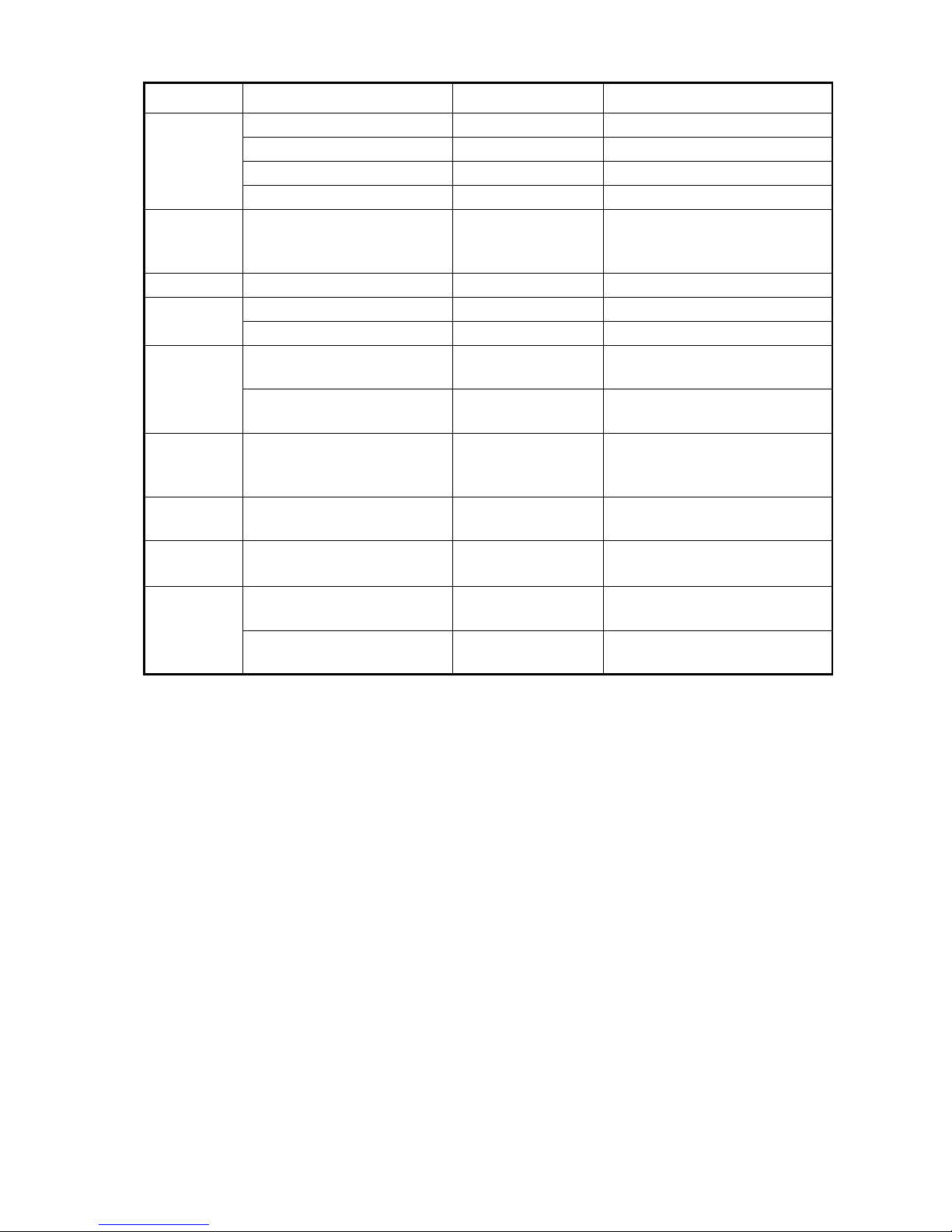

SYSTEM CONFIGURATION .........................ii

EQUIPMENT LISTS ......................................iii

1. HOW TO INSTALL THE UNITS ............ 1-1

1.1 Control Unit FAP-7001/FAP-7011...... 1-1

1.1.1 Surface mount.......................... 1-2

1.1.2 Desktop mount......................... 1-4

1.2 Processor Unit FAP-7002 .................. 1-5

1.3 Rudder Reference Unit FAP-6112 ..... 1-7

1.4 Remote Controllers (option) ............... 1-9

1.5 Distributor FAP-6800 (option) .......... 1-12

1.6 Control Unit FAP-7021 ..................... 1-13

1.7 Cable Extension Kit

FAP-7822 (option)............................ 1-13

2. WIRING.................................................. 2-1

2.1 General Wiring ................................... 2-1

2.2 Processor Unit.................................... 2-2

2.2.1 Connections inside the processor

unit ........................................... 2-2

2.2.2 How to fasten cables to the cable .

clamps...................................... 2-3

2.2.3 How to put wires into the connector

blocks....................................... 2-4

2.2.4 How to terminate of NMEA2000

connection................................ 2-5

2.2.5 Power and motor cables .......... 2-5

2.2.6 Teleflex linear sensor............... 2-7

2.2.7 CAN bus power........................ 2-8

2.2.8 Connection to TB4 ................... 2-8

2.3 Control Unit ........................................ 2-8

2.4 Remote Controllers (option) ............... 2-9

2.4.1 Example remote controller

connections............................ 2-10

2.4.2 Prohibited remote controller

connections............................ 2-11

2.5 Input/Output Sentences ................... 2-12

3. INITIAL SETTINGS ............................... 3-1

3.1 About Initial Settings, Menu Operation3-1

3.2 How to Select Language and Units,

Open the Installation Menu ................ 3-2

3.3 Display Setup ..................................... 3-4

3.4 Ship’s Characteristics Menu............... 3-5

3.5 Dockside Setup Menu ........................ 3-6

Dockside setup for RRU..................... 3-6

Dockside setup for Fantum

FeedbackTM ..................................... 3-15

3.6 CAN bus Port Setup ......................... 3-17

3.7 NMEA0183 Port Setup ..................... 3-18

3.8 Sensor Setup.................................... 3-20

3.9 Universal Port Setup ........................ 3-21

3.10 Sea Trial ........................................... 3-23

3.11 Data Calibration................................ 3-25

3.12 PARAMETER SETUP Menu ........... 3-26

3.13 AUTO OPTION Menu....................... 3-30

3.14 NAV OPTION Menu ......................... 3-31

3.15 FISH HUNTER OPTION Menu or

WIND OPTION Menu ....................... 3-34

3.15.1FISH HUNTER OPTION

menu ...................................... 3-34

3.15.2WIND OPTION menu............. 3-35

3.16 SYSTEM SETUP Menu.................... 3-36

3.17 RC (Remote Controller) SETUP

Menu ................................................ 3-37

3.18 All Clear............................................ 3-37

JIS CABLE GUIDE ................................. AP-1

PACKING LISTS........................................A-1

OUTLINE DRAWINGS...............................D-1

INTERCONNECTION DIAGRAM............... S-1

MOUNTING TEMPLATES

www.furuno.com

All brand and product names are trademarks, registered trademarks or service marks of their respective holders.