GATEXPERT BC Series User manual

DC Brushless Barrier Gate

BC Series

Instruction Manual

Website: www.gatexpertstore.com

E-mail: sales@gatexpertstore.com

Warning:

Please read this instruction manual carefully before installation, in which contains some

important information about installation, usage, maintenance and safety.

Any undefined operation under this instruction is not allowed. Improper usage will result in

damage to this product and cause serious injury or property losses.

Please keep this instruction manual properly for future reference.

The design and manufacture of the barrier gate is totally complied with the current

standards and regulations.

Considering the possibility of danger, the installation must strictly comply with the following

construction standards and electrical operation procedures:

Before installation, please check if any additional equipment or materials are needed in

order to meet the specific requirements.

The handling of packing materials must comply with local regulations.

Please do not modify any parts, except for those defined under this instruction manual.

Any undefined modification may cause troubles. Any damages to the product arising

therefrom shall be beyond the liability of the company.

Please do not leak water or liquid into the controller or any other open devices. Please

disconnect the power immediately if any mentioned cases happened.

Please keep this product away from heat and open fire. Or it may damage the

components; cause the failure or other hazards.

Nobody is allowed to stand or walk under the barrier boom, especially when it’s on

moving. Please do not stand or leave any objects within the boom rotation range of 90°

due to the collision by cars.

Spring adjustment, operation mode setting, induction devices installation must be

operated by qualified professionals.

WARRANTY

1. To repair against this warranty card and invoice during the warranty period.

2. Warranty period: 1 year after the date of invoice.

3. Without unauthorized dismantling, any product broken or damage due to

quality problem, we’ll offer the repair service for free or replace for free.

4. The malfunction and damages caused by incorrect use or man fault is not

covered by this warranty.

CONTACT US

E-mail: sales@gatexpertstore.com

Please fill in the order information in the form below.

All personal information you provided will be only used for warranty service

and kept strictly confidential.

Refer to this list when contacting GATEXPERT for technical service or

assistance with your automatic gate opener.

Order Number

Product Model

Purchase Date

Country / Region

Email Address

Issue Details

Table of Contents:

1. Product Outline………………………………………………………………………………..1

2. Functions and Features………………………………………………………………………1

3. Technical Parameter List……………………………………………………...……………..2

4. Machine Components………..….…..……………………………………………………….3

5. Installation Direction................………………………………………………………………3

6. Assembly and Installation……………………………………………………………………4

6.1. Pre-Installation Check……………………………………………………………………..4

6.2. Basic Structure Installation………………………………………………………...……..4

6.3. Boom Balance Adjustment………………………………………………………………..6

6.4. Mains Wiring…………………………………………………………….………………….7

6.5. Electrify Check………………..……………………………………………………..….....7

6.6. Vertical Adjustment of Barrier Boom ………………………….……………...………....8

6.7. Manually Open/Close………………………………………………………………….….8

6.8. Spring Configuration……………………………………………………………………..10

7. Control Board Wiring……………………………………………………………….……….11

7.1 Terminal Instruction……………………………………………………………………….12

7.2 Setting Button Instruction…………………………………...……………………………13

7.3 Parameter Setting......……………………………………………………………………13

8. Technical Support………………………………………………………...…………………15

9. Packing List…………………………………………………………………………………..16

10.Terms of Service……………………………………………………………...………….….17

1

1. Product Outline

On the basis of absorbing essence of similar products at home and abroad, the company

has researched and developed this BC series DC brushless barrier gate. This product

adopts international advanced technology, with mechanical and electrical integrated

design, which fully realizes automation and intelligence of operating, brings convenience、

safety and speed for using.

2. Functions and Features

Efficient DC brushless motor and precise gear reducer drive with mechanical and

electrical control integrated. More flexible and convenient operation, safe and

reliable for using, completely maintenance free during its service time.

Adopts precise four-bar linkage mechanism and spring balance device which enable

the barrier boom work with soft start-slow stop function in fast and stable without any

impact. Reduces the driving power in maximum, extends its service life.

Integrated machine core, small size with large power, wall-mounted installation, easy

for assembling and disassembling.

DC 24V low voltage brushless motor, adapts to global voltage (110~220±15%). It

highlights for safer use, less noise, low heat output, frequently use, energy

conservation and environmental protection.

The combination of motor hall encoder and control unit ensures the control to

mechanism moving position at the utmost.

The dedicated controller system has high integration and strong logic performance. It

can be connected with any toll system of roads and bridges、parking lots and so on.

Intelligent speed adjustment efficiently reduces the trembling of the barrier boom,

suitable for different occasions.

High-sensitivity Auto-reverse function will prevent incorrect operation and other crash

or hitting accidents.

2

Open first anti-smash function: barrier boom will perform opening action once received

an opening signal during the closing process.

Humanized anti-collision boom dropping-out mechanism, when the vehicle

accidentally hits the barrier boom, the anti-collision mechanism will rotate the boom

to avoid damage to the vehicle and the barrier gate.

High-strength precision cast steel machine case, with outdoor metal powder

electrostatic spraying surface treatment, waterproof and dustproof, protection class

up to IP54.

3. Technical Parameter List

Barrier Model

BC3015

BC4020

BC5035

BC6050

Boom Length

Round boom

φ75, ≤3m;

Octagonal boom

80×46, ≤3m

Round boom

φ75, ≤4m;

Octagonal boom

80×46, ≤4m

Octagonal

boom 100×45,

≤5m

Octagonal

boom

100×45, ≤6m

Open/Close Speed

1.5 sec

2.0 sec

3.5 sec

5.0 sec

Transmission Ratio

1:60

1:120

Max. Power

140w

Power Supply

AC110-240V±15%

Machine Case

1.5mm Steel Plate

Machine Case Size

(W×D×H)

350 × 320 × 1020mm

Net Weight

45kg

Operating Temperature

Range

-40~+60 ℃(temperature under -20℃should be equipped with

electric heating plate)

Driving Method

Brushless DC motor + Helical gear reducer

IP Grade

54

Insulation Class

F

Relative Humidity

≤ 85%

Motor Unload Speed

2400r/min

Service Life

5 million times

Remote Control Distance

≤ 30m (empty environment, sunny weather)

Running Noise

<50dB

Surface Treatment

Outdoor metal powder electrostatic spraying

3

4. Machine Components

1

2

3

4

5678 9

1010

1111

1

2

3

4

5

6

7

8

9

1010

MotorMotor

LinkLink rodrod

CrankCrank armarm

RockerRocker springspring armarm

SpringSpring

SpringSpring rod(upper)rod(upper)

ReductionReduction gearboxgearbox

OutputOutput shaftshaft

BoomBoom traytray headhead

BoomBoom

Figure 1

5. Installation Direction

Leftward Fixed Rightward Fixed

Figure 2

4

6. Assembly and Installation

6.1 Pre-Installation Check

Note:

Barrier gate installation must be carried out by qualified technician; Installation must

comply with relevant regulations. Before installation, please read this instruction manual

carefully.

Please definite the installation direction of the barrier gate to be Leftward or Rightward

fixed.

Please make sure that the boom will operate freely without any impediment.

Please make sure the mounting base is strong enough and the size is suitable.

Please make sure the installation spots for all the relative equipment are suitable to

avoid any collision.

Please check the accessories according to the packing list (page 16)

6.2 Basic Structure Installation

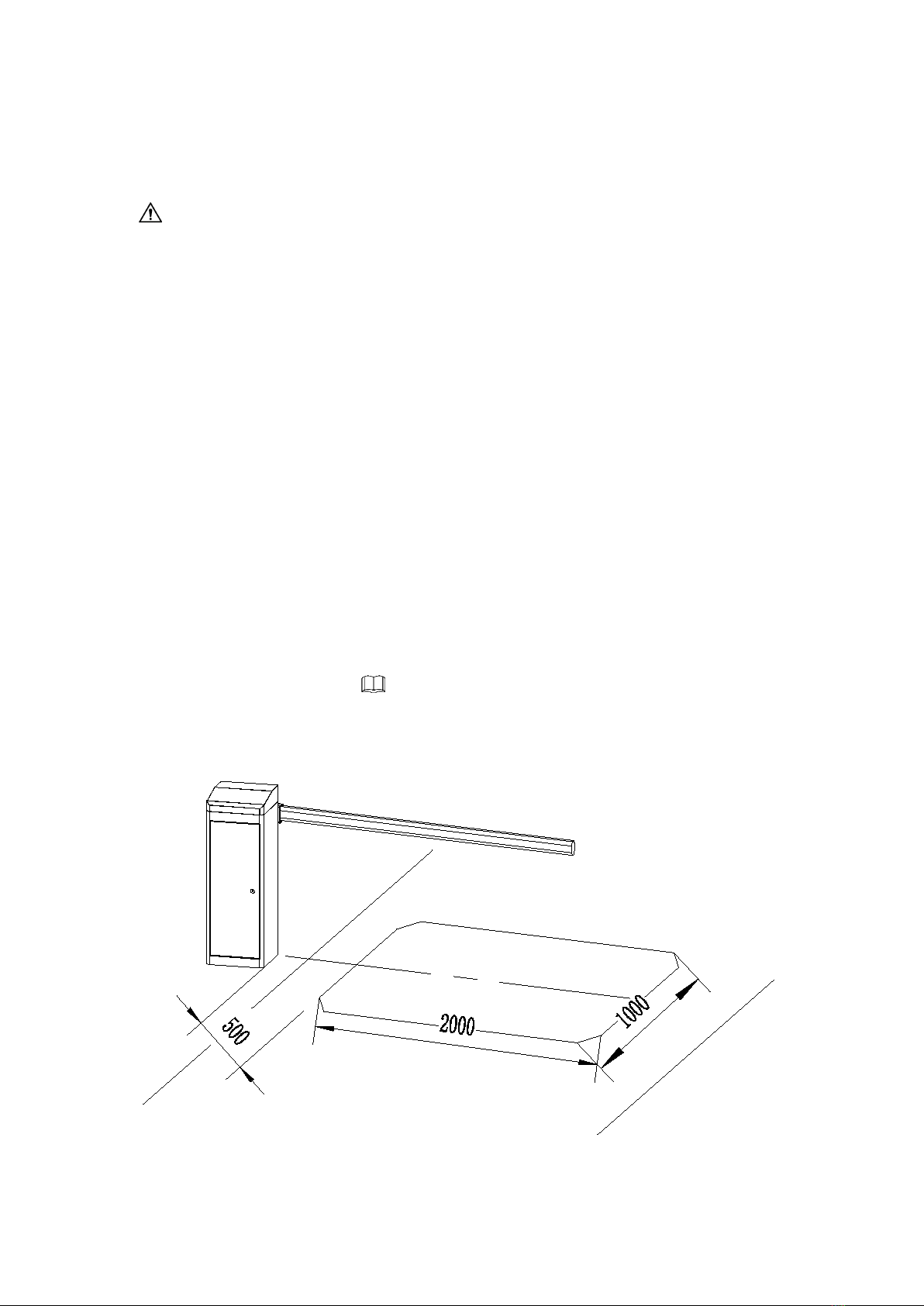

Coil Installation Instruction :

Position of the induction coil: The general size of induction coil size is 2m(L) x 1m(W), its

central axis should be right under the barrier boom, please refer to the figure 3.

Figure 3

5

Fastening Screws Installation Instruction :

If the installation site didn’t set with a foundation, then please make sure that the

installation ground is strong enough to be fix with the barrier gate. Drill holes for fastening

screws with diameter of 16mm, depth of 80mm, drive the M12 x 150mm fastening screw

into the hole, then tighten the nut before withdrawing it.

If the installation site is concreted with foundation, please make sure the foundation depth

is over 500mm, and the foundation area is over 450 x 450mm. Please pre-buy 3pcs PVC

wiring tubes with diameter of 25mm: 1 for induction coil wiring, which should be led

towards roadside and should be 50mm underneath the ground. The other 2 tubes are for

power supply and control unit wiring. Meanwhile, users can embed 4pcs M12 foundation

screws and leave 70mm of the screw thread over the ground, keep a distance of 170 x

170mm; Or users can drill the hole after the foundation hardening, and use the equipped

expansion bolts to finalize the installation, please refer to Figure 4.

Barrier Gate Installation Instruction :

Put the barrier gate in the right place (Keep the boom dropping-out and vehicle passing on

the same direction), make sure the barrier gate is vertical to the ground, align the press

board to the anchor bolts, lock and fasten them.

Barrier Boom Installation Instruction :

Place the barrier boom into boom tray, add plastic gasket on both sides, use the spanner

to clamp the boom by screws nuts. Please refer to Figure 5.

170

170

450

450

500

50

Figure 4 Figure 5

6

6.3 Boom Balance Adjustment

The tension of the spring is related to the boom length, the spring has been assembled in

the factory according to the different boom length, also the relative adjustments on

operating speed 、operating balance during opening/closing process has been set up

before delivery. Spring tense must be re-adjusted by professionals if there were any

changes on the boom length or weight. Please check and adjust according to the following

steps.

1. Open the barrier gate side door and remove the upper cover.

2. Unplug the power cord.

3. Toggle the crank from the side door to unlock it(refer to column 6.7), manually adjust the

boom to the place of 45 degrees then release the hand. If the boom keeps stable on the

place of 45 degrees’ angle, indicating that it is with the best spring force.

4. If the spring force is too large or too small, then should be adjusted. First, loosen the

nut on the top of the spring, clockwise rotating the screw to increase the tension of the

spring, counter-clockwise to decrease, then adjust the barrier boom again to its 45

degrees’ angle position to check the spring tension.

5. Through repeating the above forth step to adjust the boom to its best balance, then

fasten the double nuts, adjustment is complete.

ScrewScrew

NutNut

PressPress downdown toto unlockunlock

PressPress downdown toto unlockunlock

Figure 6

7

USE USE LED1

AC BATTERY

POWER SELECT

SW1

24V+

+ 24V -

CON2

P3

Connect to

Control Unit

L N PE

AC INPUT

ON

OFF

I

O

SW1

switch to USE AC

+ -

24V OUTPUT

POWER

AC100-240

INPUT

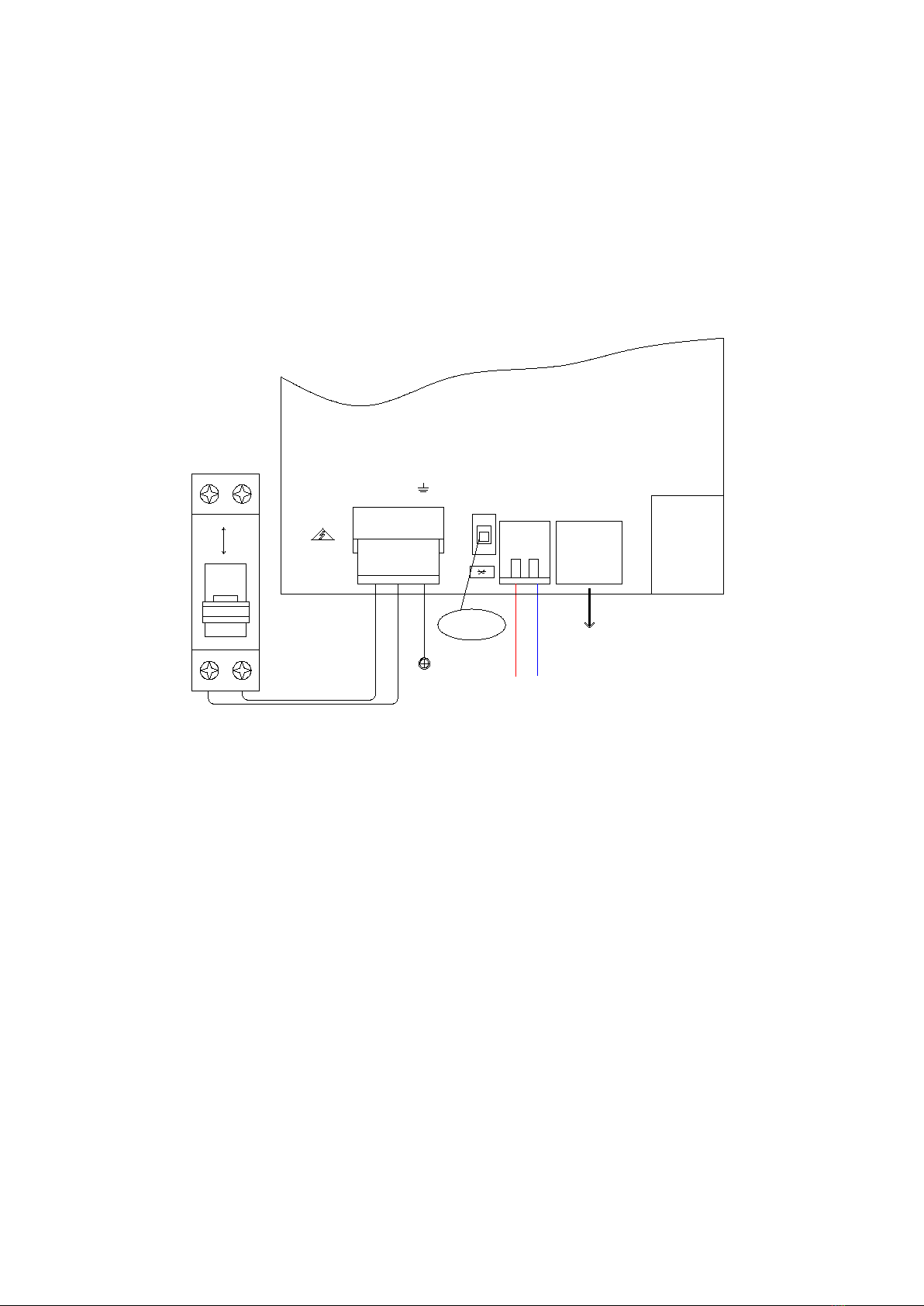

6.4 Mains Wiring

The power module of the barrier gate has been connected to the control board before

delivery. To ensure operational safety and avoid damage to the components, please

disconnect the circuit breaker first, and then connect the L and N of AC power into the

input port of circuit breaker.

Figure 7

Note: Only professional technicians can engage in the installation and after sales

maintenance for this product and are responsible for any damage caused by

improper operation.

6.5 Electrify Check

Please close the circuit breaker to connect the power after correctly wired. The indicator

light on the control board will be on once the power is connected; After powering on,

please press the open/+ and close/- buttons on the remote control, barrier gate will

automatically detect the opening/closing limit switch (both limit switches are required to be

detected). After detecting the opening/closing limit switch, the auto-detecting data will be

saved automatically, after which, the barrier gate will work properly.

8

6.6 Vertical Adjustment of Barrier Boom

If the barrier gate boom cannot open to its vertical position or close to its horizontal

position. Please take the following steps to adjust it:

1. Open the barrier gate door, unplug the power cord.

2. Open and remove the upper cover.

3. Loosen the two fasten screws on rocker spring arm when the barrier boom is in erect.

Adjust the boom to its horizontal position by hand. Use the torque wrench to tighten the

two fastening screws (locking force is 72 N·m)

4. Connect the power to work, check whether the boom opens/closes in place. If not,

please re-adjust it after power off until the performance achieving the ideal state.

ScrewScrew

Figure 8

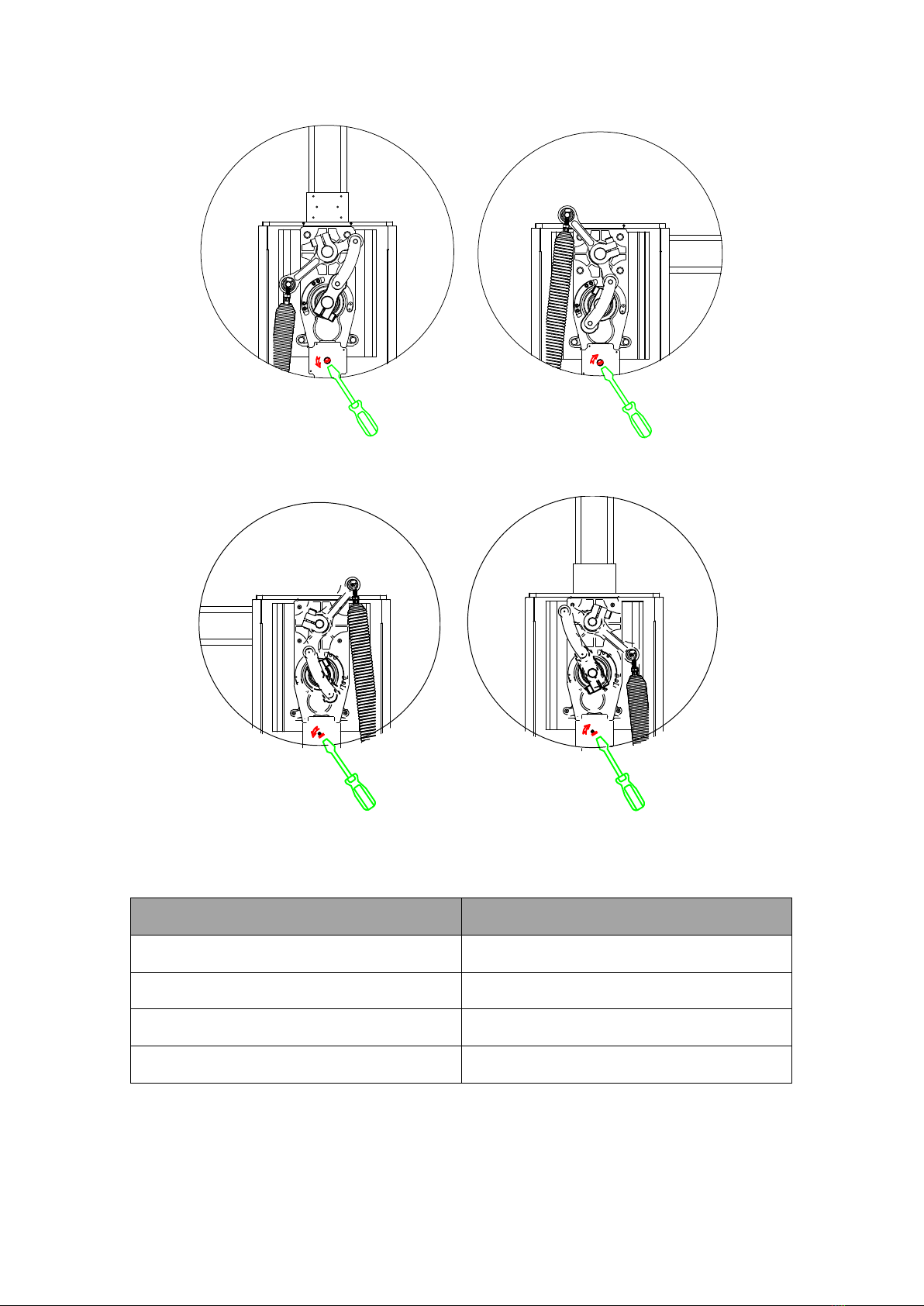

6.7 Manually Open/Close

The barrier boom may stay in the vertical or horizontal position when power is off, by this

time the barrier gate mechanism is on its self-locking position. If you need to open/close

the barrier by hand at this time, please follow the steps as below:

1. Open the barrier gate door.

2. Unplug the power cord.

3. For Leftward fixed type:

To close when boom in opened position, please counter-clockwise rotate the motor shaft

9

with a specific tool to enable the barrier boom to move, after which barrier boom can be

manually pressed down for closing.

To open when boom in closed position, please clockwise rotate the motor shaft with a

specific tool to enable the barrier boom to move, after which barrier boom can be manually

lifted up for opening. Please refer to Figure 9.

4. For Rightward fixed type:

To close when boom in opened position, please counter-clockwise rotate the motor shaft

with a specific tool to enable the barrier boom to move, after which barrier boom can be

manually pressed down for closing.

To open when boom in closed position, please clockwise rotate the motor shaft with a

specific tool to enable the barrier boom to move, after which barrier boom can be manually

lifted up for opening. Please refer to Figure 10.

Note: Please stabilize the boom when manually open it, in order to avoid any

unnecessary damage caused by the spring tension.

10

Figure 9

Figure 10

6.8 Spring Configuration

Boom Length

Spring

3M Octagonal Boom 80x46 mm

Φ4.5x1pc

4M Octagonal Boom 80x46 mm

Φ5.5x1pc

5M Octagonal Boom 100x45 mm

φ4.5 x1pc; φ5.5 x1pc

6M Octagonal Boom 100x45 mm

φ5.5x2pcs

Note: If the boom length is shorter than 4m, it’s recommended to use 80x46mm

octagonal boom, if length is longer than 4m, to use 100x45mm octagonal boom.

11

7. Control Board Wiring

Figure 11

Warning!

The controller of this product is specially designed for the use of low speed and medium

speed barrier gates. The position of the barrier boom will be continuously detected by the

motor hall during running, which replaces the limit switches used in conventional barrier

control systems.

12

The combination of the hall encoder and the controller unit ensures the maximum control

to the boom optimum running position.

Note!

For other special functions, please note that the controller's wiring may differ from which

shown in this wiring illustration.

Important Note:

All input signals (like push buttons, limit switches, etc.) must be connected in the volt-free

contact way.

7.1 Terminal Instruction

Motor Terminal: Insert an 8 ends motor cable terminal;

Power Terminal: Insert a 2 ends power cable terminal;

Light Sensor Terminal: Insert a 2 ends light sensor terminal;

External Remote Terminal: Insert a 3 ends external antenna terminal;

12V+/GND Terminal: Output +12V, maximum output current is 1A;

NA Terminal: Extended terminal;

Open in Place: When the barrier boom is open in place, the 2 terminals will be NC;

Closed in Place: When the barrier boom is closed in place, the 2 terminals will be NC;

OPEN: OPEN signal input terminal (another end connects with +12V terminal);

CLOSE: CLOSE signal input terminal (another end connects to +12V terminal);

STOP: Halfway stop during opening or closing signal input terminal (another end

connects to +12V terminal);

Radar/Loop Detector: Connect with radar or vehicle detector;

Obstacle Detector: Connect with vehicle detection coil only.

LED Display Instruction :

Display

Instruction

IDLE

Not connect to the machine, or hall sensor failure.

Possible reason: wiring loose.

STOP

Closed in place

CLOS

Barrier gate in closing

13

OPEN

Barrier gate in opening

HOLD

Open in place

LOCK

Barrier gate locked

7.2 Setting Button Instruction

There are 4 buttons on the control board for setting all the parameters: open/+, close/-,

menu/confirm, stop/cancel.

Open/+: Under normal working mode, press this button, barrier will open. While control

board in setting mode, pressing this this button will increase the value, press and hold this

button, the value will be increased to the max. then start over again from the bottom value.

Close/-: Under normal working mode, press this button, barrier will close. While control

board in setting mode, pressing this this button will decrease the value, press and hold

this button, the value will be decreased to the minimum. then start over again from the top

value.

☰/OK: There are 3 functions on this button:

1. Under normal working mode, press and hold this button for 3 sec. to enter into menu

selection, LED will display “F-XX”, press “+” or “-” to select the menu you are going to set.

2. Under menu selection status, short press this button will enter into parameter setting.

3. Save the setting after parameter confirmed.

□/CL: Under normal working mode, press this button, barrier will stop; Under parameter

setting status, pressing this button will return to previous menu.

7.3 Parameter Setting

Press and hold “menu” button on the control board for 3 sec. to enter into parameter

setting mode, the LED will display “F-XX”. Short press “+” or “-” button to select the

corresponding menu, press “menu” to enter into the setting, press “stop/cancel” button to

return to previous menu or exit the setting. After finished the setting, press “menu” to

complete. The system will exit the setting mode after 60 sec. without setting action.

Menu

Function

Default

Value

Range

Mark

F-00

Open speed

60

10-100

The larger the number is, the

14

faster the speed will be.

F-01

Close speed

60

10-100

The larger the number is, the

faster the speed will be.

F-02

Slow open position

70

45-80

The position that barrier starts to

run at a slower speed during

opening. Unit: degrees

F-03

Slow close position

45

10-60

The position that barrier starts to

run at a slower speed during

closing. Unit: degrees

F-04

Open acceleration

time

30

0-255

Acceleration time from 0 to F-00

during opening. Unit: 0.01 sec.

F-05

Close acceleration

time

30

0-255

Acceleration time from 0 to F-00

during closing. Unit: 0.01 sec.

F-06

Open in place speed

10

1-100

F-07

Close in place speed

20

1-100

F-08

Horizontal position

adjustment

6

1-255

Slightly adjustment on barrier

boom horizontal position.

F-09

Vertical position

adjustment

6

1-255

Slightly adjustment on barrier

boom vertical position.

F-10

Automatic close time

without loop detector

0

0-255

Automatic closing time for no car

passes.

Unit: sec.

F-11

Obstacle Detection

0

0-1

1:Enable 0:Disable

F-12

Delay time of closing

after vehicle passed

2

0-255

Unit:0.1 sec.

F-13

Travel auto-learn

speed

40

0-80

Barrier will run at this speed to set

the open and closed limit switch.

F-14

Remote control

pairing

0

0-60

F-15

Auto-reverse

response time after

meeting obstacle

10

1-40

Response time when meeting

obstacles. Unit: 0.05 sec.

F-16

Obstacle detection

sensitivity

10

1-40

The larger the number is, the less

the sensitivity will be.

F-17

Motor direction

0

0-3

Motor polarity and rotating

direction.

F-18

Locked current

6

0-15

Danger, set it with caution! The

larger the number is, the larger the

locked current will be.

F-19

Loop detector count

0

0-10

No counting for loop detector by

default.

F-20

Auto-testing

0

0-255

Automatic testing interval,this can

15

be used for burn-in test. 0 means

the normal working mode.

F-21

Restore factory

setting

0

0-255

5:Delete all remote controls 10:

Restore factory setting

F-28

Slow close angle

30

0-45

The angle that barrier starts to run

at a slower speed during closing.

Unit: degrees

F-29

Relay output mode

0

0-5

For different relay type

F-38

Slow open angle

90

45-100

The angle that barrier starts to run

at a slower speed during opening.

Unit: degrees

F-69

Remote control mode

0

0-1

0: Remote control in three-button

mode

1: Remote control in single-button

mode

8. Technical Support

The control unit comes with an error code display feature that allows the user to determine

the errors. For details, please refer to the following instruction of each error code.

Error Code

Cause

E-00

While operating the remotes deletion or restore factory setting,

should set the correct value.

Incorrect value will feedback this error.

E-03

Opening blocked. Possible reason: the balance spring is broken or

opening speed is too slow or open in place speed is too slow.

Solution: increase the opening speed or open in place speed.

E-04

Closing blocked. Possible reason:spring tension is too tight, boom

not fixed, closing speed or closed in place speed is too slow.

Solution: to check the spring tension, confirm boom is fixed,

increase the closing speed and closed in place speed.

E-05

Opening overtime, opening time should be in 15 sec.

Solution: to increase the opening speed or open in place speed.

E-06

Closing overtime, closing time should be in 15 sec.

Solution: to increase the closing speed or closed in place speed.

E-07

Motor type wrongly selected.

Solution: set under menu F-17 to modify to correct type.

E-08

During opening, the spring is broken and caused the motor reverse.

E-09

The remote control has been paired before, no need to pair again.

E-10

Pairing of remote control exceeds the maximum quantity.

16

If there is any operation failure that can ’t be handled by your technical staff, please

contact our authorized service representative or professional assistance.

Please provide the barrier gate model, product serial number, controller version and other

information when contact us for technical support services, which you can find in the

barrier gate machine case model plate.

9. Packing List

Number

Title

Qty

Picture

Note

1

Barrier gate machine

1

Included in machine

package

2

Machine case press

board

2

3

Expansion bolt M12

4

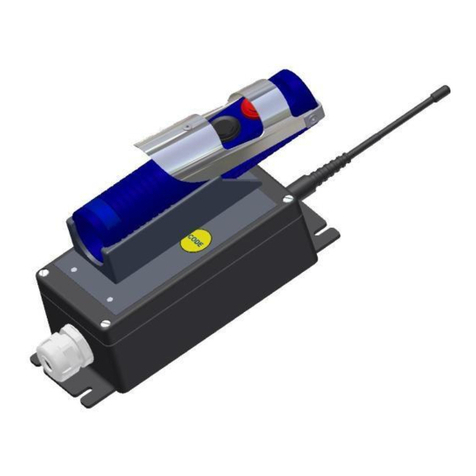

4

Remote control

2

5

Case Key

2

6

Instruction

1

7

Unlock tool

1

8

Barrier gate boom

1

Optional, separate

package

9

Boom holder

1

Optional

10

Expansion bolt M8

4

Optional, for fixing

boom holder

11

Plug-in Machine control

1

Optional

This manual suits for next models

4

Table of contents

Popular Control System manuals by other brands

Contro l4

Contro l4 Control4 Smart Home quick start guide

GSM Activate

GSM Activate GSM Auto Dialler Plus manual

Almaco

Almaco Seed Spector LRX Operator's manual

HySecurity

HySecurity WedgeSmart DCS installation instructions

SITGroup

SITGroup Proflame instruction manual

HIK VISION

HIK VISION DS-K3B530X Series user manual