If you feel confident that you do not need to read through these instructions, see page 2…. January 09

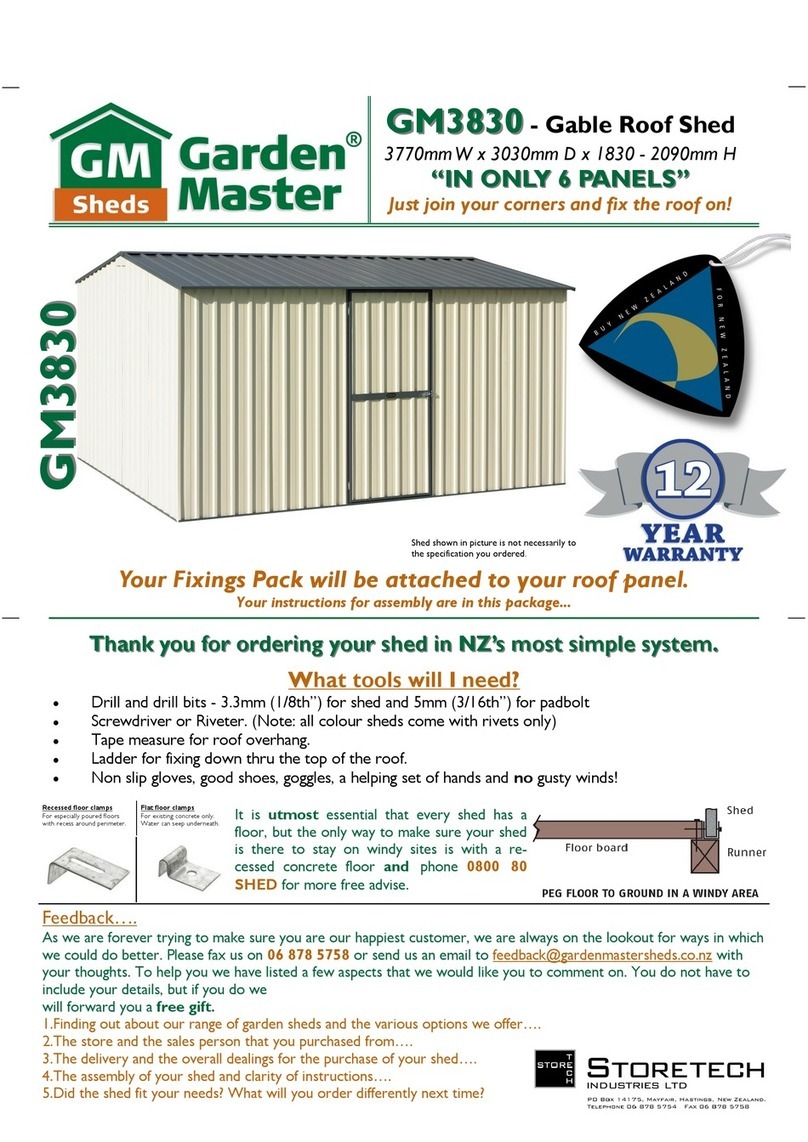

Feedback….

As we are forever trying to make sure you are our happiest customer, we are always on the look-

out for ways in which we could do better. Please fax us on 06 878 5758 or send us an email to

feedback@gardenmastersheds.co.nz with your thoughts. To help you we have listed a few aspects

that we would like you to comment on. You do not have to include your details, but if you do we

will forward you a free gift.

1.Finding out about our range of garden sheds and the various options we offer….

2.The store and the sales person that you purchased from….

3.The delivery and the overall dealings for the purchase of your shed….

4.The assembly of your shed and clarity of instructions….

5.Did the shed fit your needs? What will you order differently next time?

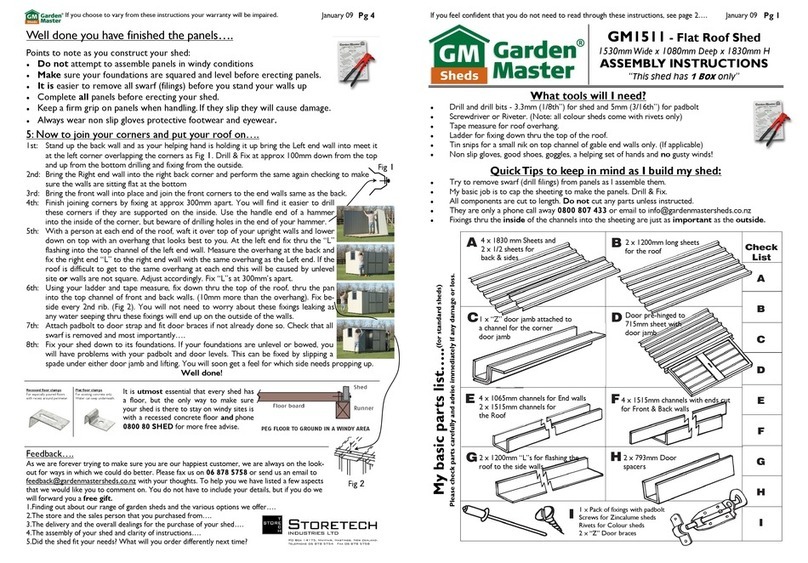

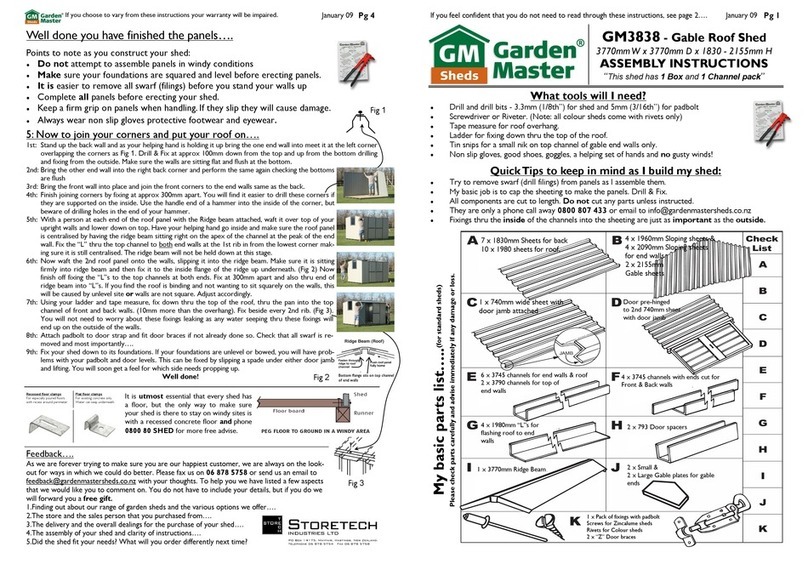

Well done you have finished the panels….

Points to note as you construct your shed:

Do not attempt to assemble panels in windy conditions

Make sure your foundations are squared and level before erecting panels.

It is easier to remove all swarf (filings) before you stand your walls up

Complete all panels before erecting your shed.

Keep a firm grip on panels when handling. If they slip they will cause damage.

Always wear non slip gloves protective footwear and eyewear.

5: Now to join your corners and put your roof on….

1st: Stand up the back wall and as your helping hand is holding it up bring the Left end wall into meet it

at the left corner overlapping the corners as Fig 1. Drill & Fix at approx 100mm down from the top

and up from the bottom drilling and fixing from the outside.

2nd: Bring the Right end wall into the right back corner and perform the same again checking to make

sure the walls are sitting flat at the bottom

3rd: Bring the front wall into place and join the front corners to the end walls same as the back.

4th: Finish joining corners by fixing at approx 300mm apart. You will find it easier to drill

these corners if they are supported on the inside. Use the handle end of a hammer in-

to the inside of the corner, but beware of drilling holes in the end of your hammer.

5th: With a person at each end of the roof, waft it over top of your upright walls and lower

down on top with an overhang that looks best to you. At the left end fix thru the “L”

flashing into the top channel of the left end wall. Measure the overhang at the back and

fix the right end “L” to the right end wall with the same overhang as the Left end. If the

roof is difficult to get to the same overhang at each end this will be caused by unlevel

site or walls are not square. Adjust accordingly. Fix “L”s at 300mm’s apart.

6th: Using your ladder and tape measure, fix down thru the top of the roof, thru the pan

into the top channel of front and back walls. (10mm more than the overhang). Fix be-

side every 2nd rib. (Fig 2). You will not need to worry about these fixings leaking as

any water seeping thru these fixings will end up on the outside of the walls.

7th: Attach padbolt to door strap and fit door braces if not already done so. Check that all

swarf is removed and most importantly….

8th: Fix your shed down to its foundations. If your foundations are unlevel or bowed, you

will have problems with your padbolt and door levels. This can be fixed by slipping a

spade under either door jamb and lifting. You will soon get a feel for which side needs

propping up.

Well done!

It is utmost essential that every shed has

a floor, but the only way to make sure

your shed is there to stay on windy sites is

with a recessed concrete floor and phone

If you choose to vary from these instructions your warranty will be impaired. Pg 4

Recessed floor clamps

For especially poured floors

with recess around perimeter.

Flat floor clamps

For existing concrete only.

Water can seep underneath.

Fig 1

Fig 2

If you feel confident that you do not need to read through these instructions, see page 2…. January 09

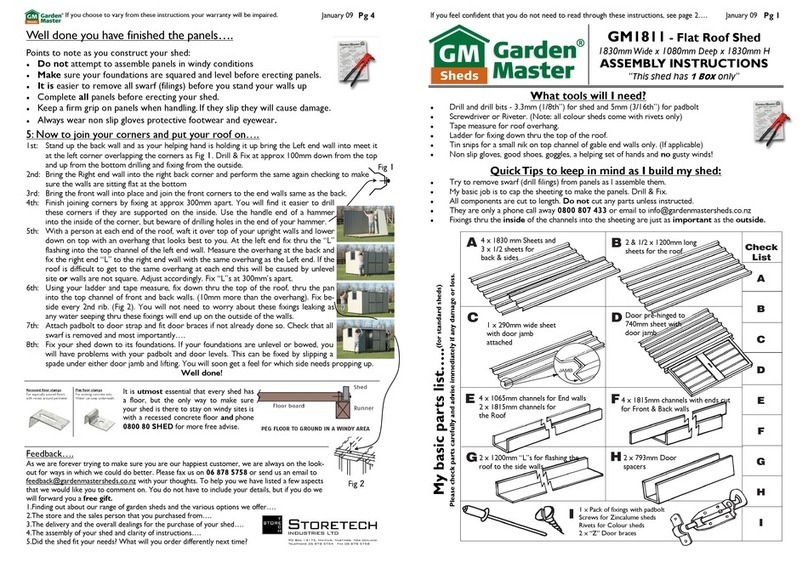

GM1811 - Flat Roof Shed

1830mm Wide x 1080mm Deep x 1830mm H

ASSEMBLY INSTRUCTIONS

“This shed has 1 Box only”

Quick Tips to keep in mind as I build my shed:

Try to remove swarf (drill filings) from panels as I assemble them.

My basic job is to cap the sheeting to make the panels. Drill & Fix.

All components are cut to length. Do not cut any parts unless instructed.

Fixings thru the inside of the channels into the sheeting are just as important as the outside.

What tools will I need?

Drill and drill bits - 3.3mm (1/8th”) for shed and 5mm (3/16th”) for padbolt

Screwdriver or Riveter. (Note: all colour sheds come with rivets only)

Tape measure for roof overhang.

Ladder for fixing down thru the top of the roof.

Tin snips for a small nik on top channel of gable end walls only. (If applicable)

Non slip gloves, good shoes, goggles, a helping set of hands and no gusty winds!

My basic parts list…..(for standard sheds)

Please check parts carefully and advise immediately if any damage or loss.

4 x 1830 mm Sheets and

3 x 1/2 sheets for

back & sides

2 & 1/2 x 1200mm long

sheets for the roof

Door pre-hinged to

740mm sheet with

door jamb

4 x 1065mm channels for End walls

2 x 1815mm channels for

the Roof

4 x 1815mm channels with ends cut

for Front & Back walls

2 x 1200mm “L”s for flashing the

roof to the side walls

2 x 793mm Door

spacers

Pg 1

1 x Pack of fixings with padbolt

Screws for Zincalume sheds

Rivets for Colour sheds

2 x “Z” Door braces

1 x 290mm wide sheet

with door jamb

attached