1

OVERVIEW

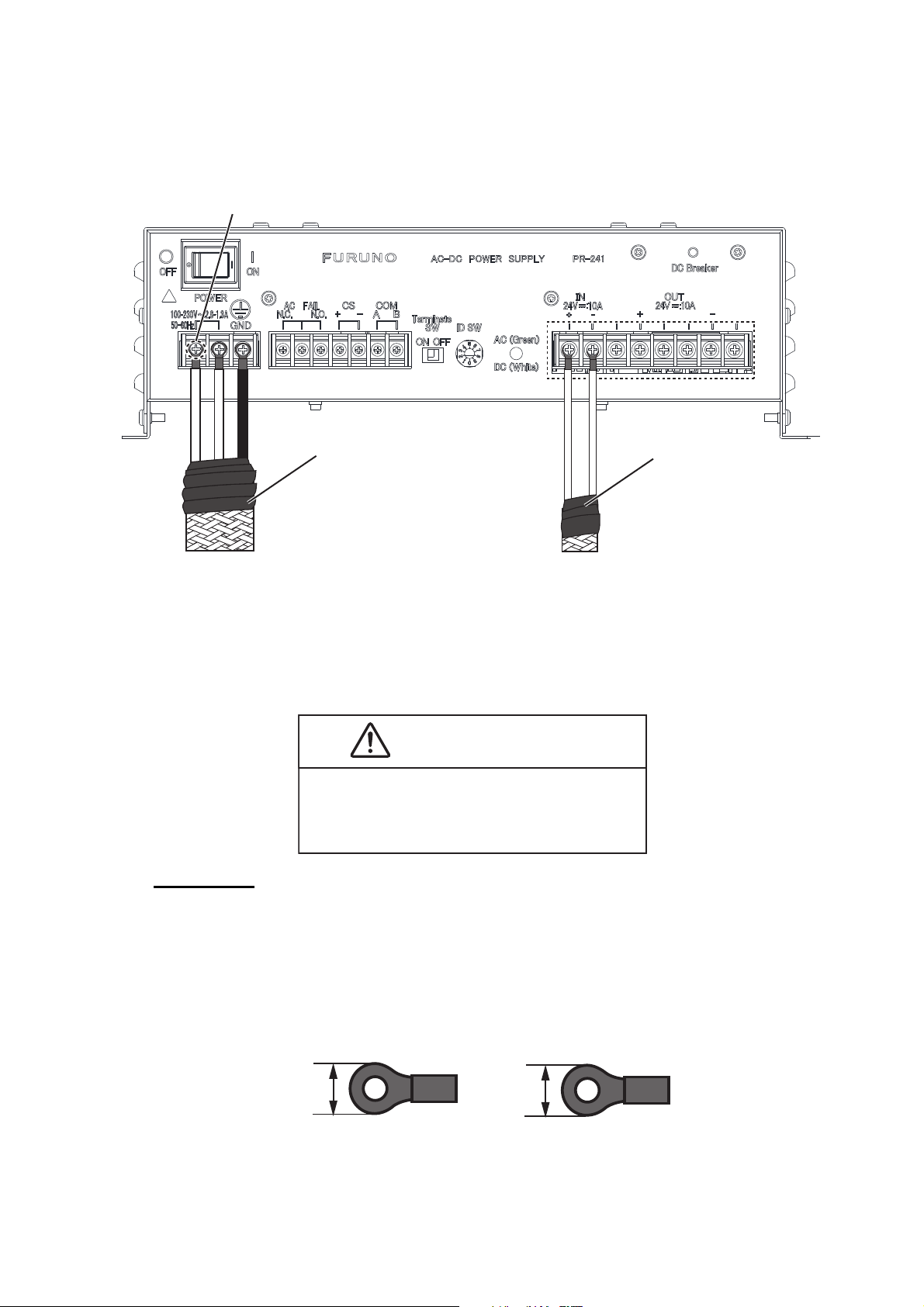

The PR-241 is a unit integrates the functions of our AC/DC power supply units and rectifiers

listed below.

• AC/DC power supply unit PR-240, PR-300

• Rectifier unit RU-1746B-2, RU-3423, and RU-3424.

Important notices

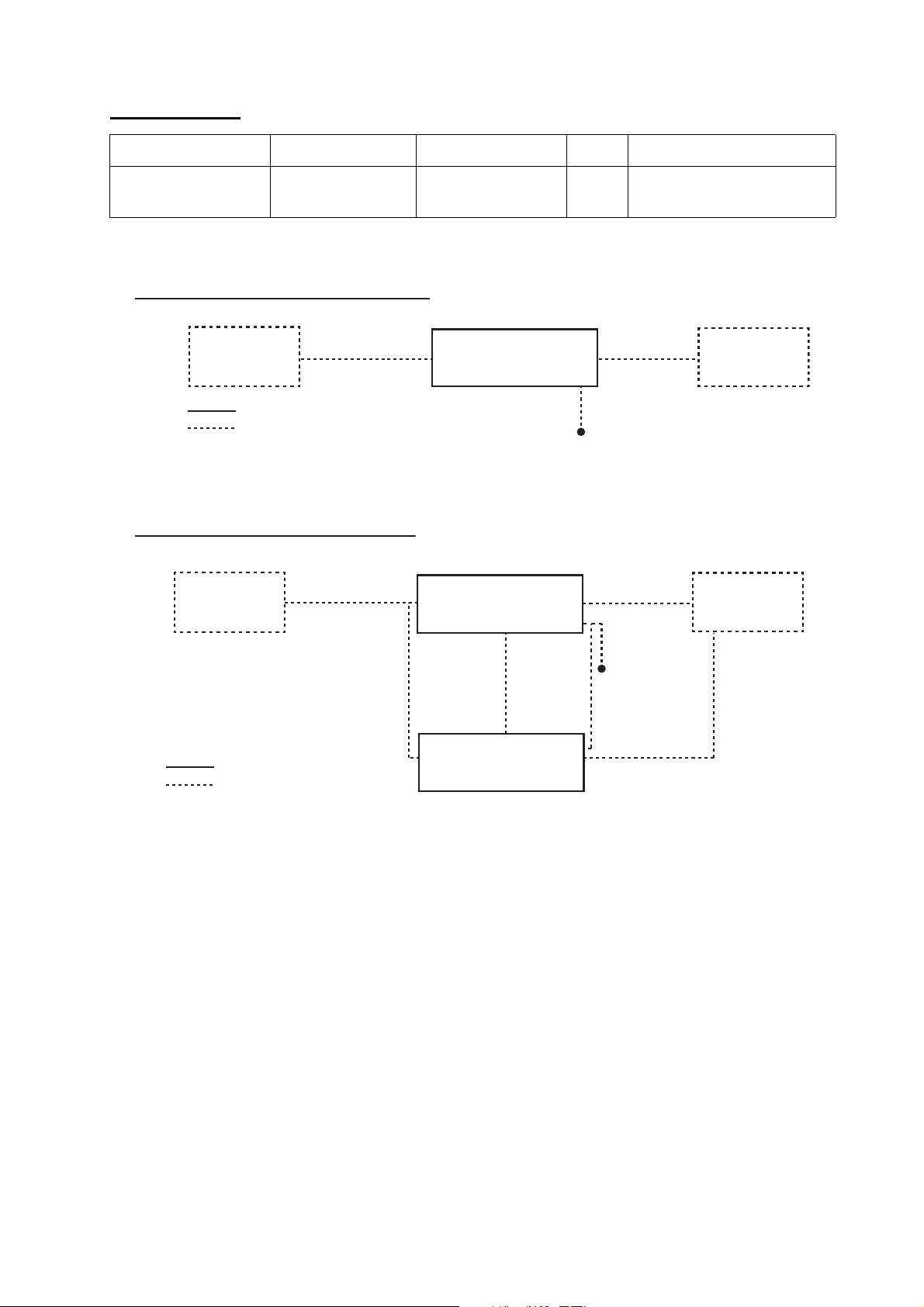

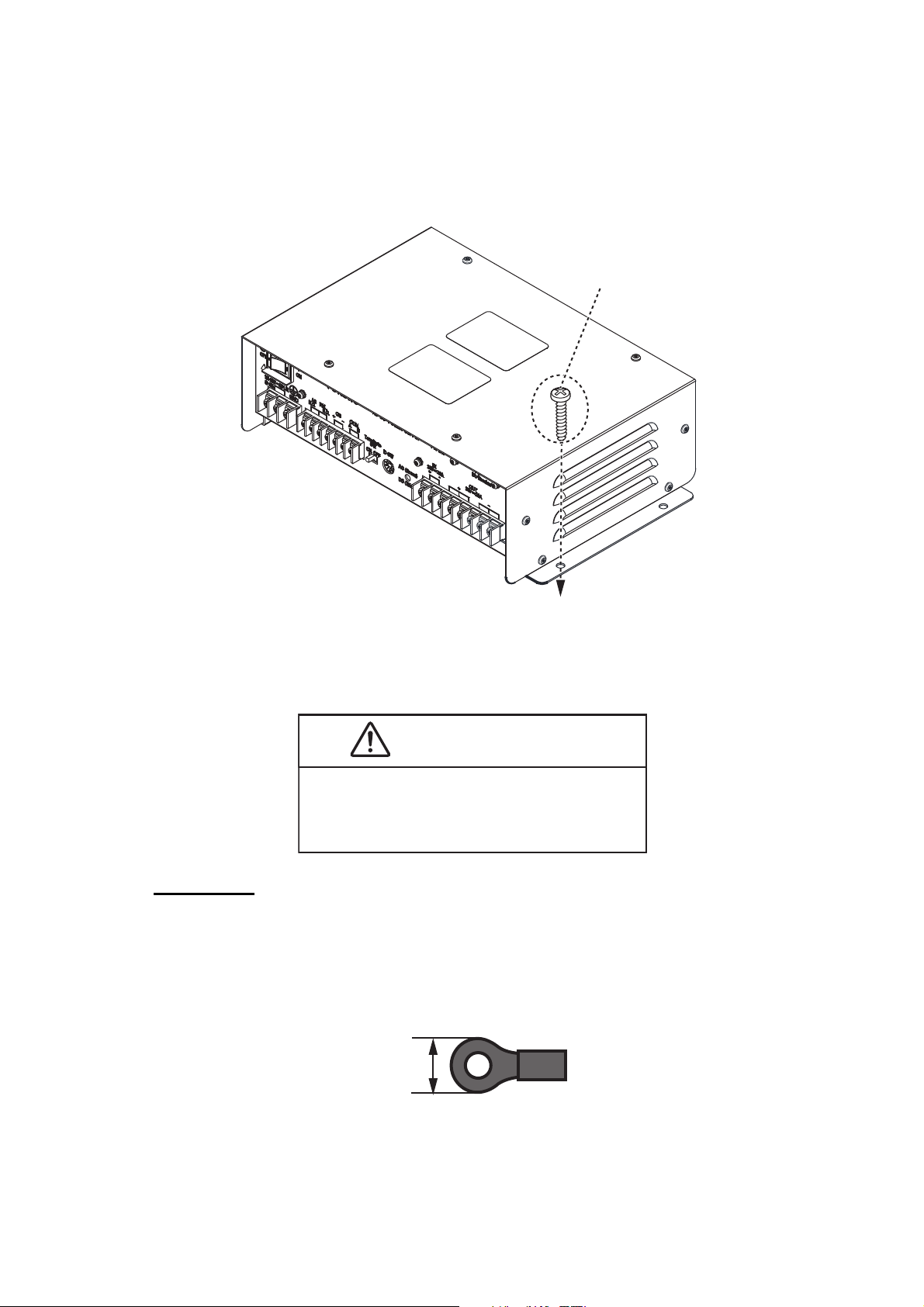

The specifications of PR-241 have been changed to be compatible with DC bypass. The DC

compatible unit has a white dot as shown in the figure below. Up to two units can be con-

nected in parallel, the same as the previous specifications. However, the DC bypass com-

patible units cannot be connected in parallel with the DC bypass non-compatible units.

The differences from the conventional PR-241 (DC bypass non-compatible units) are as

shown in the table below.

The following concern acts as our importer in Europe, as defined in DECISION No 768/

2008/EC.

- Name: FURUNO EUROPE B.V.

- Address: Ridderhaven 19B, 2984 BT Ridderkerk, The Netherland

The following concern acts as our importer in UK, as defined in SI 2016/1025 as amended

SI 2019/470.

-Name: FURUNO (UK) LTD.

-Address: West Building Penner Road Havant Hampshire PO9 1QY, U.K .

Discard this product according to local regulations for the disposal of industrial waste. For

disposal in the USA, see the homepage of the Electronics Industries Alliance (http://www.ei-

ae.org/) for the correct method of disposal.

EQUIPMENT LIST

DC bypass

non-compatible units

DC bypass

compatible units

When the input from the AC

power source is disconnected.

No power is supplied from DC

power source.

Power is automatically supplied

from DC power source.

When DC power is turned ON

while the power switch is

turned OFF.

24 VDC is not output. 24 VDC is output.

Standby power when no device

is connected.

Not generated. 4.8 W is generated.

Standard Supply

Name Type Code No. Qty. Remarks

AC/DC Power

Supply unit

PR-241 - 1

DC bypass compatible unit

DC bypass non-compatible unit

Has a

white dot.