Relays are provided as ‘dry’ contacts or ‘electromagnetically switched’ contacts. Each relay is

rated 3 Amps at 24 Vdc for a resistive load, or 1 A at 24 Vdc for an inductive load.

The relay is controlled by the assigned output in the SMB Configuration App. To make use of

the relay, terminate the positive constant supply to the common termination of the relay and

nominate either Normally Open (N/O) or Normally Closed (N/C) termination to operate the

external device.

The D8 Fuse Board provides power distribution. The board can be used to power locks,

sensors, readers, and sirens, while maintaining circuit protection. Jumpers are used to draw

either 12 Vdc or 24 Vdc from the board. The default jumper position is one which draws

24 Vdc, designed to power locks at 24 Vdc. Change the jumper to position two, if you want to

draw 12 Vdc from the board.

Reference the LifeSafety Power D8 Installation Manual for further information.

The B100 provides an additional voltage in a conjunction with the LifeSafety FPO150. The

B100 voltage input is 24 Vdc from the FPO150 and the secondary voltage output is 12 Vdc

(DC OUT). 12 V required for the controller and I/O boards and 24 V is required for powering

locks. The jumpers should not be interfered with.

Reference the LifeSafety Power B100 Installation Manual for further information.

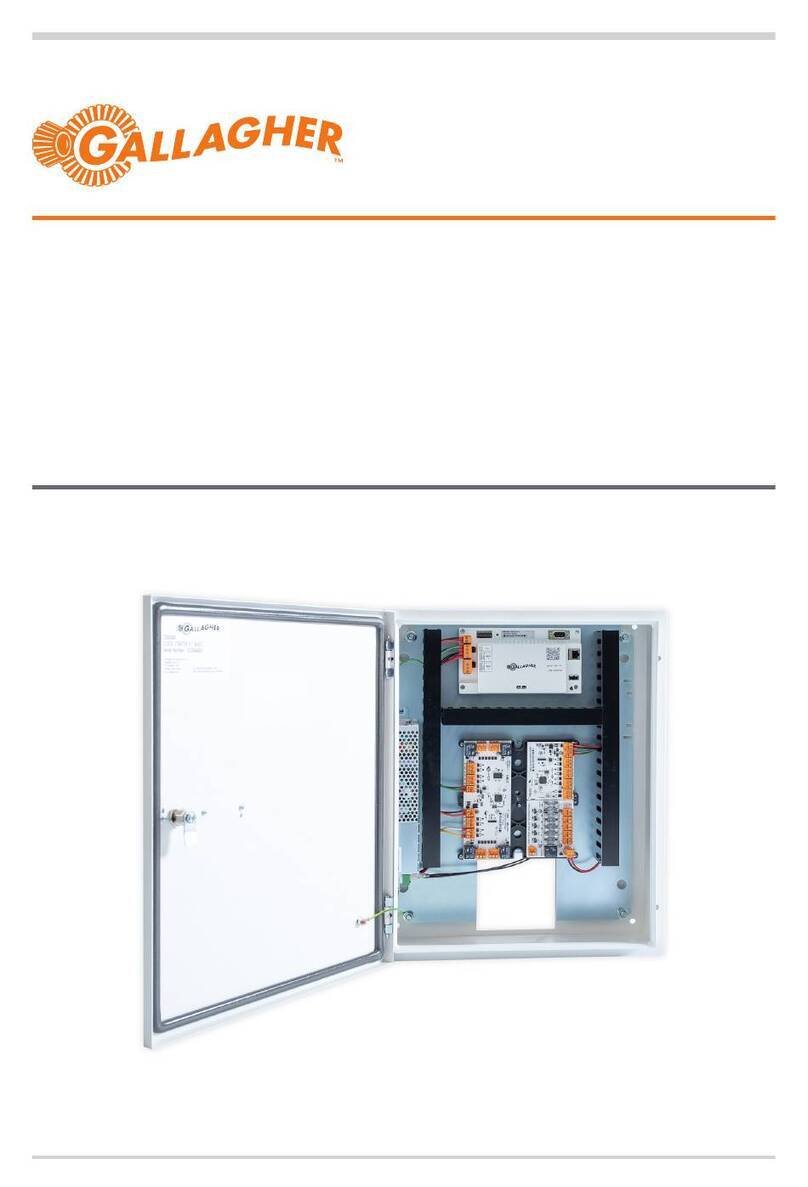

4. Connect power to the system

The cabinet comes pre-installed with a LifeSafety FPO150 which is used to power the

electrical hardware and charging up to four 7 Ah 12 V batteries (connected in a way to

support 24 Vdc backup. It provides a battery charging current of 2.5 A.

Calculating battery life

The cabinet supports up to four 7 Ah 12 V batteries. To know how long your batteries will

support your cabinet, calculate the following:

(combined battery capacity*) ÷ (total current draw in amps**) = (battery life in hours)

*To find the combined battery capacity, add the Ah values of all your batteries.

**To find the total current draw, add the current draw of the individual units in your cabinet.

Refer to the end of this installation note and separate hardware installation notes for current

draw values.