8

Setting Tension

TheGAMMA5002utilizesarotaryadjusting

knob along with a linear tension scale to

indicate the tension setting. The scale is

dividedinto3lbincrementsandeach1/3turn

of the tension knob changes tension by 1 lb.

Tosetthedesiredtension,rotatethetension

knob and align the mark on the spring guide

withthedesired tension setting onthescale.

Whenthe“0”markontheknobalignswiththe

line on the knob support the tension will be

that indicated on the scale. To increase ten-

sionby 1or 2lbsturntheknobcounterclock-

wise until the “1” or “2” mark on the knob

aligns with the line on the knob support. To decrease tension by 1 or 2 lbs, turn the knob

clockwise until the “2” or “1” mark on the knob aligns with the line on the knob support.

STRINGING THE FRAME

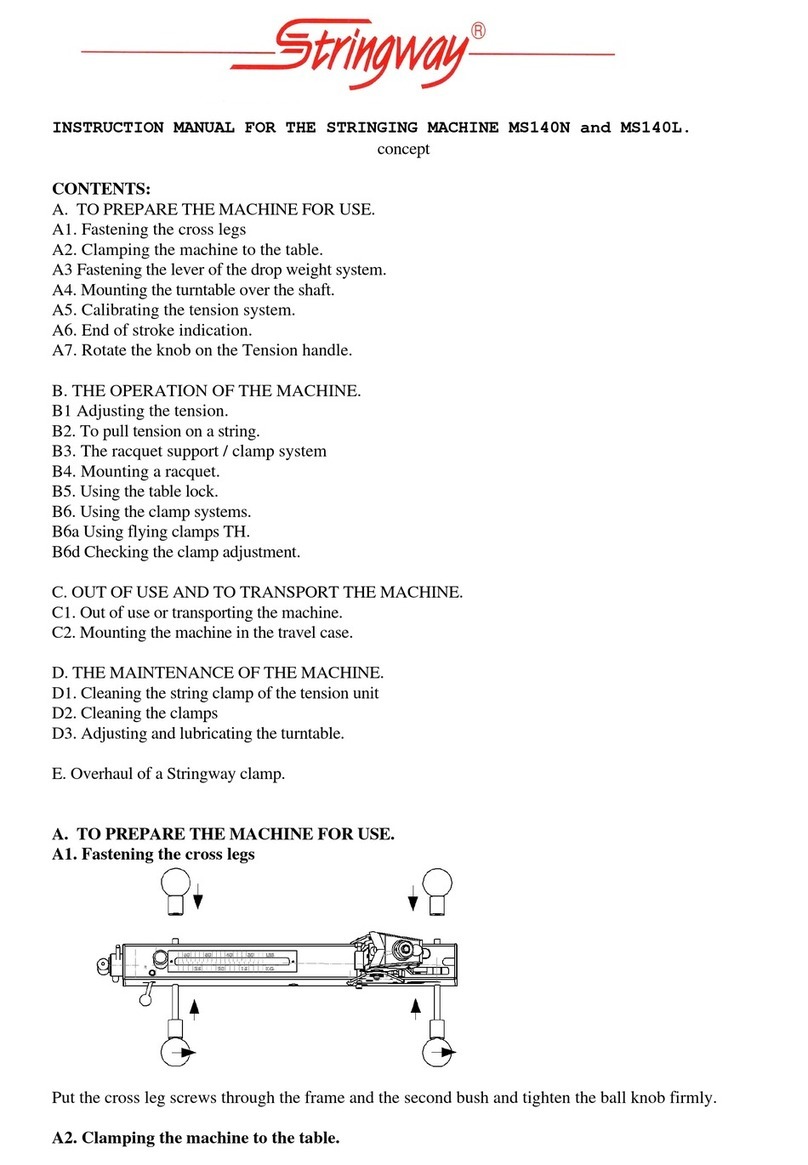

Fixed Clamp Operation - Step 1

ThefixedclampsfortheGAMMA5002areof

a dual action design. The string clamp and

the clamp base operate independently of

one another.

To clamp a string, lift the clamp head and

place the string between the jaws. Depress

the clamp head lever to secure the string.

The clamping pressure applied to the string

shouldbeadjustedtoprovidesufficientpres-

sure to secure the string when subjected to

the desired pulling tension. The diamond

coated gripper plates provide for increased

friction between the clamps and the string to allow for reduced clamping pressure while

securing and holding the string under tension.

Tensioner Travel Stop

Topreventcontactbetweenthetensionhead

and the racquet and/or turntable, a stop

screw is located about midpoint along the

tensioner bar below the gear track. In the

eventthetensionheadmustbemovedcloser

to the racquet, turn the stop screw counter-

clockwisewiththe5mmhexwrenchuntilthe

end of the stop screw no longer protrudes

beyond the surface of the tensioner bar. To

re-engage the stop, simply turn the stop

screw clockwise until the screw is seated

against the tensioner bar.

Travel Stop