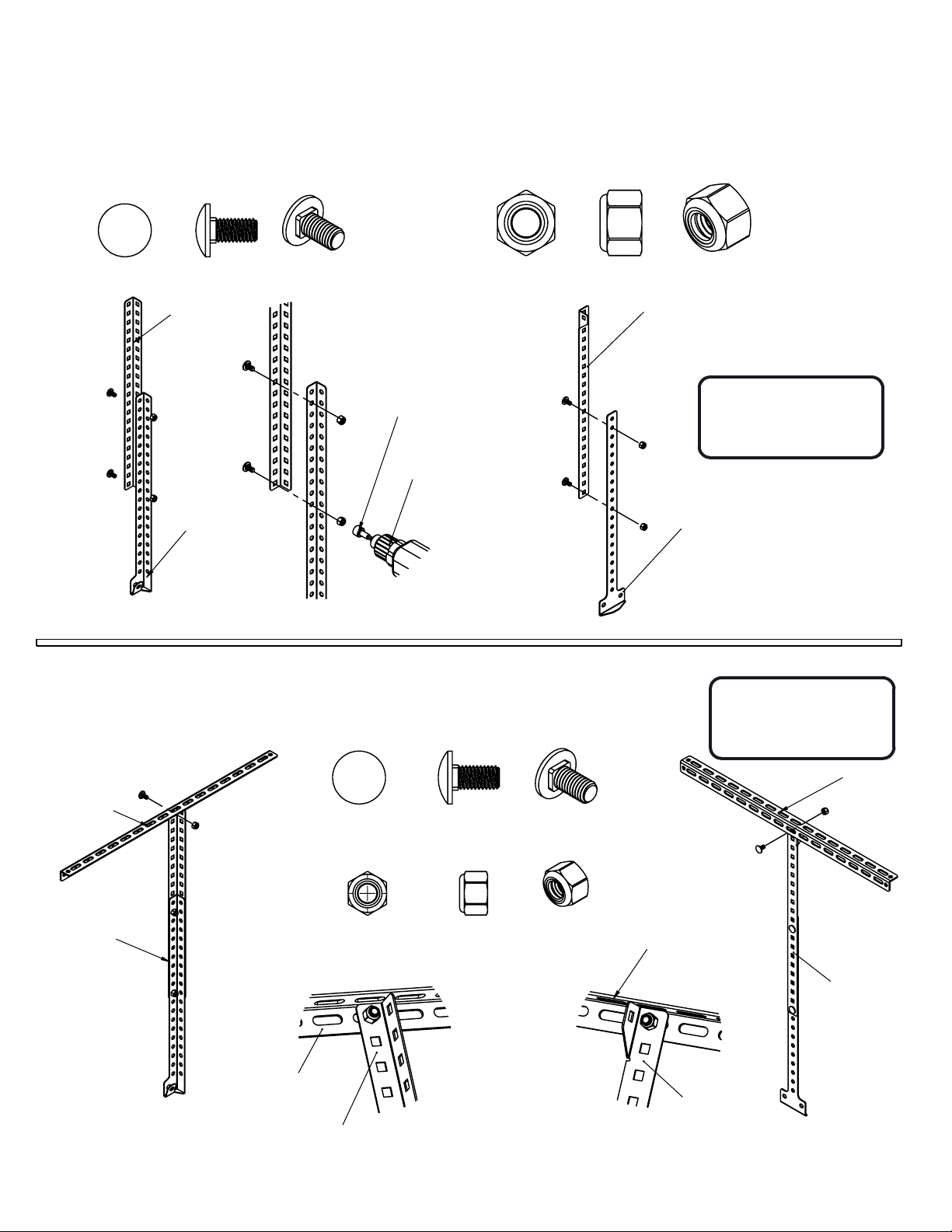

M8X1.25X12MM ROUND HEAD HEX

DRIVE MACHINE SCREW

M8X 1.25X 16mm CARRIAGE BOLT

M8X1.25 LOCK NUT WITH

NYLON INSERT

13mm (1/2") NUT DRIVER

1 PER KIT

M8X60MM HEX HEAD WOOD SCREW

5mm ALLEN KEY (FOR

M8X1.25 SCREW)

M8X1.25X 60mm LONG

CONCRETE ANCHOR

4FT X 4FT RACK: 8 PER KIT

4FT X 6FT RACK: 8 PER KIT

4FT X 8FT RACK: 12 PER KIT

SAFETY GLASSES

TAPE MEASURE

PENCIL

STUD FINDER

LADDER

ELECTRIC DRILL WITH DRILL BITS

HAMMER DRILL FOR CONCRETE

WITH MASONARY DRILL BITS

DRILL TEMPLATE: 1 PER KIT

RUBBER MALLET

DOMED LABEL

HARDWARE

4FT X 4FT RACK: 10 PER KIT

4FT X 6FT RACK: 14 PER KIT

4FT X 8FT RACK: 20 PER KIT

4FT X 4FT RACK: 10 PER KIT

4FT X 6FT RACK: 14 PER KIT

4FT X 8FT RACK: 20PER KIT

4FT X 4FT RACK: 20 PER KIT

4FTX 6FT RACK: 30 PER KIT

4FT X 8FT RACK: 44 PER KIT

4FT X 4FT RACK: 8 PER KIT

4FT X 6FT RACK: 8 PER KIT

4FT X 8FT RACK: 12 PER KIT

1 PER KIT

REQUIRED TOOLS

PAGE 3

2 PER KIT