3 0 - 6 0 c m

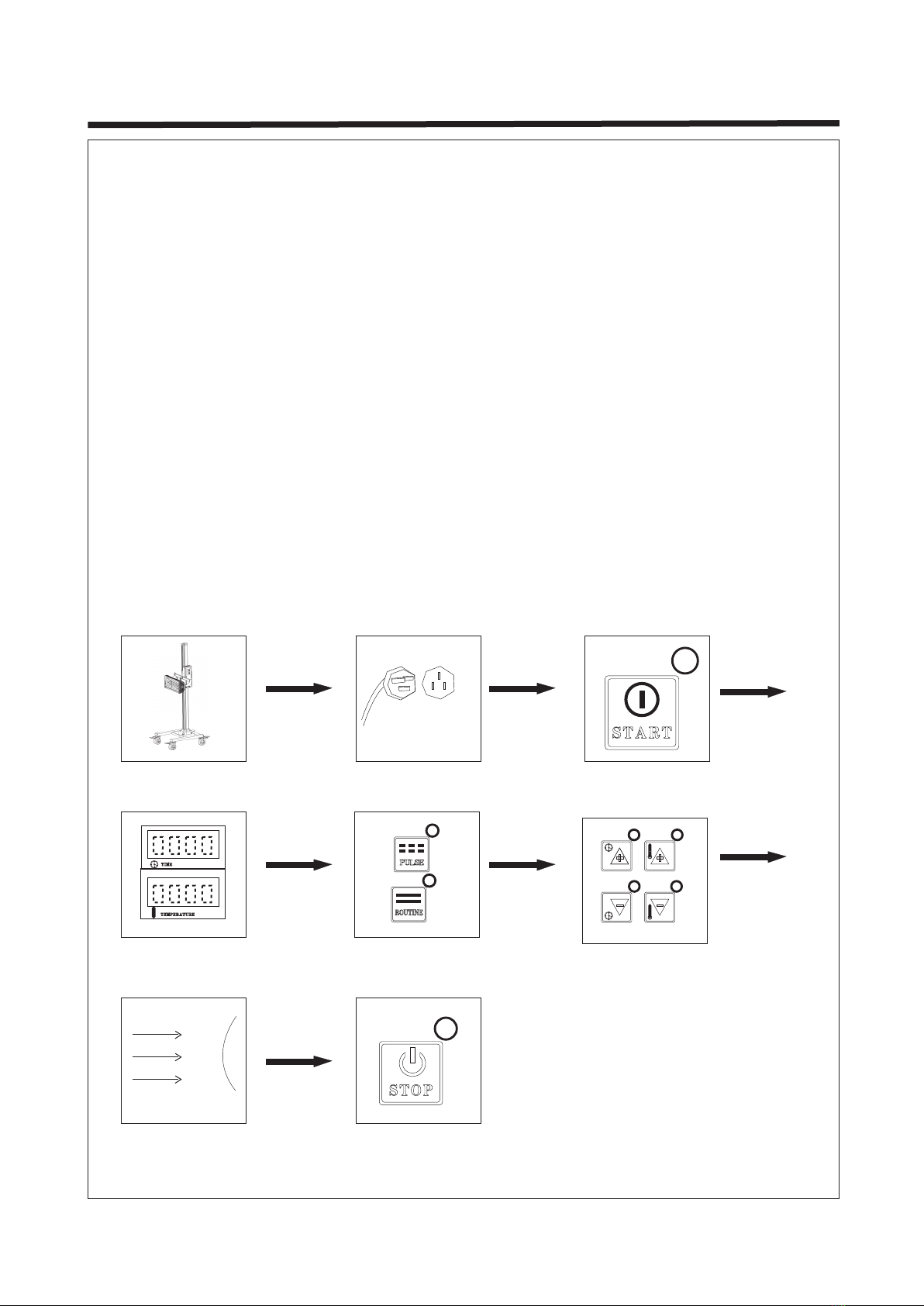

5. Operation

Page 5

2

1. Connect electricity supply. Make sure that the supply cable is at least 4mm at 220V

Note: Make sure that the facility supply voltage and frequency are the same as shown on

the equipment name plate.

2. Connect to power supply AC 220V. Switch on the equipment. Select “Pulse” or “Routine”.

Pulse curing helps to achieve more lustrous results.

3. Set time and power according to the requirements of paint used for curing to achieve the

best curing result (usually, the values are set at 15 mins in time and 70% in power).

4. Adjust the distance from heat source to paint surface (usually, keeping a distance of

45cm from the paint surface is the best). The lamp should also be kept parallel to the paint

surface.

5. Protect the lamp against shocks and vibrations even when it is cold.

6. During the curing process, the paint surface must be clean without water and impurities.

7. Preferably do not touch quartz with bare hands. If grease or chemical compound have

been deposited on quartz, simply clean before lighting with cloth moistened with alcohol.

Install machine Connect input power Switch on

Digital display data Select “Pulse” or “Routine” Set temperature and

time

Keep heat source parallel

to paint surface a distance

of 30-60cm

Switch off the machine

after curing