- 3 -

Connecting the ends of the steel wall using the

plug-in section

The clearance between the steel-wall ends should be approx.

5 mm. Depending on the overlap of the wall tracks, they

must be shortened to size in the curves. Make sure that you

shorten the wall tracks by the same amount in both semicir-

cles, as otherwise the symmetry of your pool will be spoiled.

The straight wall tracks are already cut to the correct length.

The plug-in section is sitting correctly when the bevelled

side is on the inside and at the top. By gently rocking the

plug-in rail back and forth you can ease insertion into the

plug-in section. To further facilitate insertion of the plug-in

rail you can lubricate both ends of the steel wall with engi-

neering Vaseline.

Preparing openings for connections

If built-in components are to be installed (skimmer, inlet

nozzle), you must break out the corresponding pre-punched

holes. Carefully remove burrs and treat with an anti-

corrosion agent.

Caution: Follow the instructions for built-in components!!!

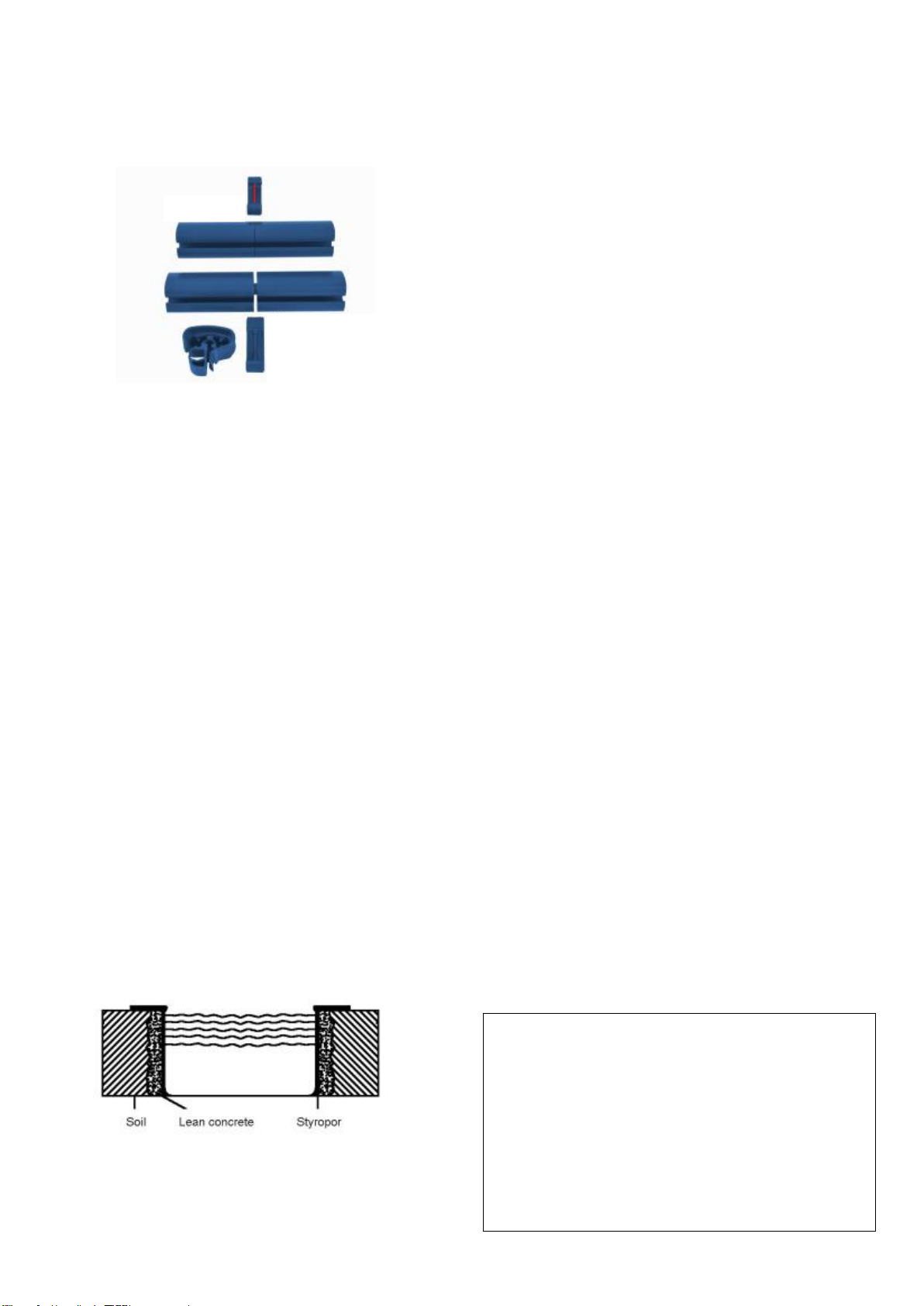

Fixing the steel wall

In the area of the retaining walls you must fix the steel wall 5

cm below the retaining-wall edge (110 cm from the floor for

a pool height of 120 cm and 140 cm from the floor for a pool

height of 150 cm) with the screws and dowels provided.

Fixing must be carried out in a horizontal line and must be

absolutely firm. If in doubt, add further screws and dowels.

Cover screw heads with PVC-compatible adhesive tape (e.g.

parcel tape) to protect the liner.

Earthing the swimming pool

According to statutory regulations, swimming pools and all

large-area metallic parts must be connected to a potential

equaliser.

Caution: All electrical work must be carried out by a recog-

nised specialist company in accordance with the relevant

DIN and VDE regulations (e.g. DIN VDE 0100 Part 702).

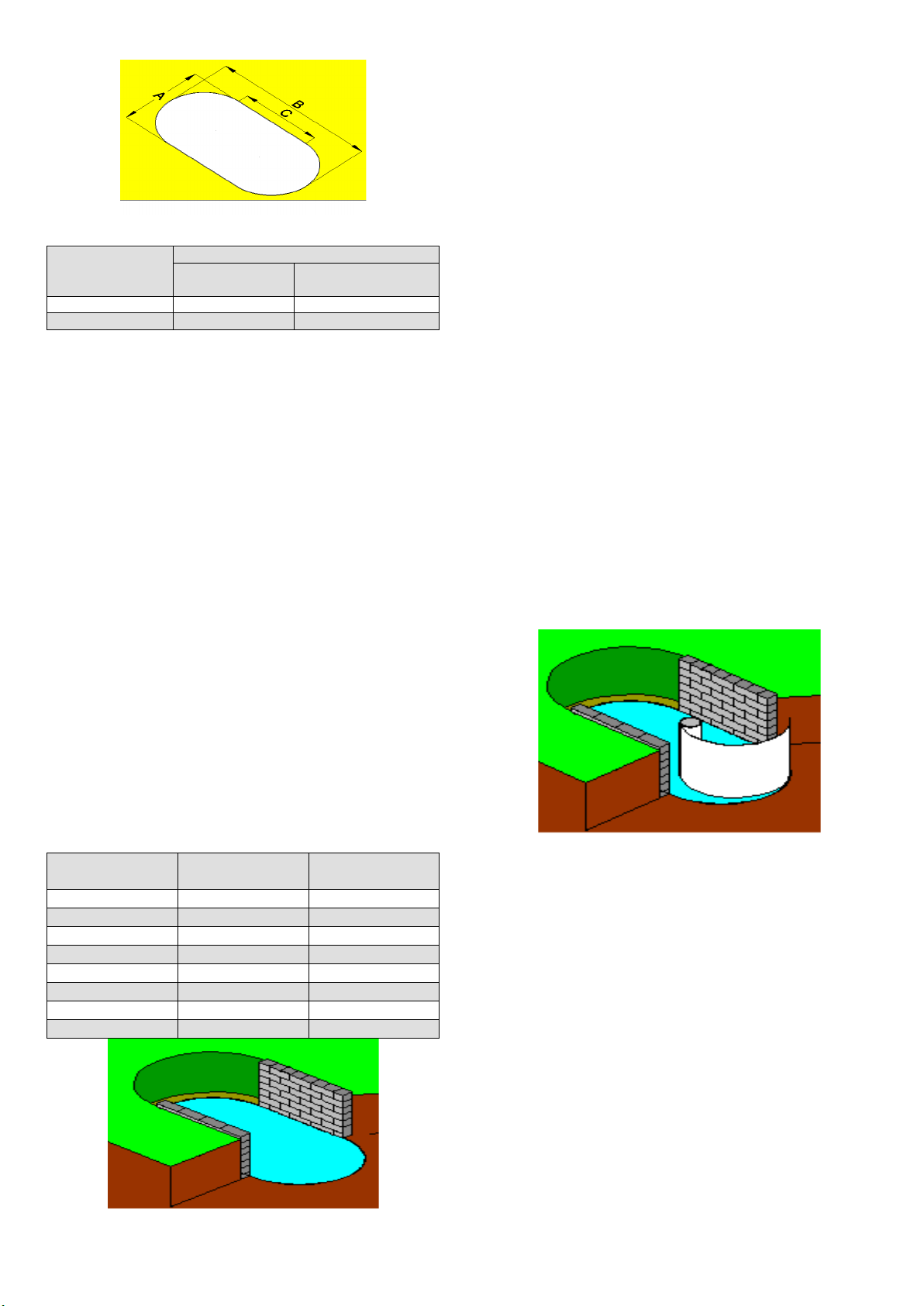

Laying out the protective matting or protective

ground tarpaulin (not supplied)

We recommend the use of a protective ground tarpaulin or

matting to protect the liner from direct contact with the

ground or with any materials which may be harmful to PVC.

Thoroughly clean the ground again and then lay out the pro-

tective matting, with the individual sheets butting up against

each other. Cut the protective ground tarpaulin or matting 5 –

10 cm larger than the pool outline and tape the resulting

overlap firmly to the steel wall. Pull the edges over the wall

tracks. To do this, use PVC-compatible adhesive tape (e.g.

parcel tape). Lay out the protective ground tarpaulin or pro-

tective matting smoothly and free of creases.

Hanging the liner

Caution: Hang the liner at temperatures between +15 and

+25° C, but not in strong sunshine! If the temperature is too

high the foil becomes soft and elastic and too large. If the

temperature is too low the liner becomes hard, inelastic and

too small.

Clean the inside of the pool again. Now place the liner in the

middle of the pool and spread it out, so that the outer bonded

seams lie up against the steel wall. The liner has a shaped

hanging fringe bonded onto the main liner. Push the liner

edges with the shaped fringe over the upper edge of the steel

wall. Provisionally fix the fringe with several individual

handrail sections.

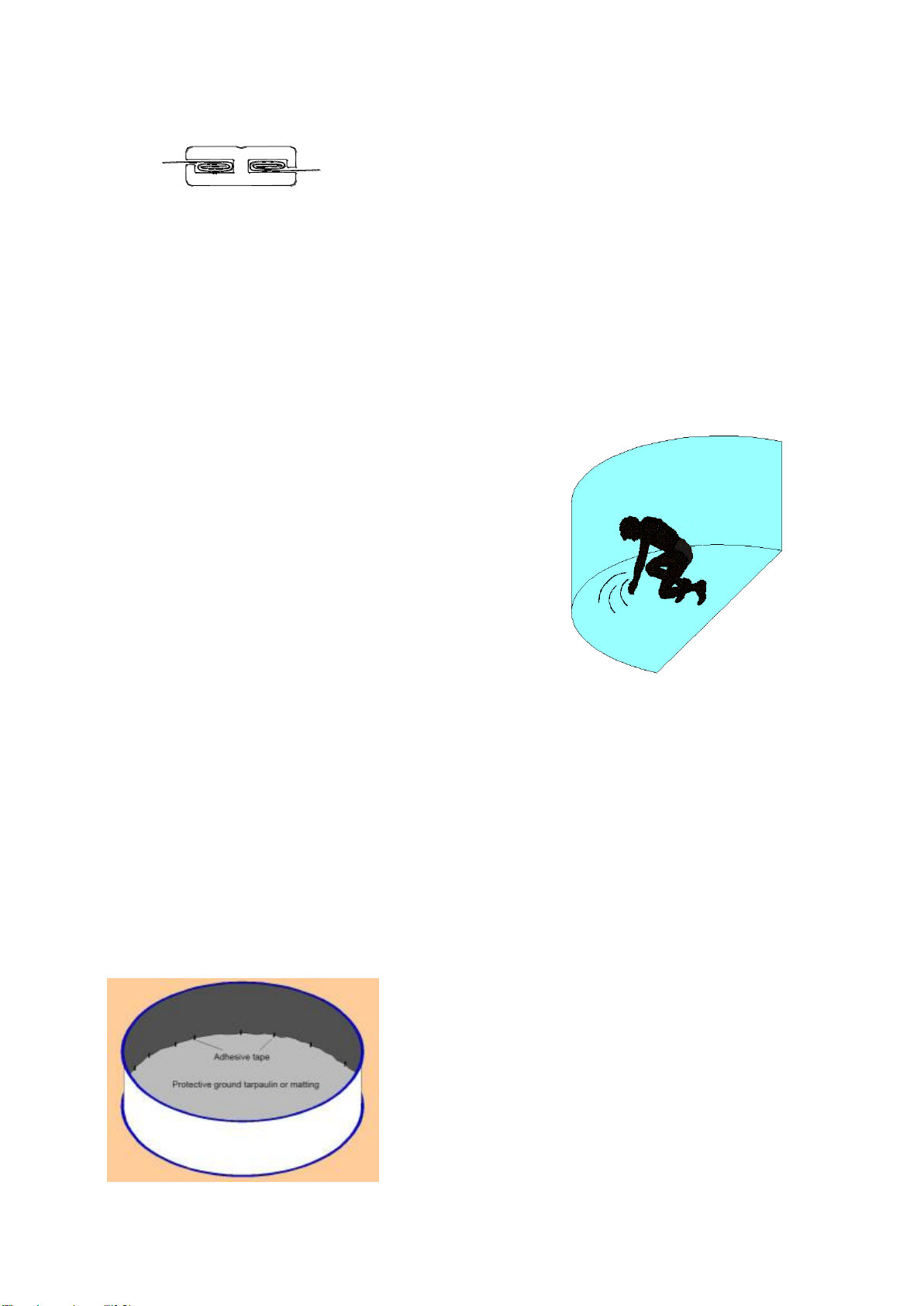

Caution: Only walk on the PVC liner barefoot or wearing

suitable shoes (no rough-studded rubber boots!).

Smoothing out the creases

Smooth the creases on the floor outwards towards the pool

wall. Now let water into the pool until the middle is covered

to a depth of approx. 2 –3 cm. Smooth any remaining

creases outwards from the centre by hand.

If the creases cannot be smoothed out:

Have the wall tracks sunk into the ground? Lift them up!

Have you overstretched the liner when hanging it in the

pool? Rehang the liner, perhaps after waiting for cooler

weather. Do not pull on the liner when hanging it! Is there

too much tension in the liner? If so, you have probably exca-

vated the foundations too deeply. Then it is essential to fill in

as necessary, not forgetting to firmly compact any fill.

Caution: from a water depth of approx. 5 –6 cm the liner

can no longer be smoothed out because of the high water

pressure.

Caution: It is essential to check that the pool is standing

absolutely vertically.

Cover the pool floor with approx. 10 cm of water. Measure

the distance between the waterline and the upper edge of the

pool at several points. If the measured values differ by

more than 2 cm the pool has been incorrectly erected. In

this case the manufacturer’s guarantee is no longer valid!