8FWE RETHERM OVENS

FWE RETHERMALIZATION AND HOLDING OVENS

FAHRENHEIT OR CELSIUS SCALE

While unit is "ON", press an hold the "START/PAUSE"KEY for five (5)

seconds. The display will read "dgF"for Fahrenheit or "dgC"for Celsius.

Press and hold to change scale.

Fahrenheit Temperature Range: 100°F to 350°F

Celsius Temperature Range: 38°C to 177°C

GENERAL OPERATING INSTRUCTIONS

"COOK BY PROBE"CYCLE: PROBE OPTIONAL

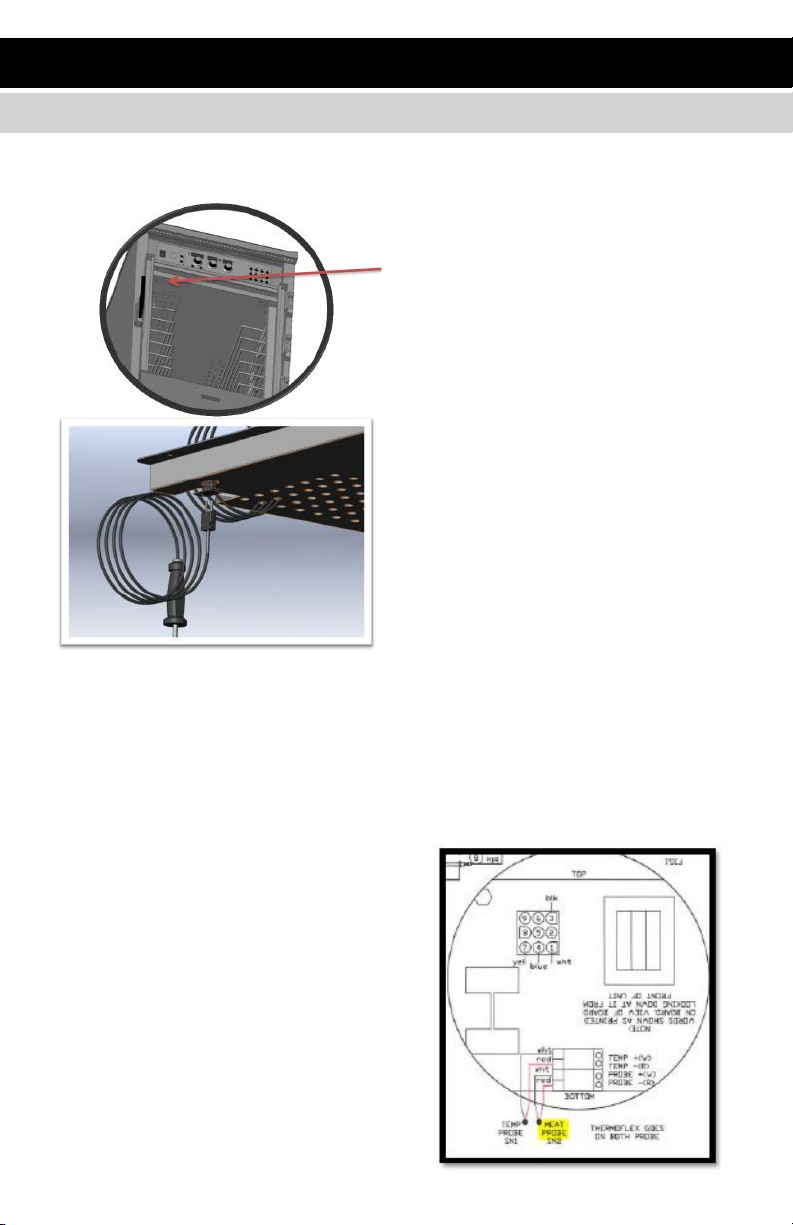

CONNECT PROBE INTO SOCKET

Place PROBE TIP outside cabinet door.

TURN ON MAIN SWITCH.

Set up cooking perimeters as shown below.

Control must display the "OFF" mode to begin selection.

PRESS "STOP CYCLE" KEY ONCE.

PRESS "COOK BY PROBE" KEY ONCE.

SELECT PROBE TEMPERATURE or desired product internal temperature by

rotating "Knob A".

SELECT CABINET OR COOKING TEMPERATURE by rotating Knob "B".

SELECT HOLD TEMPERATURE by rotating Knob "C" to desired cabinet

temperature

PRESS "START/PAUSE" KEY to start the PREHEAT CYCLE.

The Pre-heat indicator light will light and begin the Pre-heat mode untimed.

"PRHE" message will display. At the end of the Pre-Heat Cycle, the control will

beep and "RDY" ("Ready") message will display.

LOAD CABINET WITH PRODUCT.

PLACE PROBE TIP INTO CENTER OF PRODUCT.

PRESS "START/PAUSE" KEY to start the COOK BY PROBE CYCLE and the

indicator is lighted. The product internal temperature, the indicator light will go off

and the oven will automatically switch to the "HOLD" mode.

NOTE: to BYPASS PRE-HEAT, PRESS START TWICE.