Corrupt Settings Occurs if memory corruption has been detected in the EVMS

Lite’s saved settings (they will automatically be reset to defaults).

Contact us if you see this one.

BMS - low cell A BMS module has reported a cell voltage below the minimum

threshold.

Shutdown by BMS A low cell condition has been present for more than 10 seconds,

so the EVMS has shut down the traction circuit to protect the

batteries.

BMS - high cell A BMS module has reported a cell voltage above the minimum

threshold.

Charge ended by BMS A high cell condition has been present for more than 1

second, so the EVMS has shut down the charger to protect the

batteries.

BMS - overtemp A BMS module has reported a temperature above the

programmed threshold.

BMS - comms error If the EVMS Lite hasn’t received data from a BMS module for a

while (about 1 second), this error will appear and the traction

circuit will be shut down for safety.

Stationary Applications

The EVMS conguration includes a setting for Stationary Mode, intended for use in battery

backup and off-grid power applications. In this mode, the Key input enables both Main

Contactor and Charge Enable outputs concurrently. An undervoltage cell will disable the

Main Contactor output (to remove any loads on the battery) and an overvoltage cell will

disable the Charge Enable output (to disable any charging sources). In both cases the outputs

are re-enabled once the voltage has recovered by 0.4V (i.e there is ±0.2V hysteresis around

the congured thresholds).

In Stationary Mode, the Charge Sense input is no longer used, typically the Aux Ctr output

will not be used, and precharging is not supported.

For LiFePO4, we recommend an undervoltage threshold of 2.8V (which results in 2.6V cutout

and 3.0V re-enabling for any loads on the battery), and an overvoltage threshold of 3.6V (for

3.8V charger cutout and 3.4V re-enabling). These thresholds give about 1% hysteresis on the

battery state of charge to avoid rapid cycling of the charger or outputs.

Tech notes

• CAN bus power: CAN busses use a signicant amount of power when operating. In order

to minimise quiescent power consumption (and avoid attening your vehicle’s 12V battery),

the EVMS Lite powers down the CAN bus after 1 minute if the vehicle is neither driving or

charging. As such, the BMS will no longer be monitoring your cells so it is of paramount

importance that there are no loads on the traction battery when the vehicle is idle, or

batteries could be damaged from over-discharge!

If the outputs are disabled due to a BMS error (such as over-voltage or under-voltage cell),

the CAN bus will remain active for 1 hour. This is to allow a window for the BMS modules to

continue pack balancing even after the charger has been switched off, before the CAN bus

is powered down to avoid attening the auxiliary battery.

Once the CAN bus has powered down, you will be unable to enter Setup mode with a

Monitor device. To remedy this, simply turn the key on and off, or turn the EVMS Lite off and

on again, then enter Setup as normal within 1 minute.

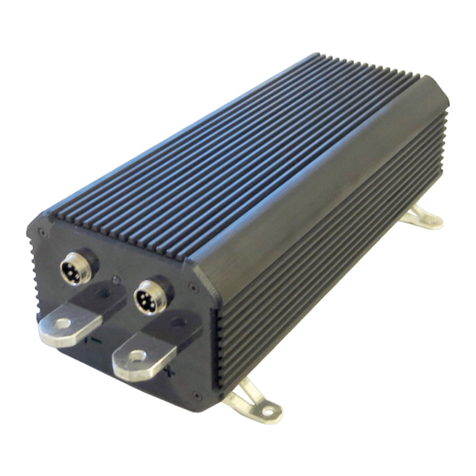

• Precharging your motor controller: Motor controllers have a large input capacitor bank

which must be precharged / soft started, to avoid a large inrush current when your contactor

closes which can damage components. The EVMS Lite includes no controller precharge

system, so you will need to arrange a precharge device for your motor controller if it does not

have one built in. (Check out our Smart Precharger on the ZEVA website for more info.)

Tech support and warranty information

All ZEVA products are covered by a 12 month warranty against manufacturing faults or

failures under normal operating conditions. The warranty does not cover misuse of the

product, including but not limited to: excessive voltage or reversed polarity on terminals,

short circuits on outputs, opening of housings and/or modication of internal electronics,

severe impact damage (e.g due to vehicle crashes), submersion in water.

We have taken great care to design a safe and reliable product, but faults can happen. If

you believe your product has a fault, please contact us via our website to discuss. If it is

determined that a hardware fault is the likely cause, we will provide an RMA number and

return address to proceed with repairs.

If you have any questions not covered by this manual, please contact us via our website:

http://www.zeva.com.au