4

Windsor series manual version 1.0 S.D 25.4.2014

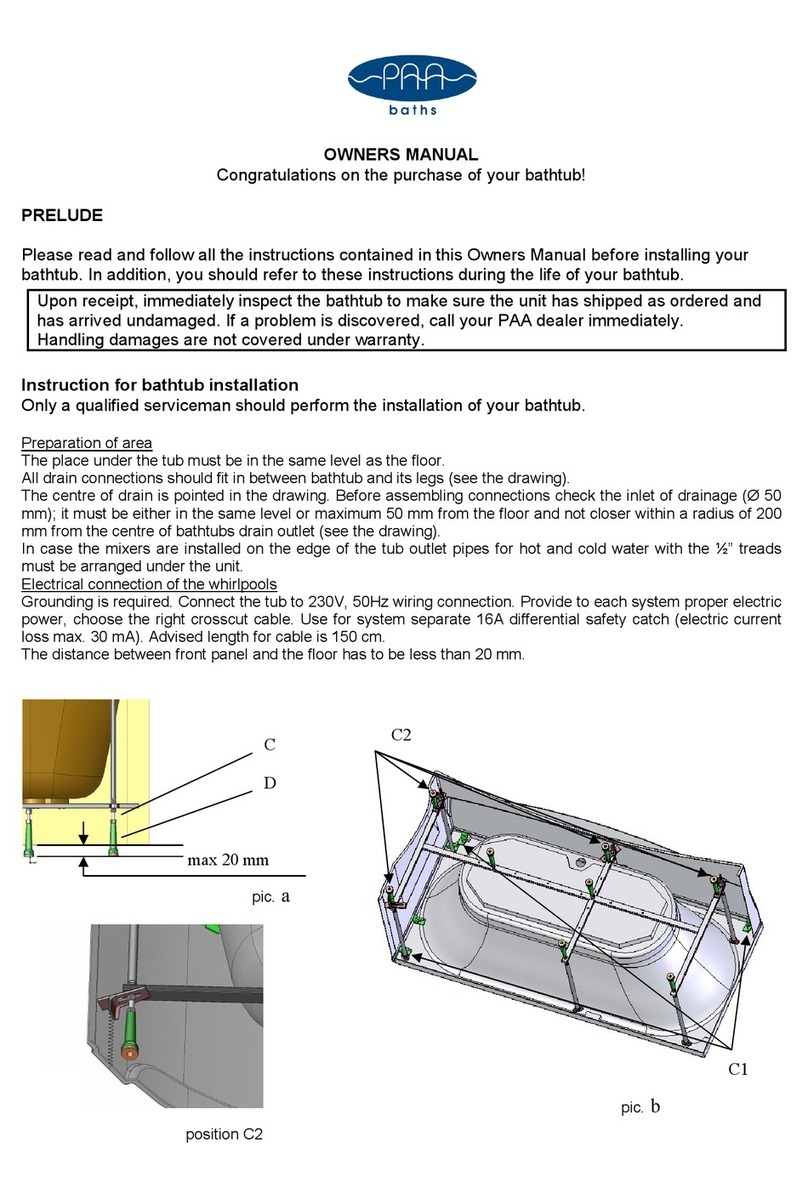

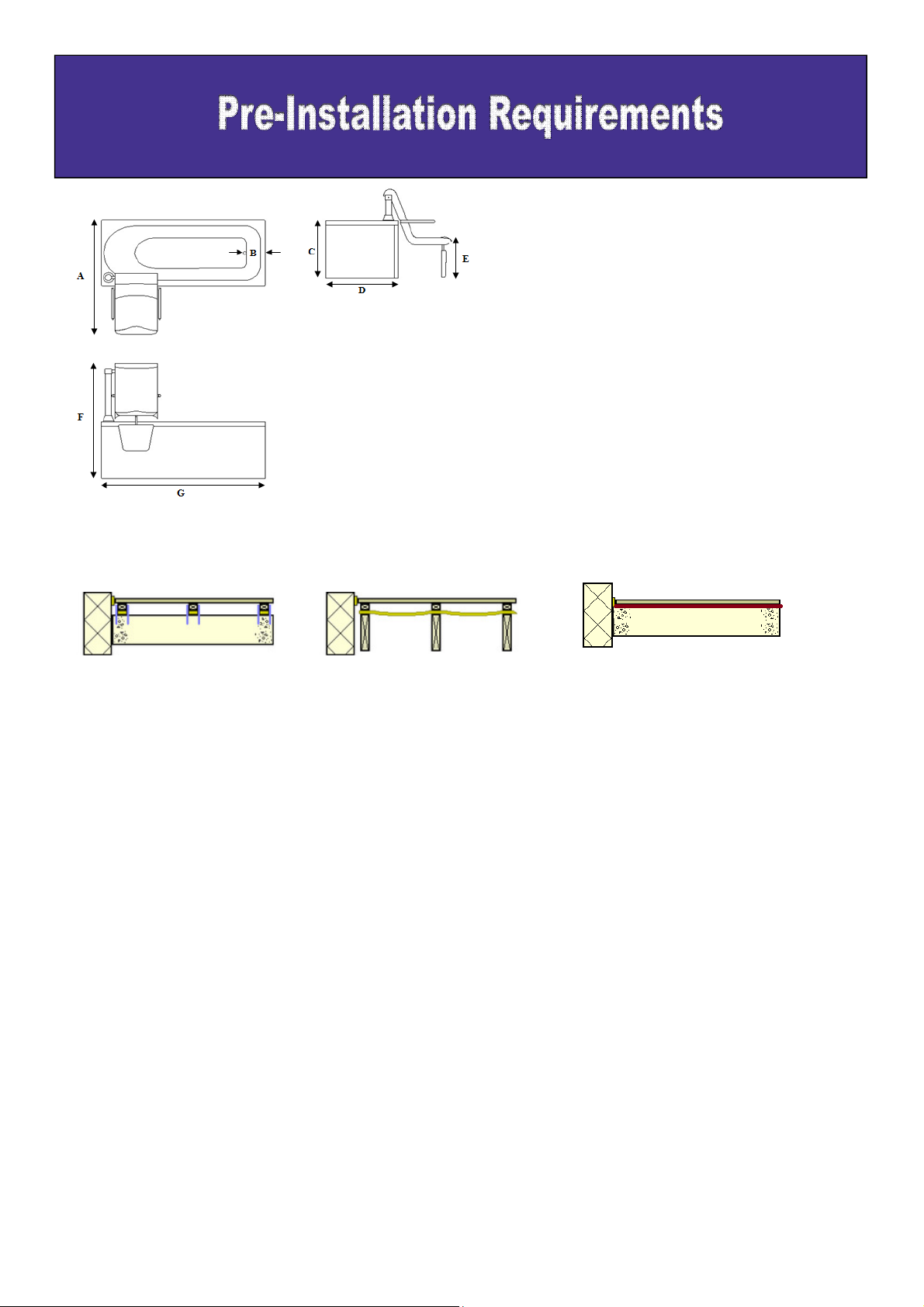

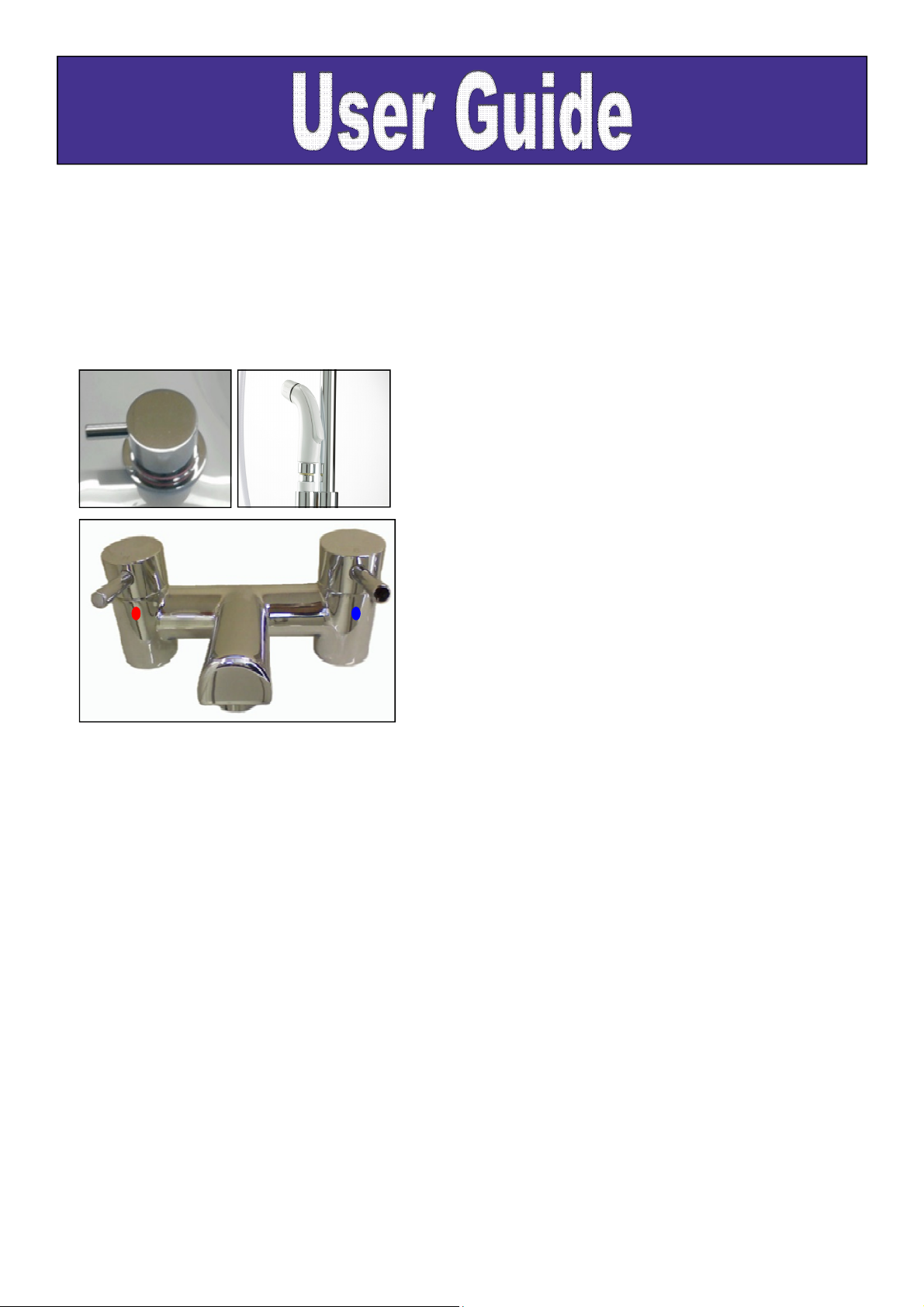

¾” BSP Male hot water inlet, 30mm from the floor, against the wall,

200mm from the left hand side of the front (tap end) of the

bath.

¾” BSP Male cold water inlet, 30mm from the floor, against the

wall, 250mm from the left hand side of the front of the bath.

40mm Waste outlet @ 3ltr/Sec, 30mm from the floor, against the

wall, 290mm from the left hand side of the front of the bath.

A 5 Amp IP65 Non Switch Fused Spur, with 2m of 1.5mm 3 core

round cable protected inside plastic conduit to the bath within

200mm of the tap end of the bath, positioning and specification

to be in accordance with current IEE regulations.

An additional power supply will be required if a spa is fitted.

Picture for visual reference only

DIMENSIONS TO BE TAKEN FROM THIS SIDE Minimum distance between the walls and baths bath

sides is 150mm.

When deciding on the position of the bath there are a

number of points that should be considered.

1. Hoist and wheel chair access

2. Access for installation and service

3. Opening doors

4. Distance from walls and other objects

5. Manoeuvring the transfer trolley

6. Under floor heating, pipe work and cables.

The floor directly under the bath and transfer

area must be a solid and even surface.

Particular attention should be paid to the shaded

area on the plan which need to be drilled to a

depth of 100mm for fixing points and must be of

solid construction with no buried services.

Electrical connection & Earth bonding.

A 30mA RCCD is required in compliance with the current IEE regulation. This should be located just outside

the bathroom or on the consumer unit covering that area of the building.

10mm Earth bonding and a minimum of 4mm cross bonding is to be fitted and tested for continuity in

accordance with IEE regulations.