GasSecure GS01-EA User manual

GasSecure GS01 and GS01-EA

Wireless Infrared Hydrocarbon

Gas Detector

User Manual

(For firmware version ≥ 3.3)

Document ID: 112464 Contact info

Release: 9 GasSecure AS

Version: 145 Hoffsveien 70 C

Doc. Status: APPROVED N-0377 Oslo

Last modified: 26.04.2017 Norway

www.gassecure.com

post@gassecure.com

GasSecure GS01

Hardware Manual

I

Note

Those who have or will have the responsibility for the operation or maintenance of

this product must carefully read this manual. The product may not perform as

designed if it is not used and maintained in accordance with the manufacturer’s

instructions.

Please read the complete manual and particularly note the paragraphs having an

exclamation mark in the margin.

This manual covers installation, operation and maintenance of the GS01 wireless

hydrocarbon detector and its battery pack.

The product warranty issued by GasSecure is voided if the product is not used

and maintained as described in this manual.

Please read also the safety instructions in Section 6.

GasSecure AS, all rights reserved.

GasSecure GS01

Hardware Manual

II

PRODUCT DATA

Manufacturer GasSecure AS

Country of origin Norway

Models GS01, GS01-EA

Gases Hydrocarbons

Range Methane configuration 0 – 100% LEL

Range Propane configuration 0 – 80% LEL

Environmental conditions

Operating temperature -30oC to +55oC

Humidity 0 to 90 RH1non-condensing

Pressure influence, 700 – 1300 hPa2≤0.15% of reading per hPa

(at 50% LEL)

Protection classification IP 66 and IP 67 3

Storage temperature -40oC to +65oC

Storage pressure 700 to 1300 hPa

Electrical

RF output power GS01 ≤12 dBm EIRP

RF output power GS01-EA ≤16 dBm EIRP

Battery type Lithium-Thionyl Chloride

Battery cells Tadiran SL-2780/S or TL-5930/S

Average power 5 mW

Explosion Protection II 2G Ex ib IIC T4 Gb -30oC to +55oC

Intrinsic safety temperature -40oC to +65oC

Gas performance temperature -30oC to +55oC

1The manufacturer verified conditions are 0-100% RH and condensing.

2Applies only for Methane configuration and outside the pressure range 850 – 1150 hPa: The

process value (PV) must be replaced with the adjusted process value PVadj. PVadj is calculated by

the controller with the measured atmospheric pressure as input according to

formula

( )

PVPV p

p

adj

5.1

0

−

=

, where p is the measured pressure and p0 is the standard atmospheric

pressure (101 kPa). Pressure p must be measured with +/-10 kPa accuracy.

3IP ratings do not imply that the equipment will detect gas during exposure to those conditions.

GasSecure GS01

Hardware Manual

III

TABLE OF CONTENTS

1. PRODUCT DESCRIPTION ........................................................................................................5

1.1 GENERAL .................................................................................................................................5

1.2 MEASURING PRINCIPLE .............................................................................................................5

1.3 INSTRUMENT DESCRIPTION........................................................................................................6

1.4 BATTERY..................................................................................................................................6

1.5 OUTLINE DIMENSIONS ...............................................................................................................6

2. INSTALLATION..........................................................................................................................9

2.1 TOOLS .....................................................................................................................................9

2.2 MOUNTING ...............................................................................................................................9

2.3 GROUNDING...........................................................................................................................10

2.4 SUN SHADE /WEATHER PROTECTION.......................................................................................10

2.5 EXTERNAL ANTENNA (APPLIES ONLY FOR GS01-EA)................................................................10

3. COMMISSIONING....................................................................................................................12

3.1 COMMUNICATION....................................................................................................................12

3.2 ISA100 WIRELESS™STANDARD.............................................................................................12

3.3 ISA100 OBJECTS....................................................................................................................12

3.4 GS01 DATA FORMAT DETAILS..................................................................................................14

3.5 MODIFICATION OF LEL............................................................................................................14

3.6 COMMUNICATION MONITORING ................................................................................................15

3.7 GS01 DETECTOR PROVISIONING .............................................................................................15

3.8 MODIFICATIONS TO AN EXISTING NETWORK..............................................................................18

3.9 VISUAL AND FUNCTIONAL CHECK .............................................................................................19

4. OPERATION.............................................................................................................................20

4.1 NORMAL OPERATION...............................................................................................................20

4.2 PROOF TEST (VALIDATION)......................................................................................................20

5. MAINTENANCE .......................................................................................................................22

5.1 ROUTINE MAINTENANCE ..........................................................................................................22

5.2 SPARE PARTS AND ACCESSORIES............................................................................................22

5.3 CLEANING ..............................................................................................................................23

5.4 BATTERY PACK.......................................................................................................................23

5.5 STORAGE...............................................................................................................................26

5.6 TROUBLESHOOTING................................................................................................................26

5.7 CONTACT GASSECURE FOR SUPPORT .....................................................................................27

6. SAFETY INSTRUCTIONS........................................................................................................29

7. CERTIFICATIONS AND STANDARDS....................................................................................30

7.1 STANDARDS ...........................................................................................................................30

7.2 REGULATORY COMPLIANCE OF RADIO FOR GS01.....................................................................31

7.3 MARKING ...............................................................................................................................31

8. TECHNICAL DATA ..................................................................................................................35

8.1 PERFORMANCE CHARACTERISTICS..........................................................................................35

8.2 CROSS SENSITIVITIES .............................................................................................................36

9. REFERENCES .........................................................................................................................38

10. APPENDIX ...........................................................................................................................39

GasSecure GS01

Hardware Manual

IV

FIGURES

FIGURE 1-1: GS01 DETECTOR LAYOUT................................................................................................................6

FIGURE 1-2: GS01 DETECTOR WITH DIMENSIONS IN [MM]...................................................................................7

FIGURE 1-3: GS01-EA DETECTOR WITH DIMENSIONS IN [MM] ............................................................................8

FIGURE 1-4: GS01 MEASURING CELL DETAILS.....................................................................................................8

FIGURE 2-1: CORRECT POSITION OF THE WEATHER CAP AND LOCATION OF EARTH POINT..................................10

FIGURE 2-2: GS01-EA LAYOUT WITH ANTENNA CONNECTIONS ........................................................................11

FIGURE 3-1: GS01 CONFIGURATOR...................................................................................................................17

FIGURE 5-1: BATTERY PACK WARNING LABEL...................................................................................................24

FIGURE 5-2: BATTERY PACK BOTTOM VIEW ......................................................................................................25

FIGURE 5-3: BATTERY PACK TOP AND BOTTOM.................................................................................................25

FIGURE 7-1: GS01 PRODUCT IDENTIFICATION PLATE.........................................................................................31

FIGURE 7-2: GS01-EA PRODUCT IDENTIFICATION PLATE ..................................................................................32

FIGURE 7-3: GS01 PRODUCT IDENTIFICATION PLATE –FM APPROVED..............................................................32

FIGURE 7-4: GS01-EA PRODUCT IDENTIFICATION PLATE –FM APPROVED .......................................................32

FIGURE 7-5: FCC COMPLIANCE LABEL..............................................................................................................33

FIGURE 7-6: BATTERY PACK IDENTIFICATION LABEL (FM APPROVED VERSION TO THE RIGHT) .........................34

FIGURE 7-7: ANTENNA IDENTIFICATION LABEL (FM APPROVED VERSION TO THE RIGHT)..................................34

FIGURE 10-1: EU DECLARATION OF CONFORMITY FOR GS01 AND GS01-EA ...................................................42

TABLES

TABLE 2-1: PROPERTIES OF STANDARD ANTENNA CABLE FOR THE GS01-EA ...................................................11

TABLE 3-1: ISA100 OBJECTS ............................................................................................................................13

TABLE 3-2: LEL VALUES IN [% VOL]ACCORDING TO IEC AND NIOSH............................................................14

TABLE 3-3: PV GAS MEASUREMENT DATA INTEGRITY ......................................................................................15

TABLE 4-1: RECOMMENDED GAS CONCENTRATIONS FOR VALIDATION..............................................................21

TABLE 5-1: IMPORTANT SPARE PARTS AND ACCESSORIES FOR THE GS01 .........................................................22

TABLE 5-2: STATUS MESSAGES RETRIEVED FROM THE DIAG_STATUS ATTRIBUTE ............................................27

TABLE 7-1: LIST OF APPLICABLE STANDARDS FOR THE GS01............................................................................30

TABLE 8-1: PERFORMANCE CHARACTERISTICS FOR THE GS01..........................................................................35

TABLE 8-2: LEL VALUES IN [% VOL]ACCORDING TO IEC60079-20. ................................................................36

TABLE 8-3: CROSS SENSITIVITIES FOR A GS01 METHANE DETECTOR................................................................36

TABLE 8-4: CROSS SENSITIVITIES FOR A GS01 PROPANE DETECTOR.................................................................36

TABLE 8-5: LEL VALUES IN [% VOL]ACCORDING TO NIOSH...........................................................................36

TABLE 8-6: CROSS SENSITIVITIES FOR A GS01 METHANE DETECTOR................................................................37

TABLE 8-7: CROSS SENSITIVITIES FOR A GS01 PROPANE DETECTOR.................................................................37

TABLE 10-1: PV_STATUS BYTE DESCRIPTION ACCORDING TO ISA100 WIRELESS™STANDARD.......................39

TABLE 10-2: CONTENT OF THE DIAG_STATUS ATTRIBUTE............................................................................39

GasSecure GS01

Hardware Manual

DESCRIPTION

5

1. PRODUCT DESCRIPTION

1.1 General

The GS01 is a wireless, battery powered point detector that monitors the

concentration of hydrocarbon gases.

It uses a combination of two sensors:

1. An ultrasonic speed-of-sound sensor that continuously monitors changes in

the ambient air composition.

2. An optical (infrared) absorption sensor that is used for accurate

measurements of the hydrocarbon gas concentration.

The infrared sensor uses more power than the ultrasonic and is therefore kept in

watch mode if the ultrasonic sensor does not detect any changes in the air

composition. The infrared sensor applies optical MEMS (micro electromechanical

system) technology to enable intermittent operation with fast start-up and

measurement, and thus very low average battery consumption.

The measured gas concentration is transmitted wireless using the ISA100

Wireless™ standard. This manual does not cover the wireless router or gateway

and the connected control system (please refer to the list of references in Section

9 providing examples of relevant documentation).

The detector is intrinsically safe, with equipment protection level Gb (Ex ib) (see

Section 7) intended for use in zone 1 and 2 areas.

Two models are available of this gas detector:

- GS01 with fixed antenna

- GS01-EA with extended antenna

All information in this manual for the GS01 also applies for the GS01-EA unless

explicitly otherwise noted.

1.2 Measuring principle

The GS01 detector utilises infrared absorption spectroscopy. The fundament is

the Beer-Lambert Law, which relates the absorption of light to the properties of the

material through which the light is travelling.

The internal radiation source emits infrared radiation through a lens and a

sapphire window into the measuring cell (cf. Figure 1-1 and Figure 1-4). A mirror

at the opposite end of this cell returns the beam back through the sapphire

window into the internal volume of the detector and onto a filter that disperses,

focuses, and modulates the incident light. This filter is a patented silicon MEMS

component proprietary to GasSecure.

By applying a control voltage to the MEMS chip it is switched between the so-

called gas state and the reference state. In the gas state a wavelength where

hydrocarbons do absorb light is focused onto the detector, whereas two

GasSecure GS01

Hardware Manual

6 CHAPTER 1

wavelengths where hydrocarbons do not absorb are focused onto the detector in

the reference state. The GS01 detector uses the same light source, light path and

photodetector for both measurements.

This single beam, triple wavelength detection is unique to the GS01 from

GasSecure.

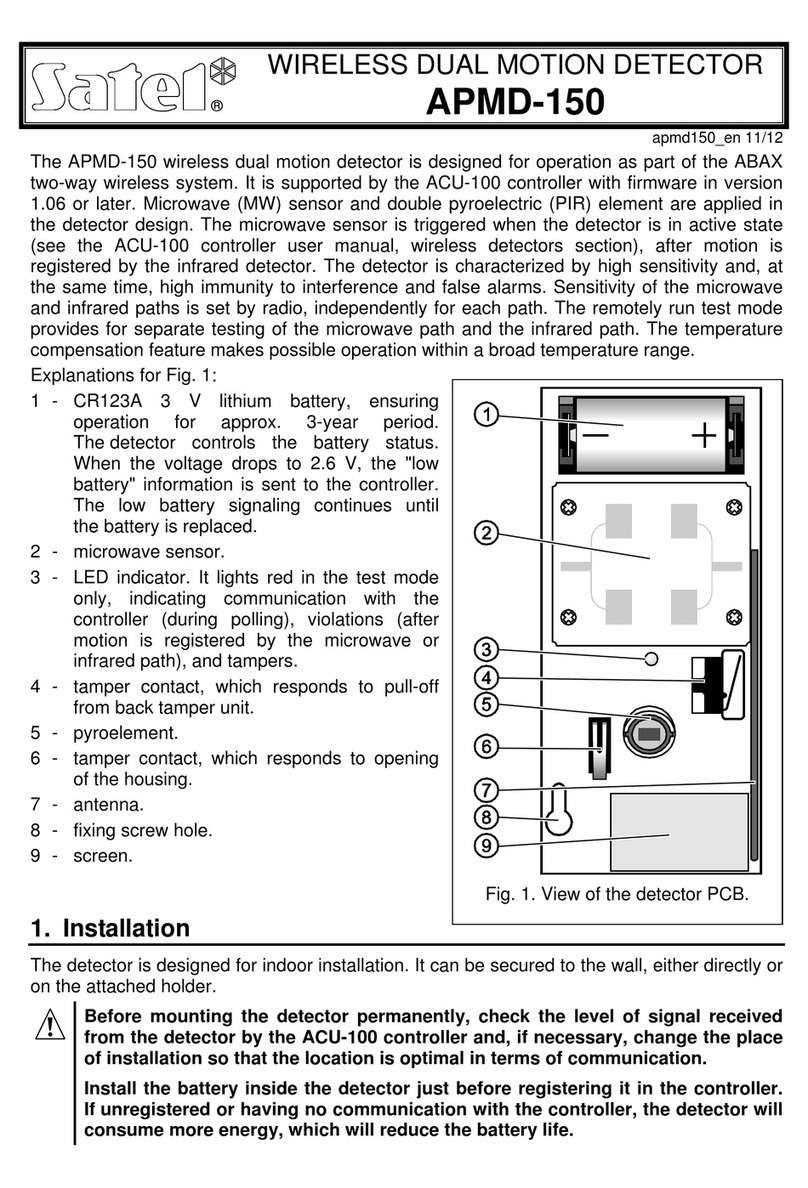

1.3 Instrument description

The GS01 consists of the main housing (316L stainless steel) with mounting

bracket, the measuring cell, an antenna (note that the GS01-EA features an

antenna connector instead), and the battery compartment (cf. Figure 1-1).

Attached to the main housing are the following detachable parts:

•Weather cap (Polyamide 6)

•Battery cap (Polyamide 6)

•Battery package (Polyamide 6)

Except for these detachable parts, the user shall not disassemble the sensor any

further. When the weather cap is removed, the infrared measuring cell with the

sapphire window on the main housing and the mirror at the outer end, is open and

accessible for cleaning. The ultrasonic sensor is protected by a perforated steel

sheet, which shall not be removed.

1.4 Battery

The GS01 may only be used with the GasSecure battery pack (Part number

10055). The battery pack is designed for two Lithium-Thionyl Chloride size D cells

in series, and has a nominal output voltage of 7.2V. The battery pack has an

internal charge counter. The battery pack is intrinsically safe (see Section 7).

1.5 Outline dimensions

Figure 1-1 shows the sensor buildup with an exploded drawing. Figure 1-2 and

Figure 1-3 depict the GS01 and GS01-EA dimensions, respectively.

Figure 1-1: GS01 detector layout

with A) Weather cap, B) Measuring cell, C) Mounting bracket, D) Antenna, E)

Stainless steel housing, F) Battery compartment, G) Battery pack, H) Battery cap

GasSecure GS01

Hardware Manual

DESCRIPTION

7

Figure 1-2: GS01 detector with dimensions in [mm]

GasSecure GS01

Hardware Manual

8 CHAPTER 1

Figure 1-3: GS01-EA detector with dimensions in [mm]

Figure 1-4: GS01 measuring cell details

showing A) External mirror, B) Infrared beam path, C) Sapphire window, D)

Ultrasonic sensor with protective sheet

GasSecure GS01

Hardware Manual

INSTALLATION

9

2. INSTALLATION

Note: The GS01 gas detector certification must comply with the legal requirements

following the area classification at the installation point.

The detector shall be installed where it is most likely to detect gas in the event of a

leakage.

For battery pack installation see Section 5.4.

In areas with significant exposure to direct sunlight and the risk of temperatures

beyond the operating temperature range, a sunshade should be considered (see

list of spare parts in Table 5-1).

2.1 Tools

The following tools are needed to install the instrument:

•Open-end spanner for M8 bolts (alternatively 5/16” bolts)

•Face spanner with two pins in size 75x6 (distance x pin diameter) as

optional tool to remove the battery cap

•Torx screwdriver T10 for battery cell replacement (cf. Section 5.4.2)

2.2 Mounting

The detector is mounted with its long axis horizontally. For the standard GS01

make sure, to the extent possible, that the antenna is vertical (pointing up or

down) and that local radio shadowing is kept at a minimum. The GS01-EA may be

mounted in any horizontal orientation.

Two M8 bolts (alternatively 5/16” bolts) with washers under the head are used to

attach the bracket. The bolts should be spaced from 85 to 95 mm to easily fit the

slots when mounting the detector.

The weather cap must be mounted with the arrow on the cap pointing upwards,

regardless if the antenna is pointing up or down (cf. Figure 2-1). If possible, mount

the GS01 with the weather cap oriented away from the prevailing wind direction.

Do not use the GS01 detector in ventilation ducts or pipes.

Do not mount the detector directly above hot or cold surfaces. If the detector is

mounted inside metallic structures or enclosures the GS01 detector with extended

antenna (GS01-EA) should be considered.

GasSecure GS01

Hardware Manual

10 CHAPTER 2

2.3 Grounding

The detector housing must be connected to ground for operation in hazardous

areas. This to avoid possible static charge build-up, which may arise from

electrically isolated metal parts. Ground the detector either by mounting it on a

grounded metallic structure or by connecting a grounded wire to the screw holes in

the mounting bracket (cf. Figure 2-1).The resistance to ground must be less than

1 GOhm.

2.4 Sun shade / weather protection

The sunshade is available as optional accessory and recommended for locations

with high ambient temperature and / or direct sunlight exposure. It may also be

used as weather protection for instance in locations with frequent heavy

precipitation. The shade is fixed to the gas detector bracket with the same M8 (or

5/16”) bolts, which are used for detector mounting. Make sure that the sunshade

is mounted the correct way so that the detector identification plate remains visible.

Figure 2-1: Correct position of the weather cap and location of earth point.

The arrow must always point up regardless of the detector orientation.

2.5 External antenna (applies only for GS01-EA)

The external antenna is connected to the detector with the antenna cable as

shown in Figure 2-2. The properties of the antenna cable supplied by GasSecure

are shown in Table 2-1. The GS01-EA detector is certified with the coaxial cable

and the omni-directional antenna in Table 5-1. Note that the approved cable

length range is 0-30 m. Do not connect any other antennas than those listed in

Table 5-1.

The external antenna is delivered with a bracket (refer to Reference [10] for

bracket dimensions) and metal bands for easy fitting to a pole (25 – 101 mm) or

External

earth point

GasSecure GS01

Hardware Manual

INSTALLATION

11

similar. Make sure, to the extent possible, that the antenna is mounted vertical

(pointing up or down) and that local radio shadowing is kept at a minimum. Please

read also the safety instructions in Section 6.

Table 2-1: Properties of standard antenna cable for the GS01-EA

Loss/m at 2.5 GHz

[dB]

Diameter

[mm]

Bend radius

[mm]

Weight per m

[g]

0.21

10.3

100

115

Figure 2-2: GS01-EA layout with antenna connections

Omni-directional antenna

N-type connector

Antenna cable

Housing

N-type connector

GasSecure GS01

Hardware Manual

12 CHAPTER 3

3. COMMISSIONING

The GS01 detector(s) is (are) set up in a wireless sensor network with a gateway

and router. The exact commissioning procedure depends on the selected type of

gateway. Therefore, this manual must be used together with the relevant

documentation written for the respective gateway. Some references for such

documentation are provided in Section 9.

On completion of commissioning, the proof test, as described in Section 4.2,

should be executed to validate the correct mapping of the detector output data.

3.1 Communication

The GS01 detector complies with the ISA100 Wireless™ standard for wireless

communication.

Each GS01 detector must be paired with a single gateway, before it can

communicate with the network. The gateway is the interface between the wireless

and plant networks. It marks the transition between communications compliant to

the standard and other communications, and acts as a translator between ISA100

Wireless™ and other protocols (Modbus, PROFINET, etc.).

The pairing process, where the device obtains the appropriate security credentials

and network-specific information, is referred to as provisioning and is explained in

Section 3.7.

3.2 ISA100 Wireless™ standard

ISA100 Wireless™ is a wireless networking technology standard developed by the

International Society of Automation (ISA).

This ISA standard is intended to provide reliable and secure wireless operation for

safety, control, and monitoring applications. This standard defines the protocol

suite, system management, gateway, and security specifications for low-data-rate

wireless connectivity with fixed, portable, and moving field devices supporting very

limited power consumption requirements. The application focus is to address the

performance needs for periodic monitoring and process control where latencies on

the order of 100 ms can be tolerated with optional behaviour for shorter latency.

3.3 ISA100 objects

ISA100.11a defines a communication protocol, with an application layer that

includes a simple but extensible set of input and output objects.

The GS01 detector publishes the measured values and diagnostic information as

ISA100 objects with attributes. It is distinguished between standard attributes and

GS01 device specific attributes.

3.3.1 Standard objects

The GS01 publishes ISA100 standard objects with attributes for process value

and diagnostic status as outlined in Table 3-1 below. The gas measurement value

GasSecure GS01

Hardware Manual

COMMISSIONING

13

is sent as User Application - Analog Input Object with the attribute “Process Value”

(PV). Note that the user may choose which gas configuration to read out by

selecting the corresponding PV object (Methane or Propane) for publication. The

device health information is compiled and sent as User Application Management

Object with the attribute “Diagnostic Status” (DIAG_STATUS).

The concentrator of the gas detector is per default set up to publish the gas

measurement and the diagnostic status. The concentrator can be configured

differently in the gateway interface.

For short detector response time (<5 sec as per GS01 datasheet), the gateway

must be set up with a 2 sec sampling interval (also referred to as publication

period). In the absence of hydrocarbon gas, the detector will not publish on all

available time slots, but per default only publish on every 6th time in order to save

battery power. In the presence of hydrocarbon gas of sufficient concentration

(defined by the internal low alarm limit see Table 8-1), all time slots will be used.

Table 3-1: ISA100 objects

Descriptive

name

Access

-ibility

Octet

no.

Content

Modbus input

registers

Data type

PV

(Methane or

Propane) READ

1

PV_Status

Register N

UINT 16 bit

2

PV_Value (1/4)

Register N+1

32 bit (4 octets)

float, according to

IEEE 754_Float32

3

PV_Value (2/4)

4

PV_Value (3/4)

Register N+2

5

PV_Value (4/4)

DIAG_STATUS READ

1

Diag_Status (1/4)

Register M UINT 16 bit

2

Diag_Status (2/4)

3

Diag_Status (3/4)

Register M+1

4

Diag_Status (4/4)

The content of the PV_Status byte (PV = process value) is explained in Table

10-1 in the Appendix.

The full mapping of the content of the DIAG_STATUS attribute is explained in

Table 10-2 in the Appendix.

Note that a controller is required to display the diagnostic information including

fault or alarm conditions.

Recommendations for which status and diagnostic information to integrate in the

control and maintenance loop are also provided in the Appendix.

3.3.2 GS01 specific objects for safe communication

In addition to the standard objects, the GS01 can be configured to publish and

subscribe to the custom data object “SafeData”. This object is used for safe

GasSecure GS01

Hardware Manual

14 CHAPTER 3

communication. The GS01 uses the PROFIsafe profile over PROFINET as tool for

safe communication. In this setup the GS01 acts as F-Slave, a passive

communication peer able to perform PROFIsafe. Its counterpart is the F-Host, a

data processing unit able to perform PROFIsafe and to trigger the F-Slave for data

exchange. The F-Host must be compliant with the PROFIsafe requirements so

that end-to-end communication through a black channel, defined by the IEC

61508 standard, can be established.

Please refer to the GS01 safety manual [RD 9] for further information on how to

set up safe communication with PROFIsafe. For applications without PROFIsafe

the “SafeData” object shall be disregarded.

3.4 GS01 data format details

The GS01 data objects can be mapped into 16 bit Modbus input registers.

The “PV” object (cf. Section 3.3.1) normally populates three registers; the

PV_Status byte populates the last 8 bits of the first register and the 32 bit float

number populates the following two registers.

The “UAPMO.DIAG_STATUS” object (cf. Section 3.3.1) is normally mapped into

two 16 bit registers. Some gateways will also add a status byte into the preceding

register. This status byte may be ignored, because its information is already

contained in the PV_status byte.

The procedure for Modbus register mapping depends on the specific gateway,

please consult the respective gateway manual on how to achieve this mapping.

GasSecure can assist with advice if needed.

3.5 Modification of LEL

Regionally different conversion factors may apply for the display of measured

concentrations in percent of the lower explosion limit (LEL). The GasSecure GS01

gas detector allows you to select one of two LEL categories, which basically

correspond with common explosion limits in the USA (NIOSH Pocket Guide to

Chemical Hazards4) and Europe IEC 60079-20), cf. Table 3-2. The factory default

setting is LEL according to IEC. The LEL category may be changed with the GS01

Configurator tool as part of device provisioning as explained in Section 3.7.

Note that this feature is supported for GS01 firmware version ≥3.3.

Table 3-2: LEL values in [% vol] according to IEC and NIOSH

LEL values [% vol] for

IEC (factory default)

NIOSH

Methane

4.4

5.0

Propane

1.7

2.1

4See http://www.cdc.gov/niosh/npg/

GasSecure GS01

Hardware Manual

COMMISSIONING

15

3.6 Communication monitoring

The PV_Status byte (see Table 3-1) can be used for monitoring the

communication status and the data integrity. See Table 10-1 in the Appendix for

all details. With no error present (e.g. beam block or critical low power) and the

detector communicating with the gateway, the status byte will be decimal value 64

or higher; please refer to Table 3-3 below for the three main classes of data

integrity.

The status byte is updated by the gateway if the communication with the detector

is lost. The time from reception of the last packet and until the status byte is

updated to flag “lost communication” is defined via the stale limit parameter.

Please consult the gateway manual for information about setting this stale limit.

GasSecure’s recommendation is a sampling interval of 2 sec (see Section 3.3.1)

together with a stale limit of 30 times, so that “lost communication” is flagged after

maximum 60 sec. Under no circumstances the stale limit must be set to less than

6, because this would disable communication between detector and gateway.

Note that the timeout, as defined by the stale limit, can be checked by removing

the battery and monitoring the time until the PV_Status byte is updated.

Table 3-3: PV Gas measurement data integrity

Data integrity

Octet decimal

number

Explanation and actions

Bad

< 64

No communication or hardware failure.

Check communication. Contact GasSecure if

this failure persists.

Uncertain

64 to 127

The integrity of the data is uncertain. As

example, the sensor range or

temperature

range may be exceeded.

Good

= 128

Normal operation. The detector is providing

reliable gas measurements.

3.7 GS01 detector provisioning

All GS01 detectors have to be provisioned so that they will join the correct

network. Provisioning the GS01 requires the following:

•The GS01 serial adapter together with the GS01 Configurator software

(both accessories from GasSecure)

•FTDI virtual comport driver for the GS01 serial adapter

•The network (or subnet) ID of the gateway or backbone router

•For Yokogawa gateway only: A Capability File (CF) for the GS01 device.

GasSecure GS01

Hardware Manual

16 CHAPTER 3

Software tools, drivers, and files (e.g. CF) are available for download at

http://tools.gassecure.com.

This procedure can be carried out with an unprovisioned GS01 or with a GS01

that earlier has been provisioned to another gateway.

3.7.1 Yokogawa gateways

a) Connect the GS01 to a PC with the GS01 Configurator installed using the

GS01 serial adapter.

b) Run the GS01 Configurator and select the correct COM port. Keep the

default mode “Provision one GS01 device”. Press the “Connect” button and

verify that the device information is displayed, cf. Figure 3-1. Press the

“Read version info” button if the device information does not show

automatically. Press the “Read” button so that the current provisioning

status of the device is displayed.

c) Enter the device tag and the required network ID in decimal format, cf.

Figure 3-1.

d) For the join key there are two options.

i. Specific (user-defined) join key: Type a 32-bit hexadecimal number

in the “join key” field.

ii. Generate a random join key: Press the “Generate random join key”

button.

e) Check and set the LEL category to either IEC or NIOSH as defined in Table

3-2.

f) Check the destination folder for the ypif file and change it by pressing the

“...” button if necessary. Press the “Generate ypif file” button. This file must

be uploaded to the gateway (explained in reference [RD 4]) to enable

communication. Press the “Apply” button (do not make any changes to the

provisioning input data between pressing the two buttons!).

g) Close and exit the GS01 Configurator and disconnect the GS01 detector

from the PC.

h) Power up the GS01 by inserting the battery pack.

i) The GS01 device should join the network within 5-20 minutes, if it is within

radio distance to the gateway and the gateway is set up properly (refer to

reference [RD 4]). If the gateway is out of radio range, the GS01 device will

try to connect for a period of 60 min and then enter a power-saving mode.

In this mode it will try to connect for a 5 min period once per hour.

GasSecure GS01

Hardware Manual

COMMISSIONING

17

Figure 3-1: GS01 Configurator

3.7.2 Nivis gateway VR800/900

a) Connect the GS01 to a PC with the GS01 Configurator tool installed using

the GS01 serial adapter.

b) Run the GS01 Configurator and select the correct COM port. Keep the

default mode “Provision one GS01 device”. Press the “Connect” button and

verify that the device information is displayed, cf. Figure 3-1. Press the

“Read version info” button if the device information does not show

automatically. Press the “Read” button so that the current provisioning

status of the device is displayed as well.

c) Enter the device tag and the required network ID in decimal format, cf.

Figure 3-1.

d) For the join key there are two options.

i. Specific (user-defined) join key: Type a 32-bit hexadecimal number

in the “join key” field.

ii. Generate a random join key: Select “randomize join key”. Press the

“Generate random join key” button.

Note down the join key. It is needed for configuring the Nivis gateway.

e) Check and set the LEL category to either IEC or NIOSH as defined in Table

3-2.

f) Press the “Apply” button.

g) Close and exit the GS01 Configurator and disconnect the GS01 detector

from the PC.

GasSecure GS01

Hardware Manual

18 CHAPTER 3

h) Power up the GS01 by inserting the battery pack.

i) The GS01 device should join the network within 5-20 minutes, if it is within

radio distance to the gateway and the gateway is set up properly. If the

gateway is out of radio range, the GS01 device will try to connect for a

period of 60 min and then enter a power-saving mode. In this mode it will

try to connect for a 5 min period once per hour.

3.7.3 Over the air (OTA) provisioning

a) Connect the GS01 to a PC with the GS01 Configurator installed using the

GS01 serial adapter.

b) Run the GS01 Configurator and select the correct COM port. Keep the

default mode “Provision one GS01 device”. Press the “Connect” button and

verify that the device information is displayed, cf. Figure 3-1. Press the

“Read version info” button if the device information does not show

automatically. Press the “Read” button so that the current provisioning

status of the device is displayed.

c) Press the “Reset radio to factory defaults” button.

d) Close and exit the GS01 Configurator and disconnect the GS01 detector

from the PC.

e) Power up the GS01 by inserting the battery pack.

f) The GS01 can now be provisioned over the air (OTA) using either special

field tools or the field wireless access points. Refer to references [RD3],

[RD6] or [RD 8] for possible solutions from different vendors.

3.8 Modifications to an existing network

1. Add a detector

Provision the GS01 as described in Section 3.7.

Mount the GS01 with battery.

Re-configure the gateway to accommodate the additional detector(s) (cf.

Section 9 for gateway relevant documentation).

2. Replace a detector

Power down the GS01 in question by removing its battery.

Provision the replacement GS01 by following all steps in Section 3.7.

Mount the replacement GS01 with battery.

Re-configure the gateway to accommodate the replacement detector(s) (cf.

Section 9 for gateway relevant documentation).

3. Remove a detector

Power down the GS01 in question by removing its battery pack.

Optional: Re-configure the gateway in order to remove the detector from

the list of publishers (cf. Section 9 for gateway relevant documentation).

GasSecure GS01

Hardware Manual

COMMISSIONING

19

3.9 Visual and functional check

The following activities are recommended before putting into operation the GS01

detector:

•The axis of the detector shall be horizontal.

•Verify the correct orientation of the weather cap (cf. Figure 2-1).

•Check that all bolts and screws are securely tightened.

•Carry out a validation as described in Section 4.2.

•It is moreover recommended to read the procedures described in IEC

60079-29-2 for reference.

This manual suits for next models

3

Table of contents