Garson Industries CFtoSCSI User manual

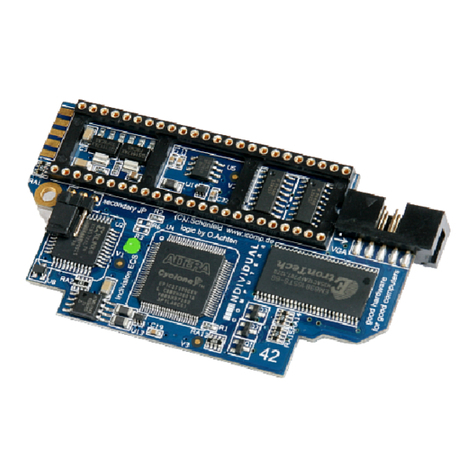

CFtoSCSI Disk Bridge

User Guide

Garson Industries

http://www.garsonindustries.com

Overview

•The CFtoSCSI bridge PCB is a general purpose SCSI bridge PCB for a Compact

Flash (CF) Card. A regular CF card is plugged into the 3M CF socket at the end

of the PCB and this is presented as a regular SCSI disk to a SCSI Host via the

standard SCSI interface the other end of the board.

•The PCB mounts in a standard 3.5” form factor tray. It requires 5V only which is

supplied via a standard disk power connector

When connected to a SCSI Host, the Host sees the PCB as a regular SCSI disk

The SCSI bridge PCB carries its microcode in Flash, that can be simply updated via

the SCSI or Serial ports. It has an optional standard display module interface to drive

a 2 line by16 character backlit, CD display.

Features

•3.5 inch form factor

•Standard 50 pin SCSI1/2 interface

•10 Mbytes/sec SCSI burst rate

•Internal active SCSI termination, disabled/enabled by jumper

•Optional HVD SCSI interface

•Compatible with most CF cards

•Various emulations available.- SCSI2/SCSI1 or SASI

•Can emulate a standard SCSI tape drive—DAT/D T or 3490 etc – consult the

factory

HOST SCSI INTERFACE

CF Card

CFtoSCSI bridge

Quick install

•Set the SCSI ID as required at J6

J6 – position 1

SCSI ID = 0 no jumpers

SCSI ID = 1 jumper position 1

SCSI ID = 2 jumper position 2

SCSI ID = 3 jumper position 1 & 2

SCSI ID = 4 jumper position 3

SCSI ID = 5 jumper position 1 & 3

SCSI ID = 6 jumper position 2 &3

SCSI ID = 7 jumper position 1,2 &3

CF SOCKET

J6 positions 4-7 –see

appendix

Display connector

–pin 1

Ensure CF card is inserted and

home

Power connector –

only 5V required

SCSI connector—NOTE

pin 1

SET SCSI ID – J6 positions 1,3,5

Heartbeat ED

Disable termination – K2 – jumper

installed = termination enabled

Serial port Display connector

Export Termination power jumper K1

Termination Power present ED1

J4 Serial

Connector

Tx,Gnd, Rx

Disk coming ready ED (green)

Disk Activity ED (red or green )

Serial port enable

• Set Termination Disable/Enable at K2 -- If jumpered termination is ENAB ED

•Do you need to export termination power? -- This is generally not necessary –If so

jumper K1. Note that the internal terminators always have power.

•Connect the SCSI cable – Note that pin 1 of the cable is at the edge of the PCB.

•Connect the 5V power. Note that a standard 5V/12V disk power lead can be used

here as the 12V pin is a no-connect on the board.

•Note the green heartbeat ED will flash. Also note that the 5mm front panel green

ED will briefly flash while the CF card is being initialised.

SCSI Command handling Notes

SCSI Unload:

When the unit receives a SCSI Unload command it will go not-ready to

the Host and flash the (not ready) green LE . This situation remains

until the media is removed and replaced.

Installation:

Use M3x6mm screws ( and no longer) to install the tray

INTERNA DIAGNOSTICS

The Diagnostic Feature is accessed via the RS232 port of the CFtoSCSI Board. This

feature is most useful to gain insight into unexpected operating system exceptions.

This section of the manual assumes that problems with SCSI ID, SCSI Termination

and other hardware issues have been solved, but system problems which have to do

with software, timing or protocol are present.

Connect a TT compatible RS232 terminal or a PC running a terminal emulation to

the 9-pin bulkhead connector on the PV enclosure or direct to the 3-pin header at

location JP4 on the board. Set the terminal at 19200 baud, 8 bits and no parity.

The cable contacts are as follows:

Signal name J4

RS232

9-Pin Connector

RS232

25-Pin Connector

Receive in 1 3 2

Ground 2 5 7

Transmit out 3 2 3

After the problem has occurred, key in (Control Z) on the terminal to enter the

diagnostic mode. The Diagnostic Menu will appear on the terminal screen.

The Diagnostics are designed to run as a ‘background’ task to the ‘foreground’

operation of the SCSI handling routines. This means that the user may ‘dial’ into the

diagnostic menu options at any time without any significant degradation of SCSI

performance in order to activate the real-time SCSI trace.

The diagnostic command list shown below is by no means complete. Other

commands: Display, Modify and Fill memory; Execute from Specified Address and

specialised commands listed may prove useful to isolate problems where the Real

Time Trace fails to provide an answer.

Diagnostic Command Function

A Activate SCSI Real Time Trace

C Display Firmware Revision and Checksum

F Firmware Upload from Serial Port using Intel HEX

Format

H Display this Diagnostic Menu

Z Execute a Power-on Reset

The command prompt is PV>

Menu Choice A: Activate SCSI Real Time Trace

This option requires special firmware

The SCSI Real Time Trace consists of three modes of operation:

(a) Print mode = nothing (power-on default)

(b) Print mode = only errors

(c) Print mode = all

These options may be cycled and advanced to the next mode by the keying of the ‘A’

character.

PV> A

Real time trace, print mode nothing

This effectively disables the logging and display capability of the Real Time Trace.

PV> A

Real time trace, print mode only errors

This mode displays both the command which caused the drive to generate a check

condition status and the corresponding Request Sense command with bytes 2, 12 and

13 extracted from the sense data returned.

Example Monitor Trace:

PV>

CDB 00 00 00 00 00 00, STS 02.

CDB 03 00 00 00 FF 00, SENSE 06, ASC 2900.

CDB 00 00 00 00 00 00, STS 02.

CDB 03 00 00 00 FF 00, SENSE 02, ASC 0401.

PV> A

Real time trace, print mode all

This mode displays all logged commands with their associated data phases.

Example Monitor Trace:

PV>

CDB 00 00 00 00 00 00, STS 02.

CDB 03 00 00 00 FF 00, SENSE 02, ASC 0401.

CDB 12 00 00 00 FF 00.

CDB 1A 00 00 00 FF 00

MODE DATA 10 85 10 08 8C 45 F8 40 00 00 00 00 0E 00 80 80

07 .

CDB 15 00 00 00 0C 00

MODE DATA 00 00 10 08 8C 00 00 00 00 00 00 00.

NB: Logging the data for diagnostic purposes - In order to redirect the displayed

information from the standard output device, ie VDU, the user may copy the output to

a log file on a local disk y keying Alt-F1.

Menu Choice C: Display Firmware Revision and Checksum

Entering a “C” at the command prompt will display the revision level and checksum

of the electronics firmware.

Example Monitor Trace:

PV> Checksum 66A8, code revision B01f

Menu Choice D: Download Intel HEX Code from EPROM to Serial Port

Menu Choice F: Firmware Upload from Serial Port using Intel HEX Format

The CFtoSCSI card has a Flash PROM installed. In order to update the code on this

PROM, the card needs to be connected to the serial port on a PC and the code

downloaded, as follows.

1 Run Procomm or a Terminal Emulator of your choice.

2 Set Baud rate to 19.2 K, no parity, 8 data bits, one stop bit.

3 Switch on PV card. Reset message will appear together with ‘Enter a

“CONTRO -Z” to invoke the Diagnostic Mode!”

4 Get the PV Diagnostic Utility, and select ‘F - Firmware upload from serial

port using INTE HEX format’.

Example Monitor Trace:

PV> F

Firmware upload using Intel HEX transfer.

Backing up FLASH in case serial transfer fails !

To stop the transfer press ESCAPE if using PROCOMM then

press ^C to restore FLASH and reset PG card.

Relocating Code...

Amd Device - 16k Programmed Okay

Amd Device - 16k Programmed Okay

Amd Device - 16k Programmed Okay

Amd Device - 16k Programmed Okay

Validating Code...

5 Message appears ‘Start your ASCII upload of the HEX file now’:

HEX ADDR = 0000

6 Initiate upload - selecting ASCII transfer (filename ******.HEX).

7 When complete ADDR = FFFF, then Checksum test is carried out.

If Checksum test passes, board is reset.

If Checksum test fails, backup of code is restored at the end of the PROM

and the old code is restored for use (if one line fails during upload, then need

to

exit transfer and old code will be restored).

Example Monitor Trace:

Amd Device - 16k Programmed Okay

Amd Device - 16k Programmed Okay

Amd Device - 16k Programmed Okay

This option is available for use by Garson Industries Personnel only.

Amd Device - 16k Programmed Okay

Flash Programming Done

Checksum test PASSED.

RESET! *** Enter a "CONTROL-Z" to invoke the Diagnostic Mode! ***

+++AT E0 B1 X1 M1 L2 &C0 &D0 S0 1 S7 60 S11 55 O

Menu Choice G: Go (Execute) from Specified Address

Menu Choice H: Display this Diagnostic Menu

Typing an “h” or “H” will cause the diagnostic menu to be re-displayed.

Menu Choice M: Display/Modify/Fill/Tabulate Memory

Menu Choice Q: Quit Diagnostics

Hang up modem phone.

Menu Choice Z: Execute a Power-on Reset

Exits the diagnostic mode by executing a power on reset.

FIRMWARE UPGRADES FOR PG UNITS

Firmware can be upgraded via the serial port, or by replacing the flash/EPROM

memory. New code can be sent via e-mail.

Connect to J4 to the computer's serial port with a standard serial (extension) cable.

If you have some other configuration without the DB9 connector a three wire cable

assembly can be configured as follows:

DB25 female or DB9 female to J4

2 3 1 (rx in)

7 5 2 (gnd)

3 2 3 (tx out)

Start a communications program such as Procomm with the parameters 9600,N,8,1

(19200 baud is the factory (default) standard as shipped, if you have changed it with

This option is available for use by Garson Industries Personnel only.

This option is available for use by Garson Industries Personnel only.

the Setup menu, please use that value - we suggest 19200). The terminal

communications for the CFtoSCSI product REQUIRES xon/xoff control.

Please refer to the hints below for configuration.

Power up the CFtoSCSI board . Make a note of the firmware level displayed on the

bottom line of the CD display. This will be used to confirm the firmware upgrade.

The communication program should show a menu of items. Select F for firmware

upgrade.

Start the ASCII file upload (for ProComm type page-up, select ASCII format, and

specify the file.hex to transfer).

When the transfer is done the screen will show the outcome of the transfer and then

reset the unit. Observe the Revision level of the firmware now displayed on the CD

display to verify the new firmware is running.

PROB EMS:

If installing an EPROM observe the white outline on the PCB for orientation.

HINTS:

ProComm should be set up as follows

Terminal Setup/Flow Control=xon/xoff

Ascii Transfer/Character pacing=0, line pacing=0

APPENDIX

J6 jumper positions 4-7.

Microcode CFG4K and later :

J6-4 - unused

J6-5 - Write protect jumper – set this to write protect the media . Can be wired to an

external Switch

J6-6 - Custom setting

J6-7 - Custom setting

Table of contents

Popular Computer Hardware manuals by other brands

RadiSys

RadiSys ATCA-4616 Reference

Individual Computers

Individual Computers Indivision ECS Short manual

Mannesmann

Mannesmann HYQUIP VT-SWKA-1 Commissioning instructions

QSC

QSC DDI-11 installation guide

Tripp Lite

Tripp Lite SRGASKET owner's manual

Element14

Element14 Wireless Connectivity Cape quick start guide