1

TABLEOFCONTENTS

PAGE1 ................................................................................................ WARRANTY

PAGE2 ...................................................................................................FEATURES

PAGE3 ....................................................................... ASSEMBLYINSTRUCTIONS

PAGE4 .............................................................................. MOUNTINGTHEFRAME

PAGE5 .............................................................................. STRINGINGTHEFRAME

PAGE8 ...................................................................................... PATHFINDERAWL

PAGE9 ............................................................................ FIXEDCLAMPUPGRADE

PAGE10 ....................................................................... FIXEDCLAMPOPERATION

PAGE11 .......................................................................................... MAINTENANCE

PAGE12 ............................................................................................... PARTSLIST

PAGE13 .......................................................................... EXPLODEDPARTSVIEW

PAGE14 ....................................................................... MOUNTINGSTANDPARTS

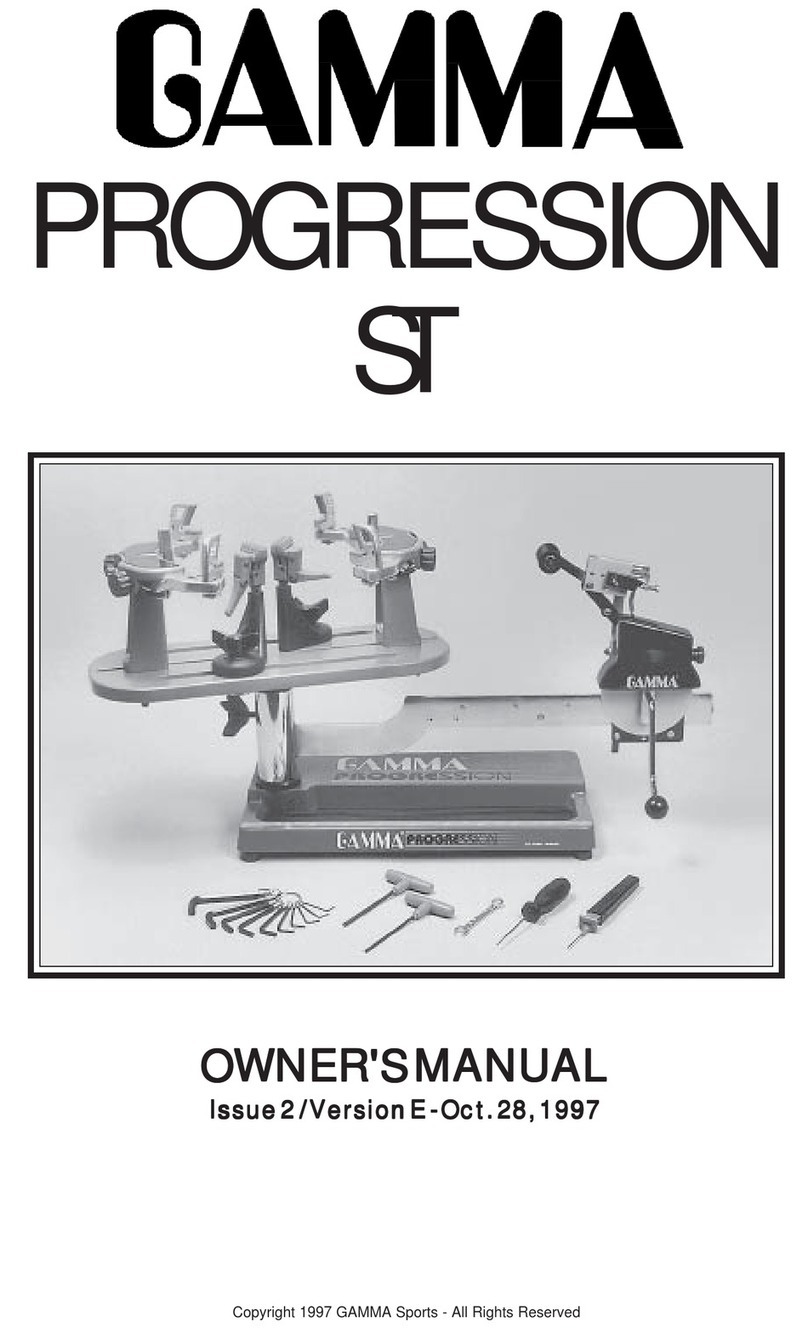

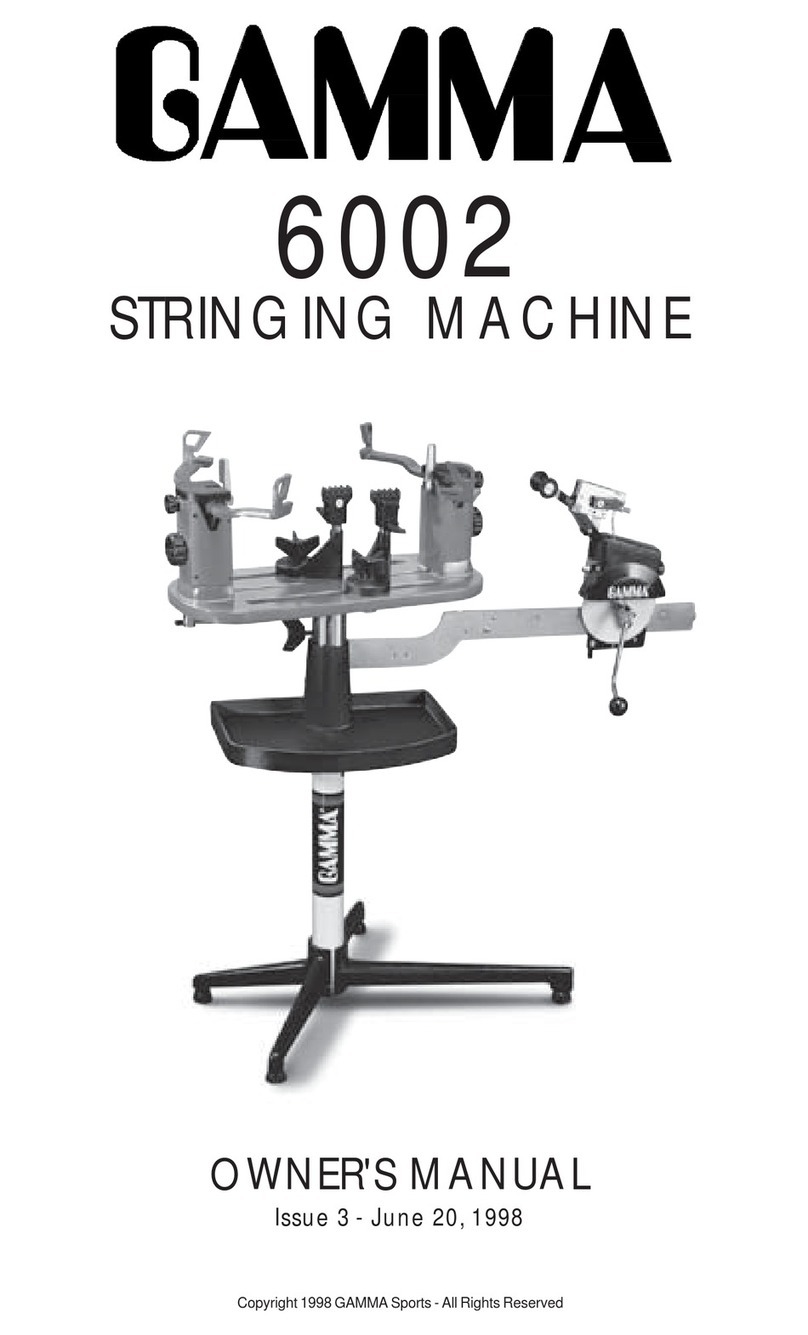

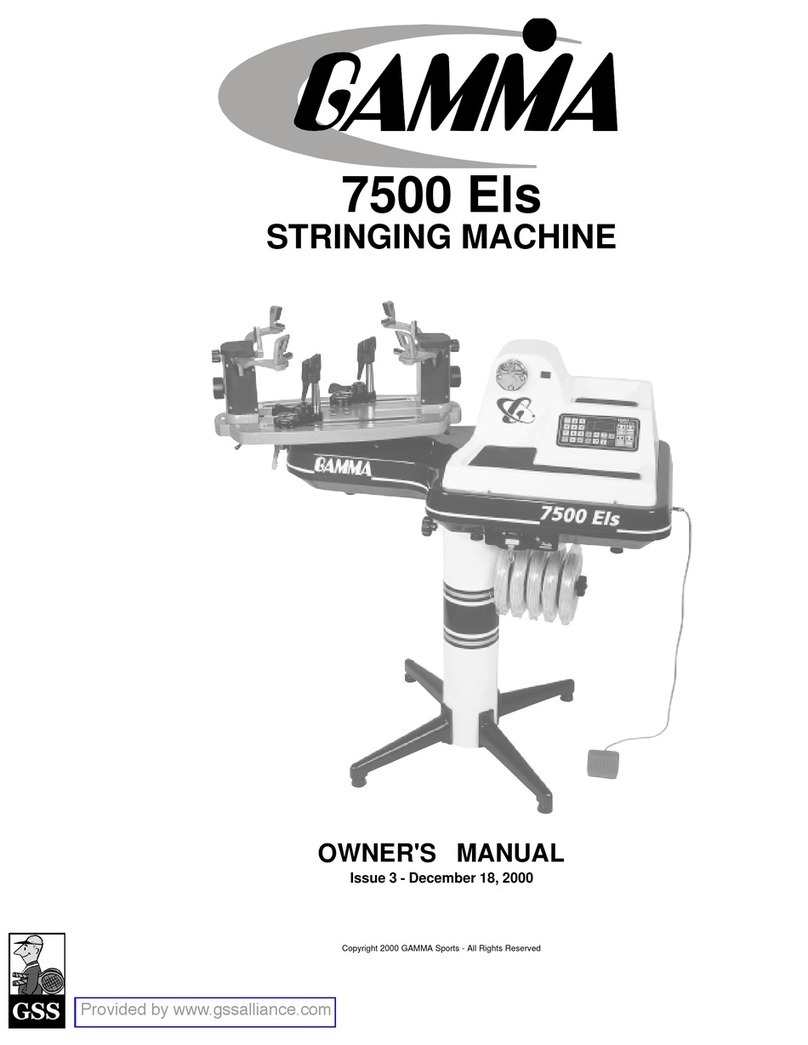

OWNER'SMANUAL

PROGRESSION600/600FC

LIMITED WARRANTY

GAMMASPORTS("GAMMA")warrantstotheoriginalpurchaserthattheGAMMAPROGRESSIONstringingmachine("EQUIP-

MENT")purchasedisfreefromdefectsinmaterialsandworkmanshipforaperiodoffive(5)yearsfromthedateoforiginalpurchase

formechanicalparts(excludingelectricalpartsandstringclamps),andforaperiodofone(1)yearfromthedateofpurchaseforall

electricalpartsandstringclamps.Shouldanydefectsdevelopundernormalusewithinthespecifiedtimeperiods,GAMMAwillat

itsoption,repairorreplacethedefectiveEQUIPMENTprovideditisreturnedtoGAMMAprepaidatthepurchaser'sexpense.This

warrantydoesnotapplytoanydamageordefectcausedbynegligence,abuse,misuse,unauthorizedalteration,shipping,handling,

orpartwearandtearasaresultofnormaluse.

GAMMA'sobligationunderthiswarrantyislimitedtorepairorreplacementofdefectiveEQUIPMENT,andnooneisauthorizedto

promiseanyotherliability.GAMMAshallinnoeventbeliableforanyincidentalorconsequentialdamages.

ToreturndefectiveEQUIPMENT,areturnauthorization(RA#)mustbeobtainedfromaGAMMAcustomerservicerepresentative

bycalling1-800-333-0337.TheRA#mustbemarkedontheoutsideoftheshippingcartonbeingreturned.Allreturnsmustbeshipped

prepaidbythecustomertoGAMMA.Pleaseretaintheoriginalshippingcartonandpackingmaterialsforanyfutureshipments.

GAMMAwillnotberesponsibleformachineswhicharenotsentintheoriginalundamagedpackaging.