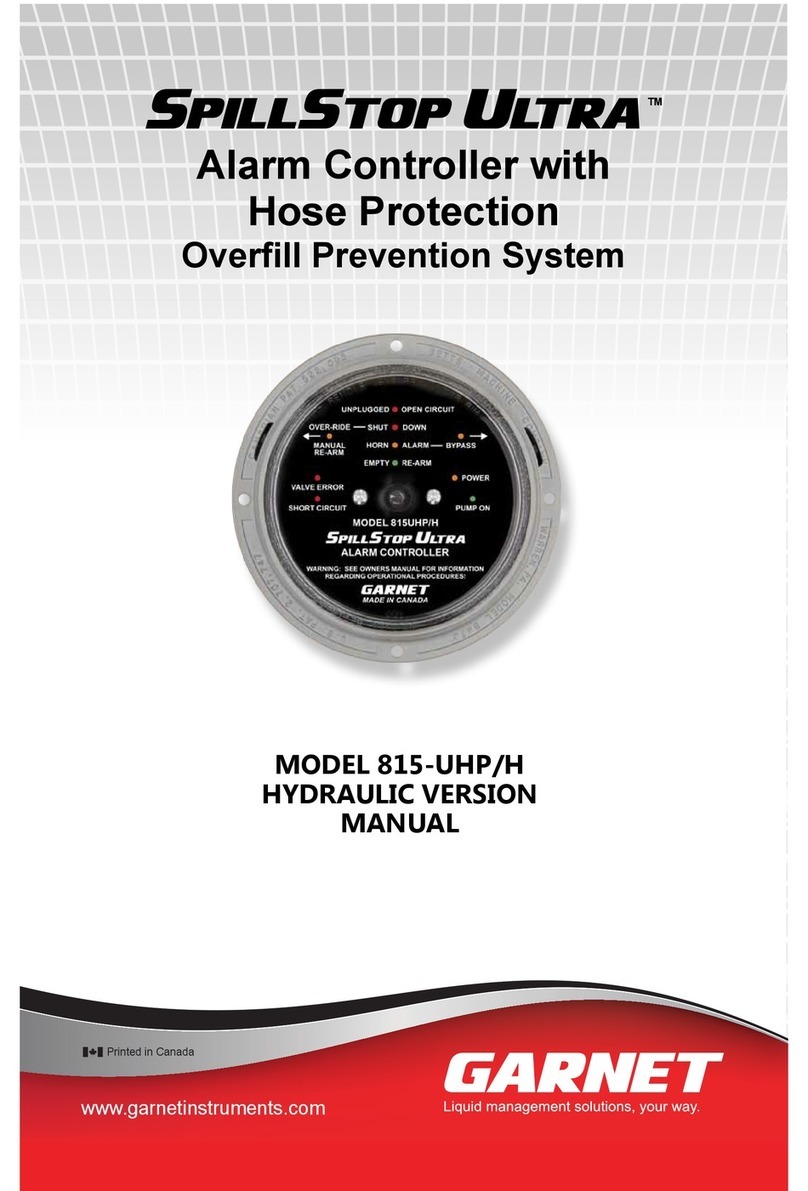

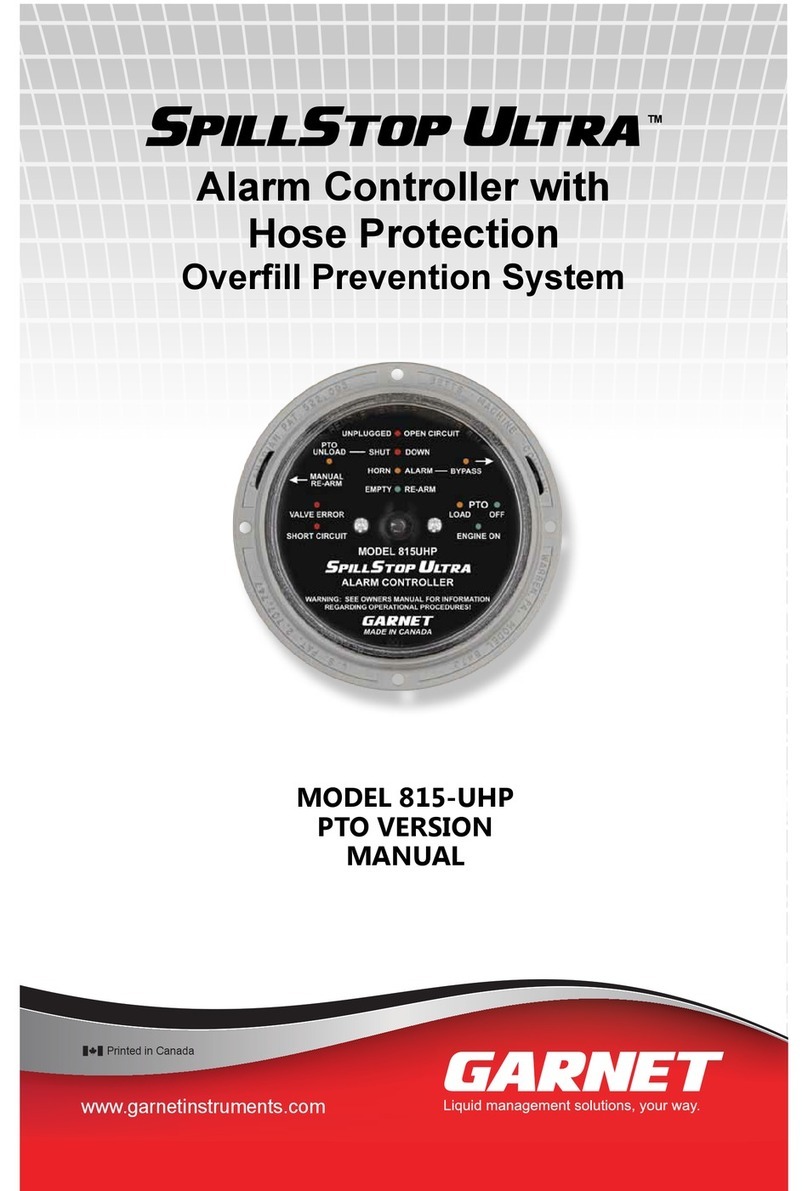

Garnet SPILLSTOP ULTRA 815-U User manual

Page 1815U Manual

Printed in Canada

www.garnetinstruments.com

TM

SPILLSTOP ULTRA

Overll Prevention System

MODEL 815-U MANUAL

Page 2 815U Manual

Table of Contents

CHAPTER 1 - OVERVIEW ...................................................................... 3

CHAPTER 2 - FEATURES AND OPERATION......................................... 4

CHAPTER 3 - INSTALLATION GUIDE ................................................... 7

CHAPTER 4 - WIRING DIAGRAMS...................................................... 11

CHAPTER 5 - TROUBLESHOOTING GUIDE......................................... 12

CHAPTER 6 - SERVICE AND WARRANTY INFORMATION................ 13

MAIL IN WARRANTY .......................................................................... 15

GARNET

SPILLSTOP ULTRA

TM

Overll Prevention System

MODEL 815-U MANUAL

815-U Manual_v2.0 - 25-Jan-18

Page 3815U Manual

C

ongratulations on purchasing the Garnet Instruments Model

815 SPILLSTOP ULTRA

™

overll prevention system. The

SPILLSTOP

represents the state of the art in spill control for crude

oil and chemical hauling. The

SPILLSTOP™

is designed to work in

conjunction with a Garnet Model 810PS2 SEELEVEL PROSERIES

™

or a

Model 808P2 SEELEVEL SPECIAL

™

system to assist the truck operator

with truck tank overll protection in applications where the uid is

loaded with a PTO driven pump.

T

he 815U system is designed as an emergency backup system. The

operator should still be responsible for loading and unloading of

the tank, but in the event that the operator is unable to shut down

loading when the tank is full, the 815U system will prevent a spill.

The 815U is easy to install and operate, and is designed to

withstand the rigors of mobile applications. The Model 817 Truck

Gauge Programmer is used to set the alarm points in the 810PS2

SEELEVEL PROSERIES

™

or the 808P2 SEELEVEL SPECIAL

™

gauge, which

are programmed with the horn alarm and shutdown points. The

system can shut down either the truck engine or hydraulically

operated loading pumps. A horn alarm is provided to warn of an

impending shut down condition.

CHAPTER 1 - OVERVIEW

Page 4 815U Manual

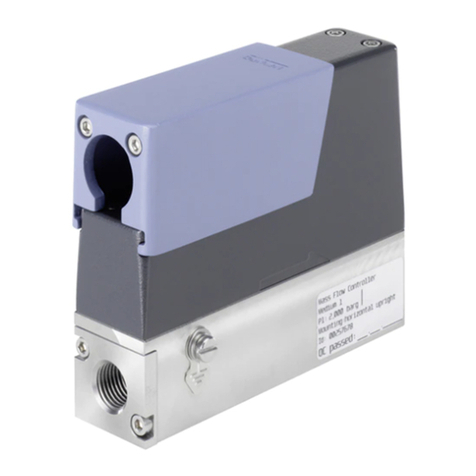

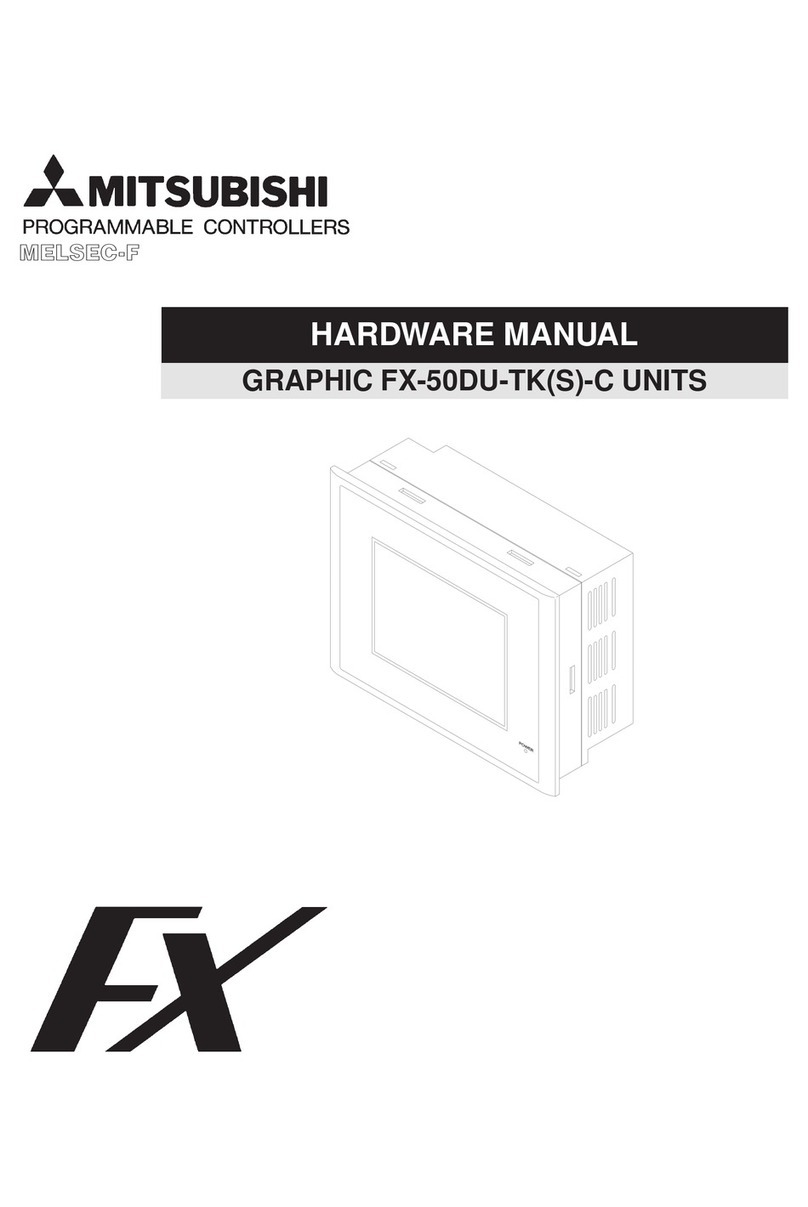

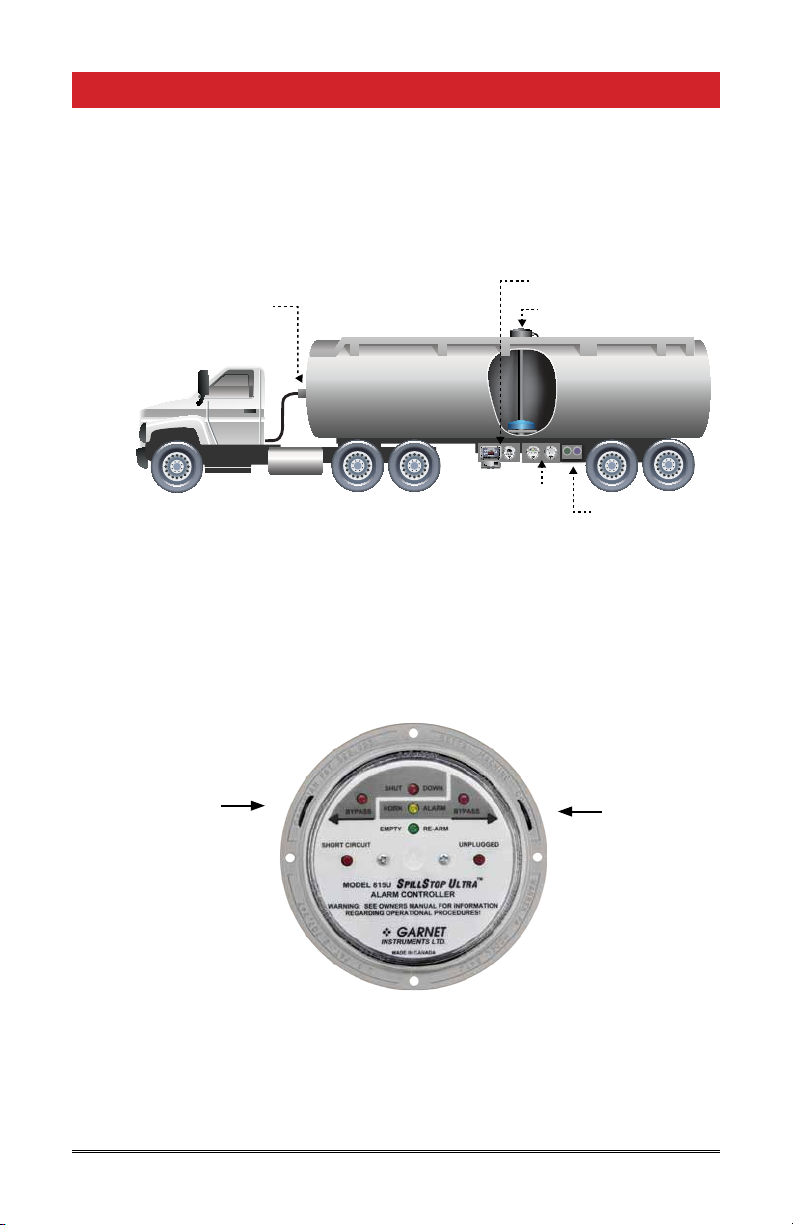

The following sketch shows the basic components and

connections of the SPILLSTOP for a tractor trailer application.

A body truck application would be similar except that the 7 pin

plug & socket would not be required since the tank is never

disconnected from the truck.

MODEL815UD

DUALALARMCONTROLLER

WARNING:SEEOWNERSMANUALFORINFORMATION

REGARDINGOPERATIONALPROCEDURES!

SPILLSTOPULTRA

TM

UNPLUGGED

SHUTDOWN

HORNALARM

TANKEMPTY

RE-ARM

SHORTCCT

PUMP ON

REARFRONT

PERMITTHERMB

OPTIC THERMA

MODEL688

OPTIC/THERMISTORLOADINGRACKCONTROLLER

MultiRackTM

SHUT DOWN

HORN ALARM

EMPTY RE-ARM

BYPASS BYPASS

SHORTCIRCUIT UNPLUGGED

MODEL815U

WARNING:SEEOWNERSMANUALFORINFORMATION

REGARDINGOPERATIONALPROCEDURES!

S

PILL

S

TOP

U

LTRA

TM

ALARMCONTROLLER

810-X Bar

815U SPILLSTOP

Controller and

688 MULTIRACK

7 Pin Plug

& Socket

Rack Plugs Wired

to MULTIRACK

808P2 SEELEVEL SPECIAL

or 810PS2 SEELEVELPROSERIES 2

The SPILLSTOP consists of three main components: the controller

on the truck, the optional plug module inside the 7 pin socket

housing on the trailer, and the gauge module inside the SeeLeveL

PROSERIES

truck gauge (the gauge module is built in to the SeeLeveL

Special display).

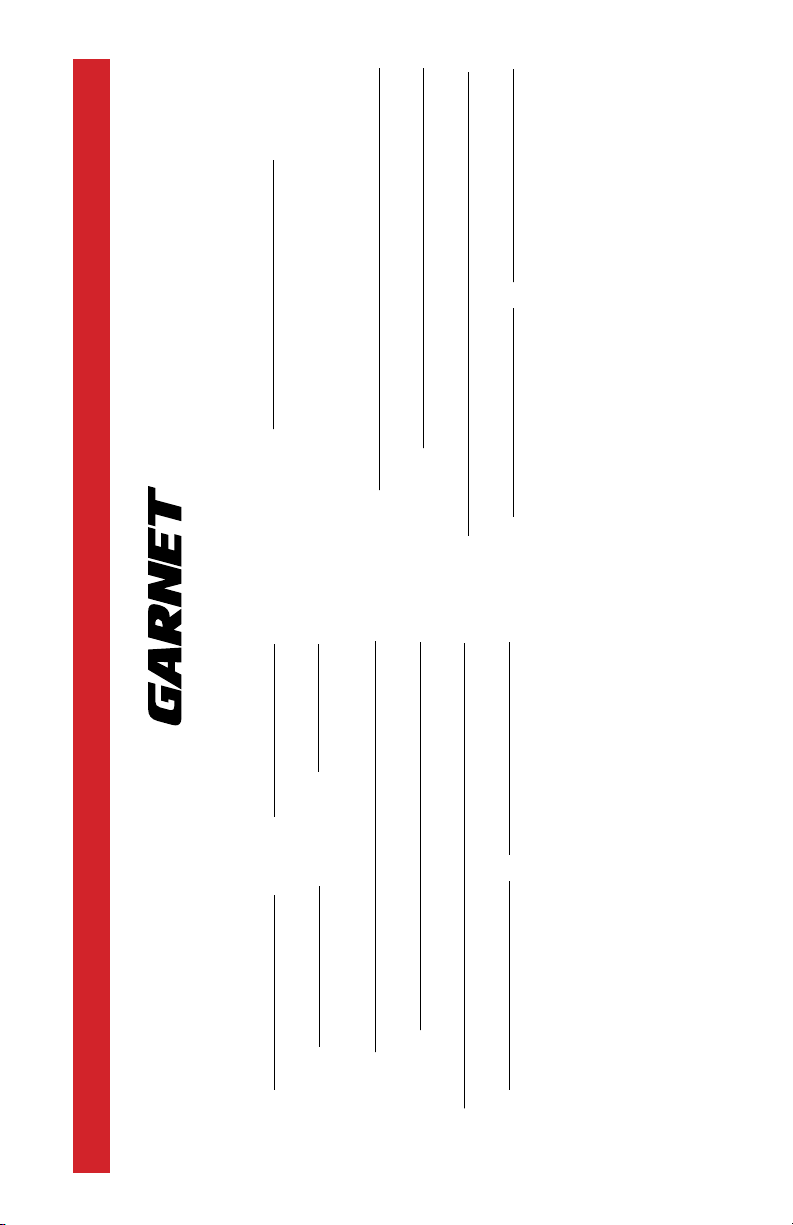

The 815U alarm controller monitors and displays the alarm status

of the gauge, and activates a horn if the uid level in the truck tank

is at the full point, and shuts off the pump or vehicle engine if a

spill is imminent. Each 815 Ultra controller accommodates one

compartment.

Horn Alarm Bypass Button

Shut Down Bypass Button

CHAPTER 2 - FEATURES AND OPERATION

Page 5815U Manual

WARNING: The SPILLSTOP ULTRA is intended as an emergency

backup system only, and is not intended as a substitute for

operator diligence during the loading process.

The operation of the SPILLSTOP Ultra during the loading operation

is as follows: When the tank is empty, the green EMPTY/RE-

ARM indicator is on, the horn is off, and the engine or pump is

allowed to run. As the uid level starts to rise, the EMPTY/RE-

ARM indicator goes out. When the horn alarm point is reached,

the yellow HORN ALARM indicator comes on and the horn is

activated with a 1 second on, 1 second off cycle. Depressing the

horn alarm BYPASS at this point lights the red horn alarm bypass

indicator and silences the horn. If the uid level continues to rise

and reaches the engine shutdown point, the red SHUT DOWN

indicator will come on and the pump or truck engine will be shut

off. Depressing the shutdown BYPASS at this point lights the red

shutdown bypass indicator and allows the pump or engine to be

restarted. When either one of the BYPASS switches are depressed,

the associated alarm indicator remains on even though the alarm

function has been suppressed; this reminds the operator that

the uid level situation which triggered the alarm still exists. As

the tank is unloaded the alarm indicators will go out when the

uid level drops below the alarm points, and the bypasses will

be cleared (the system is re-armed) when the EMPTY/RE-ARM

indicator comes back on. This automatic feature means that

there is no need for the operator to re-arm the system, removing

the possible operator error of forgetting to re-arm. If the tank is

not lled to the alarm point, the system can still be bypassed to

prevent sloshing from sounding the horn or shutting down the

engine during driving. If the tank is to be lled from more than

one location, the alarms can be bypassed during driving between

loading sites, and the system manually re-armed to re-establish

spill protection for the second load. Re-arming is done by pressing

both of the BYPASS buttons at the same time for two seconds.

The SPILLSTOP Ultra has a number of convenience and safety

features built into it. When the tank is empty, the bypasses will

not work, preventing accidental bypassing before loading. Delays

are incorporated into the system to prevent electrical noise or

momentary bad connections from disrupting operation. A short

circuit in the wiring to the gauge, or plugging the SPILLSTOP plug

into the trailer lighting socket, lights the red SHORT CIRCUIT

indicator and shuts down the pump or engine. An open circuit

in the wiring to the gauge, or a disconnection of the plug to the

trailer, lights the red UNPLUGGED indicator, sounds the horn, and

shuts down the pump or engine. The alarms from an unplugged

situation can be bypassed to allow operating the tractor without

the trailer connected. The pulse signal between the gauge and the

Page 6 815U Manual

controller cannot be corrupted by poor connections or moisture

in the wiring; if the signal is too badly degraded it defaults directly

to an open or short circuit condition. A failure of the

SEELEVEL

or

SEELEVEL

Special gauge causes the controller to default to the horn

alarm and shut down condition. The controller will operate at

truck voltages from 8 to 16 volts, and draws less than 1/8 amp so

it can operate from any convenient 12 volt circuit. The controller

is also fully weatherproof, so it can be mounted outside of the cab

of the truck.

Page 7815U Manual

Refer to the appropriate wiring diagram during installation of

the SPILLSTOP system. The wiring diagrams are in chapter 4.

Follow these instructions for a tractor trailer installation:

1. Pick a spot for the SPILLSTOP Ultra controller to be mounted. It

can be inside or outside of the cab, but it should be mounted

on the truck, rather than the trailer. The only situation

where the controller can be mounted on a trailer is where

the loading pump is also located on the trailer so that the

shutdown wiring does not need to go through a plug. In this

case the 12 volt power should be generated at the trailer, or

a loss of power to the trailer should result in the shutdown of

the loading pump. Do not mount the controller where it can

be kicked and it should be easy to see and out of direct road

spray. It is recommended that the controller be mounted

close to the PTO control.

2. Mount the display enclosure using the mounting ange holes,

being certain to shim the enclosure away from the mounting

surface with the spacers provided to allow water drainage.

Broken display enclosures caused by water freezing

behind the enclosure are NOT covered by warranty.

IMPORTANT: When connecting wiring, all connections should

be soldered.

3. Mount a standard 7 pin socket to the front of the trailer and a

7 pin plug and cable from the tractor.

4. A single wire needs to be connected between the green wire

of the 808P2, the grey wire of the 810PS2 and the yellow wire

of the 815U SPILLSTOP Ultra controller through the 7 pin socket.

From inside the displays, seal the wire entry into the

SEELEVEL

enclosure with RTV silicon rubber. Make sure that the RTV

fully surrounds the wire where it goes though the tting.

5. Connect the 808P2 or 810PS2 and the 815U SPILLSTOP Ultra

controller to the same chassis ground using each displays

ground wires. Verify the truck and trailer are grounded

together through the 7 pin plug.

6. Connect the 815U controller red wire to a 12 volt source.

This 12 volt source should be an ignition source so the truck

battery is not drained when the truck is off.

7. Locate an electrical shutoff switch (such as the key switch) in

the truck. Break the connection to the switch and connect

the two wire ends to the contact terminals (#30 & #87) of the

CHAPTER 3 - INSTALLATION GUIDE

Page 8 815U Manual

auxiliary ESD relay (supplied). Connect one of the auxiliary

ESD relay coil terminals (#86) to the 12 volt source and the

other coil terminal (#85) to the green wire in the controller. It

is a good idea to mount the auxiliary ESD relay close to the

existing shutoff wiring to minimize any extra wire length in the

truck shutoff circuit.

8. Connect the PTO sense relay (supplied) as shown in the wiring

diagram. Use a standard clearance lamp (not supplied) as the

PTO indicator light. The PTO sense relay functions so that the

ESD (Engine Shutdown) relay cannot operate unless the PTO

is engaged. This prevents the engine from being accidentally

shutdown if uid sloshing occurs and raises the oat above

the engine shutdown point.

9. Connect the orange controller wire to the truck’s electrical

horn switch (or button). Make sure that grounding this

connection will cause the horn to sound. This connection is

normally to the horn relay coil, not to the horn itself.

10. Program the alarm points in the gauges. Program alarm #1 as

SHUT DOWN at the point where the engine or pump should

be shut down. Program alarm #2 as SHUT DOWN at the point

where the horn alarm should come on. Program alarm #3 as

SHUT DOWN at the point where the tank is considered empty,

normally a few inches off the bottom. Do not program the

empty point right at the bottom, since any buildup of debris

on the anchor will prevent the system from clearing the

bypasses. See the 808P2 or 810PS2 manual for programming

details.

Example: The tank is 58 inches high, with a bottom reading of 4.6

inches. Suggested points would be alarm #1 at 55 inches, alarm

#2 at 53 inches, and alarm #3 at 6 inches.

WARNING: To properly determine the shutdown point, raise the

SEELEVEL

oat to the top of the tank, and then lower the oat by at

least one inch. Record this point as the shutdown value. Ensure

that the truck operator is aware of this value. Ensure that

this value and the empty reading are recorded in the provided

area in the operator’s manual. The truck operator must be

given the owners manual upon delivery with all front page

data lled in.

11. Put the cover back on the

SEELEVEL

gauge, and test the system

for proper operation by lifting the oat. As the oat is raised,

the horn should turn on rst, and then the engine or pump

should shut off with the oat at least one inch below the top

of the tank. Bypass the horn and shutdown and ensure that

the bypasses are removed with the oat at least one inch

above the bottom of the tank.

Page 9815U Manual

Follow these instructions for a body truck installation:

1. Pick a spot for the SPILLSTOP Ultra controller to be mounted.

It can be inside or outside of the cab. Do not mount the

controller where it can be kicked and it should be easy to

see and out of direct road spray. It is recommended that the

controller be mounted close to the PTO control.

2. Mount the display enclosure using the mounting ange holes,

being certain to shim the enclosure away from the mounting

surface with the spacers provided to allow water drainage.

Broken display enclosures caused by water freezing

behind the enclosure are NOT covered by warranty.

IMPORTANT: When connecting wiring, all connections should

be soldered.

3. A single wire needs to be connected between the green wire

of the 808P2, the grey wire of the 810PS2 and the yellow

wire of the 815U SPILLSTOP Ultra controller. From inside the

displays, seal the wire entry into the

SEELEVEL

enclosure with

RTV silicon rubber. Make sure that the RTV fully surrounds the

wire where it goes though the tting.

4. Connect the 808P2 or 810PS2 and the 815U SPILLSTOP Ultra

controller to the same chassis ground using each displays

ground wires.

5. Connect the 815U controller’s red wire to a +12 volt source.

This +12 volt source should be an ignition source so the truck

battery is not drained when the truck is off.

6. Locate an electrical shutoff switch (such as the key switch) in

the truck. Break the connection to the switch and connect

the two wire ends to the contact terminals (#30 & #87) of the

auxiliary ESD relay (supplied). Connect one of the auxiliary

ESD relay coil terminals (#86) to the 12 volt source and the

other coil terminal (#85) to the green wire in the controller. It

is a good idea to mount the auxiliary ESD relay close to the

existing shutoff wiring to minimize any extra wire length in the

truck shutoff circuit.

7. Connect the PTO sense relay (supplied) as shown in the wiring

diagram. Use a standard clearance lamp (not supplied) as the

PTO indicator light. The PTO sense relay functions so that the

ESD (Engine Shutdown) relay cannot operate unless the PTO

is engaged. This prevents the engine from being accidentally

shutdown if uid sloshing occurs and raises the oat above

the engine shutdown point.

Page 10 815U Manual

8. Connect the 815U controller’s orange wire to the truck’s

electrical horn switch (or button). Make sure that grounding

this connection will cause the horn to sound. This connection

is normally to the horn relay coil, not to the horn itself.

9. Program the alarm points in the gauges. Program alarm #1 as

SHUT DOWN at the point where the engine or pump should

be shut down. Program alarm #2 as SHUT DOWN at the point

where the horn alarm should come on. Program alarm #3 as

SHUT DOWN at the point where the tank is considered empty,

normally a few inches off the bottom. Do not program the

empty point right at the bottom, since any buildup of debris on

the anchor will prevent the system from clearing the bypasses.

See the 808P2 or 810PS2 manuals for programming details.

Example: The tank is 58 inches high, with a bottom reading of

4.6 inches. Suggested points would be alarm #1 (shutdown) at

55 inches, alarm #2 (horn) at 53 inches, and alarm #3 (reset) at 6

inches.

WARNING: To properly determine the shutdown point, raise the

SEELEVEL

oat to the top of the tank, and then lower the oat by at

least one inch. Record this point as the shutdown value. Ensure

that the truck operator is aware of this value. Ensure that

this value and the empty reading are recorded in the provided

area in the operator’s manual. The truck operator must be

given the owners manual upon delivery with all front page

data lled in.

10. Put the cover back on the

SEELEVEL

gauge, and test the system

for proper operation by lifting the oat. As the oat is raised,

the horn should turn on rst, and then the engine or pump

should shut off with the oat at least one inch below the top

of the tank. Bypass the horn and shutdown and ensure that

the bypasses are removed with the oat at least one inch

above the bottom of the tank.

Page 11815U Manual

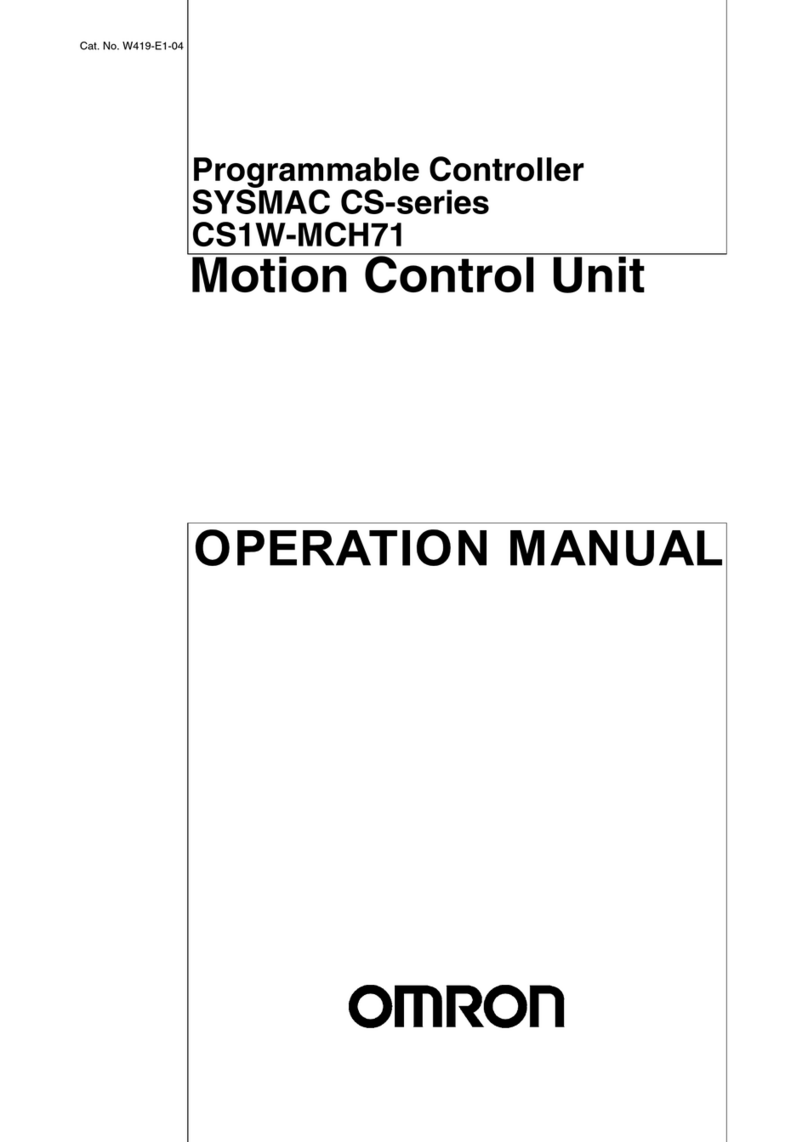

EXISTING

KEY

SWITCH

FROM UNSWITCHED

+12 VOLT

BREAK

SINGLE COMPARTMENT WIRING DIAGRAM

#85#86

#30#87

AUX

ESD

RELAY

- COIL -

- CONTACTS -

EXISTING

HORN

SWITCH

BLACK GREEN

SeeLeveL

Special

GAUGE

LIGHT

INDICATOR

PTO

PTO PRESSURE SWITCH

(CLOSED WHEN PTO ENGAGED)

#85#86

#30

#87

PTO

SENSE

RELAY

COIL

CONTACTS

#87A

NOTE: Relay contacts 30 and 87A are the

normally closed (NC) contacts.

Relay contacts 30 and 87 are the

normally open (NO) contacts.

TO FUEL SHUTOFF

FROM HORN

RED (12V INPUT)

YELLOW (GAUGE)

GREEN (SHUTDOWN)

SPILL STOP

ULTRA

CONTROLLER

ORANGE (HORN)

BLACK (GROUND)

WITH PTO PRESSURE SWITCH APPLICATION

CHAPTER 4 - WIRING DIAGRAMS

Wiring Guide

Wire Color Operation

Yellow Signal Line

Green Shutdown output

Orange Horn alarm output

Black Ground

Red +12VDC

Purple Horn alarm bypass wire

White Shutdown bypass wire

Page 12 815U Manual

IF problems are encountered, check the following:

1. Is the controller getting at least 8 volts?

2. Are all the wires properly connected, with no short circuits?

3. Are the 808P2 or 810PS2

SEELEVEL

gauges working properly?

4. Are the 808P2 or 810PS2

SEELEVEL

gauges programmed

properly?

5. If the horn is not sounding, does the horn itself work?

To test the various components, substitute a known good

component to see if the rest of the system is working. If the

engine will not start, ground the green wire from the controller.

If the engine still does not start, the problem is in the relay or

associated wiring. If the engine now starts, and the controller

indicates no shutdown alarm (or is bypassed), then the controller

is bad. If the horn will not sound, ground the orange wire from

the controller. If the horn still does not sound, the problem is in

the horn or associated wiring. If the horn now sounds, and the

controller indicates a horn alarm that is not bypassed, then the

controller is bad.

CHAPTER 5 - TROUBLESHOOTING GUIDE

Page 13815U Manual

CHAPTER 6 - SERVICE AND WARRANTY INFORMATION

T

he warranty will only apply only if the warranty card that is shipped with the equipment

has been returned to Garnet Instruments Ltd.

DISCLAIMER OF WARRANTY ON HARDWARE

Garnet Instruments Ltd. warrants equipment manufactured by Garnet to be free from defects

in material and workmanship under normal use and service for a period of one year from the

date of sale from Garnet or an Authorized Dealer. The warranty period will start from the date

of purchase or installation as indicated on the warranty card. Under these warranties, Garnet

shall be responsible only for actual loss or damage suffered and then only to the extent of

Garnet’s invoiced price of the product. Garnet shall not be liable in any case for labor charges

for indirect, special, or consequential damages. Garnet shall not be liable in any case for

the removal and/or reinstallation of defective Garnet equipment. These warranties shall not

apply to any defects or other damages to any Garnet equipment that has been altered or

tampered with by anyone other than Garnet factory representatives. In all cases, Garnet will

warrant only Garnet products which are being used for applications acceptable to Garnet and

within the technical speci cations of the particular product. In addition, Garnet will warrant

only those products which have been installed and maintained according to Garnet factory

speci cations.

LIMITATION ON WARRANTIES

These warranties are the only warranties, expressed or implied, upon which products are

sold by Garnet and Garnet makes no warranty of merchantability or tness for any particular

purpose in respect to the products sold. Garnet products or parts thereof assumed to be

defective by the purchaser within the stipulated warranty period should be returned to the

seller, local distributor, or directly to Garnet for evaluation and service. Whenever direct

factory evaluation, service or replacement is necessary, the customer must rst, by either

letter or phone, obtain a Returned Material Authorization (RMA) from Garnet Instruments

directly. No material may be returned to Garnet without an RMA number assigned to it or

without proper factory authorization. Any returns must be returned freight prepaid to: Garnet

Instruments Ltd, 286 Kaska Road, Sherwood Park, Alberta, T8A 4G7. Returned warranted

items will be repaired or replaced at the discretion of Garnet Instruments. Any Garnet items

under the Garnet Warranty Policy that are deemed irreparable by Garnet Instruments will be

replaced at no charge or a credit will be issued for that item subject to the customer’s request.

If you do have a warranty claim or if the equipment needs to be serviced, contact the

installation dealer. If you do need to contact Garnet, we can be reached as follows:

CANADA UNITED STATES

Garnet Instruments Ltd. Garnet Technologies Inc.

286 Kaska Road 201 M&M Ranch Road

Sherwood Park, AB T8A 4G7 Granbury, TX 76049

CANADA USA

MODEL NO. SERIAL NO.

DATE PURCHASED DATE INSTALLED

YR/MO/DAY YR/MO/DAY

COMPANY NAME

PRINCIPAL CONTACT

ADDRESS

TELEPHONE FAX

IN CANADA RETURN TO:

Garnet Instruments Ltd.

286 Kaska Road

Sherwood Park, AB T8A 4G7

CANADA

SENDER BAR SERIAL NO. (if applicable)

IMPORTANT: WITHOUT THE SERIAL NUMBER OF EACH UNIT IT IS

DIFFICULT TO DETERMINE WARRANTY VALIDITY

DEALERS NAME

WARRANTY CONTACT

ADDRESS

TELEPHONE FAX

IN UNITED STATES RETURN TO:

Garnet Technologies Inc.

201 M&M Ranch Road

Granbury, TX 76049

USA

IMPORTANT: RETURNING THIS CARD WILL ENABLE US TO NOTIFY YOU IN THE EVENT OF A PRODUCT RECALL OR TO SUPPLY YOU WITH REQUIRED PRODUCT SAFETY INFORMATION.

TO MAXIMIZE YOUR WARRANTY PLEASE REGISTER ONLINE AT www.garnenstruments.com OR MAIL THIS FORM IN TO GARNET.

LIMITED WARRANTY REGISTRATION

MAIL IN WARRANTY

Printed in Canada

www.garnetinstruments.com

CANADA

Garnet Instruments Ltd.

286 Kaska Road

Sherwood Park, AB T8A 4G7

USA

Garnet Technologies Inc.

201 M&M Ranch Road

Granbury, TX 76049

P: 780-467-1010

F: 780-467-1567

TF: 1-800-617-7384

P: 817-578-8601

F: 817-573-0005

TF: 1-877-668-7813

Table of contents

Other Garnet Controllers manuals