Stitch Regulation

(Automatic Mode)

In this mode you will set the desired

stitches per inch. The stitching does

not start until you move the machine

head. While stitching in this mode

you may change the number of

stitches per inch. You cannot switch

from automatic mode to manual

mode while stitching in either mode.

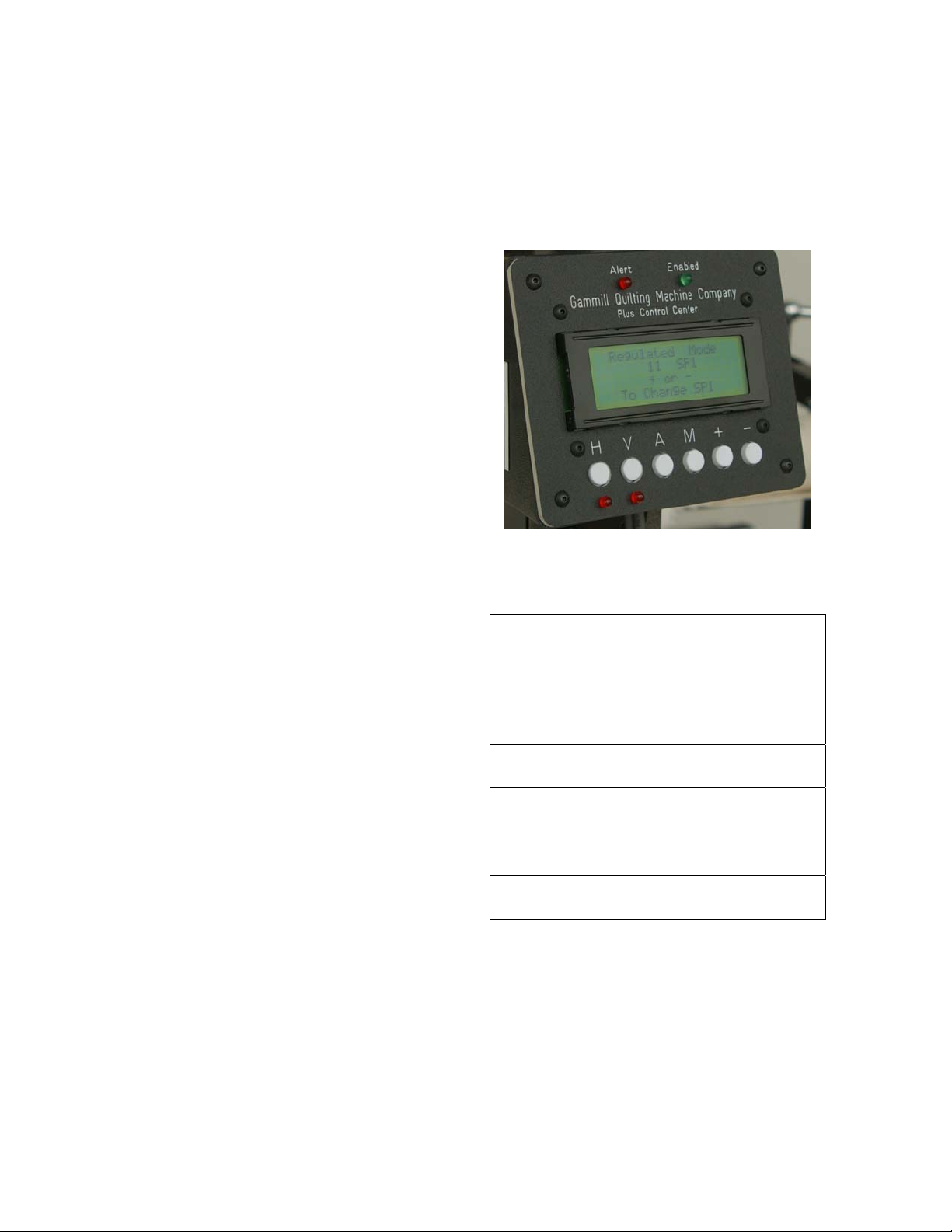

1. Press Ato enter Automatic

mode. The word "Regulated" is

displayed on the control center.

2. Press the +(plus) or – (minus)

button to increase or decrease

the stitches per inch. You can

press these keys while stitching

as well to increase or decrease

the stitches per inch as you sew.

3. To begin sewing, press and

release the right handle switch.

Immediately after releasing the

switch, an audible beep sounds

and the green LED is illuminated

on the display unit. If the needle

is positioned down, the needle

will rise up out of the fabric. The

display unit will warn you that

automatic mode is enabled and

sewing head movement will

cause the sewing motor to run.

4. Move the sewing head to begin

sewing. While in automatic mode

you are free to speed up or slow

down movement of the sewing

head while still maintaining even

stitch length, however, rapid

speed changes should be

avoided. Moving the machine

rapidly or suddenly slowing the

machine after rapid movement

may result in a variation in stitch

length. Smooth machine

movement will result in better

quality stitching.

5. If you wish to increase or

decrease the stitch length as you

sew, simply press the +(plus) or

–(minus) button while continuing

to move the sewing head.

6. After sewing is complete, press

and release the run/stop switch.

If the needle positioner was

set in the down position

before you started stitching,

the needle will take a ½ stitch

and remain down in the fabric.

If the needle positioner was

set in the up position, it will

stop in the up position.

Constant Speed (Manual Mode)

In this mode you set the motor speed

then press the Run/Stop switch.

This starts the motor running at a

constant speed. You must

coordinate the movement of the

machine with the motor speed.To

enter Manual Mode, press the M

button. Set the motor speed by

pressing the +(plus) or –(minus) to

set the desired motor speed from 1

to 99% with +(plus) increasing the

speed and –(minus) decreasing the

speed. This speed can be adjusted

as you sew as well.

To begin sewing, press and release

the run/stop switch. The motor starts

running immediately after it is turned

on so you must be ready to

coordinate the movement of the

machine with start of the motor. Try

to maintain a smooth, even

movement of the sewing head which

3