This entire book is filled with important safety information--please

read it carefully.

INTRODUCTION

SAFETY MESSAGES

Safety Labels

Safety Messages

Safety Headings

Safety Section

Instructions --how to use this tiller correctly and safely.

Your safety and the safety of others are very important.And using this

tiller safely is an important responsibility.

To help you make informed decisions about safety,we have provided

operating procedures and other information on labels and in this

manual.This information alerts you to potential hazards that could

hurt you or others.

Of course,it is not practical or possible to warn you about all the

hazards associated with operating or maintaining a tiller.You must

use your own good judgment.

You will find important safety information in a variety of forms,

including:

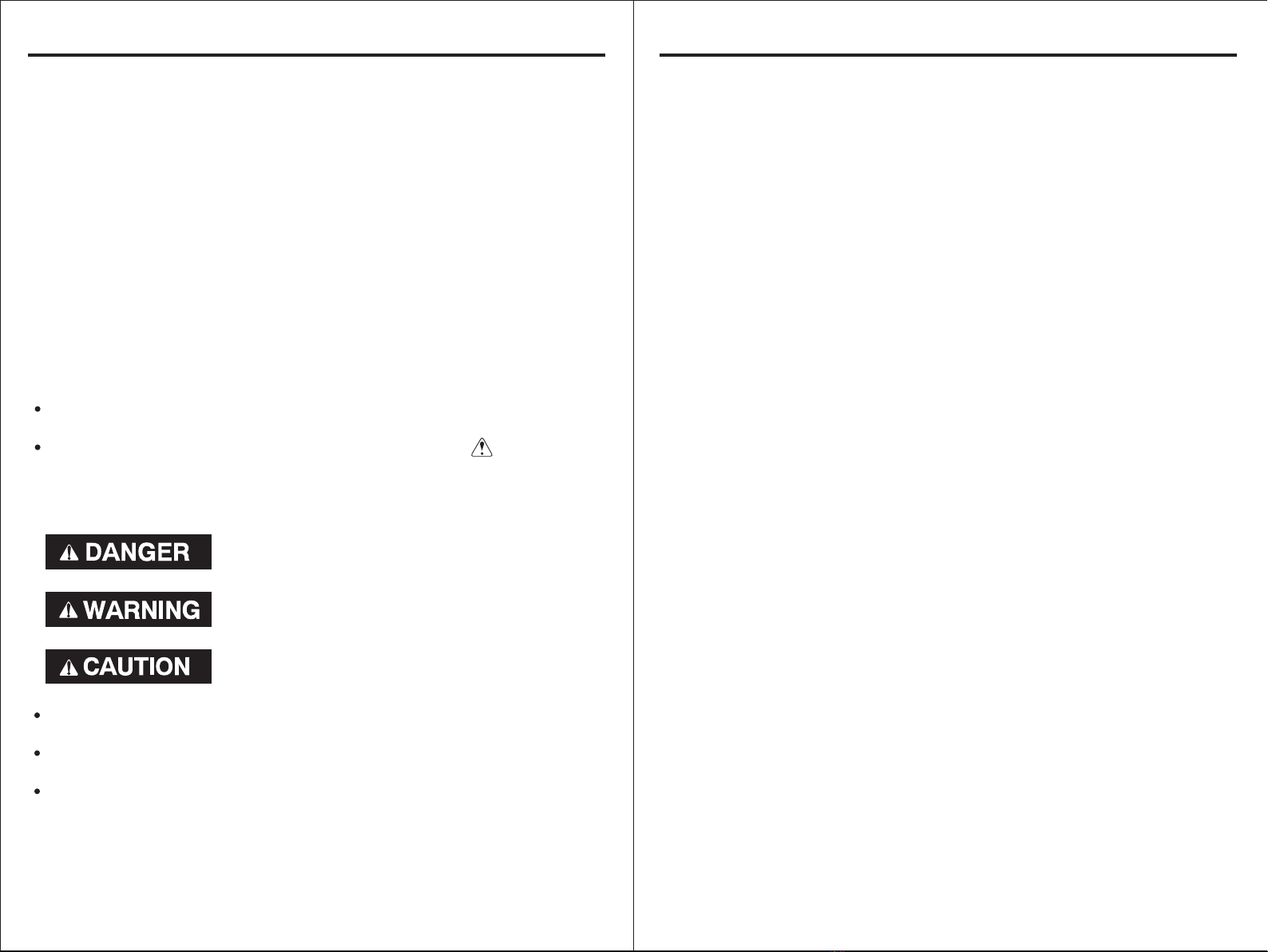

-- preceded by a safety alert symbol and one

of three signal words: DANGER,WARNING,or CAUTION.

These signal words mean:

You WILL be KILLED or SERIOUSLY HURT if

you follow instructions.don't

You CAN be KILLED or SERIOUSLY HURT if

you don't follow instructions.

You CAN be HURT if you don’t follow

instructions.

--such as

IMPORTANT SAFETY INFORMATION.

--such as

TILLER SAFETY.

STORAGE

STORAGE PREPARATION..........................................................................31

STORAGE PRECAUTIONS..........................................................................35

TAKING CARE OF UNEXPECTED PROBLEMS............................................................36

CONTENTS

TILLER SAFETY .................................................................................................1

CONTROLS ........................................................................................................4

IMPORTANT SAFETY INFORMATION .... .......2.................................................

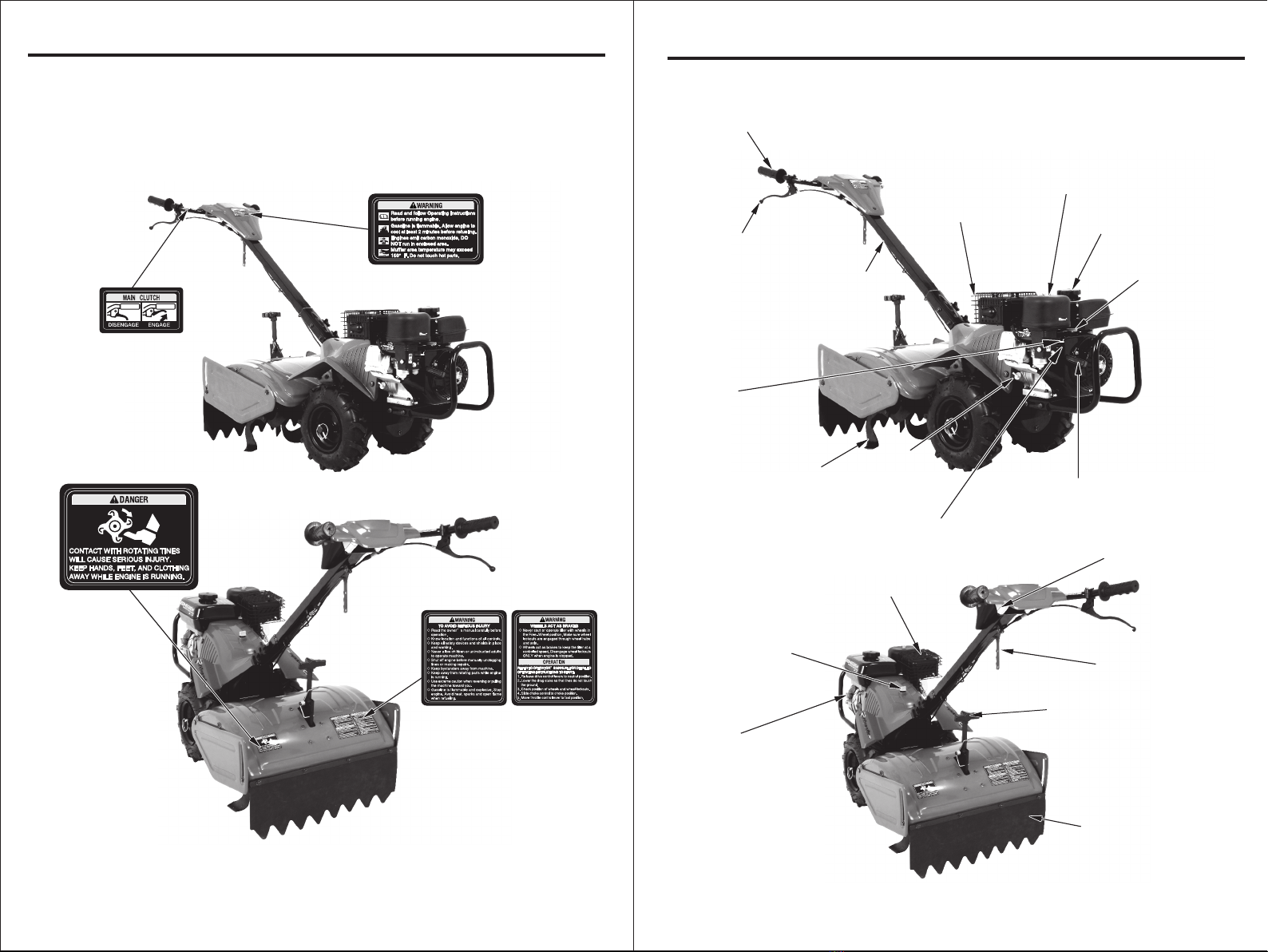

SAFETY LABEL LOCATIONS..........................................................................3

COMPONENT &CONTROL LOCATIONS.......................................................4

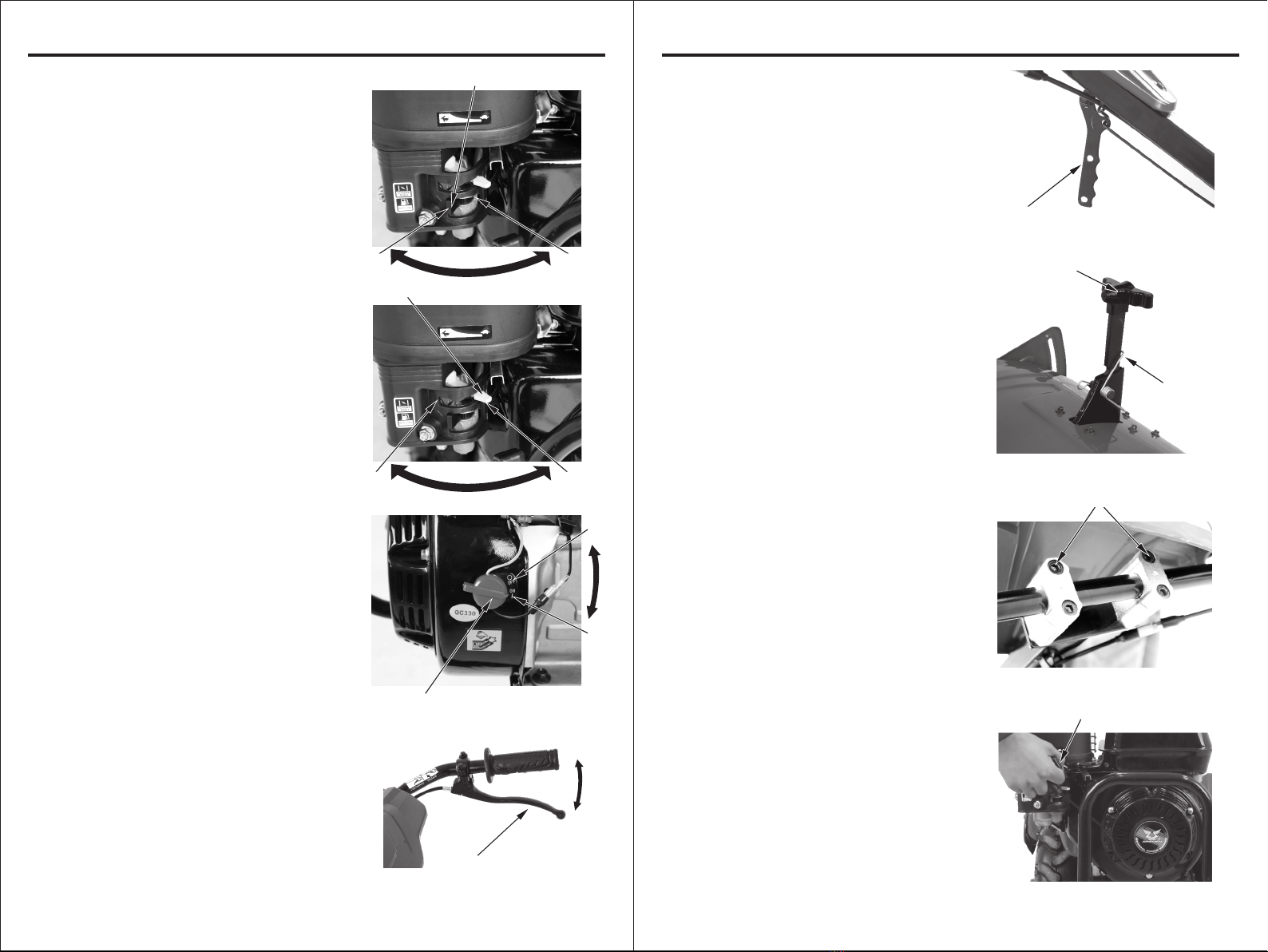

CONTROLS ....................................................................................................5

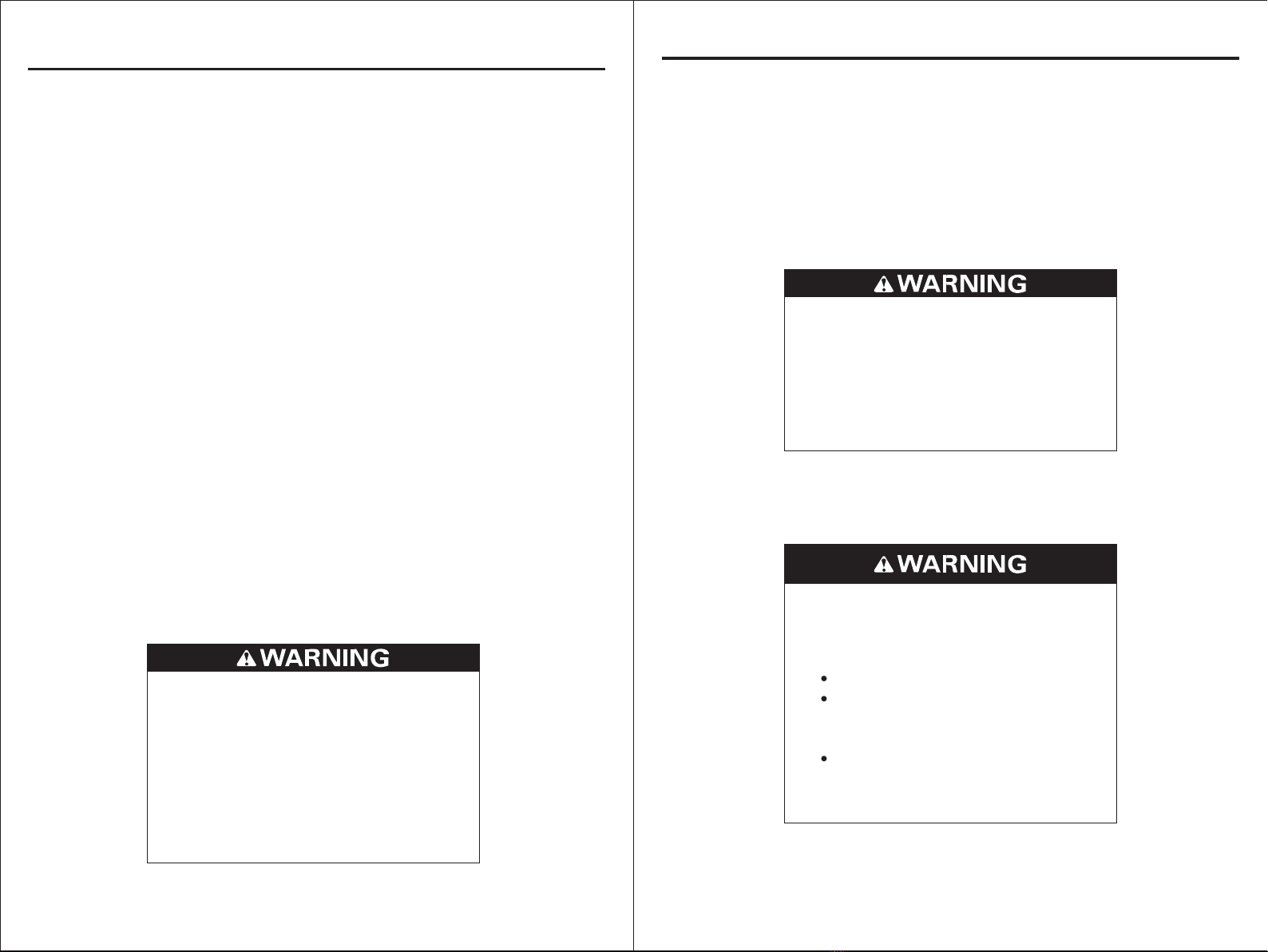

SETTING UP YOUR NEW TILLER ...................................................................7

WHEEL ASSEMBLY.......................................................................................8

BUMPER ASSEMBLY....................................................................................8

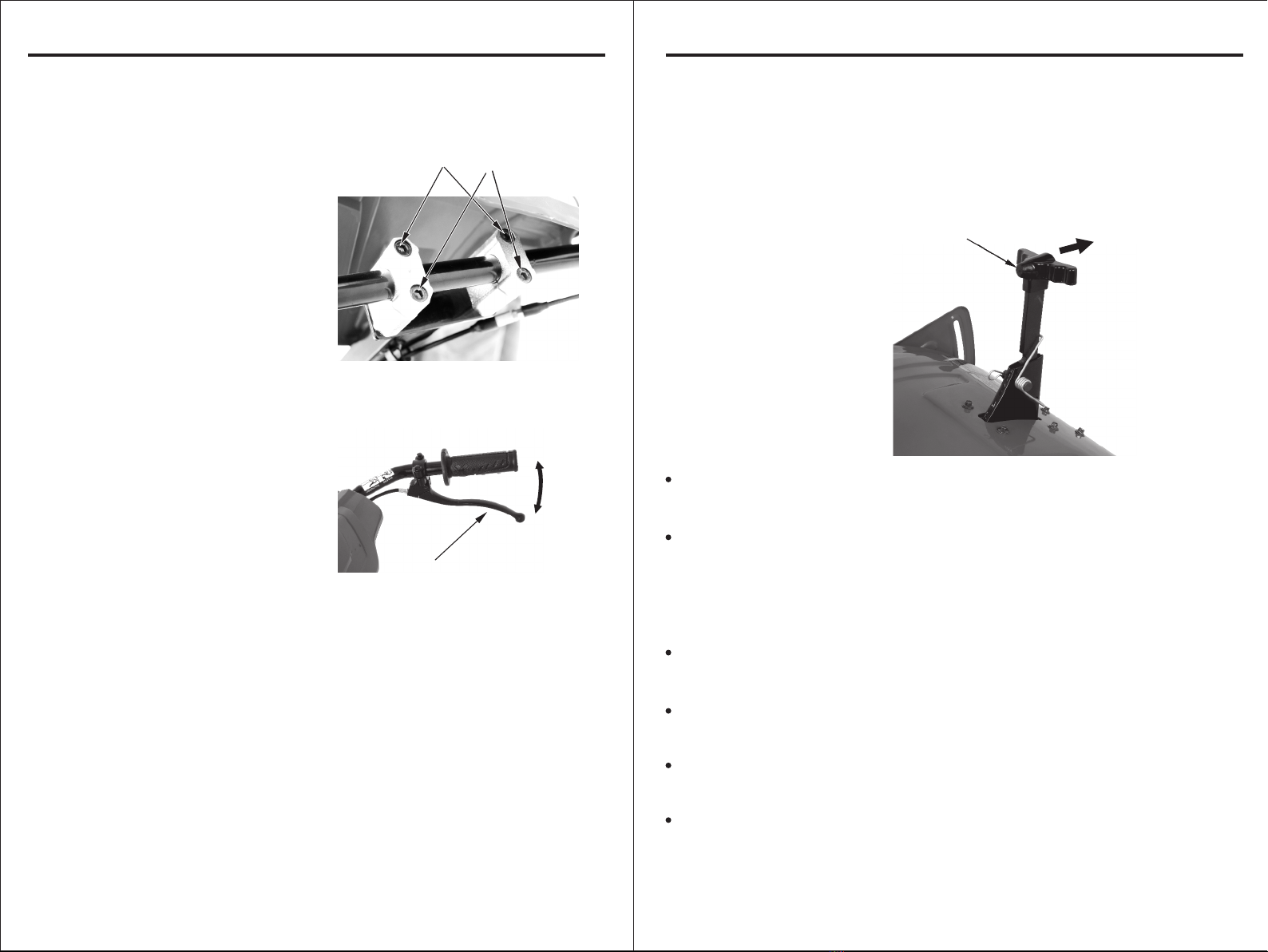

HANDLE BAR BRACKET ASSEMBLY ..........................................................7

REVERSE CA ASSEMBLY......................................................................7BLE

CLUTCH CA ASSEMBLY.........................................................................7BLE

BEFORE OPERATION.......................................................................................9

OPERATION.....................................................................................................10

ARE YOU READY TO GET STARTED...........................................................9

IS YOUR TILLER READY TO GO...................................................................9

SAFE OPERATING PRECAUTIONS............................................................10

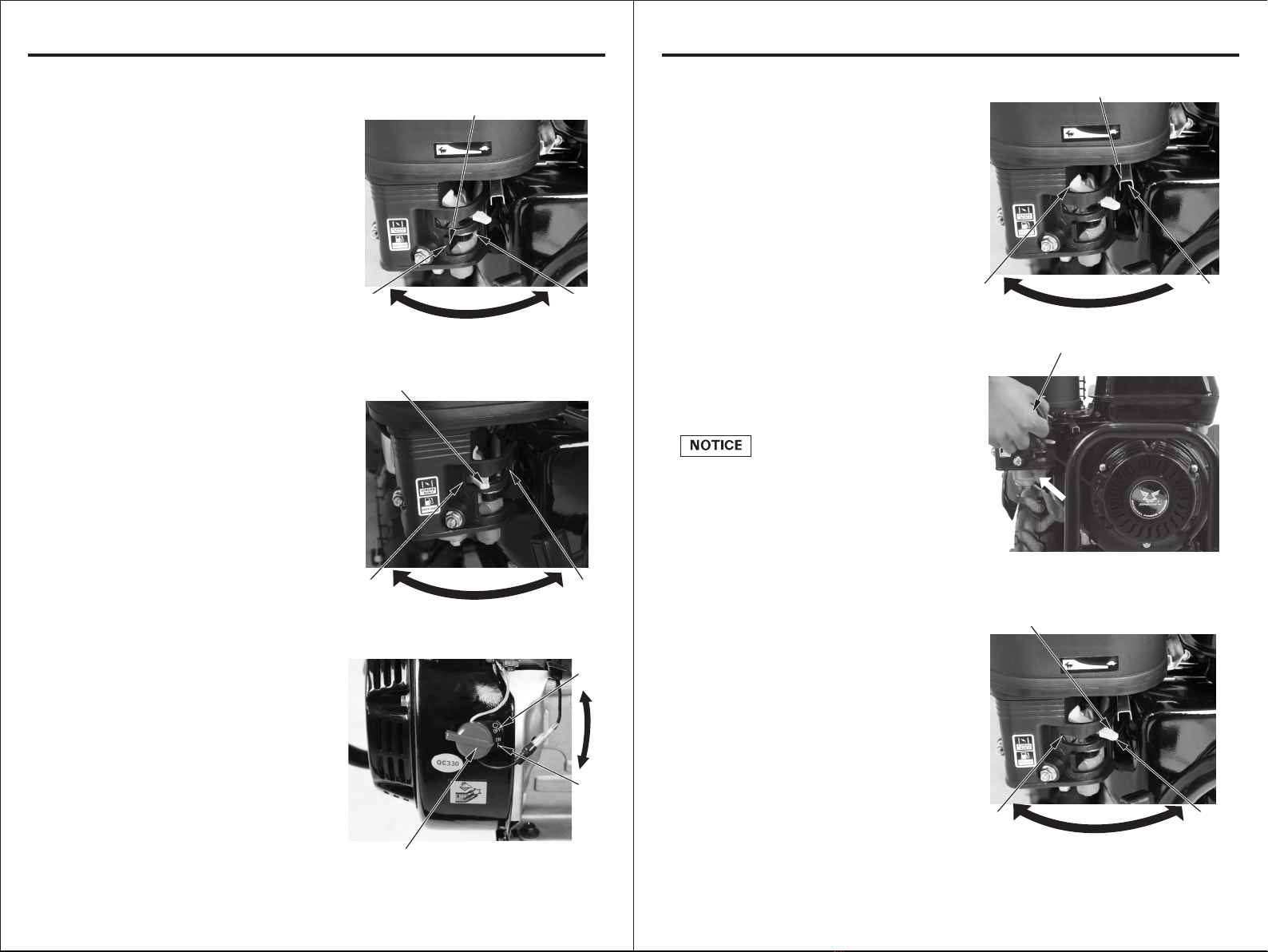

STARTING THE ENGINE..............................................................................10

OPERATING THE CONTROLS FOR TILLING.............................................13

HANDLING TIPS...........................................................................................14

STOPPING THE ENGINE.............................................................................15

CLUTCH CABLE ADJUSTMENT...................................................................24

REVERSE CABLE ADJUSTMENT................................................................24

SERVICING YOUR TILLER.............................................................................16

THE IMPORTANCE OF MAINTENANCE.....................................................16

MAINTENANCE SAFETY.............................................................................17

MAINTENANCE SCHEDULE........................................................................18

REFUELING..................................................................................................19

FUEL RECOMMENDATIONS.......................................................................20

ENGINE OIL LEVEL CHECK........................................................................20

ENGINE OIL CHANGE..................................................................................21

ENGINE OIL RECOMMENDATIONS............................................................22

TRANSMISSION OIL RECOMMENDATIONS...............................................22

AIR FILTER INSPECTION.............................................................................23

AIR FILTER CLEANING................................................................................23

DRIVE BELT CHANGE.................................................................................26

TINE REPLACEMENT..................................................................................29

SPARK ARRESTER SERVICE (optional equipment ) ..................................29

TIRE PRESSURE CHECK............................................................................30

SPARK PLUG SERVICE...............................................................................24