JA3-018M

02-9/2019 Rev.0

1/2

2

6

3

6

6

4

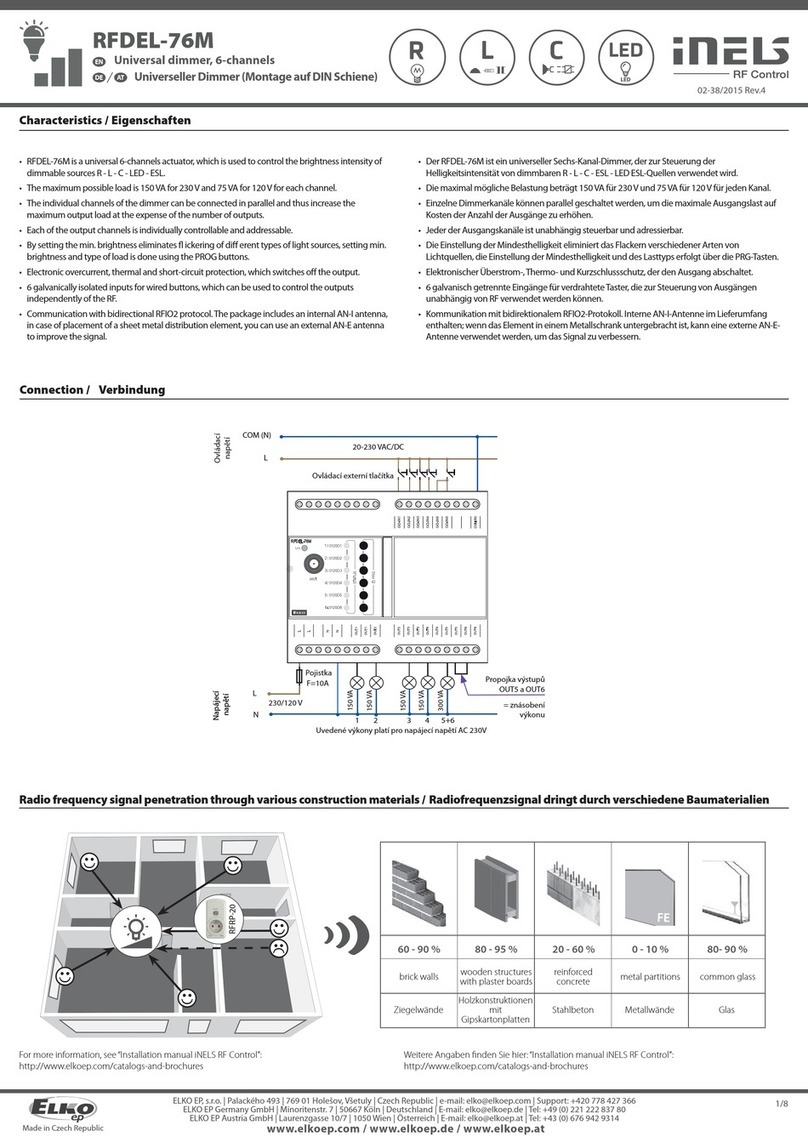

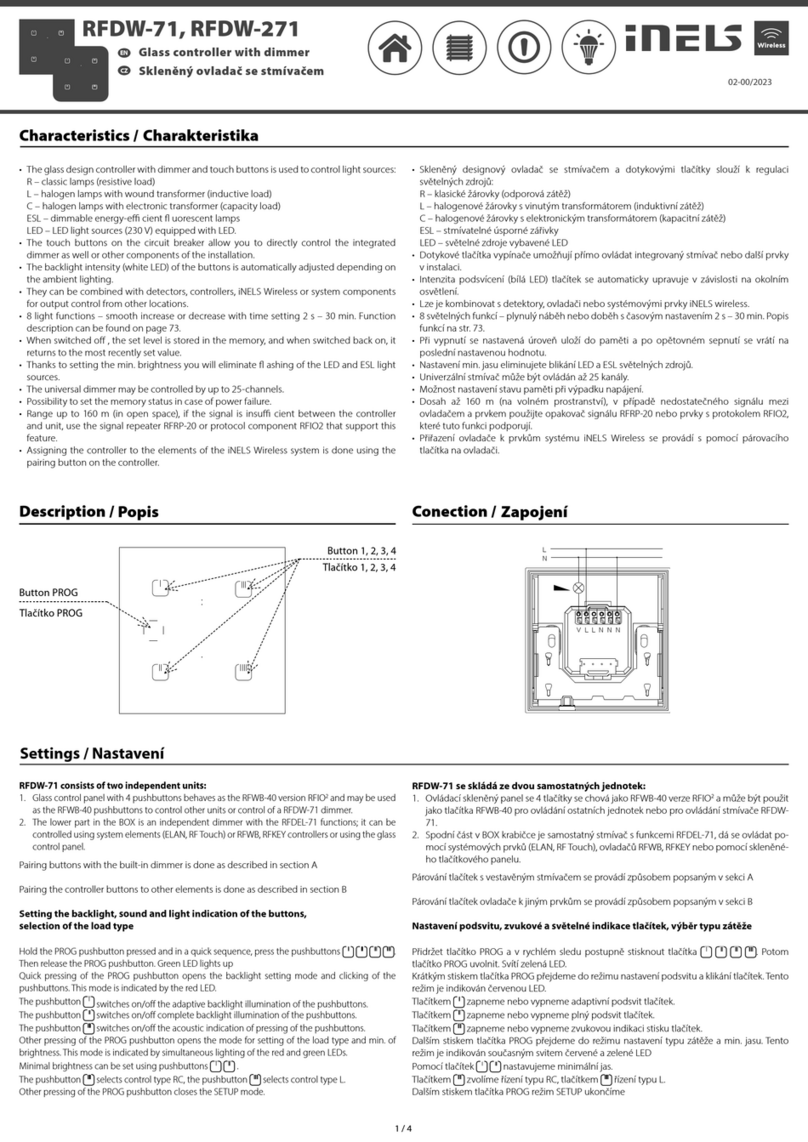

BUS +

BUS -

N

L

L

N

M M M

M M M

M M M

N

L

1

4

5

5

UP x

COM x

DOWN x

Shutter Actuator, 18-channel

EN

Characteristics

General instrucions

Description of device

Connection

CONNECTION TO THE SYSTEM, INSTALLATION BUS

iNELS3 peripheral units are connected to the system through the BUS installation. Installation

BUS conductors are connected to the terminal units to BUS+ and BUS- terminals, wires cannot be

interchanged. For installation of BUS it is necessary to use a cable with a twisted pair of wires with

a diameter of at least 0.8 mm, the recommended cable is iNELS BUS Cable, whose features best

meet the requirements of the BUS installation. Bearing in mind that in terms of all the properties

is it is possible in most cases also use the cable JYSTY 1x2x0.8 or JYSTY 2x2x0.8, however it

is not recommended as the best option. In the case of a cable with two pairs of twisted wires

it is not possible to use the second pair of the other for modulated signal due to the speed of

communications; it is not possible within one cable to use one pair for one segment BUS and the

second pair for the second segment BUS. For installation of BUS it is vital to ensure that it is kept

at a distance from the power lines of at least 30 cm and must be installed in accordance with its

mechanical properties. To increase mechanical resistance of cables we recommend installation

into a conduit of suitable diameter. BUS topology installation is free except for the ring, wherein

each end of the bus must terminate at the terminals BUS + and BUS- peripheral unit. While

maintaining all the above requirements, the maximum length of one segment of the installation

BUS can reach up to 500 m. Due to the data communication and supply of units in one pair of wires,

it is necessary to keep in mind the diameter of wires with regards to voltage loss on the lead and

the maximum current drawn. The maximum length of the BUS applies provided that they comply

with the tolerance of the supply voltage.

CAPACITY AND CENTRAL UNIT

It is possible to connect to the central unit CU3-01M or CU3-02M two independent BUSes by means

of terminals BUS1+, BUS1- and BUS2+, BUS2-. It is possible to connect to each BUS up to 32 units,

so it is possible to connect directly to the central unit a total of 64 units. It is necessary to comply

with the requirement of a maximum load of one BUS line - maximum up to 1000 mA current. When

connecting units which draw greater than 1A, BPS3-01M with 3A sampling can be used. It is the

sum of the rated currents of the units connected to the BUS line, other units can be connected

using the units MI3-02M, which generate further BUSes. These are connected to the CU3 unit via

the system BUS EBM and you can connect a total of 8 units via EBM BUS to the central unit MI3-02M.

SUPPLYING THE SYSTEM

For supplying power to system units, it is recommended to use the power source of ELKO EP titled

PS3-100/iNELS. We recommend backing up the system with backup batteries connected to the

source of PS3-100/iNELS (see sample diagram of connecting the control system).

GENERAL INFORMATION

To operate the unit, it is necessary that the unit is connected to a central unit CU3 series, connected

to the central unit of the system CU3, or to a system that already contains this unit as its expansion

to include further system.

All unit parameters are set through the central unit CU3-01M in the software iDM3.

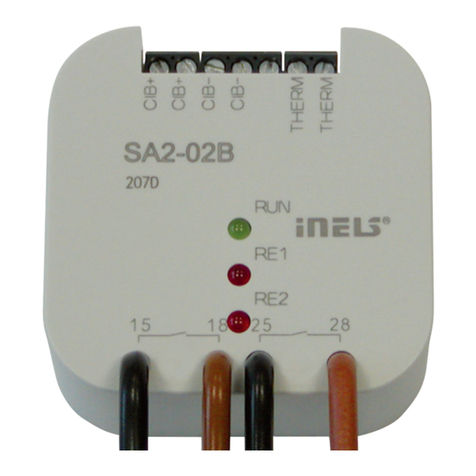

There is LED diode on the PCB for indication of supply voltage and communication with the

central unit series CU3. In case that the RUN diode flashes at regular intervals, so there is standard

communication between the unit and BUS. If the RUN diode lights permanently, so the unit is

supplied from BUS, but there is no communication between BUS and unit. In case that RUN diode

is OFF, so there is no supply voltage on the terminals BUS+ and BUS-.

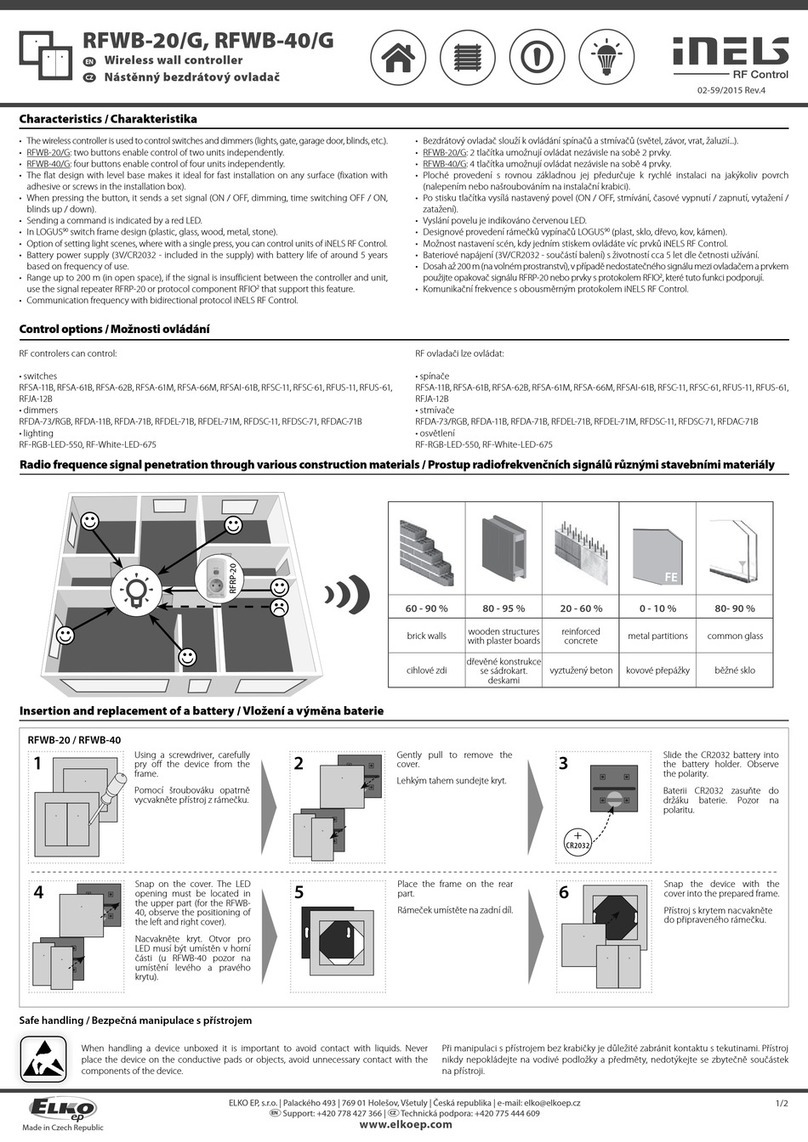

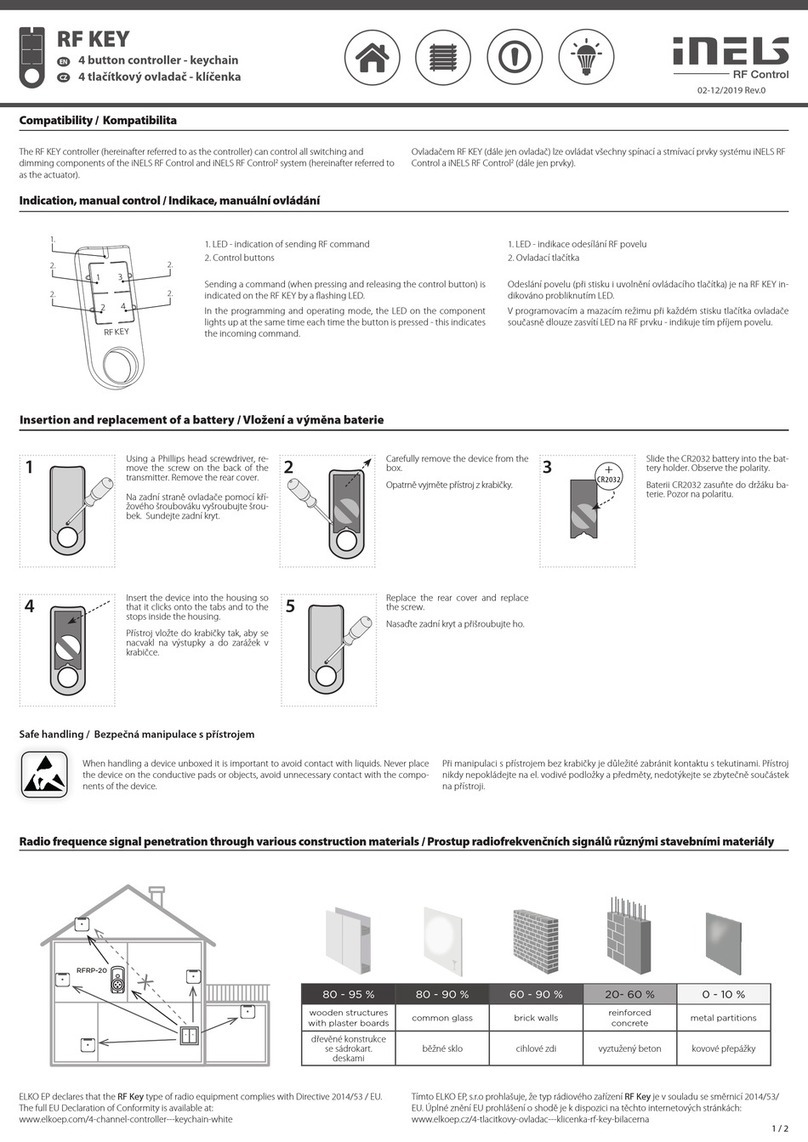

1. Supply terminals

2. Data BUS

3. LED indication of unit´s state

4. Output LED indication

5. Control buttons

6. Relay contacts

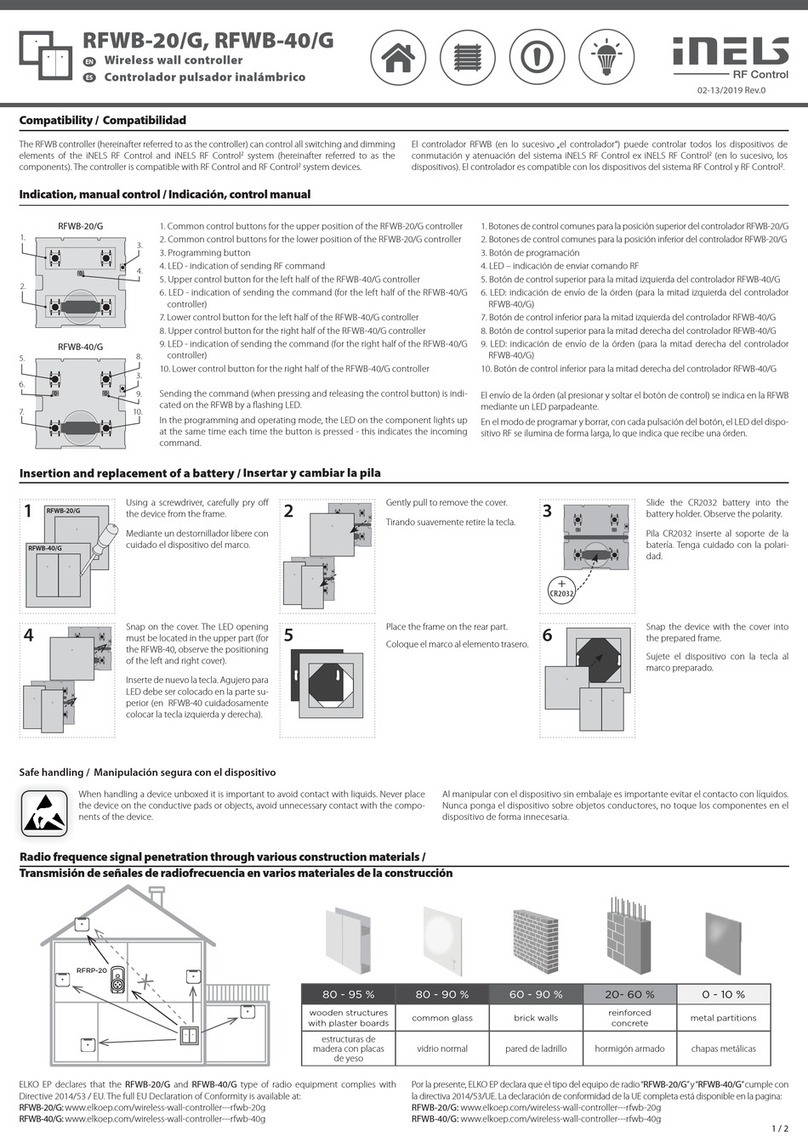

• JA3-018M is an actuator designed for control of roller shutters, blinds, awnings, garage doors,

entrance gates, etc.

• It controls electric drives that are controlled in two directions and have a built-in limit switch.

• The unit's status is indicated by the green RUN LED on the front panel

- If the power supply is connected, but there is no communication via BUS with master, the LED

RUN is on continuously.

- If the supply voltage is connected and the unit communicates by BUS, the LED RUN flashes.

• The status of the output contacts is indicated by the U/D LED:

- When the blind / roller blind is moving up / down, the corresponding LED lights up.

- If the number of switching operations per minute is exceeded, the corresponding LED flashes.

• JA3-018M in 6-MODULE version is designed for mounting into a switchboard on DIN rail EN60715.