Gastrofrit TW-350 User manual

This manual suits for next models

3

Table of contents

Popular Pasta Maker manuals by other brands

Falcon

Falcon E9241 User, installation and servicing instructions

Lotus cooker

Lotus cooker CP-74ETX Instructions for installation and use

Cuisinart

Cuisinart PRS-50 Quick reference guide

Electrolux

Electrolux WKGROAOOOO Specification sheet

Philips

Philips HR2660 user manual

Perfecto Express

Perfecto Express EDAPM-1020A user manual

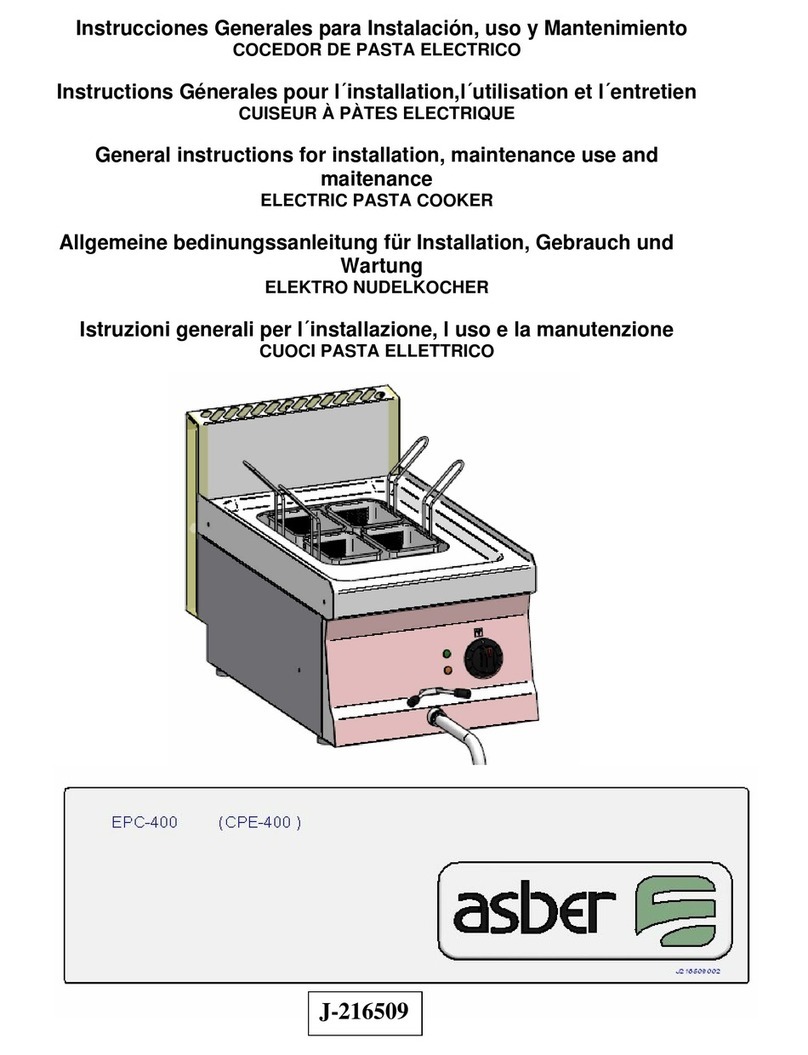

ASBER

ASBER EPC-400 General instructions for installation, maintenance use and maitenance

KitchenAid

KitchenAid KPEXTA Instructions and recipes

Cuisinart

Cuisinart PRS-50C INSTRUCTION AND RECIPE BOOKLET

Princess

Princess 1945 Instructions for use

Todd English

Todd English TEPM2 instructions

Salvis

Salvis Master operating instructions

Masterpro

Masterpro BGMP-9145 instruction manual

Alico

Alico Proxe70 74GPCM Instructions for installation, operation and maintenance

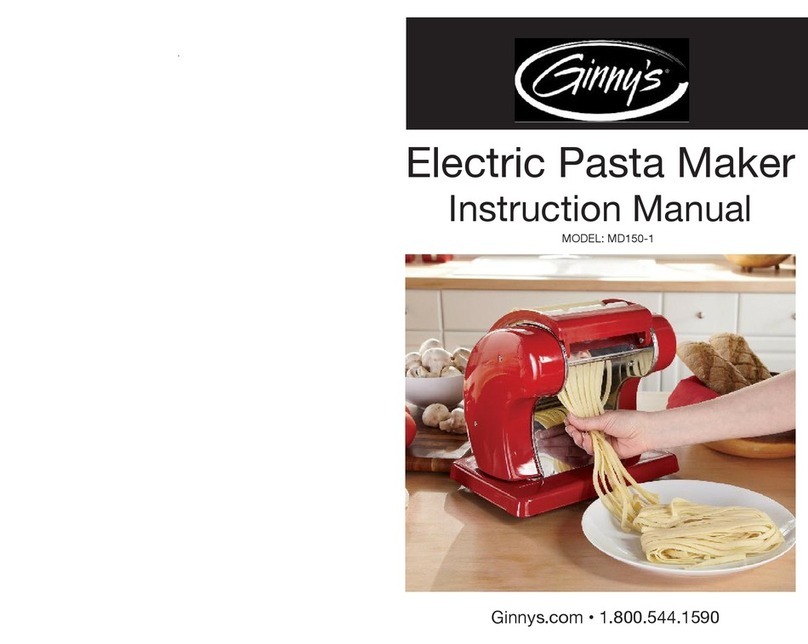

Ginnys

Ginnys MD150-1 instruction manual

Waring

Waring WPC100 manual

Lincat

Lincat LPB Installation, operating and servicing instructions

Marcato

Marcato AtlasMotor Wellness Instructions for use and maintenance