9

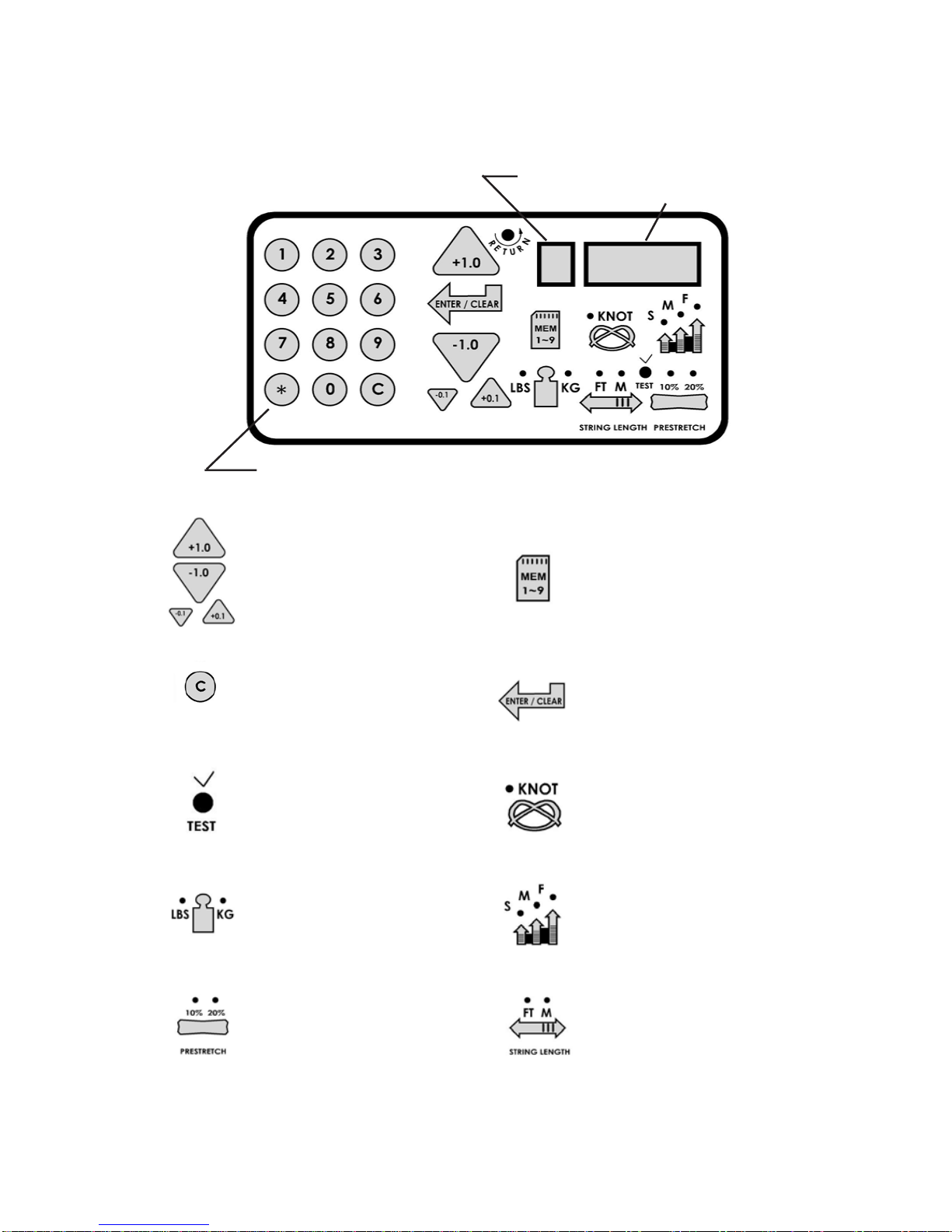

CONTROL PANEL FUNCTIONS

AND FEATURES

Single Digit (1-9)

Memory LED Display

Three Digit (XX.X)

Tension SettingDisplay

or String Length LED

Display

12 Button Keypad - Usedto entertensionsettings

Lbs/Kgs Button - Changes tension

display from Lbs to Kgs. Each press of

the button toggles back and forth

between Lbs and Kgs.

Speed Button - Changes pulling speed

of winder from Fast (default) to Medium

to Slow. Slow speed is recommended

for low stretch strings, such as Kevlar.

Each press of the button toggles

between Fast, Medium and Slow

speeds.

Pre-Stretch Function - Pulls string

10% or 20% over the tension setting (up

to 90 lbs / 40.8 kgs), releases the string,

and repulls to the tension setting. Each

press of the button toggles between

10%, 20% or no pre-stretch.

String Length Meter Button - Enables

string length meter function. Each press

of the button toggles back and forth

between Meters and Feet measure-

ment. To switch back to tensioning

function, press the “Lbs/Kgs” button.

Clear Button - Clears display to enter a

newtensionor toreset StringLength

Metermeasurement

Knot Function - Increases pulling tension

by 10% over the setting value (max 90 lbs /

40.8 kgs) for one pull. During the pull the

LED stays lit to indicate the Knot function is

enabled.

Tension Index Buttons - Changes

tensionsetting in+/-1.0 or+/-0.1 Lbor

Kgincrements.Holdingthebutton down

will scroll the tension setting values up

or down. Tension settings entered with

the tension index buttons are placed

into temporary memory setting “0”.

Memory Button -Indexesfrom9 preset

tension settings that can be stored in

memory. Settings are retained even if

machine is turned off. Each press of the

button indexes to the next memory setting.

Memorysettings1-9 must beentered using

thekeypadfollowedbypressingthe“ENT”

button.

Enter Button -Savesdisplayedtension for

Memorysetting-when tension isentered

usingthekeypaddisplayflashesuntilthis

buttonispressedtosave the setting.Also

Clearsdisplay forStringLength Meter

measurements

Test Button & Racquet Strung - Press

onceforapproximatenumberofracquets

strung. Pressagain toreturn. Pressand

holdfor5secondsandthemachinedoes

aninternaldiagnosticcheck, suchas the

oneperformedatstart-up.