Gas Data GFM600 User manual

GAS DATA

Monitoring the Environment

GFM600 Velocity

Monitor User Manual

D O C U M E N T C O N T R O L S H E E T

GFM600 Velocity Monitor User Manual

Issue A, Revision 0 Issue Date: April 9, 2007

Copy No: 1 Copy Holder: Archive

User guide to the operation of the GFM600 portable

Velocity monitor.

Issue Description:

New manual - February 2007.

Revision Description:

First release - for proof checking.

©

Gas Data

Pegasus House, Wheler Road, Seven Stars Estate, Coventry CV3 4LB, United Kingdom

Phone +44 (0)24 7630 3311 • Fax +44 (0)24 7630 7711

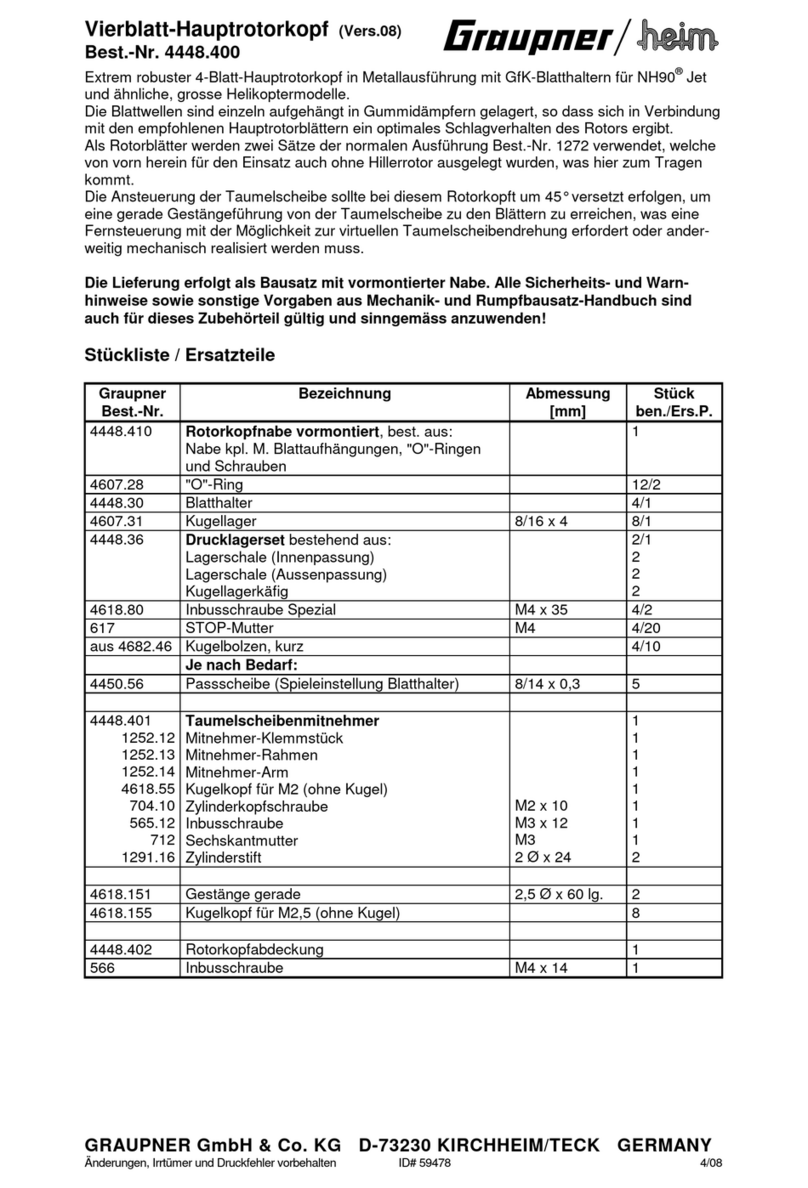

GFM600 GFM600 Velocity Monitor User Manual

Table of Contents

Introduction

1

General handling tips 17

Warranty policy

1

Conditions and exclusions

1

Safe use of the GFM600 Velocity

Monitor

2

Safe practice

2

Important safety related points

2

In the case

3

Operation

4

Connections

4

Gas velocity measurement

5

Auto Turn Off 6

Maintenance

7

Low Battery warning

7

Batteries 7

Factory calibration

8

Technical Specification 9

Conversion charts 10

Understanding instruments for use in

flammable atmospheres 13

Hazardous areas classified by zones 13

Different gas types. 13

Design and construction of

intrinsically safe instruments for use

in flammable atmospheres. 14

Testing and certification 15

Schiltknect Vane Anemometer 16

Operating Instructions 16

Important notes 16

Response Time 17

Technical data –MiniAir 6 Micro 17

Cleaning and maintenance 17

i

G F M 6 0 0 U S E R M A N U A L

Introduction

The Gas Data GFM600 is designed

specifically for measuring gas

velocity in a variety of applications.

Operation is extremely simple, yet

the readings obtained are highly

accurate. The instrument uses a

plug-in vane anemometer to

measure gas velocity and provides a

digital read-out of velocity in ms-1.

The GFM600 has rechargeable

Nickel Metal Hydride batteries

giving around twenty hours use

between charges. A battery charger

and mains unit is supplied with the

instrument and a field replaceable

battery pack is also available as an

optional extra.

Warranty policy

This instrument is guaranteed, to the original end user purchaser, against defects in

materials and workmanship for a period of one year from the date of shipment to

the user. During this period, Gas Data Limited will repair or replace defective parts

on an exchange basis. Freight charged to and from the Gas Data factory or

authorised service centre will be paid by the end user. The decision to repair or

replace will be determined by Gas Data Limited.

Conditions and exclusions

To maintain this warranty, the purchaser must perform maintenance and

calibration as prescribed in this user guide. This includes prompt replacement or

repair of defective parts and such other necessary maintenance, calibration and

repair as may be required according to the use of the equipment in the reasonable

judgement of Gas Data Limited.

Normal wear and tear, and parts damaged by abuse, misuse, negligence or accidents

are specifically excluded from the warranty.

GFM600 - 1 - GFM600 Velocity Monitor User Manual

G F M 6 0 0 U S E R M A N U A L

Safe use of the GFM600 Velocity Monitor

The Gas Data GFM600 Velocity Monitor has been designed to operate in typical

field environments where flammable gases may be present. The following points

should be observed.

Safe practice

•

BEFORE entering a known hazardous zone, switch on the instrument and

make sure the display is visible.

•

BEFORE entering a known hazardous zone, check that the keys respond.

Important safety related points

•

Use only Gas Data spares and accessories.

•

Do not operate the GFM600 Velocity Monitor in ambient temperatures

outside the range of -10 to +40C.

•

Do not attempt to dismantle the instrument. It contains no user replaceable

parts.

•

Do not operate the unit if it is damaged in any way (i.e. loose front panel,

missing screws etc.).

•

Do not connect or remove plugs from the battery charger socket in the

hazardous area.

•

Only charge the batteries in a safe well-ventilated area using the charger

supplied.

IMPORTANT - The GFM600 Monitor Series is not infallible. As the usage

of the instrument is beyond Gas Data’s control, Gas Data cannot accept any

liability for loss or damage due to its usage. Satisfy yourself that the unit is

suitable for the application that you intend to use it for. If in doubt about the

suitability of a GFM600 Velocity Monitor instrument for a particular

application call Gas Data for further advice.

GFM600 - 2 - GFM600 Velocity Monitor User Manual

G F M 6 0 0 U S E R M A N U A L

In the case

The GFM600 instruments are supplied in a fitted case containing the following

items:

GFM600 instrument

Vane

anemometer

Battery charger

GFM600 - 3 - GFM600 Velocity Monitor User Manual

G F M 6 0 0 U S E R M A N U A L

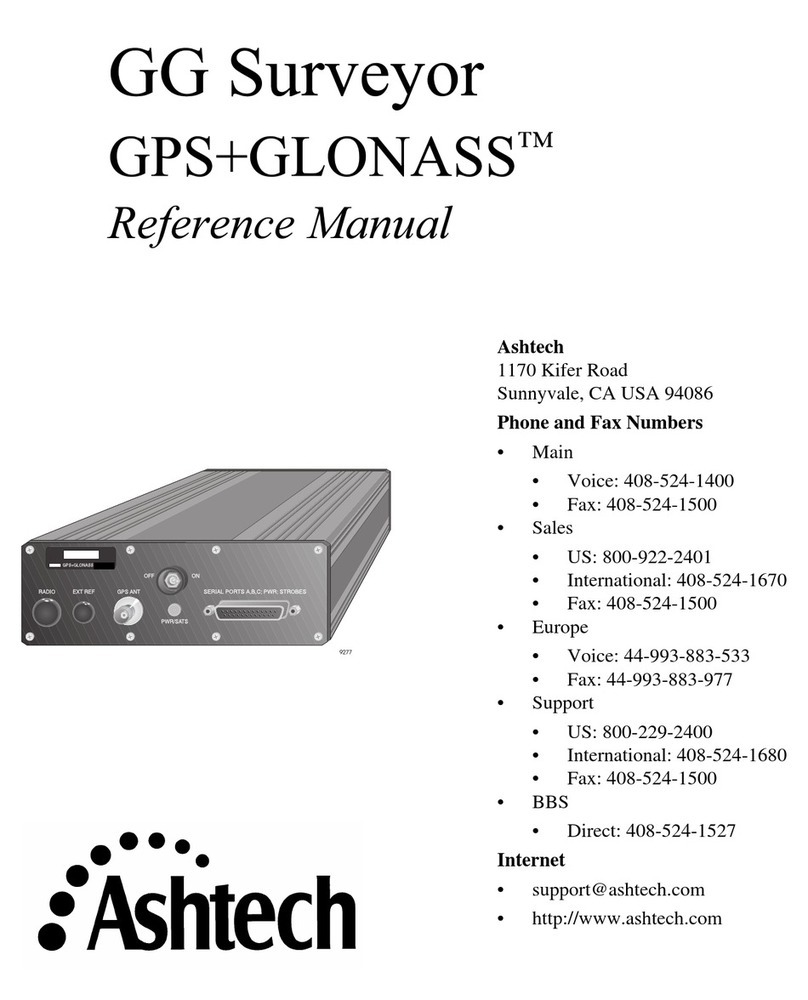

Operation

1. This key allows you to switch the backlight

on or off.

2. Not used.

3. This key allows you to start the sample.

4. This buttons allows you to move to the velocity

screen.

5. Power ON/OFF. This key simply toggles the

instrument on or off. Under battery power, the

instrument will automatically turn itself

off if no key is pressed for 10 minutes. The

instrument backlight can be switched on at

anytime during the sampling process.

Connections

Communications/anemometer port

Battery

charger socket

GFM600 - 4 - GFM600 Velocity Monitor User Manual

Section

1

G F M 6 0 0 U S E R M A N U A L

Gas velocity measurement

IMPORTANT

Schiltknect anemometers do not form part of the ATEX certification of the

Gas Data GFM series. Contact Gas Data for further advice on the safe use of

these probes.

Before attempting to measure gas velocity, make sure that the vane

anemometer is long enough to reach the centre of the pipe through which

the gas is flowing.

Connect the vane anemometer to the Communications/Anemometer port on the

top end of the instrument case.

After you have switched the instrument on, the display screen will first show the

start-up banner, which contains details of the instrument model, serial number and

recalibration date. A battery condition indicator at the top right-hand side of the

screen informs you about the state of charge of the battery.

Press the right arrow to continue to the velocity screen.

GFM600 - 5 - GFM600 Velocity Monitor User Manual

G F M 6 0 0 U S E R M A N U A L

Locate a suitable gland or bung on the

pipework and insert the vane anemometer,

taking care to ensure that the anemometer is

correctly orientated. The arrow on the tip of

the anemometer should be in line with the

pipe, NOT at right angles to it. When the

anemometer is as far into the gland as

possible, without opening the tap, re-check

the orientation and open the gas tap. Finally,

push the anemometer into the gland far

enough to ensure that the vane head is in

the centre of the gas pipe.

The display screen will change to show the

last retained gas velocity reading indicated

by the highlight around the velocity figure.

Now press the ‘sample’key. The instrument will now measure the velocity of the

gas flowing through the pipework

.

When the reading has stabilised, press the ‘sample’key again to retain the reading.

This will return the highlight area around the velocity figure.

Carefully remove the vane anemometer from the gland on the gas pipe, pausing to

turn off the gas tap before removing it completely.

This completes the measurement.

Auto Turn Off

To help conserve battery life, the GFM600 instrument features an auto power off

facility. This ensures that the instrument will switch itself off after 10 minutes if no

keys are pressed.

- 6 - GFM600 Velocity Monitor User Manual

Take great care

when inserting the

anemometer to

avoid gas leakage

.

Take great care

when removing the

anemometer

. In

particular, avoid

standing with your

face in direct line

with the gland

because gas can

be expelled at

great force.

GFM600

G F M 6 0 0 U S E R M A N U A L

Section

2

Maintenance

Low Battery warning

A series of vertical bars at the top right-hand side of the display screen indicates the

state of charge of the rechargeable batteries.

When there is a single bar of battery life left, it is time to recharge the batteries or

replace them with another battery pack. If the batteries become completely

exhausted the single bar of battery life will flash and then the instrument will

automatically switch off. Make sure the batteries receive a full recharge.

To recharge the batteries, simply plug in

the battery charger lead to the socket on

the top end of the instrument and plug

the charger into the mains. The batteries

will be fully charged in about three

hours.

Batteries

The GFM600 Series uses rechargeable Nickel

Metal Hydride cells.

To change the batteries, remove the two screws on

the rear of the instrument, then lift the battery

cover and remove the battery pack from the recess.

Place the new battery pack in the recess, making

sure that the metal contacts on the battery pack are

placed face down on the spring contacts in the

base of the battery box. Replace the battery cover

and secure with the two screws.

Always replace the battery pack in dry, clean

conditions, preferably indoors. NEVER allow

dust or moisture to enter the battery compartment.

GFM600 - 7 - GFM600 Velocity Monitor User Manual

G F M 6 0 0 U S E R M A N U A L

Do not use excessive force on the battery cover fixing screws.

Make sure the rubber seal is correctly in place.

If you replace the batteries in the field, you can, of course, recharge them later

when you return to base.

If the instrument is to be stored for more than four weeks, ensure that the batteries

are fully charged. After four weeks, charge the batteries again.

However, if the instrument does not operate after prolonged storage, the batteries

have become discharged and will be unable to ‘fast charge’. They will, therefore,

need a longer charge time.

Factory calibration

The instrument is not supplied with a calibration certificate. The instrument is

supplied with a functional check sheet.

It is recommended that the instrument be returned to Gas Data Limited once every

five years for a general inspection.

GFM600 - 8 - GFM600 Velocity Monitor User Manual

G F M 6 0 0 U S E R M A N U A L

Appendix

A

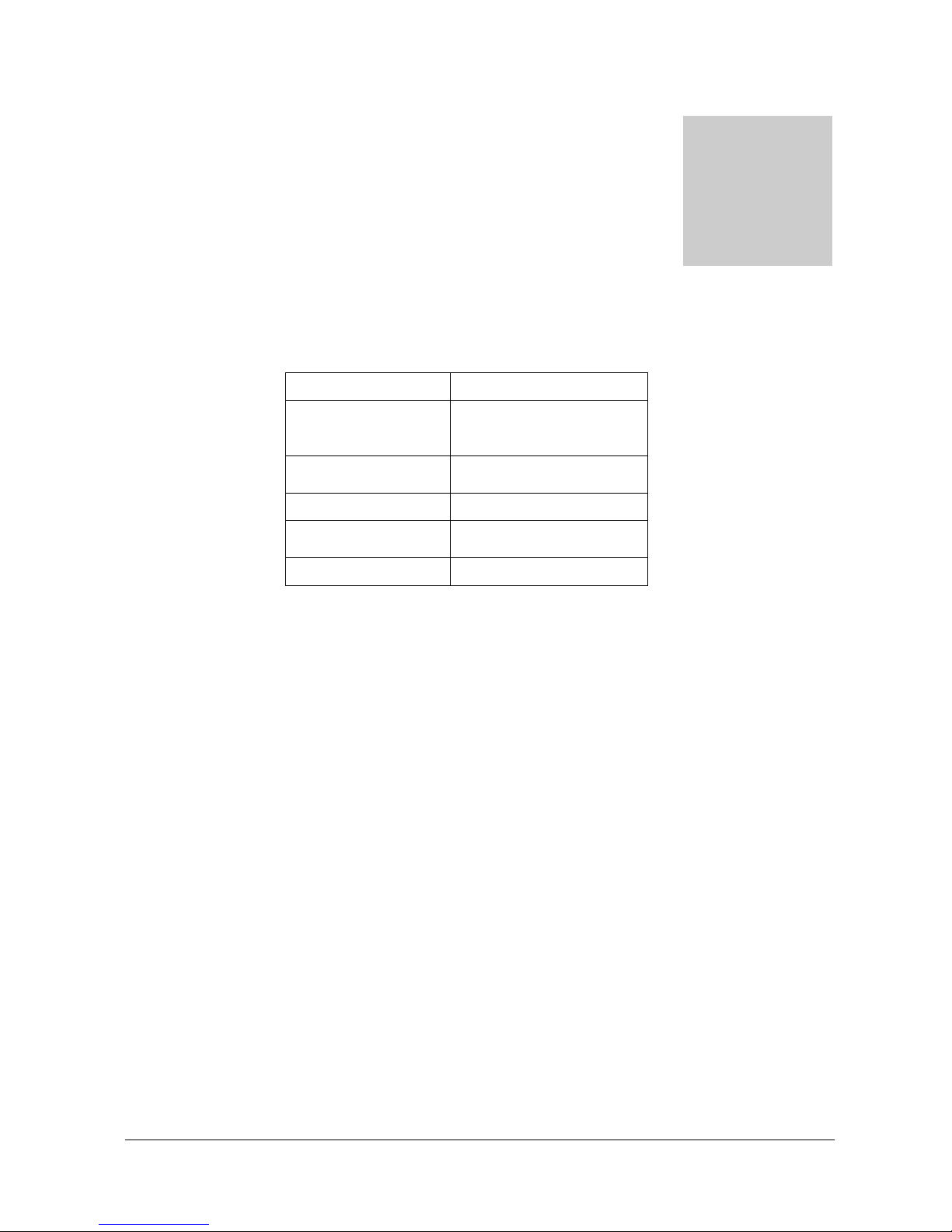

Technical Specification

GFM600 - 9 - GFM600 Velocity Monitor User Manual

Range

Vane anemometer

12mm diameter x

340mm long.

0-40 m/s

Size

200mm x 90mm x 50mm

approx

Weight

400g (approx.)

Battery type

Rechargeable Nickel metal

hydride

Battery run time

>18 hours (backlight off)

G F M 6 0 0 U S E R M A N U A L

Appendix

B

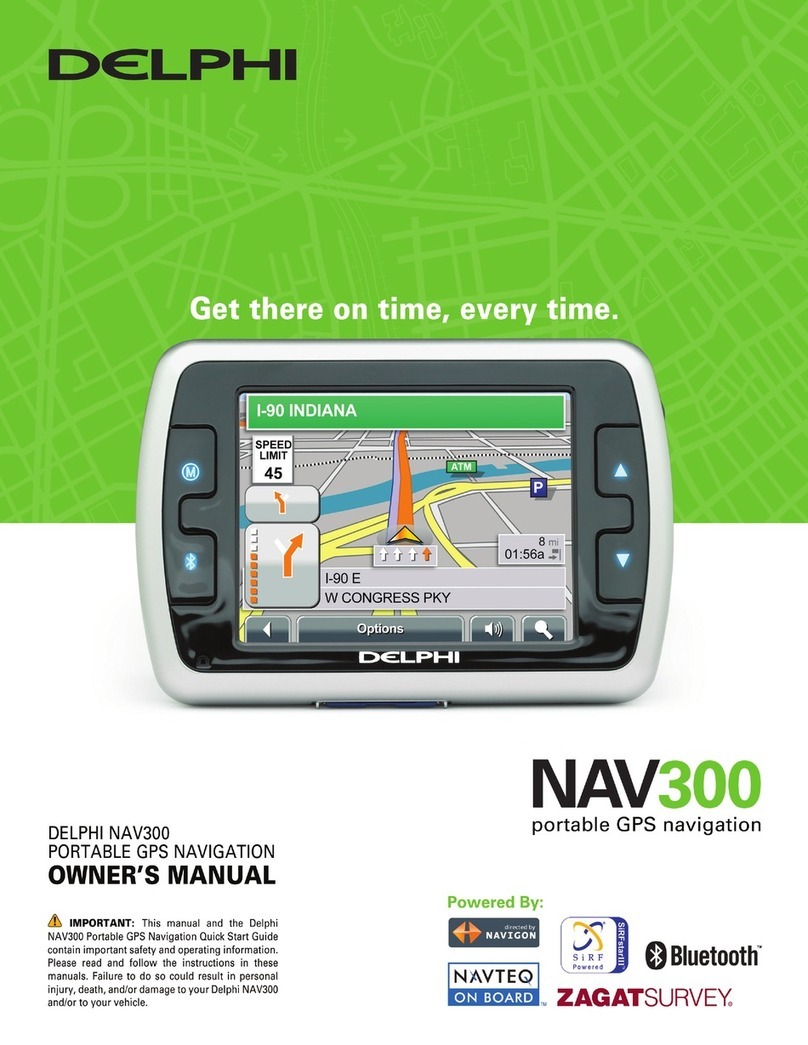

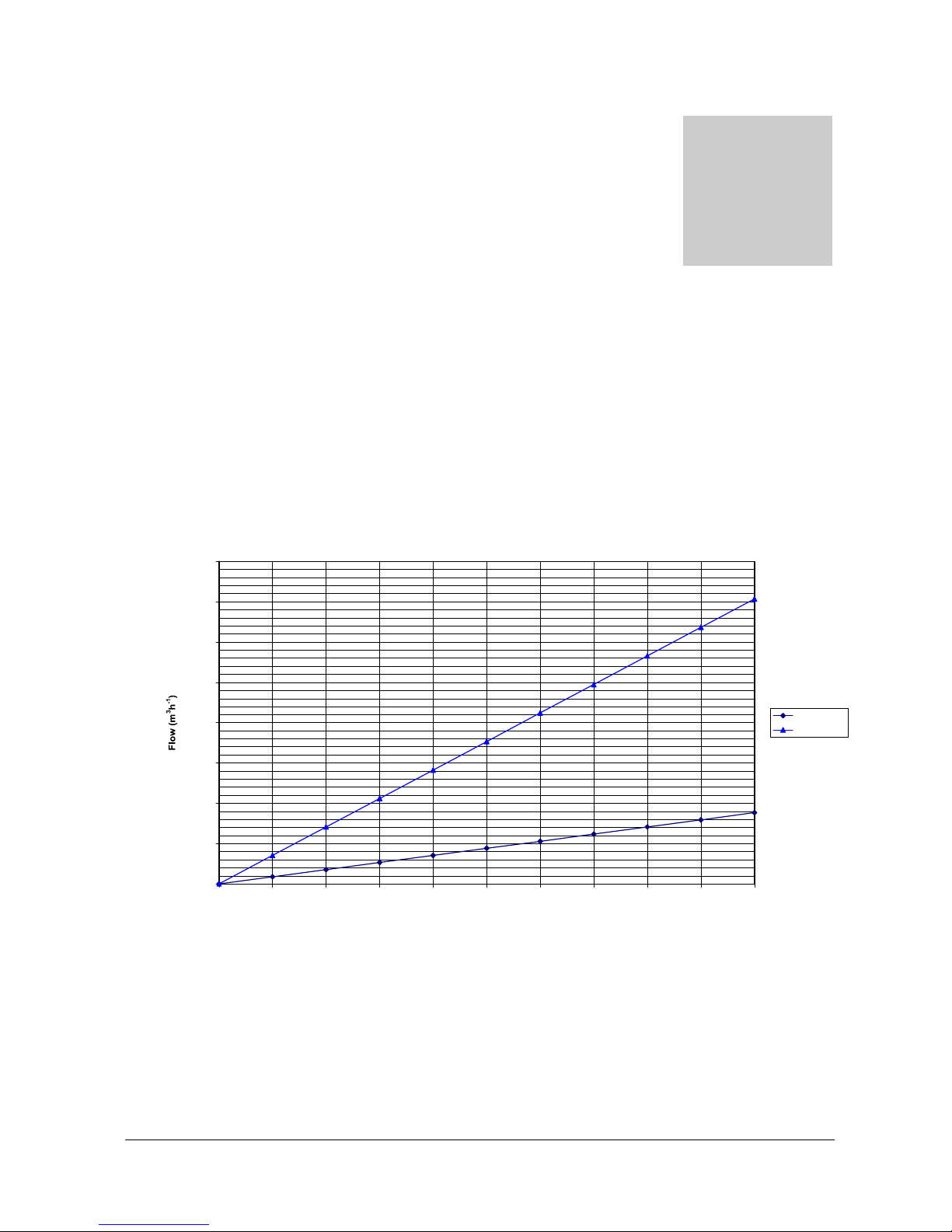

Conversion charts

The following charts are included to enable you to make quick and easy

conversions from velocity measurements provided by the vane anemometer to

flow rates.

Velocity - Flow conversion chart

160.00

140.00

120.00

100.00

80.00

60.00

40.00

20.00

0.00 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

Velocity (ms-1)

GFM600 - 10 - GFM600 Velocity Monitor User Manual

d = 50mm

d = 100mm

G F M 6 0 0 U S E R M A N U A L

Velocity - Flow conversion chart

600.00

500.00

400.00

300.00

200.00

100.00

0.00 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

Velocity (ms-1)

Velocity - Flow conversion chart

6000.00

5000.00

4000.00

3000.00

2000.00

1000.00

0.00 0 5 10 15 20 25 30 35 40

Velocity (ms-1)

GFM600 - 11 - GFM600 Velocity Monitor User Manual

d = 50mm

d = 100mm

d = 150mm

d = 180mm

d = 220mm

d = 250mm

d = 300mm

d = 50mm

d = 100mm

d = 150mm

d = 180mm

d = 220mm

d = 250mm

d = 300mm

G F M 6 0 0 U S E R M A N U A L

The formula for calculating the conversion is:

f =0.00283d v

where f = flow in m3h-1

d = pipe inside diameter in mm

v = velocity in ms-1

GFM600 - 12 - GFM600 Velocity Monitor User Manual

2

G F M 6 0 0 U S E R M A N U A L

Appendix

C

Understanding

instruments for use in

flammable atmospheres

Hazardous areas classified by zones

There are three zones defined to guide users as to the necessary precautions, which

should be taken when working in potentially flammable atmospheres:

1. Zone 0 - An area in which an explosive gas/air mixture is continuously

present, or present for long periods.

2. Zone 1 - An area in which an explosive gas/air mixture is likely to occur in

normal operation.

3. Zone 2 - An area in which an explosive gas/air mixture is not likely to

occur in normal operation and if it does occur will exist only for a short time.

Make certain that the area in which you intend to work can be described by one of

the zones above. THE GFM600 SERIES IS SUITABLE FOR USE IN

ZONE 1 AND ZONE 2.

Different gas types.

Different gases are grouped according to how easily they are ignited. Some

examples are given below. (For other gases please contact Gas Data).

GFM600 - 13 - GFM600 Velocity Monitor User Manual

Gas

Relative Ignition

Group

Hydrogen/Acetylene

Most easily ignited

IIC

Ethylene

IIB

Carbon monoxide

IIB

Hydrogen sulphide

IIB

Ammonia

IIA

Propane

IIA

G F M 6 0 0 U S E R M A N U A L

THE GFM600 SERIES IS SUITABLE FOR USE IN FLAMMABLE

ATMOSPHERES CAUSED BY THE PRESENCE OF GASES IN

GROUP I, GROUP IIA AND GROUP IIB.

Design and construction of intrinsically safe instruments for use in

flammable atmospheres

.

The technique of intrinsically safe design and construction is defined in the

European Standard EN50020:1995. The technique identifies potential sources of

ignition (by spark or by heat) and specifies the design of safety circuits that limit the

energy of the spark and/or the component temperatures such that they cannot

ignite the gases expected within the hazardous area. There are two categories if

intrinsically safe instruments;

1. ‘ia’ The safety circuits used will prevent the generation of a spark or

temperature capable of igniting the gas even if the instrument develops TWO

faults.

2. ‘ib’The safety circuits used will prevent the generation of a spark or

temperature cable of igniting the gas even if the instrument develops ONE fault.

THE GFM600 SERIES IS DESIGNED TO MEET THE

REQUIREMENTS OF CATEGORY ‘ib’.

By testing components in fault conditions (as required by ‘ib’) the worst case

temperature within the instrument is determined. This is used to give the

instrument a temperature classification. A guide to temperature classifications is

given below.

The higher the T class the lower the temperature.

Different gases will be ignited at different temperatures. Some examples are given

below.

GFM600 - 14 - GFM600 Velocity Monitor User Manual

Petrol vapour

IIA

Methane

Least easily ignited

I

Temperature Class

Maximum Temperature (C)

T1

450

T2

300

T3

200

T4

135

T5

100

T6

85

G F M 6 0 0 U S E R M A N U A L

THE GFM600 SERIES IS DESIGNED TO MEET THE

REQUIREMENTS OF CLASS T1.

Testing and certification

The GFM600 Series has been submitted for European Type Assessment. This

assessment examines the design and construction criteria set out above and

controls the manufacture. This process is defined in Annex II of the European

ATEX Directive 94/9/EC. This allows the instrument to carry the ‘Ex’logo

followed by a summary of the level of protection that is incorporated into the

instrument.

GFM600 - 15 - GFM600 Velocity Monitor User Manual

Gas

MINIMUM Required T class

Acetylene

T2

Hydrogen

T1

Ethylene

T2

Carbon monoxide

T1

Hydrogen sulphide

T3

Ammonia

T1

Propane

T1

Methane

T1

G F M 6 0 0 U S E R M A N U A L

Appendix

D

Schiltknect Vane

Anemometer

NOTE:

Schiltknecht anemometers do not form part of the ATEX certification of the

Gas Data GFM series. Contact Gas Data for further advice on the safe use of

these probes.

Operating Instructions

These operating instructions are intended to ensure that the Schiltknecht measuring

instrument and probe remain perfectly serviceable, guaranteeing fault-free and safe

operation. We therefore ask you to read these instructions carefully before placing

the instrument in operation for the first time.

Immediately after unpacking the instrument, please check for any mechanical

damage. Any damage detected should be immediately reported to the relevant post

office or to the carrier at your company's location.

Avoid moisture, extreme temperatures and vibrations.

Do not shake!

Cleaning of probes and indication unit only according cleaning instruction!

Strong electromagnetic interference (e.g. transformers, radio transmitting

equipment) may affect the accuracy of the measuring instrument.

Important notes

Every Schiltknecht instrument has a designed operating range. The transducers

have been developed and produced for this envisaged operating range. The

calibration corresponds to the actual state at the moment measurements are made.

It is influenced by incorrect handling and in the course of the period of use.

It must be ensured that the instrument is operated only by trained personnel the

instrument is regularly serviced and calibrated no changes are made to the

instrument except those described in the operating instructions.

GFM600 - 16 - GFM600 Velocity Monitor User Manual

G F M 6 0 0 U S E R M A N U A L

-Streamline Measuring Head

The form of the measuring head guarantees a high direction insensitivity which is

approx. +/- 20 degrees for Micro head and +/- 25 degrees for Mini head.

Response Time

Response Time of electronic:

When connected to supply (on/off): immediate

Time to reach 63 % of end value: 424 ms

Response Time of Vanes:

Increase of flow: 1.0 sec.

Decrease of flow: 8.0 sec.

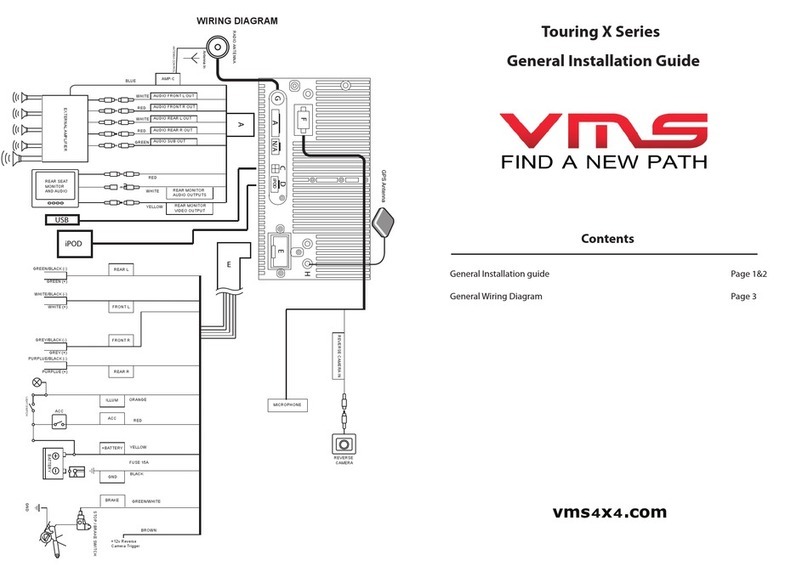

Technical data –MiniAir 6 Micro

Cleaning and maintenance

Schiltknecht instruments are precision products which will give fault-free service if

correctly handled. If you handle them as described in the operating instructions,

your instruments and probes will remain in a serviceable condition and guarantee

the reliable operation of the measuring system. Each instrument has its designed

range of application and is only to be used for this.

If faults should nevertheless occur, do not attempt to open the instrument and

repair it yourself; always have repairs carried out by our after-sales service.

General handling tips

-Protect the probes against severe vibration

-Do not kink the connector cable (risk of cable break)

-Never allow hard objects to contact rotating impellers.

-Always carry out probe cleaning according to the cleaning instructions -Never

immerse probes in solvent

GFM600 - 17 - GFM600 Velocity Monitor User Manual

Measuring range

0.7 –40 m/s

Accuracy +/-

1.0% fs

Operating temp.

-10 to +80°C

Head dimensions

11 x 15mm

Access opening

16mm

Probe length

165mm

Storage temp.

-65 to +150°C

Table of contents