www.furuno.com

ll brand and product names are trademarks, registered trademarks or service marks of their respective holders.

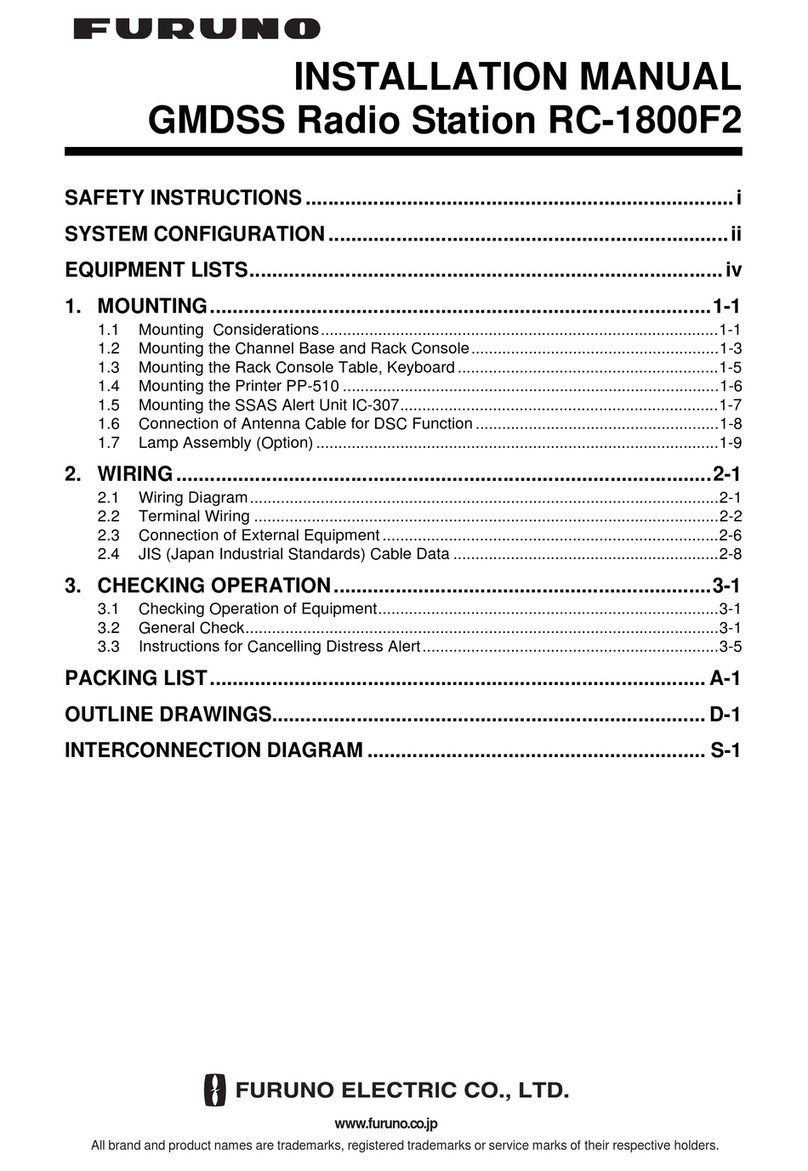

Installation Manual

GMDSS Radio Station

Model RC-1800T

(FS-1575/FS-2575 installation-in-field specification)

SAFETY INSTRUCTIONS ................................................................................................ i

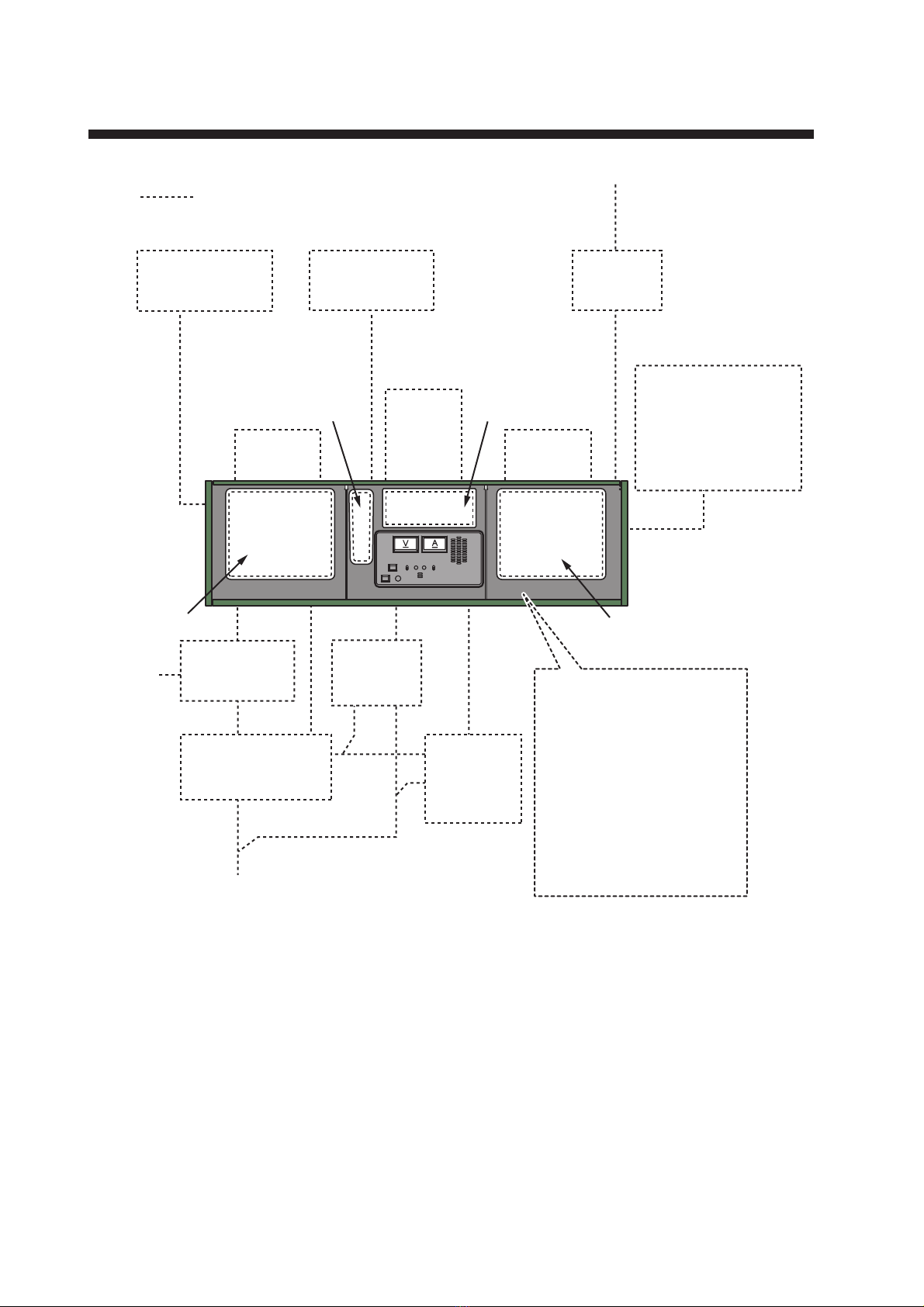

SYSTEM CONFIGURATION ........................................................................................... ii

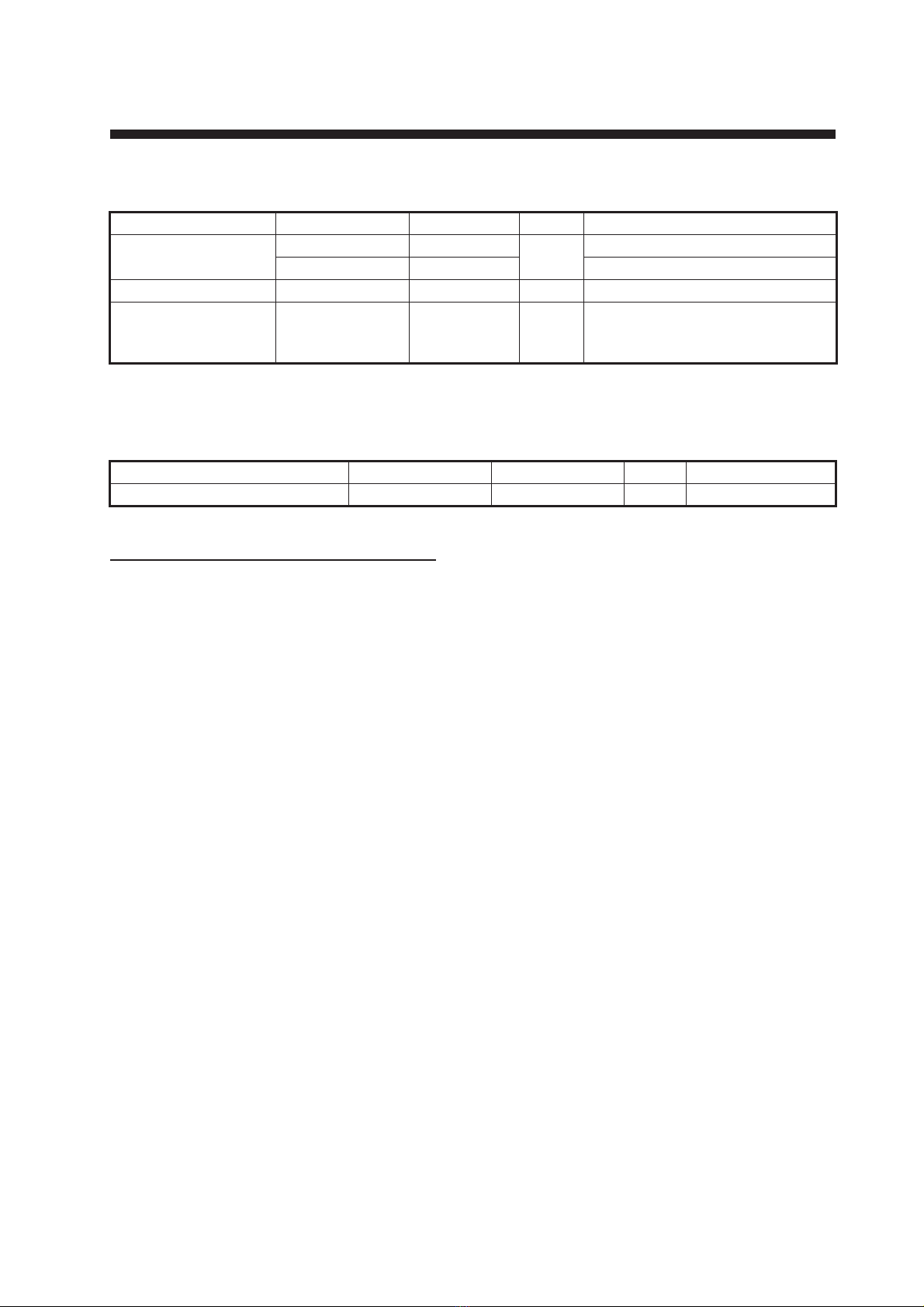

EQUIPMENT LISTS........................................................................................................ iii

1. INSTALLATION.......................................................................................................1-1

1.1 Installation Considerations.................................................................................................1-1

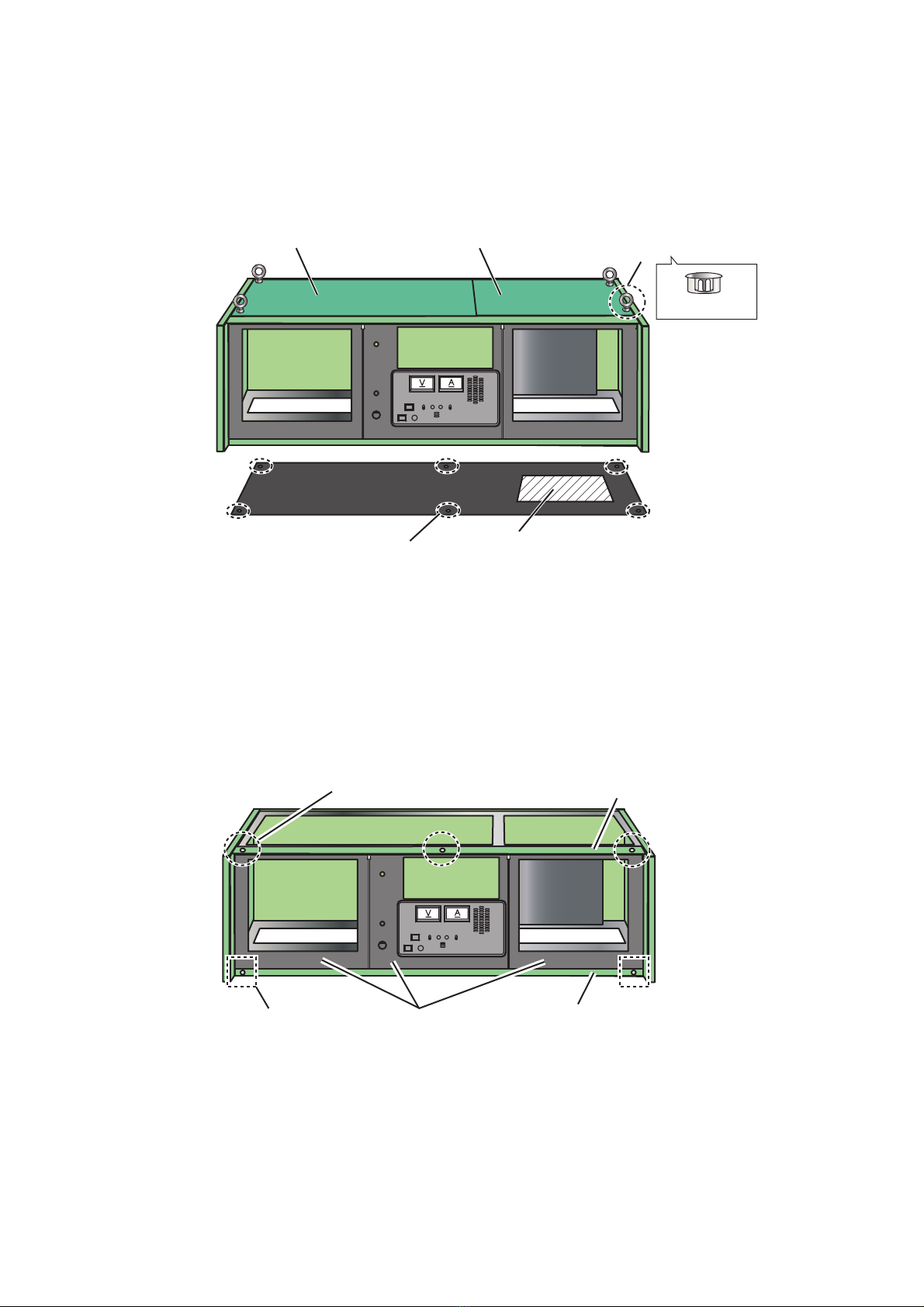

1.2 Rack Console Installation ..................................................................................................1-2

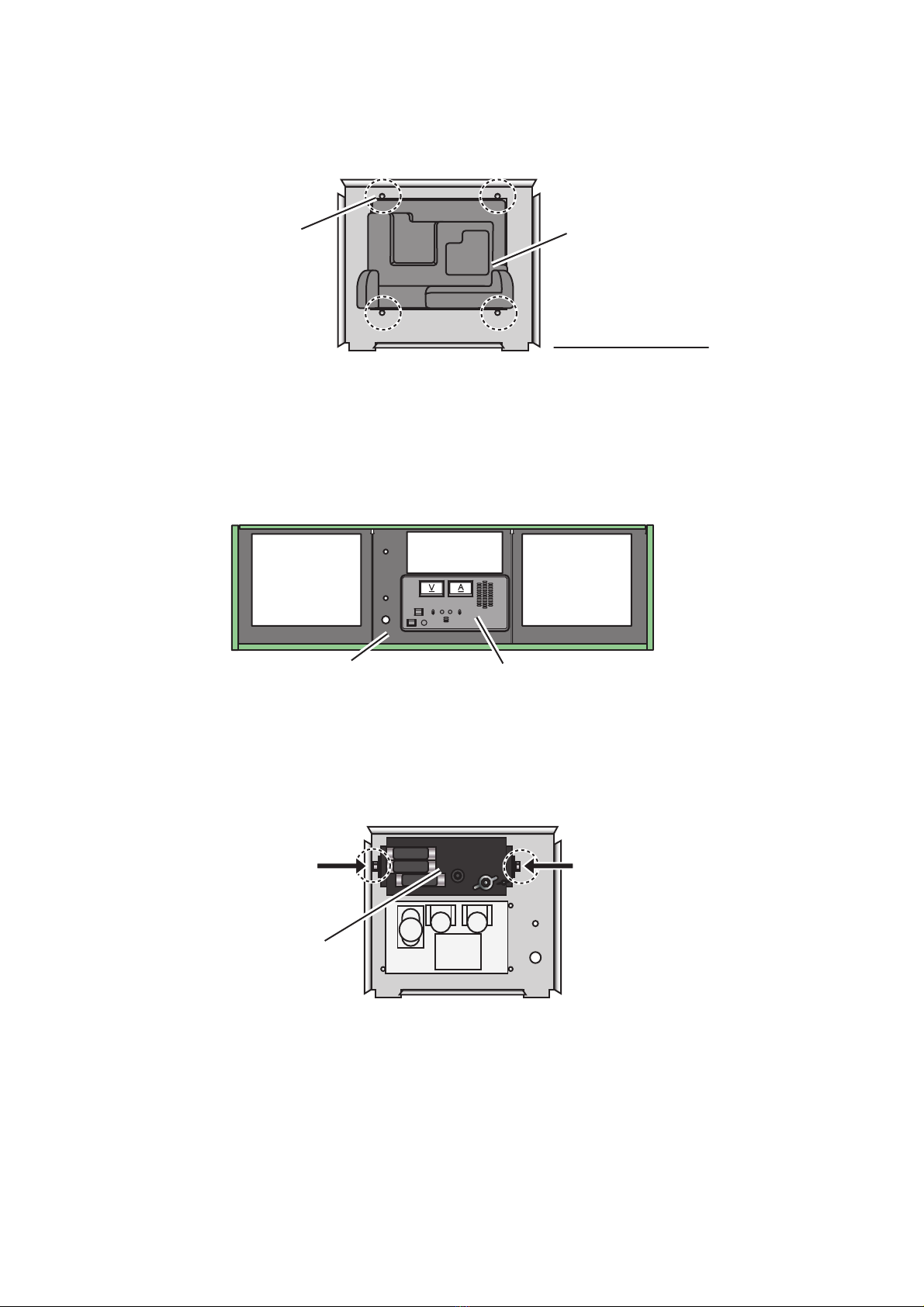

1.3 Terminal Unit (IC-218/IB-585)............................................................................................1-3

1.4 SSB Radiotelephone (FS-1575/FS-2575)..........................................................................1-4

1.5 Printer (PP-520) .................................................................................................................1-7

1.6 Fuse Box (SB-180) ............................................................................................................1-8

1.7 Distress Alert/Received Call Unit (IC-305)/Alarm Unit (IC-350).........................................1-8

1.8 Alarm Unit (IC-306)............................................................................................................1-8

1.9 SSAS Alert Unit (IC-307) ...................................................................................................1-9

1.10 AC/DC Power Supply Units (PR-300/PR-850)...................................................................1-9

1.11 Other Equipment................................................................................................................1-9

2. WIRING....................................................................................................................2-1

2.1 Wiring Diagram ..................................................................................................................2-1

2.2 Location of Terminal Blocks Inside the Rack Console.......................................................2-2

2.3 Connection of Equipment Installed in the Console ............................................................2-2

2.4 Connection of External Equipment ....................................................................................2-3

2.5 Fuse Box (SB-180) ............................................................................................................2-6

2.6 Charger Unit (BC-6158-SS/6200) ......................................................................................2-7

2.7 Power Supply Unit (PR-300/PR-850A) ..............................................................................2-9

3. CHECKING OPERATION........................................................................................3-1

3.1 Checking Operation of Equipment .....................................................................................3-1

3.2 General Check ...................................................................................................................3-1

APPENDIX 1 JIS CABLE GUIDE .............................................................................AP-1

PACKING LISTS ......................................................................................................... A-1

OUTLINE DRAWINGS ................................................................................................ D-1

INTERCONNECTION DIAGRAM ................................................................................ S-1