6 01.02.2021

Cod. 80005780a - GB

The refrigeration circuit is hermetically sealed; therefore, repairing interventions on the circuit are not possible

without breaking the vacuum.

In the event that vacuum breaking is needed for carrying out maintenance operations, follow the following provi-

sions:

• The operation can not take place inside the store or indoors.

• The unit must be moved to a suitable environment and guarantee the adequate safety. Work outdoors or alter-

natively in a properly ventilated environment; in this case, the ventilation shall be able to disperse outside (in the

atmosphere) any possible refrigerant losses.

uring the installation, maintenance or dismantling operations, all the possible ignition sources (smoking includ-

ed) must be strictly avoided.

If it is necessary to carry out welding or brazing operations or other operations which cause the generation of

heat and high temperatures; strictly follow the requirements of this section. It is recommended that you do the follow-

ing:

• Remove the refrigerant

• Flush the circuit with inert gas

• Evacuate

• Flush the circuit again with inert gas

• Open the circuit and carry out the maintenance

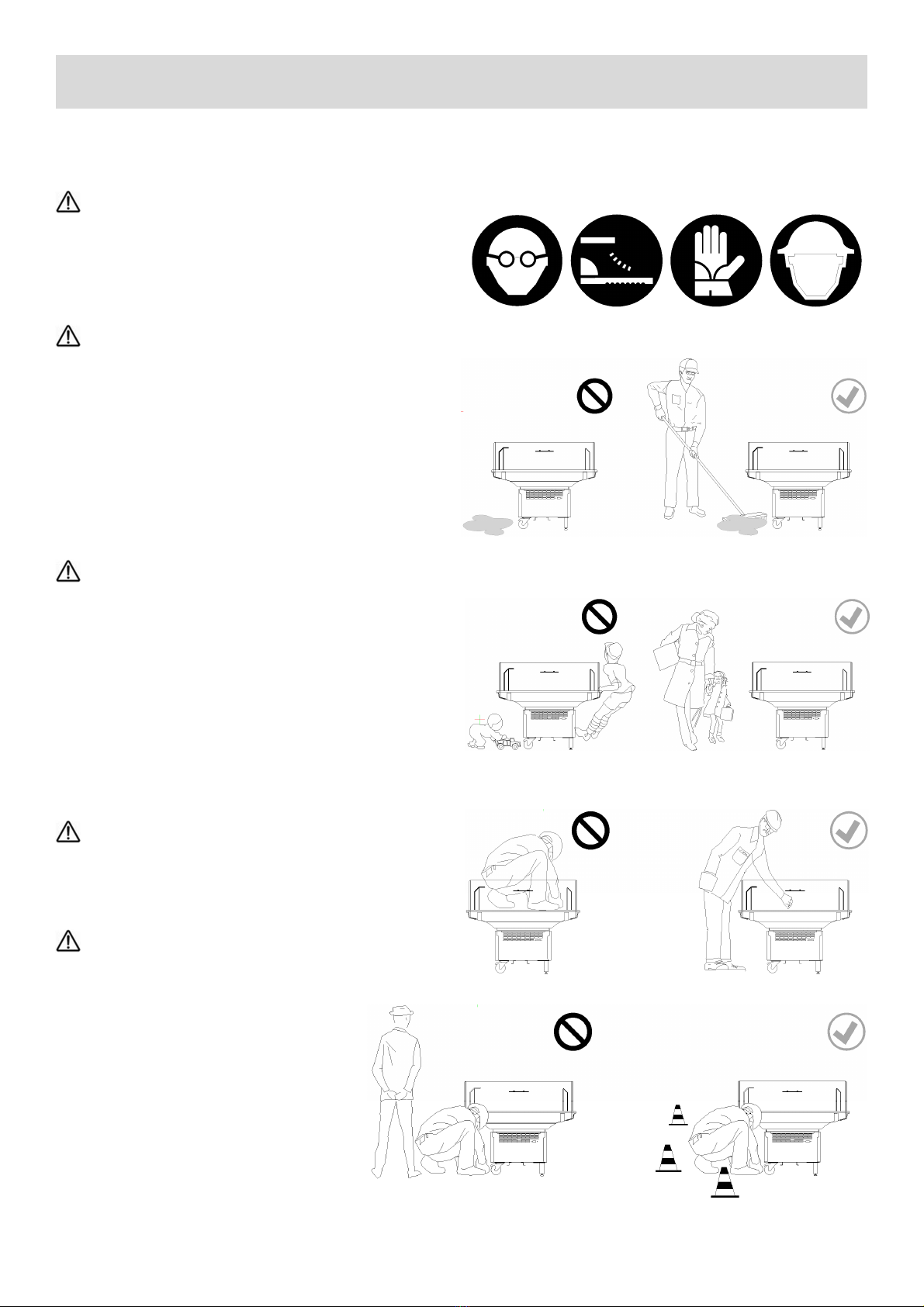

1.3 “Residual hazards”

Residual hazards are risks that remain even after all possible protection measures are taken in the design phase and

the unit is fitted with additional protection guards. This information chapter is an integral part of the measures adopted

by the designer to minimize residual hazards and it is meant for the store operators. Therefore, every operator must

know the residual risks of the unit to prevent possible accidents.

General measures to reduce hazards:

• Implement the surveillance of the market and intervene in the case of non-compliant use by users (i.e. custom-

ers).

• Manage the unit properly according to the provisions contained in this manual. Periodically check the integrity

of the unit and its visible parts. In case of doubt, contact the assistance service.

• Wear adequate PPE while cleaning, maintaining and loading the goods (i.e. work clothes, protection gloves and

glasses, safety shoes, helmet).

• o not remove the protection and safety systems. Check for the integrity of all the plates and tags of the refrig-

erating cabinet.

• o not modify the refrigerated cabinet and make sure that original spare parts are used in the event of a tech-

nical intervention.

1. For our safet