Page date: April 24, 2020 iii

Tableof Contents

List of Revisions ...............................................................................................................................................ii

Obtaining Revisions .........................................................................................................................................ii

Table of Contents ...........................................................................................................................................iii

Introduction....................................................................................................................................................iv

Definition of Warnings, Cautions and Notes ...................................................................................................v

Units and Conversions.....................................................................................................................................v

Glossary of Terms, Abbreviations and Symbols..............................................................................................vi

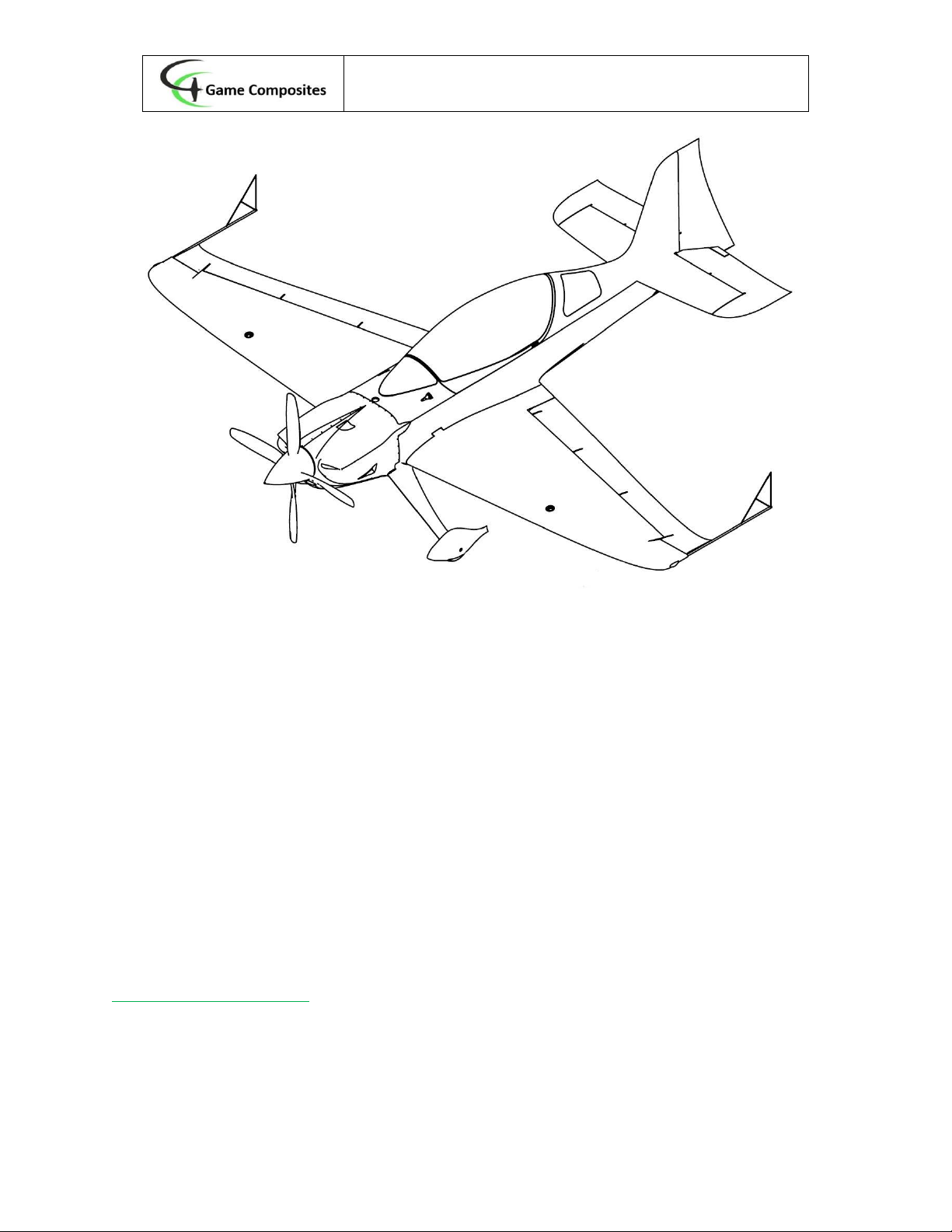

Description................................................................................................................................... 1-1

Airworthiness Limitations............................................................................................................ 4-1

Time Limits, Access, Maintenance Checks................................................................................... 5-1

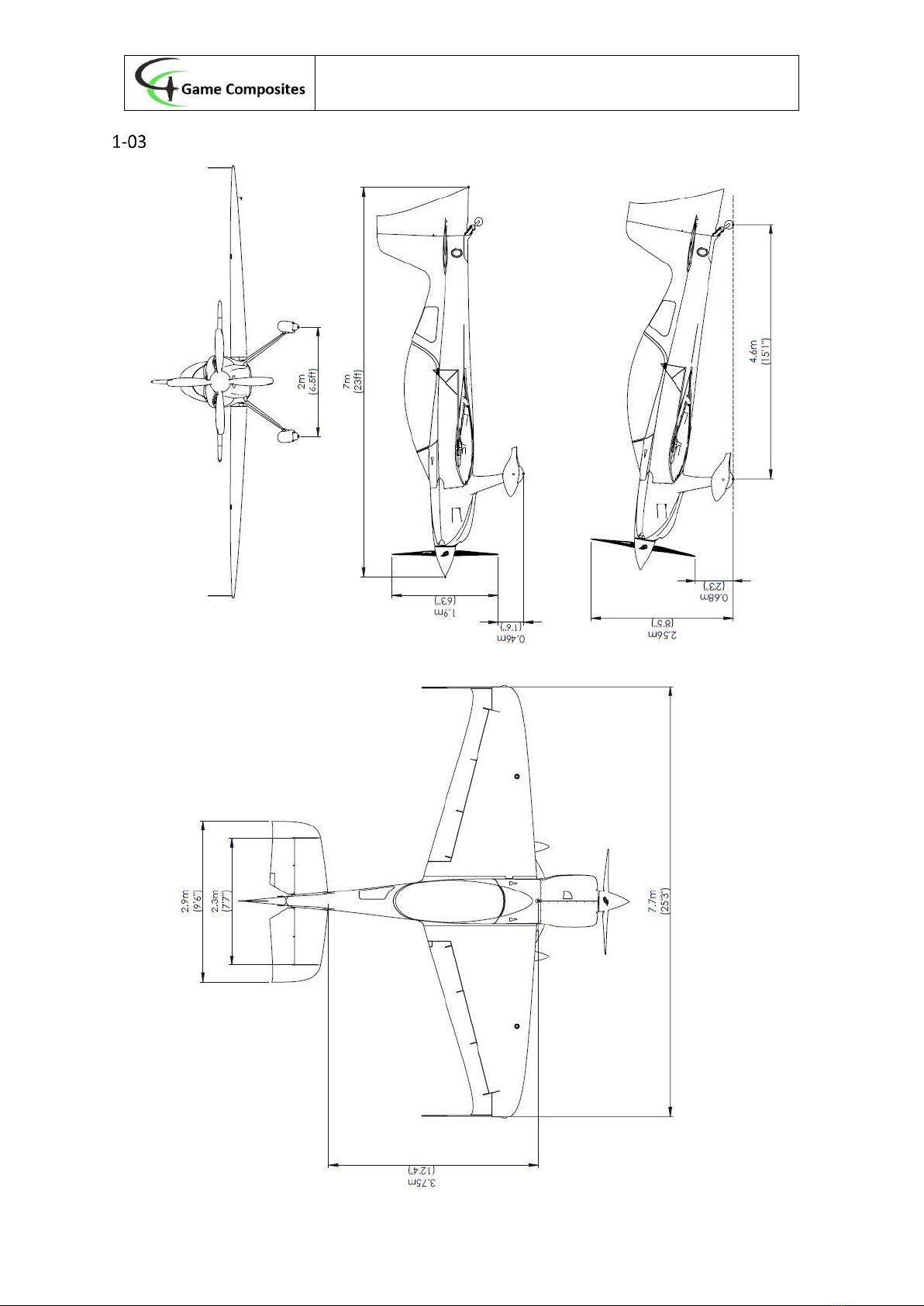

Dimensions and Rigging Information........................................................................................... 6-1

Lifting and Supporting ................................................................................................................. 7-1

Levelling and Weighing................................................................................................................ 8-1

Moving and Towing ..................................................................................................................... 9-1

Parking, Mooring, Storage & Return to Service......................................................................... 10-1

Placards...................................................................................................................................... 11-1

Tools, Servicing, Cleaning .......................................................................................................... 12-1

Standard Practices and Shipping ............................................................................................... 20-1

Air Conditioning ......................................................................................................................... 21-1

Autopilot.................................................................................................................................... 22-1

Communication ......................................................................................................................... 23-1

Electric Power including Switches & Breakers........................................................................... 24-1

Equipment and Furnishings ....................................................................................................... 25-1

Flight Controls............................................................................................................................ 27-1

Fuel System................................................................................................................................ 28-1

Mechanical Flight Instruments & pitot-static system................................................................ 31-1

Landing Gear including Wheels and Brakes............................................................................... 32-1

Lights.......................................................................................................................................... 33-1

Navigation.................................................................................................................................. 34-1

Instrument Panels...................................................................................................................... 39-1

Avionics...................................................................................................................................... 40-1

Ballast ........................................................................................................................................ 41-1

Baggage Compartment .............................................................................................................. 42-1

Structure Repair Manual............................................................................................................ 51-1

Canopy and Windshield............................................................................................................. 52-1

Fuselage..................................................................................................................................... 53-1

Stabilizers................................................................................................................................... 55-1

Wings ......................................................................................................................................... 57-1

Propeller, Governor and Spinner............................................................................................... 60-1

Engine Mount and Cowling........................................................................................................ 71-1

Engine and Propeller Control..................................................................................................... 73-1

Engine Indicating System........................................................................................................... 77-1

Exhaust ...................................................................................................................................... 78-1

Engine Oil System ...................................................................................................................... 79-1

Smoke System............................................................................................................................ 85-1