Gas Detection GDA 40125 User manual

GDA 40125 Toxic Or Oxygen Gas Detection

Controller

Operating Manual

WARNING: THIS INSTRUMENT CONTAINS DELICATE COMPONENTS AVOID DROPPING OR

EXCESSIVE VIBRATION

This Sensor/Controller is designed and manufactured by

This manual must not be copied or reproduced in part without the express written permission

of Gas Detection (Australia) Pty Ltd. All information contained here is subject to modification.

Gas Detection (Australia) Pty Ltd Page 2 of 11 M-GDA-40125-06/08/2018

System Specification:

Power

requirements

24V DC, <25mv

ripple 0.5A

This can be supplied by plug in mains power

supply or via plug jack on side of unit

Sensors

1

GD2525-02 (Carbon Monoxide 0-200ppm)

GD2528-02 (Oxygen 0-25%VOL)

Display

2 x 12 char line back

lit LCD

Fault relays

1SPCO

Relay is energised on power up

Alarm relays

2SPCO

Alarm levels are programmable levels and can be

rising or falling latched or non latched

Alarm relay

specification

3A @ 30VDC

Non inductive load

Alarm hysteresis

0-40% of alarm

value

Analogue outputs

1

4-20mA, Max 800R loop impedance

Internal buzzer

93db 0.5M

Mutable from front panel

External buzzer

24V 100mA

Designed for: AV20R/Y - 24V Sounder and

Flasher

User interface

1 button

Mutes buzzer and resets latched alarms

2 Setup Buttons

Allows changes to controller setup (Internal)

Zero and Span

adjustment pots

Allows changes for calibration (Internal)

Test Pot

Allows simulation of a 4-20mA input. (Internal)

WARNINGS

The GD40125 Toxic Gas / Oxygen Detector and Controller is only to be used in areas classified as SAFE

AREAs. The sensor is not designed for use in classified HAZARDOUS AREAs.

The GD40125 sensor uses electrochemical sensors which have a shelf life of 6 months unpowered. If the

sensor is not powered up in this period, the sensor performance may have degraded and may require re-

calibration.

The sensor element contains substances that can be harmful to health. In the unlikely event of a sensor

element leaking, the sensor contents should not be touched. If the sensor contents come in contact with eyes

or skin, please seek immediate medical attention.

It is important not to exceed the specified voltage as indicated in this manual.

Gas Detection (Australia) Pty Ltd Page 3 of 11 M-GDA-40125-06/08/2018

Mounting Requirements:

Each Applications Is Unique And the Table Below Is For General Guidance

Gas

Sensor position from Ground

Oxygen (O2)

1.8m

Carbon Monoxide (CO)

1.8m

Hydrogen Sulphide (H2S)

300-500mm

Ammonia (NH3)

300-500mm

In all cases please take into account any air movement and heat sources

Avoid mounting the sensor in direct sunlight

Avoid direct water spray

Mount the sensor in the direction shown below

Mount the sensor as close as is practical to the potential source of the leak

152 mm

91 mm

20mm

20mm

10mm

10mm

6.9mm

MUTE BUTTON

SENSOR

ALARM LEDS

BACKLIT DISPLAY

Ground

//////////////////////////////////////////////////

///////////////////////////////////////////

Gas Detection (Australia) Pty Ltd Page 4 of 11 M-GDA-40125-06/08/2018

Electrical connections:

Please ensure that 24v connector is placed in the correct position or else it will damage

the circuit board if in the wrong position

Wiring Connection

Down

Set

Down

Set

NOTE:

RELAYS SHOWN DE-ENERGISED

ALARM RELAYS ENERGISE ON

ALARM

FAULT RELAY IS NORMALLY

ENERGISED AND DENERGISES ON

FAULT

Setup Buttons

24v Mutable

Sounder/Flasher

O/P

4-20mA o/p

24V DC Power

Supply

Area for

MODBUS Card

and connector if

required

Sensor Input

Calibration &

Setup Jumper

Alarm Relay Outputs

Links Must Be In Place And In This

Position For System To Work

Correctly

To Buzzer/

Flasher

24V DC

Power Supply

4-20mA Output

0V

0V

0V

+24

v

+24

v

Span Pot

Zero Pot

Sensor Type Jumper

On = Toxic

Off = Oxygen

Sensor Connection

Sensor Type Jumper

On = Toxic

Off = Oxygen

Test Pot

NC | C | NO

Test Jumper

Gas Detection (Australia) Pty Ltd Page 5 of 11 M-GDA-40125-06/08/2018

Ancillary Equipment:

24V Power Supply (GDP 024-050):

Input Voltage: 100-240V AC 50/60Hz 0.5A

Output Voltage: 24V DC 0.75A mA 18W Max

Connection: Free end wires (3m length)

Operating Temp Range: -10~45℃

Dimension:70*45*30.8mm(L*W*H)

Alarm Flasher & Sounder (AVR20-R/Y):

Intput Voltage: 12-24V DC

Output Specifications: 90 db within 1M at 24V

Connection: Free end wires (150mm black /red)

Operating Temp Range: -10 ~45℃

Enclosure Material: ABS Plastic

IP Rating of enclosure: IP55

Dimension: 122.2*72.8*43mm(L*W*H)

-

+

White Tracer wire = +24V

Unmarked = GND

Gas Detection (Australia) Pty Ltd Page 6 of 11 M-GDA-40125-06/08/2018

Operation:

The 40125 is fully set and up and calibrated when shipped. If the power is connected as

shown the system will function and display the current level of gas which should be zero or

20.9%vol if is an oxygen sensor. The sensor takes approx 30 seconds to reach 10%

operational accuracy and will reach full operational accuracy within 10 minutes of switch on.

The alarm levels are preset in the factory and are shipped with the certificate of calibration,

1. Apply 24V DC to the unit

2. The display will show

3. After a short period (5 seconds) The sensor will enter its operational mode. The

sensor will enter a warm up stage and an alarm may occur but will deactivate as

soon as the sensor has stabilised. (If the sensor has not stabilised after 10 minutes

refer to Calibration part of manual and perform Zero .) The display will then read the

ambient level of gas as shown.

The reading shown is for illustration only this is the normal mode

4. When the detected gas level reaches the preset gas alarm level the display will show.

The LED’s will flash and the Buzzer will sound . Alarm Relay 1 will operate

5. The internal and External Buzzer can be muted by pressing the button on the front

panel .

6. The alarm 1 relay will remain operational until the gas level drops below the alarm

level by an amount of 5% (Hysteresis) or whatever set amount. Relay 1 will then

automatically deactivate

7. The same procedure will occur for alarm level 2. When alarm level 2 is reached and

alarm level 1 has been muted the buzzer will sound, the LED’s will flash and the

external buzzer activate. The Buzzer's can be muted by pressing the MUTE button on

the front panel .

GDA 40125

MODBUS 1.02

CO 0pm

O2 20.9%V

CO 30ppm

Alarm 1

O2 19.5%V

Alarm 1

CO 32ppm

Alarm 1 Mute

O2 19.2%L

Alarm 1 Mute

Gas Detection (Australia) Pty Ltd Page 7 of 11 M-GDA-40125-06/08/2018

8. If the unit looses power the FAULT relay, which is normally activated, will deactivate.

The FAULT relay will also deactivate if the sensor encounters an abnormal condition

or the internal electronics fail

9. Pressing the mute button in any state will not deactivate the alarm relays.

10. 4-20mA o/p

This o/p represents the sensors current o/p of the toxic gasses detected in its

range or the current level of oxygen present. The 40125 can drive into a

maximum loop impedance of 800R. The o/p is NON ISOLATED. Care must be

exercised when 0V referencing the sensor to other apparatus so as not to

inject ground (0V) noise into the 40125. The connecting equipment should

not use an earth tied 0v line. GDA recommends the use of The GD 690

Galvanic isolator in the 4-20mA o/p in safety critical applications

Response time . The sensor is a electrochemical sensor which the Toxic gas or oxygen has to

naturally diffuse into. The sensor response time to gas is <10 seconds. However it may take

longer to diffuse through the sensor and displace all the gas in the electrochemical sensor as

the sensor uses natural diffusion to allow gas into the chamber.

Setup:

ALL systems are factory set up with the sensors ordered and this section will not have to

be followed

To enter setup mode, jumper the right most pins on P7. (On the Setup Option)

Use S1 and S2 to change the setup options. S1 (Top most button) is down while S2 (Bottom

most button) is set.

To change the setting, press the DOWN button, (some settings allow the value to be

incremented by larger steps when the Down button is held for at least 1 second) when the

correct value is indicated press the SET button this saves the selected value to unit and

moves to the next setting option.

If the setup jumper is removed, the current setting will NOT be saved to unit., only pressing

the SET button will save the value If a mistake is made, then removing the jumper will not

save that value.

The setting and its current value is displayed on the screen. During setup no alarms will

sound or relays activated except the Fault relay.

After Setup is complete remove jumper link from board.

Gas Detection (Australia) Pty Ltd Page 8 of 11 M-GDA-40125-06/08/2018

The following numbers show each setting and the values. The default value is shown in bold.

Gas Type:

O2, CO2, CO, Flammable (FLM), H2S, NH3, NO2, Gas, R22, [R]123, [R]134[a], [R]407,

[R]410, Ref

Units:

ppm (pm), % Volume (%V), % Lower Explosive Limit (%L)

Range:

1, 3, 5, 10, 25, 50, 100, 200, 500, 1000, 2000, 5000, 9999

Alarm 1 Type:

Rising, Falling

Alarm 2 Type:

Rising, Falling

Alarm 2 Level can only be set to falling when Alarm 1 is falling. When Alarm 1 is

rising, Alarm 2 cannot be changed from Rising.

Alarm 1 Level:

0-Range (500 steps), 20%V

When the Down button is held, the level will jump 20 steps.

Alarm 2 Level:

0-Range (500 steps), 20 %V

When Alarm 1 is rising, Alarm 2 can only be set to the Alarm 1 level or greater.

When Alarm 2 is falling (and Alarm 1), the Alarm 2 Level must be less than Alarm

level 1.

NOTE: When using default values it is possible to violate the above conditions if the

values are not changed.

When the Down button is held, the level will jump 20 steps.

Alarm Validation Period: (The period the gas has to be present to cause an alarm)

0-250 seconds, 0seconds

When the Down button is held, the level will jump 20 steps.

Alarm Operation:

Latched, Unlatched

Hysteresis:

2%, 5%, 10%, 20%, 40%

Modbus Address:

0-127, 20

When the Down button is held, the address will jump 20 steps.

Gas Detection (Australia) Pty Ltd Page 9 of 11 M-GDA-40125-06/08/2018

Calibration:

The sensor must be fully powered and in a fresh air (21% oxygen balance Nitrogen) for a

minimum of one (1) hour before calibration is carried out.

To enter calibration mode, place jumper link in the left most pins on p7. (on the cal option)

Zero:

THIS MUST BE PERFORMED IN CERTIFIED FRESH AIR. IF ZEROING THE SENSOR

IS NOT PERFORMED IN FRESH AIR THE SENSOR CALIBRATION WILL BE

INVALID AND THE SENSOR READINGS INVALID.

When in calibration mode the value on display is displaying the true value output of the

sensor and should be reading 3.9 to 4.0mA.

If the display is not displaying the 3.9 to 4.0mA adjust the Zero Pot on the back of the unit

until it displays the correct value. DO NOT ALTER THE SPAN POT.

Span:

Spaning of the should be undertaken by PERSONS QUALIFIED BY GDA

Calibration of the sensor should last 6-24 months dependent on environmental conditions

NEVER ALTER THE SPAN POT AS THIS REQUIRES SPECIALISED EQUIPMENT AND WILL EFFECT

THE SENSOR CALIBRATION AND ACCURACY .

***After Calibration or zero is complete remove the CAL jumper link from board.***

THE SENSOR IS FACTORY SET AND WILL NOT REQUIRE ADJUSTMENT PRIOR TO USE .THIS

WORK SHOULD BE UNDERTAKEN BY PERSONS QUALIFIED BY GDA

Calibration

4.0mA

Zero pot

Span pot

Gas Detection (Australia) Pty Ltd Page 10 of 11 M-GDA-40125-06/08/2018

Testing:

The system functionality can be tested without using gas to exercise the sensor unit. This test will

prove the whole system works but will not prove the actual sensor head. The sensor when supplied

comes with a certificate of calibration. The only sure way to test the sensor itself is to expose the

sensor to the target gas.

Testing the system outputs, alarms, sounder and display.

NOTE: if equipment is connected to the any of the o/p devices (relays, 4-20mA o/p, sounder) then

these will activate at the pre-set alarm thresholds. Disconnect any loads that are not to be

activated.

1. Connect the test jumper link as shown

2. Use a screwdriver to turn the test Pot to simulate the sensor output

3. DO NOT ADJUST ANY OTHER POT AS THIS WILL INVALIDATE THE CALIBARTION OF THE

INSTRUMENT.

4. The display will indicate the simulated gas concentration by turning the test Pot.

5. Turn the Pot to activate the relays / sounders and check against gas level displayed on the

display

6. When testing is complete return the test link to the position shown. This is very important.

If this is not undertaken the sensor will not detect gas.

Gas Detection (Australia) Pty Ltd Page 11 of 11 M-GDA-40125-06/08/2018

This product and operating manual are subject to change without prior notice for the improvement

of product performance and ease of use.

Gas Detection (Australia) Pty Ltd

Unit K1, USQ, Baker Street Toowoomba, QLD 4350

PO BOX 597, Darling Heights, QLD 4350 +61 7 4613 5111

www.gasdetectionaustralia.com.au sales@gasdetect.com.au

Thank You for Supporting

Australian Manufacturing

Table of contents

Popular Controllers manuals by other brands

Mitsubishi Electric

Mitsubishi Electric AG-150A Instruction book

Parker

Parker R34 Installation & service instructions

Carel

Carel EVD evolution user manual

Siemens

Siemens 1PL622 operating instructions

Inovance

Inovance AC800 Series user guide

Warner Electric

Warner Electric slo-syn 440 installation instructions

Mitsubishi Electric

Mitsubishi Electric Ecodan PAR-WT50R-E Operation manuals

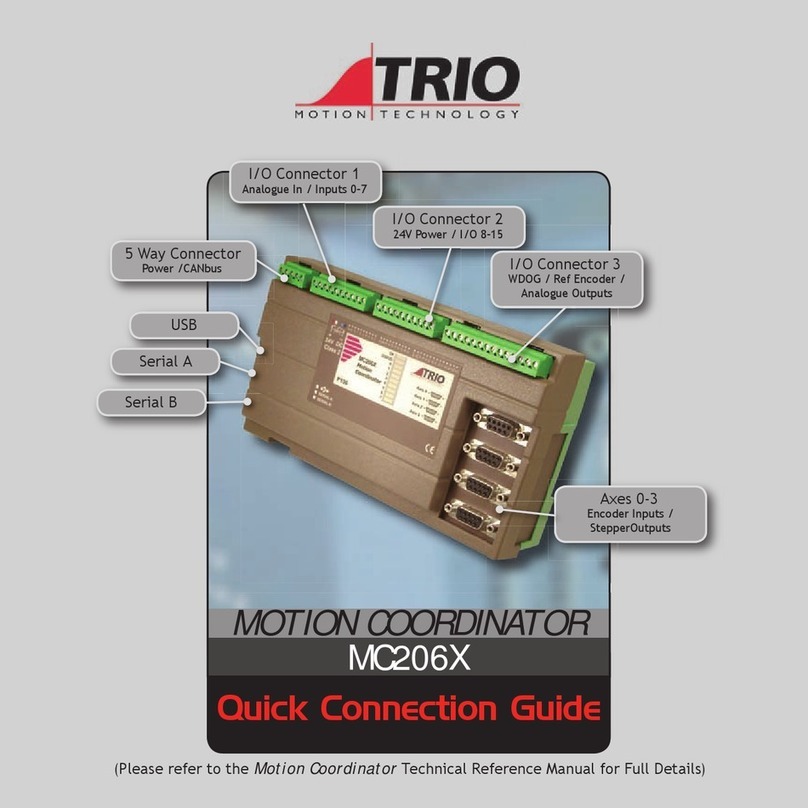

Trio

Trio MC206X Quick connection guide

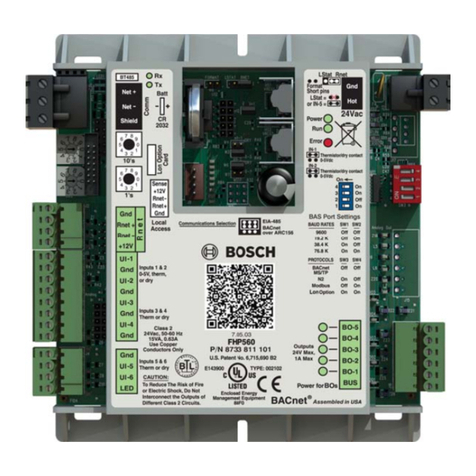

Bosch

Bosch FHP560 Applications manual

Yamaha

Yamaha RCX240 Supporting supplement manual

Vega

Vega VEGATOR 142 operating instructions

Bray

Bray Series 70 Installation, operation and maintenance manual