TABLE OF CONTENTS

LIMITED WARRANTY

GAMMA SPORTS ("GAMMA") warrants to the original purchaser that the GAMMA stringing machine ("EQUIPMENT") purchased is free from defects in

materialsandworkmanshipforaperiodoffive(5)yearsfromthedateoforiginalpurchaseformechanicalparts(excludingelectronicpartsandstringclamps),

and for a period of one (1) year from the date of purchase for electronic parts and string clamps. Should any defects develop under normal use within the

specified time periods, GAMMA will at its option, repair or replace the defective EQUIPMENT provided it is returned to GAMMA prepaid at the purchaser's

expense. This warranty does not apply to any damage or defect caused by negligence, abuse, misuse, unauthorized alteration, shipping, handling, or part

wear and tear as a result of normal use.

GAMMA's obligation under this warranty is limited to repair or replacement of defective EQUIPMENT, and no one is authorized to promise any other liability.

GAMMA shall in no event be liable for any incidental or consequential damages.

ToreturndefectiveEQUIPMENT, a return authorization(RA#)mustbe obtained from aGAMMAcustomerservice representative by calling1-800-333-0337.

TheRA#mustbemarked on theoutsideoftheshippingcarton being returned.Allreturnsmustbeshipped prepaid by thecustomertoGAMMA. Please retain

the original shipping carton and packing materials for any future shipments.

7500 Els

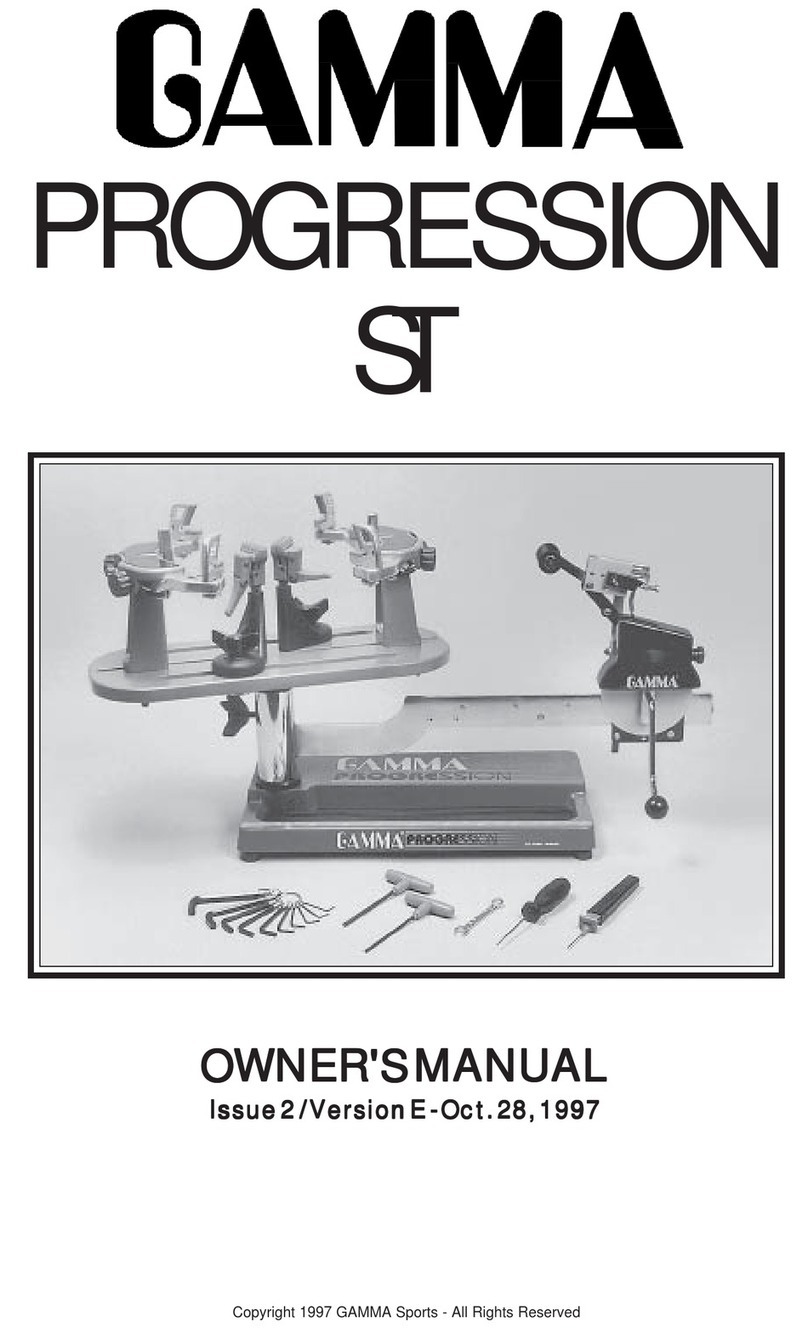

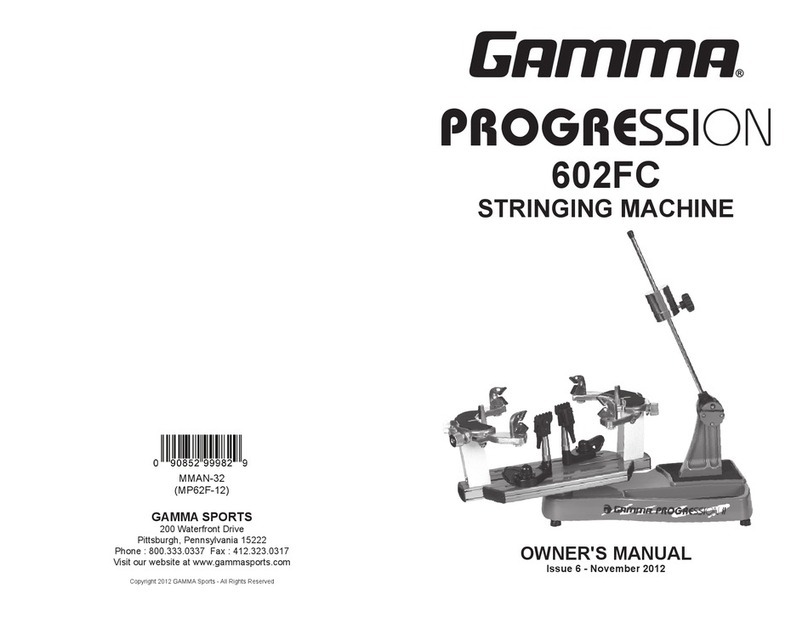

Owner’s Manual

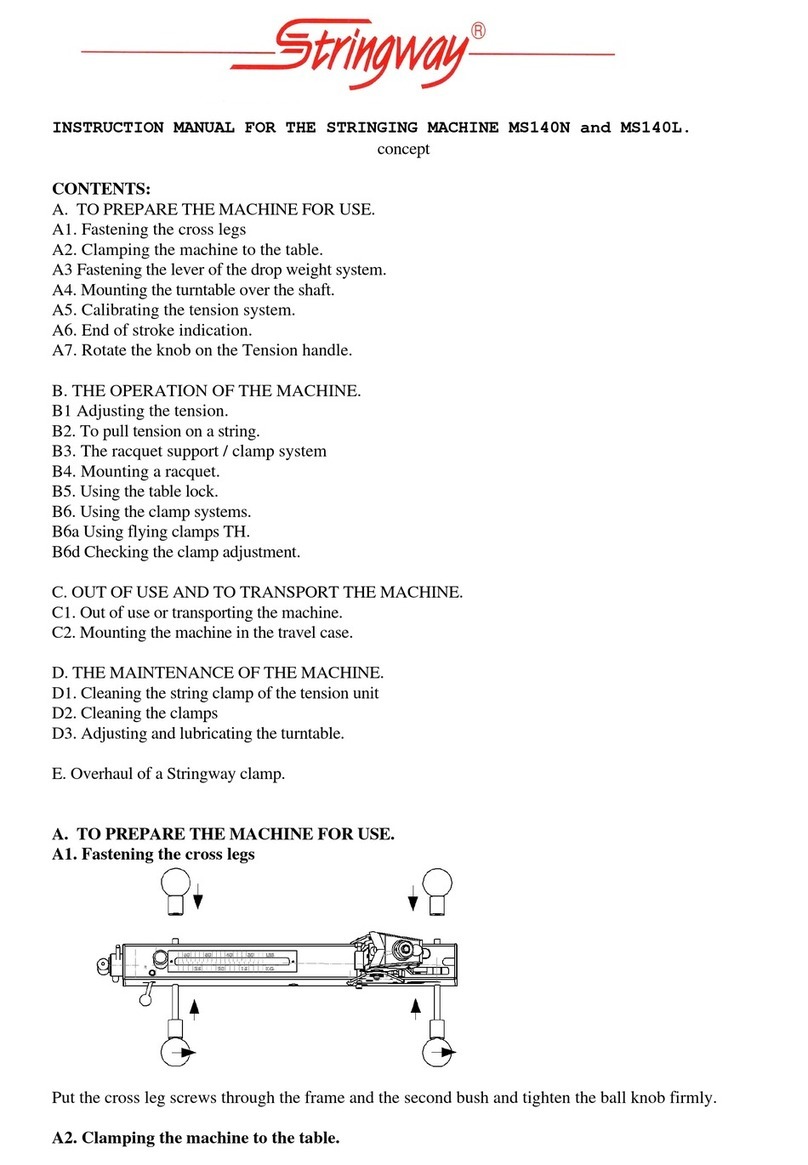

INSIDE FRONT COVER .....................................................................WARRANTY

PAGE 1................................................................................................. FEATURES

PAGE 2................................................................ CONTENTS AND UNPACKING

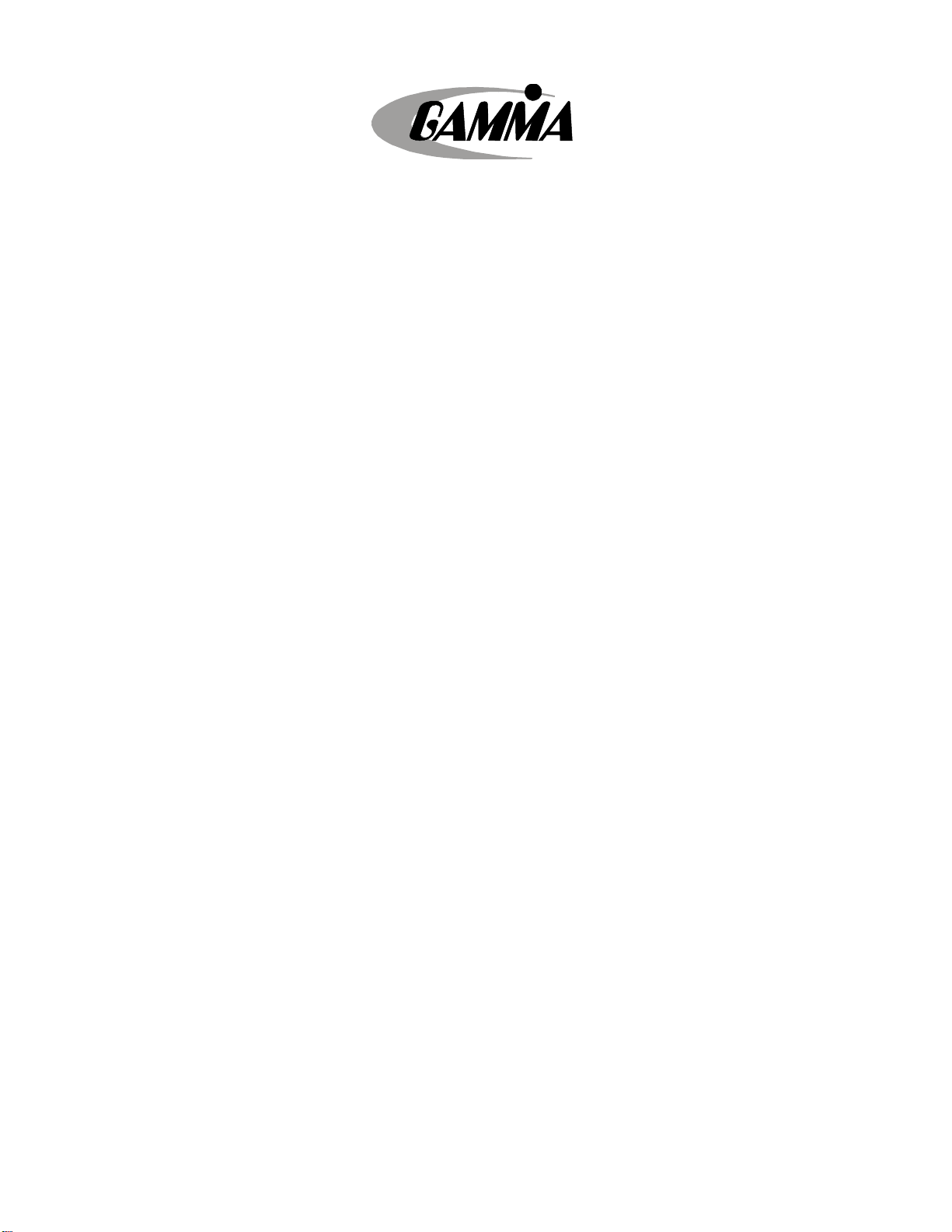

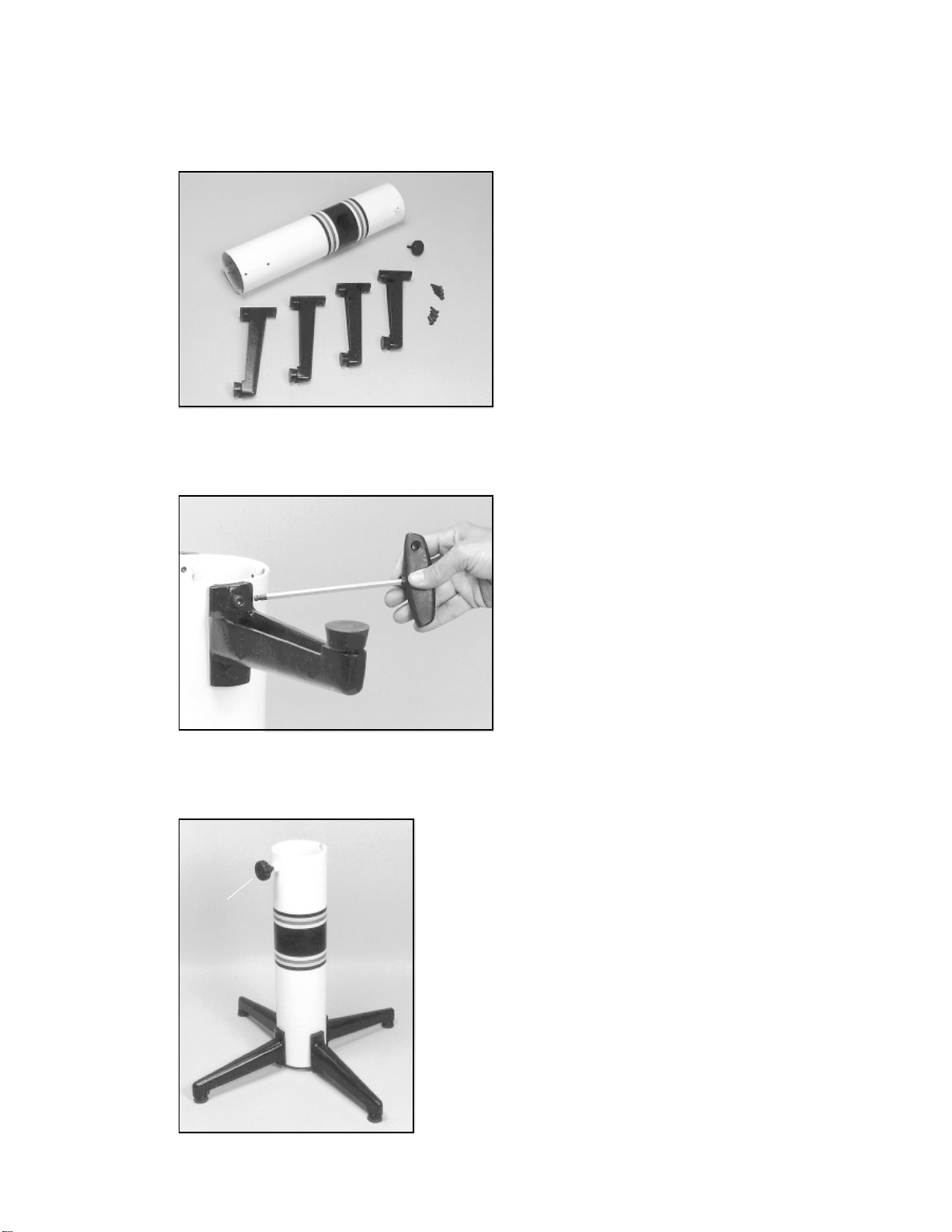

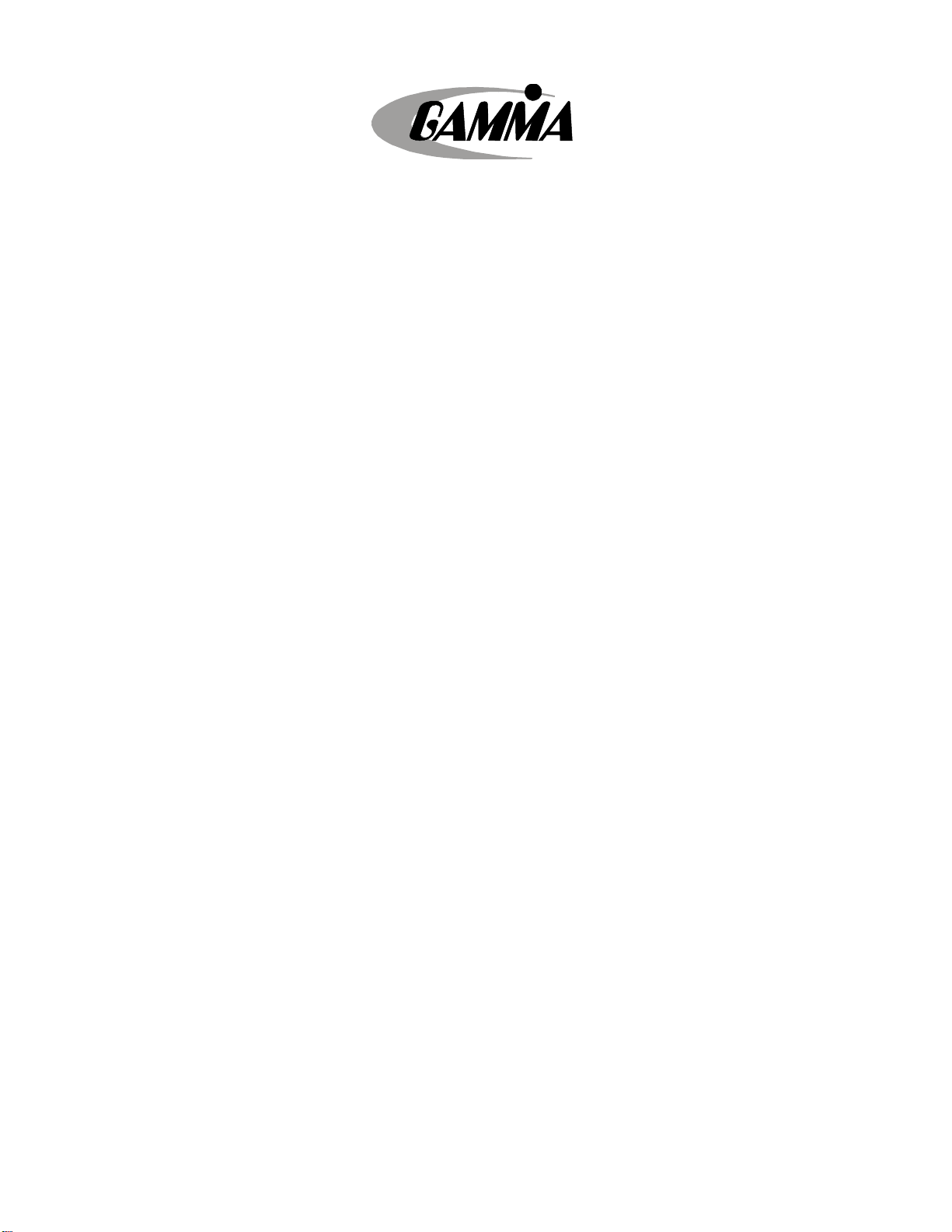

PAGE 3.....................................................................ASSEMBLY INSTRUCTIONS

PAGE 9.................................................... POWER CONNECTIONS & CONTROL

PAGE 10................................ CONTROL PANEL FUNCTIONS AND FEATURES

PAGE 11.................................................STRING LENGTH METER OPERATION

PAGE 12........................................................... CAM-LOCK CLAMP OPERATION

PAGE 13.................................... STRING GRIPPER / TENSIONER OPERATION

PAGE 14.........................................................................MOUNTING THE FRAME

PAGE 15........................................................................ STRINGING THE FRAME

PAGE 16............................................................PATHFINDER AWL OPERATION

PAGE 17................................................... MAINTENANCE AND ADJUSTMENTS

PAGE 18............................................................................ CARE AND CLEANING

PAGE 19....................................................................TROUBLE SHOOTING TIPS

PAGE 20..............................................................PART NUMBERS AND LISTING