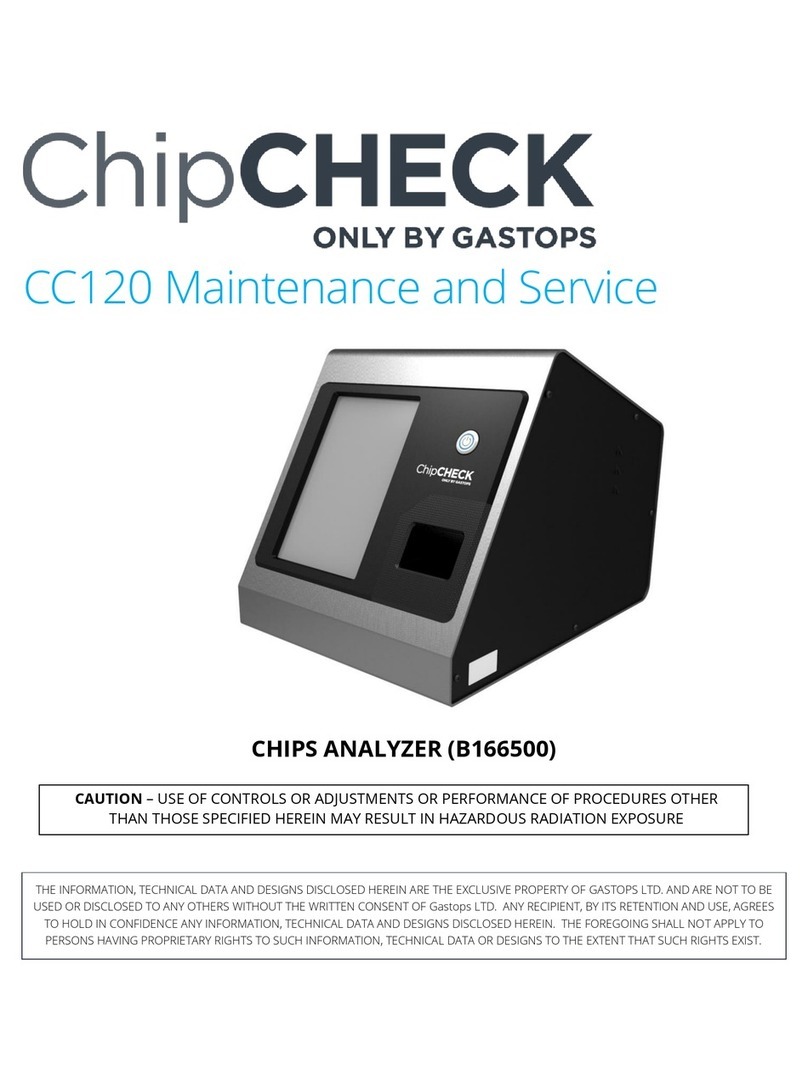

Gastops ChipCHECK CC120 Operating instructions

CC120 Health and Safety

CHIPS ANALYZER (B166500)

CAUTION –USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER

THAN THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE

THE INFORMATION, TECHNICAL DATA AND DESIGNS DISCLOSED HEREIN ARE THE EXCLUSIVE PROPERTY OF GASTOPS LTD. AND ARE NOT TO BE

USED OR DISCLOSED TO ANY OTHERS WITHOUT THE WRITTEN CONSENT OF Gastops LTD. ANY RECIPIENT, BY ITS RETENTION AND USE, AGREES

TO HOLD IN CONFIDENCE ANY INFORMATION, TECHNICAL DATA AND DESIGNS DISCLOSED HEREIN. THE FOREGOING SHALL NOT APPLY TO

PERSONS HAVING PROPRIETARY RIGHTS TO SUCH INFORMATION, TECHNICAL DATA OR DESIGNS TO THE EXTENT THAT SUCH RIGHTS EXIST.

Gastops Ltd.

C009423, Rev. 4 page 4

All use of this publication and ChipCHECK by user shall be subject to the restrictions and conditions as set out in this publication.

2.0 Health and Safety

2.1 Operational Safety

CAUTION – USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER

THAN THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

CAUTION – PRIOR TO ANY USE, THE EQUIPMENT MUST BE INSPECTED FOR ANY DAMAGE

(INCLUDING BUT NOT LIMITED TO DENTS, IMPACT MARKS, DEFORMATIONS IN PANELS, ETC.) FAILURE

TO DO SO MAY RESULT IN HAZARDOUS RADIATION EXPOSURE. IF DAMAGE IS OBSERVED, UNPLUG

THE EQUIPMENT AND CONTACT THE MANUFACTURER IMMEDIATELY.

To ensure safe and proper use of the ChipCHECK system, Users of ChipCHECK must be aware of and

adhere to all safety precautions and procedures as discussed herein. Users shall use this section to

become acquainted with the specific safety features included with ChipCHECK system.

Laser Parameters:

Product Laser Classification

Class 1

Wavelength

1064nm

Laser Power / Peak Power

12mW / 600kW

Pulse Energy

1.2mJ

Emission Type

Pulsed

Optical Pulse Width

2ns

Beam Diameter (at aperture)

4.5mm

Divergence

< 0.8mRad

NOTE:

•Never use or operate the equipment without full understanding and compliance with this

Operator Manual.

•This Laser Product is designated as Class 1 during all procedures of operation.

•There is no scheduled maintenance required to keep the product in compliance.

•Refer to Section 6.0 for the allowable User maintenance.

•There is absolutely NO SERVICE ALLOWED by the User. There are no User serviceable parts.

•This equipment is to be serviced or repaired only by Gastops authorized technicians.

•The User is not allowed to attempt to alter, interfere, modify, remove, circumvent, defeat or

de-active any safety features or interlocks (see Section 2.2.2 and Figure 2-1 & 2-6).

•The User is strictly forbidden from reverse-engineering, altering, interfering, modifying,

removing, circumventing, or de-activing any part of the equipment.

•Never remove any labels or remove any covers.

Gastops Ltd.

C009423, Rev. 4 page 5

All use of this publication and ChipCHECK by user shall be subject to the restrictions and conditions as set out in this publication.

•Objects and/or material not required for operation must not be kept near the equipment

operating area.

•Keep the equipment dry at all times and avoid spilling liquid into the equipment. If any

liquids or spills enter the interior of the equipment, switch off power and contact Gastops

Customer Support (Section 8.0).

•Do not use flammable gases around the equipment or volatile gas or liquids inside the

equipment. Fire or explosions could result.

•Never use or operate the equipment if the equipment:

-Is defective, shows visible signs of damage, or was subject to events (including weather)

that could have damaged the equipment (non-visible damages)

-If any safety system feature or seal is damaged

-Fails to perform the intended measurement

-Has been subject to prolonged storage in unfavorable conditions

-Has been subject to severe transport stresses

If any of the above has occurred, then switch off the power and contact Gastops Customer Support

(Section 8.0).

2.2 Safety Features

This section describes the integrated safety features that ensure the User’s safety throughout the

operation of the equipment. It is these safety features that render the classification of this product as

Class 1. As a result, the User is strictly forbidden to alter, interfere, modify, remove, circumvent, defeat

or de-active any of these features. Refer to Figures 2-1 through Figures 2-5 below for a schematic

describing all of the integrated safety features. It is critical that the User becomes familiar with the

location and purpose of each safety feature in order to ensure safe use of the equipment.

Gastops Ltd.

C009423, Rev. 4 page 6

All use of this publication and ChipCHECK by user shall be subject to the restrictions and conditions as set out in this publication.

Figure 2-1: Location of all ChipCHECK Safety Features

2.2.1 Safety Labels

This section reviews all of the labelling information associated with the equipment. It is imperative that

the User becomes familiar with the labels, their location, and their meaning.

The following images depict all of the labels found on the equipment and within this document. Each

figure below has been assigned a number which corresponds to the label placement schematic below.

Refer to Figure 2-2 through Figure 2-5 below to become familiar with the specific location of each label.

Figure 2-2: Explanatory Label (1) – Not Found On Unit

Gastops Ltd.

C009423, Rev. 4 page 7

All use of this publication and ChipCHECK by user shall be subject to the restrictions and conditions as set out in this publication.

Figure 2-3: Explanatory, Manufacturer’s Identification, and Certification Label (2)

(Note that only one of the two shown above will be applied to the unit.)

Figure 2-4: Protective Housing, Non-Interlocked Label (3)

Gastops Ltd.

C009423, Rev. 4 page 8

All use of this publication and ChipCHECK by user shall be subject to the restrictions and conditions as set out in this publication.

Figure 2-5: Laser ChipCHECK Label Placement Schematic

(Numbers shown correspond to the label titles above)

2.2.2 Interlocks

The equipment is equipped with a forced contact redundant interlock system that provides the User

with the required level of safety when operating the equipment. The two interlocks in this system are

placed on the Sample Access Panel and ensure that power to the laser is severed prior to any opening

being made in the equipment during operation (i.e.: opening the Sample Door). Having these interlocks

ensures that the User is never exposed to laser radiation above a Class I classification. As a result, this

panel shall not be modified in any fashion, and the User is strictly forbidden from attempting to alter,

interfere, modify, remove, circumvent, defeat or de-active these safety interlocks.

Figure 2-6 indicates the location of the Sample Access Panel safety interlocks.

Gastops Ltd.

C009423, Rev. 4 page 9

All use of this publication and ChipCHECK by user shall be subject to the restrictions and conditions as set out in this publication.

Figure 2-6: Sample Access Panel Interlock (Location)

Other manuals for ChipCHECK CC120

1

This manual suits for next models

1

Table of contents

Other Gastops Measuring Instrument manuals