Gascat Celtic N Instruction manual

Installation, Operation & Maintenance Manual

Blanketing Pressure Regulator - Celtic N

Gascat – Indústria e Comércio Ltda

Gascat Ind Com Ltda

Installation, Operation & Maintenance Manual

Blanketing Pressure Regulator – Celtic N MI-20

Prepared by Checked by / Approved by CSQ (Quality Control) Date Revision Page

Vanizio Vanizio Lizo / Celso Schettini Rubens 31/08/09 0 2 of 11

1 – INSTRUCTIONS PRIOR TO COMMISSIONING

It should be clearly understood that the information given under the Commissioning Instructions below do not

intend to revoke or substitute instructions laid out by any relevant entity, and reference should be made to the relevant

Standards and/or existent recommendations on the subject.

It is implied that before Commissioning, the performance of the appropriate "Cleaning and Purification Procedures"

shall be observed and all the instructions contained in "Pressurization" and "Labor Safety and Health Standards" shall

be strictly followed.

The recommendations of valves' suppliers, as for instance, "open slowly" or "open very slowly" should be strictly

observed.

2 – HEALTH AND SAFETY

Regulators, valves, and other pressurized components that contain toxic or flammable gases, or other hazardous

products, are potentially dangerous if not correctly operated and maintained. It is mandatory that all users of these

equipments are properly instructed and warned on their potential danger, and certify yourself that the personnel

responsible for installation, test, commissioning, operation, and maintenance of the plant are skilled enough to perform

their duties. Instruction manuals are provided for orientation of the operators, but it is supposed that they have a basic

knowledge level. If any doubts or ambiguities remain that could affect the proper procedures ask Gascat Indústria e

Comércio Ltda., which will be pleased to instruct, or to provide the suitable service or instruction. DO NOT TAKE ANY

RISK. Our telephone, fax numbers, and e-mail are the following:

Gascat Indústria e Comércio Ltda.

Rodovia SP 73, 1141 – Indaiatuba / São Paulo.

CEP 13347-990

Brazil

Phone: 55 19 3875-7511

Fax: 55 19 3894-5674

Email: vendas@gascat.com.br

The comments below, while not completely inclusive, provide guidance on possible sources of risk to safety and

health.

2.1 – NOISE

Regulators, valves, and other pressure reducers can produce high noise levels, which can be harmful to persons

exposed to them for long time periods. Users should assure themselves that appropriate provisions will be taken, in

order to foresee health safety of employees and/or third parties, according to standards and recommendations in

force.

2.2 – INSTALLATION

All equipment, piping, and vessels are designed to support mechanical efforts, as, for instance, torque and bending

momentum, in addition to internal pressure. However, careful shall be exercised during installation not to develop

excessive efforts, which can cause cracks that may result in serious breakage when the regulator is put into operation.

Excessive tensions can also be caused if the equipment is overburden by piping, which should be otherwise

appropriately supported.

All regulators, shutoff valves, relief valves, etc., shall be installed taking into account the correct flow sense.

Impulse lines are important components of any control system and it is essential for them to be correctly installed

according to instructions.

Impulse lines should be appropriately supported to reduce excessive vibration, which can provoke fatigue breaks.

They should also be positioned so that they cannot serve as feet or hands supports. Impulse lines should be slightly

sloping so that liquids and condensates drain towards the main piping.

When necessary, (in underground installations or internal areas), a ventilation piping should be installed starting

from the ¼” NPT thread positioned in the bell or diaphragm housing, which should be extended and positioned at a

safe and ventilated place, with the vent outlet protected to avoid rain water input and of insects that could obstruct

ventilation.

Auxiliary systems should not be changed, or modified, without knowledge of the operation conditions and

permission of the responsible in charge.

Gascat Ind Com Ltda

Installation, Operation & Maintenance Manual

Blanketing Pressure Regulator – Celtic N MI-20

Prepared by Checked by / Approved by CSQ (Quality Control) Date Revision Page

Vanizio Vanizio Lizo / Celso Schettini Rubens 31/08/09 0 3 of 11

2.3 – OPERATION

Depending on the regulator type, its valve can be positioned fully open. Consequently, when a regulator is put into

operation, the shutoff valves should be open slowly so that the regulator valve can assume its regulating position. If

the valves are quickly opened, the upstream pressure can pass downstream through the regulator and over-

pressurize downstream the main line.

All regulators, etc., should operate with the regulating spring specified by the manufacturer. This provision is

particularly important when operating relief or shutoff valves, since incorrect springs can hinder a relief valve to open

and a shutoff valve to close at the proper time.

Provisions should be taken to avoid water input through breathing and ventilation openings.

2.4 – MAINTENANCE

Regulators and valves contain gases at pressures that sometimes are higher than the atmospheric pressure.

Before trying to investigate any problem or to perform service maintenance of the equipment, they should be safely de-

pressurized. Furthermore, as most gases can be flammable, poisonous, corrosive, or somehow, dangerous, it may be

necessary to purge the installation with an inert gas, as nitrogen. Special precautions are necessary for operation with

oxygen or hydrochloric gas and the user should be reassured that appropriate procedures are implemented.

Eventually, it is not enough to isolate the high-pressure device, since high pressures can be retained downstream

of isolation valves. Do not try to remove covers, plugs, etc., before these parts are properly freed-up. Even so, it is

advisable to consider if high-pressure gas can be present at the time of removal of covers and plugs.

Most regulators use spiral springs as the loading device. It is important to reduce the load of these springs relieving

their loaders as much as possible. In some cases, some residual load may last, even though the spring is relaxed to

the limits of its housing.

3 – INTRODUCTION

The Celtic N Regulator construction is extremely compact and entirely built in stainless steel AISI 316 material. It

has a single internal pilot and can be supplied with a 5-µm filter installed at the pilot input. Some components are

polished nearly to sanitary finish, for higher durability. Due to its compact size and small weight, the regulator does not

require special brackets for installation and is widely applicable in the Chemical and Oil Industry.

Celtic N regulators are used in applications that require injection of an inert gas into storage tanks, thereby

creating a neutral atmosphere over the upper level of the liquid at rest inside the tank, or the gas is pumped out of the

tank; the positive-pressure gas blanket prevents contamination of the stored product by the external environment, or

the formation of an explosive atmosphere within the vapor space over the product stored inside the tank.

The regulator can control and maintain pressure, in the range of 5 mmWC (0.5mbar) to 150 mmWC (15mbar),

with a measurement uncertainty up to +1.5 mmWC of the set pressure.

Due to its top-entry feature, there is no need to remove it from the line for maintenance or replacement of parts.

This characteristic greatly facilitates maintenance.

For information on CELTIC N sizing, technical characteristics and specifications, please refer to the product

specific catalog.

4 – OPERATION PRINCIPLE

The Celtic N regulator, with internal pilot directly actuated by the sensor diaphragm, monitors and controls the

vapor pressure of the vapor space over the liquid surface of a liquid within a tank. If small pressure variations occur in

this vapor layer, for example, when the tank cools and vapor of the stored product condenses, the regulator internal

pilot, or the regulator, will return the pressure to the regulated setpoint.

When the liquid is pumped out of the tank, the vapor space pressure on the liquid surface decreases quickly, which

is perceived by the regulator sensor diaphragm that activates the internal pilot at the same time.

This pilot, fed by the inlet pressure through a calibrated orifice, actuates to restore this pressure, but since the flow

required to restore this pressure is larger than the capacity of the pilot shutter, or of the calibrated orifice, the pressure

applied to the piston falls rapidly, allowing full passage of the blanketing gas to the tank. When the tank preset

pressure, set by the adjusting screw, is reached, this pressure, of a few millimeters of water column, raises the

regulator-sensing diaphragm causing the pilot to close, thus rapidly raising the pressure on the piston, which shuts the

Regulator. The piston spring and the pilot shutter spring provide a positive shutting load leading to absolute tightness.

Small pressure variations are perceived as a function of the large area of the sensor diaphragm, what guarantees

a much faster response either to the regulator opening or closing.

Gascat Ind Com Ltda

Installation, Operation & Maintenance Manual

Blanketing Pressure Regulator – Celtic N MI-20

Prepared by Checked by / Approved by CSQ (Quality Control) Date Revision Page

Vanizio Vanizio Lizo / Celso Schettini Rubens 31/08/09 0 4 of 11

During the tank filling, the blanketing regulator does not operate, and the excess inert gas is dumped into the

atmosphere by the pressure relief valve or by a double function, relief + vacuum-breaker valve.

Without the tank product inflowing or discharging, the system remains hermetically sealed. If there are leaks in the

tank connections or welds, the regulator will operate to maintain the system pressure.

FIGURE 1

5 – CONSTRUCTION

Connections: Threaded ND 1”NPT or ND 1.1/2”NPT (according to ANSI B1.20.1) or BSP (according to

BS 21 – DIN 2999)

Flanged: ND 1.1/2”/ND 2”150#/300# ANSI B16.5 / Ø50mm DIN PN16

Interconnecting connection to the Tank: Connector in AISI 316 1/2”OD

Options of the capacity restrictor: 30%, 50%, 70%

Body, Intermediary, Caps, Internals, Screws in AISI 316 / CF8M stainless steel.

Diaphragm in Fluorocarbon film (FEP) with operating temperature ranging from -240°C to 205°C, chemically

neutral to most known chemicals.

Viton elastomers (std.) / EPDM / FFKM.

Can be supplied with Filter and Fault Monitor Pressure Gauge

Topy Entry.

6 – INSTALLATION

The Regulator is supplied tested and calibrated by the factory.

The pressure settings, spring range and leak checking are carried out in a test bench according to the supply and

blanketing pressures specified by the client.

After being tested and calibrated, no further adjustment to the CELTIC N components is required, except for an

eventual fine adjustment of the setscrew.

CELTIC N

Gascat Ind Com Ltda

Installation, Operation & Maintenance Manual

Blanketing Pressure Regulator – Celtic N MI-20

Prepared by Checked by / Approved by CSQ (Quality Control) Date Revision Page

Vanizio Vanizio Lizo / Celso Schettini Rubens 31/08/09 0 5 of 11

Remove the protective plastic plugs from the Regulator connections and carry out a visual inspection to check for

any eventual damage occurred during transport.

Check if the supply pressure and the regulator setup are compatible with the operating conditions for which the

valve has been specified. Observe the correct flow direction, according to marking on the main regulator body.

Check if the piping has already been purged and cleaned. We advise a complete purge of the line with nitrogen or

compressed air.

6.1 – GENERAL INFORMATION

The Regulator shall be installed in the horizontal position, with the adjustment screw facing upwards.

It is recommended to install the Regulator on the tank top. However, if it is necessary to install the regulator below

the tank maximum product level, drainage points shall be provided at the main line and the sensor line lower sections.

Under these conditions, drainage shall be made periodically to avoid condensate buildup.

The blanketing gas shall already be filtered; however, for very long piping a 200 MESH (minimum) filter shall be

foreseen upstream of the Regulator, independently of the Pilot Filter, if any.

Interconnecting connections from the regulator body and the sensor diaphragm to the tank shall be independent

and installed in such a way as not to build condensate accumulation.

6.2 – PIPE DIMENSIONS

The recommended dimensions for pipes are:

Supply line = Main regulator ND.

Tank interconnection sensor line = ND 3/4"

Line downstream of main regulator > Main Regulator ND.

To ease future maintenance, provision shall be made for shut-off valves' installation in the supply, sensor and

downstream lines of the main regulator.

We recommend installing a pressure gauge in the sensor line to allow fine adjustment of the sensor regulator.

7 – OPERATION OF THE CELTIC N REGULATOR (START-UP) – (see Figure 1)

Slowly open the inert gas supply-blocking valve (upstream) to the Celtic N Regulator.

Slowly open the blocking valve between the tank and the Celtic N Regulator sensor diaphragm.

Observe in the vacuum gauge (when available) if the set pressure corresponds to the desired blanketing

pressure.

If a small adjustment is necessary, this shall be made later after the tank is fully pressurized.

The gas will start to flow into the tank only through the internal pilot of the Celtic N Regulator, slowly starting to

pressurize the same.

Slowly open part of the blocking valve (downstream) between the main regulator and the tank.

The blanking gas flow rate will increase because it will flow through the main regulator (high flow) and the

internal pilot.

The time to pressurize will depend on the size of the tank and the volume of steam to be pressurized with the

inert gas.

Once the tank pressurizing is completed, the Regulator Celtic N will ensure that the internal pressure will be

maintained at the set value. The pressurizing completion can be checked by the monitor gauge (if available),

which will indicate the same pressure as the pressure available upstream of the Celtic N Regulator. Then,

both, the internal pilot and the main shutter will be closed.

7.1 – Regulator Adjustment

To perform an adjust of the Regulator, it is necessary to remove the protection cap from the diaphragm

spring.

By turning the adjusting screw clockwise the final set pressure (blanketing pressure) increases.

By turning the adjusting screw counter-clockwise the final set pressure (blanketing pressure) decreases.

7.2 – Spring Change

Gascat Ind Com Ltda

Installation, Operation & Maintenance Manual

Blanketing Pressure Regulator – Celtic N MI-20

Prepared by Checked by / Approved by CSQ (Quality Control) Date Revision Page

Vanizio Vanizio Lizo / Celso Schettini Rubens 31/08/09 0 6 of 11

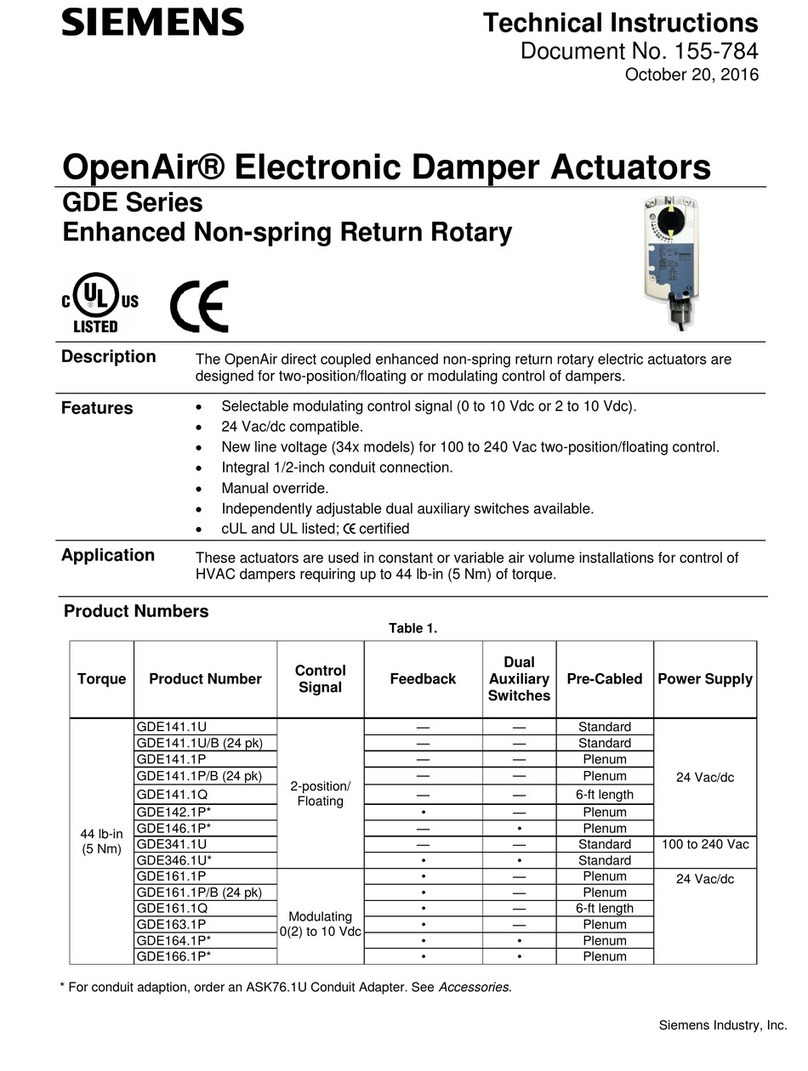

To change the final pressure setting of the Celtic Regulator N (blanketing pressure), adjust the setup screw or

replace the spring according to the table below, using the option best suitable for the application.

Shutter Spring (Piston)

Inlet Pressure Outlet pressure regulating spring

(On the sensor diaphragm)

01.52.46B

Up to 1.5 bar 01.53.02 01.53.02A 01.53.02B 01.53.02C

01.52.46C

1.5 to 4.0 bar 05 / 30 mmWC

10 / 50 mmWC 15 / 80 mmWC 30 / 150 mmWC

01.52.46D

3.5 to 8.0 bar - 05 / 30 mmWC 10 / 55 mmWC 30 / 130 mmWC

To replace the setup spring, proceed as follows (FIG.2):

Remove the cap (47) of the adjusting screw.

Release the adjusting screw (rendering the spring unloaded)

Remove the hood (52) from the housing, which will come out together with the adjusting screw.

Remove the spring adjuster (45) and the spring (3) to be replaced. Insert the new spring, the spring

adjuster and the hood in the reverse order of the disassembly.

Readjust the final blanketing pressure of the Celtic N regulator.

Lock the adjusting screw with the lock nut and replace the cap.

Gascat Ind Com Ltda

Installation, Operation & Maintenance Manual

Blanketing Pressure Regulator – Celtic N MI-20

Prepared by Checked by / Approved by CSQ (Quality Control) Date Revision Page

Vanizio Vanizio Lizo / Celso Schettini Rubens 31/08/09 0 7 of 11

Gascat Ind Com Ltda

Installation, Operation & Maintenance Manual

Blanketing Pressure Regulator – Celtic N MI-20

Prepared by Checked by / Approved by CSQ (Quality Control) Date Revision Page

Vanizio Vanizio Lizo / Celso Schettini Rubens 31/08/09 0 8 of 11

Gascat Ind Com Ltda

Installation, Operation & Maintenance Manual

Blanketing Pressure Regulator – Celtic N MI-20

Prepared by Checked by / Approved by CSQ (Quality Control) Date Revision Page

Vanizio Vanizio Lizo / Celso Schettini Rubens 31/08/09 0 9 of 11

Gascat Ind Com Ltda

Installation, Operation & Maintenance Manual

Blanketing Pressure Regulator – Celtic N MI-20

Prepared by Checked by / Approved by CSQ (Quality Control) Date Revision Page

Vanizio Vanizio Lizo / Celso Schettini Rubens 31/08/09 0 10 of 11

5. – MAINTENANCE

Defect Likely cause Solution

Drop of the tank internal

pressure

Lack of supply gas or drop in gas supply

pressure Check the gas supply source.

Deregulated setpoint (below the required

blanketing pressure) Readjust.

Downstream or upstream main regulator

blocking valve fully or partially closed Check

Filter obstruction upstream of the main

regulator (if installed) Clean or replace filter element.

Defect Likely cause Solution

Response time for

regulator to open or close

is too high

Check calibrated orifice (27)

Damaged pilot shutter

Clean or replace

Replace the shutter

The main shutter (35) may be dirt or the

Teflon ring (36) damaged; also, non-

compliant shutting spring

Clean, check rings and spring.

Replace, if necessary

Increased tank internal

Leakage in sensor line tubing Check and repair leak.

Direct passage in the internal pilot

Check the shutter/seat assembly. Replace

if necessary

.

Gascat Ind Com Ltda

Installation, Operation & Maintenance Manual

Blanketing Pressure Regulator – Celtic N MI-20

Prepared by Checked by / Approved by CSQ (Quality Control) Date Revision Page

Vanizio Vanizio Lizo / Celso Schettini Rubens 31/08/09 0 11 of 11

pressure

Regulator setpoint deregulated Readjust.

Diaphragm rupture

(it can be identifiable by the leakage of

gas through the same)

Replace the diaphragm assembly.

Direct passage through the main

regulator

Check the shutter assembly (piston/o-

rings) and replace if necessary.

Poor sealing in the internal pilot groove Replace the o-ring

9 – STORAGE

The regulators should not suffer mechanical shock, not to risk causing internal components' damages.

The regulators should be stored at a clean and dry place, protected from bad weather.

10 – GENERAL RECOMMENDATIONS

We test our regulators and valves at the requested operation conditions.

Criteria and maintenance steps are contained in manuals, however, for any doubt on the use, operation, or

maintenance, contact Gascat's technical department that will provide you proper guidance.

Gascat supplies, on request, a complete replacement kit.

11 – WARRANTY

We warrant our products, for a 12 months period from the date of invoicing, if the products are in operation,

extending the warrant up to 18 months, in case they are in stock. Such warranty only covers those cases for which the

occurrence of production defects is evidenced, which remained unnoticed at the time the product delivery.

To present warranty is not valid if it is found that the defect or mishap was caused by accident, normal wear,

inadequate installation, improper maneuvering or use, inadequate storage, assembly disregarding technical standards

or if the buyer undertook repairs or changes in equipment by himself, without the manufacturer's previous

authorization.

The information contained in this manual contains GASCAT's supply conditions, independently of the verified

performance.

The information herein contained shall not be interpreted or suggest performance warranty in relation to the final

products, or the system usage purpose, nor should they serve as usage recommendation for any product or process

mentioned in the specifications. This system should only be operated by qualified technician trained for this purpose;

and no changes that may affects the system safety can be executed without our previous authorization.

Gascat Ind. and Com. Ltda. withholds the right to make changes without notice, introducing improvements in the

described products drawings or specifications.

Table of contents

Popular Controllers manuals by other brands

Plum

Plum ecoMAX920P1-K Installation and operating manual

Siemens

Siemens OpenAir GDE141.1U Technical instructions

Thomson Neff

Thomson Neff WIESEL POWERLine WM40 Mounting and Maintenance Instructions

Johnson Controls

Johnson Controls FA-33-741 Series Contents

Adjustables

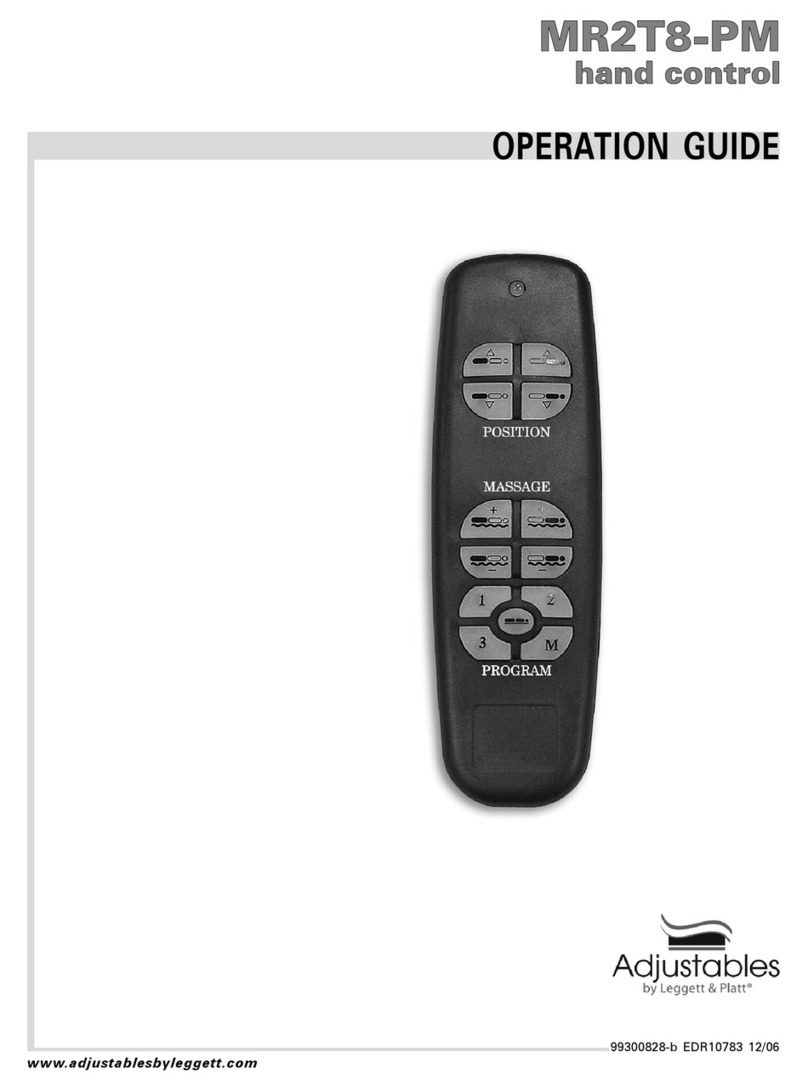

Adjustables MRT2T8-PM Operation guide

SMSCOM

SMSCOM FanController manual