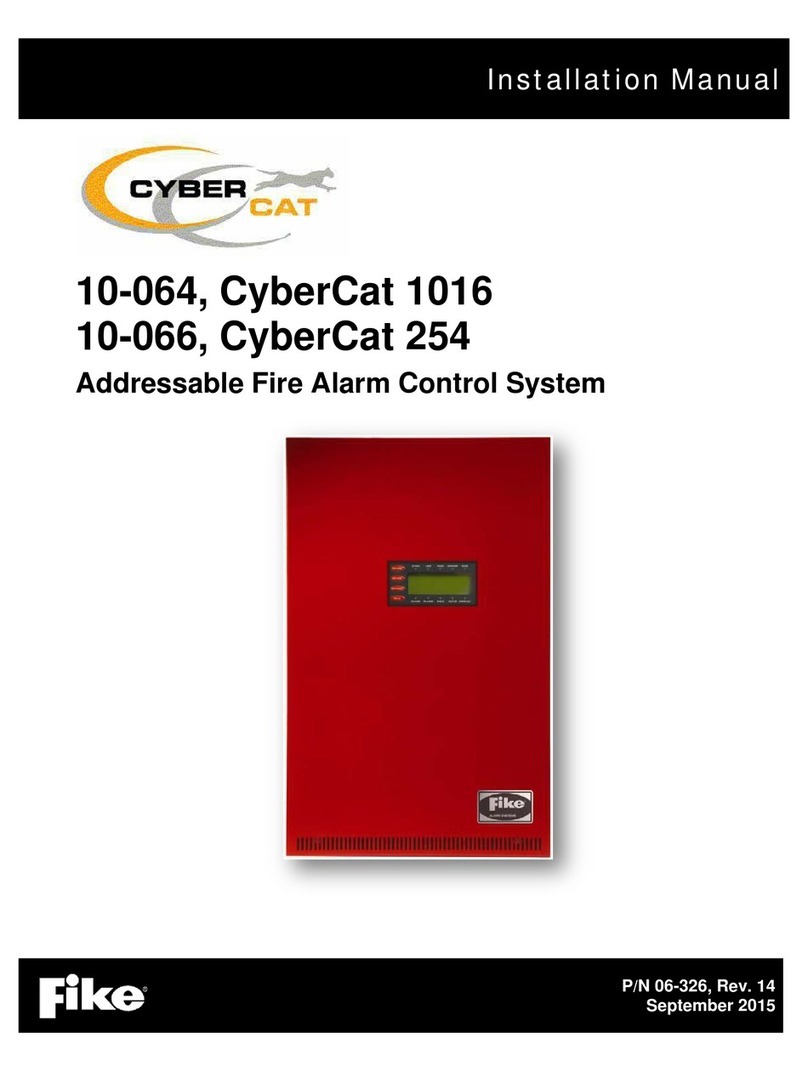

Fike Epaco User manual

User’s Manual

P/N E06-091, Rev. 0

January 2010

EXPLOSION PROTECTION (ACTIVE) CONTROL SYSTEM

DEVELOPED BY Fike

704 SW 10th Street

P.O. Box 610

Blue Springs, Missouri 64013 U.S.A.

Phone: (888) 628-FIKE (3453)

(816) 229-3405

Fax: (866) 211-9239

COPYRIGHT NOTICE Copyright 2010, All rights reserved.

Fike copyrights this manual and products it describes. You may not reproduce,

transmit, transcribe, or any part of this manual without express, written

permission from Fike.

This manual contains proprietary information intended for distribution to

authorized persons or companies for the sole purpose of conducting business

with Fike. If you distribute any information contained in this manual to

unauthorized persons, you have violated all distributor agreements and we may

take legal action.

TRADEMARKS Fikeis a registered trademark of Fike.

QUALITY Fike has maintained ISO 9001 certification since 1996. Prior to shipment, we

thoroughly test our products and review our documentation to assure the highest

quality in all respects.

WARRANTY Fike provides a one-year limited manufacturer’s warranty on this product. All

warranty returns must be returned from an authorized Fike Distributor. Contact

Fike’s Marketing department for further warranty information.

Fike maintains a repair department that is available to repair and return existing

electronic components or exchange/purchase previously repaired inventory

component (advance replacement). All returns must be approved prior to return.

A Material Return Authorization (MRA) number must be indicated on the box of

the item being returned. Contact the appropriate Regional Sales Manager for

further information regarding product return procedures.

LIMITATIONS OF LIABILITY Installation in accordance with this manual, applicable codes, and the

instructions of the Authority Having Jurisdiction is mandatory. Fike can not be

held liable for any incidental or consequential damages arising from the loss of

property or other damages or losses resulting from the use or misuse of Fike

products beyond the cost of repair or replacement of any defective components.

Fike reserves the right to make product improvements and change product

specifications at any time.

While every precaution has been taken during the preparation of this manual to

ensure the accuracy of its content, Fike assumes no responsibility for errors or

omissions.

EPACO USER’S MANUAL

Revision Date: January, 2010 P/N E06-091 (Rev 0)

REVISION HISTORY

Document Name: EPACO USER’S MANUAL

Original Release Date:..................................................................................................................January, 2010

Revision / Description of Change Revision Date

EPACO USER’S MANUAL

P/N E06-091 (Rev 0) Revision Date: January, 2010

TABLE OF CONTENTS

SECTION PAGE NO.

1.0 INTRODUCTION.......................................................................................................................................... 1

1.1 PRODUCT SUPPORT ................................................................................................................................. 1

1.2 SAFETY INFORMATION ............................................................................................................................. 1

1.3 RELATED DOCUMENTATION .................................................................................................................... 2

2.0 EPACO™ SYSTEM OVERVIEW................................................................................................................. 3

2.1 EXPLOSION PROTECTION CONTROLLER.............................................................................................. 4

2.1.1 OPERATION.............................................................................................................................................. 5

2.1.2 EPC DIAGNOSTICS ................................................................................................................................. 6

2.1.3 EPC SPECIFICATIONS ............................................................................................................................ 7

2.2 POWER SUPPLY UNIT ............................................................................................................................... 8

2.2.1 OPERATION.............................................................................................................................................. 8

2.2.2 PSU DIAGNOSTICS ................................................................................................................................. 9

2.2.3 PSU SPECIFICATIONS .......................................................................................................................... 10

2.2.4 PSU VOLTAGE CHART.......................................................................................................................... 11

2.3 ANNUNCIATOR MODULE........................................................................................................................ 12

2.3.1 OPERATION............................................................................................................................................ 12

2.3.2 AM SPECIFICATIONS ............................................................................................................................ 14

2.4 RELAY CARD MODULE ........................................................................................................................... 15

2.4.1 OPERATION............................................................................................................................................ 15

2.4.2 RC8 LED DIAGNOSTICS........................................................................................................................ 15

2.4.4 RC8 SPECIFICATIONS .......................................................................................................................... 16

3.0 MAINTENANCE......................................................................................................................................... 17

3.1 ROUTINE INSPECTION ............................................................................................................................ 17

4.0 DECOMMISSIONING PROCEDURE....................................................................................................... 18

APPENDIX A-RC8 MODULE STATUS CODES.............................................................................................. 19

APPENDIX B–ANNUNCIATOR MODULE DISPLAY HISTORY CODES........................................................ 24

APPENDIX C-PRESSURE CORRELATION CHART ...................................................................................... 25

EPACO USER’S MANUAL

Revision Date: January, 2010 P/N E06-091 (Rev 0) Page: 1

1.0 INTRODUCTION

This manual is intended for those individuals who are responsible for the interfacing with Fike’s EPACO

explosion protection system. The first-time operator should thoroughly read and understand the instructions

contained within this manual before interfacing with the EPACO system components.

1.1 PRODUCT SUPPORT

If you have any questions or encounter a problem not covered in this manual, you should first try to contact

the Fike Explosion Protection distributor that installed the system as noted below.

For technical support, please contact:

Company Name: _________________________________________

Phone Number: _________________________________________

Fax Number: _________________________________________

E-Mail Address: _________________________________________

If you can not locate the distributor, please call Fike Customer Service using the numbers indicated bellow for

assistance in locating your nearest distributor, or go to our web-site at www.fike.com.

Fike Blue Springs, USA

Phone: +1-816-229-3405

+1-800-979-FIKE (3453)

Option 23 Explosion Protection Support

Fax: +1-816-229-0314

Or

Fike Europe

Phone: +32-14-21-00-31

Fax: +32-14-21-07-43

1.2 SAFETY INFORMATION

Important safety admonishments are used throughout this manual to warn of possible hazards to persons or

equipment.

aWARNING

Warnings are used to indicate the presence of a hazard

which will or may cause personal injury or death, or loss of

service if safety instructions are not followed or if the hazard

is not avoided.

ICaution

Cautions are used to indicate the presence of a hazard

which will or may case damage to the equipment if safety

instructions are not followed or if the hazard is not avoided.

LNotes: Notes indicate the message is important, but is not

of a Warning or Caution category. These notes can be of

great benefit to the user and should be read.

EPACO USER’S MANUAL

Page: 2 P/N E06-091 (Rev 0) Revision Date: January, 2010

1.3 RELATED DOCUMENTATION

Document Title Part Number

EPACO System, Explosion Protection Controller (EPC) Installation and Operation Manual E06-051

EPACO System, Explosion Protection Controller (EPC) Solenoid Installation and Operation

Manual E06-090

EPACO System, Power Supply Unit (PSU) Installation and Operation Manual E06-052

EPACO System, Annunciator Module (AM) Installation and Operation Manual E06-053

EPACO System, Relay Card (RC8) Installation and Operation Manual E06-054

EPACO USER’S MANUAL

Revision Date: January, 2010 P/N E06-091 (Rev 0) Page: 3

2.0 EPACO™ SYSTEM OVERVIEW

The EPACOexplosion detection and control system is comprised of explosion detectors, control unit (EPC),

power supply unit (PSU), optional annunciator module (AM) and relay cards (RC8). EPACOcombines the

latest in addressable technology with simplicity of installation and maintenance. All system modules are DIN

rail mounted to allow for a variety of installation options. Three (3) bus type communication circuits tie the

various system modules into one easy to operate protection system. A non-volatile history buffer allows for

enhanced diagnostic ability to troubleshoot process situations. The optional Annunciator Module (AM), the

customer has the ability to step through a menu format to retrieve process history without having to wait for a

service agency to arrive on site.

EPACOis designed to detect and control any of Fike’s Active explosion suppression and isolation systems;

which range from chemical suppression, mechanical isolation (gate and pinch valve), chemical isolation or

any combination thereof. Detection is achieved by either pressure and/or flame radiation detectors designed

to sense the incipient explosion and trigger the explosion suppression and/or isolation systems.

EPACO System Block Diagram

2A2A2A2A2A2A

RC8 AMEPC-3 EPC-4EPC-1 EPC-2

24VDC

VOLTAGE

25VAC

OUTPUT

DB9

24VDC

DB9

ADD

2A

2

4

1

3

24VDC

6

DB9

5

ADD MODE

78

2A

1

2

34

- 2A -

DB9

ADD MODE

24VDC

2A

R

EIGHT (8) PROGRAMMABLE RELAYS

NEMA ENCLOSURE

ALARM RELAY

TROUBLE/SUPERVISORY RELAY

SERIES FIRING CIRCUIT UP

TO (6) RELEASING DEVICES

CHEMICAL

ISOLATION MECHANICAL

ISOLATION

SUPPRESSION

CONTAINER

GATE VALVE

DETECTION

CIRCUIT #2

DETECTION

CIRCUIT #1

SYSTEM DISABLE INPUT

SUPERVISORY INPUT

CONTACT CLOSURE INPUT

OR DETECTION CIRCUIT #3

XFMR

BATTERY BATTERY

NOTES:

1. MAXIMUM OF FOUR (4) EPC'S PER EPACO

SYSTEM. EACH CAPABLE OF SUPPORTING TWO

4-20 mA DETECTORS.

2. CAPABLE OF SUPPLYING POWER TO FOUR (4)

RELAY CARDS, FOUR (4) EPC CONTROLLERS AND

ONE (1) ANNUNCIATOR MODULE.

3. CAPABLE OF SUPPORTING FOUR (4) RELAY

CARDS, FOUR (4) EPC CONTROLLERS AND ONE

(1) POWER SUPPLY UNIT.

4. MAXIMUM OF FOUR (4) RELAY CARDS PER

ANNUNCIATOR MODULE.

EPACO USER’S MANUAL

Page: 4 P/N E06-091 (Rev 0) Release Date: January, 2010

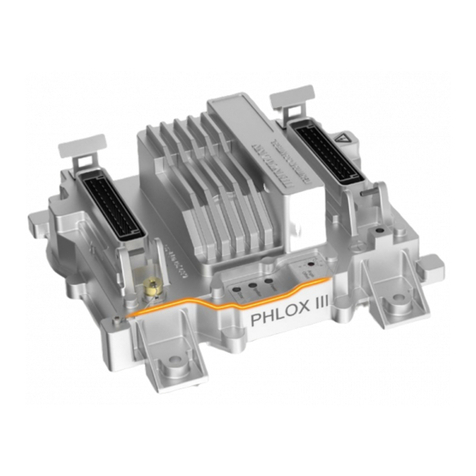

2.1 EXPLOSION PROTECTION CONTROLLER

The Explosion Protection Controller (EPC) is the cornerstone of

the EPACOsystem. The EPC is an addressable panel that has

the ability to retain an event history for enhanced system

diagnostics. The EPC is DIN rail mounted which allows mounting

of the controller in close proximity to the protected environment,

thereby minimizing field wiring. Shorter wire runs greatly reduce

the interference from electrical and radio frequency sources,

allowing for a much more reliable protection system.

The EPC’s detection inputs can be programmed for pressure

warning, threshold detection, and rate of rise detection. It also

has a contact closure detection circuit to support thermal, infrared,

or other switch-closure type detection devices. A supervisory

input circuit is provided to monitor suppression container pressure

or other similar system status safeguards. The EPC has a remote

disable input contact to allow for disabling the EPC from a

customer PLC or other remote device during product loading,

cleaning, or maintenance. An RS232 connection is available at

each module for connection to a PC. Using the EP WorksTM

software, an authorized user can access system diagnostics and

perform complex programming by PC.

The following tasks are accomplished by the EPC:

Monitors all supervised circuits for wiring faults (Open, Short, or Activation)

Two detection circuits are monitored on a 250 micro second (0.25 msec) rate and examined for rate

of rise and threshold levels

When activation requirements are met by the detection circuit, it activates the series firing output

within 2 milli-seconds

Communicates system status to other EPC’s connected locally so that they can respond within 4 milli-

seconds

Communicates system status to Annunciators and Relay Control Modules for user interface

EPACO USER’S MANUAL

Release Date: January, 2010 P/N: E06-091 (Rev 0) Page: 5

2.1.1 OPERATION

The EPC is equipped with three (3) colored LEDs that provide instant visual indication of system status. EPC

operation can be classified into three main states: Normal, Trouble and Alarm. A general description of each

state is described below.

EPC Normal State

When power is applied to the EPC, it performs a 4 second initialization. At the

end of the initialization, the trouble LED blinks slow and the local piezo beeps in

long recurring sound. It can then enter the “NORMAL” state if the power is of an

appropriate voltage and there are no troubles or alarms. In the Normal State the

green Power LED is ‘ON’, the local piezo is ‘OFF’, the trouble and alarm relays

are energized. All other LED’s are ‘OFF’.

EPC Trouble State

A trouble occurs on the EPC if any one of the supervised circuits experiences a

wiring fault open or short condition, if the EPC configuration is invalid, if the

system is disabled, if a process pressure warning level is exceeded, or if the input

voltage drops below 18VDC. In the Trouble State the yellow Trouble LED is ‘ON’,

the local piezo is ‘ON’, and the P6 trouble relay is de-energized. Depending on

the cause of the trouble, the system may or may NOT be completely functional.

Each trouble should be investigated to determine the cause and promptly fixed.

Each trouble, except for remote disable, will latch at the EPC. If the trouble is

resolved, the EPC trouble can be cleared by disabling and re-enabling via the

remote disable input, by cycling of the power input to the EPC, or by disabling

and re-enabling the EPC via the Annunciator Module. If the remote disable is

active, the EPC will enter the trouble state. When the remote disable is returned

to normal, the EPC will automatically clear to the normal state, if no other troubles

are present, without cycling the power.

EPC Alarm State

When the detection circuits have exceeded the alarm conditions required by the

configuration, the EPC enters the Alarm State. In the Alarm State the red Alarm

LED is ‘ON’, the local piezo ‘ON’, the Alarm relay is de-energized, and the series

firing output is activated. The alarm state is latching. If the alarm is cleared, the

EPC requires cycling of the power input to clear the alarm.

Red

24VDC

Green

Yellow

EPACO USER’S MANUAL

Page: 6 P/N E06-091 (Rev 0) Release Date: January, 2010

2.1.2 EPC DIAGNOSTICS

In addition to the EPC’s three system status LEDs, an integral buzzer is provided to assist in diagnosing

problems with the system. The following table identifies how the LEDs and buzzer will operate in response to

expected system events.

Power

LED

on

on

on

on

on

on

on

on

on

on

on

on

on

Piezo

off

long-short

pulse

short-short

pulse

long

pulse

off

on not

latched

off

on

off

on

off

on not

latched

off

Trouble

LED

on

on

on

blink slow

off

on latched

on

on (1)

on

on

off

on latched

no change

Trouble

Relay

De-energized

De-energized

De-energized

De-energized

Energized

De-energized

latched

De-energized

De-energized

(1)

De-energized

De-energized

Energized

De-energized

latched

no change

Alarm Relay

De-energized

De-energized

De-energized

Energized

Energized

Energized

Energized

De-energized

Energized

Energized

Energized

Energized

no change

Alarm LED

off

slow blink

off

off

off

off

off

on

on

on

fast blink

off

off

Condition

Initial power up [first 4 seconds]

Power up in an alarm state

Invalid configuration or

Prevent restart after activation

Initializing [follows initial power up]

Normal State

Trouble State

Disabled State

Alarm State

Disabled State & alarm

Return to Armed from previous state

1st alarm in AND configuration

[cross zoned]

Warning pressure level

PC mode

(1) Trouble relay and LED following trouble condition on series firing output due to release action.

EPACO USER’S MANUAL

Release Date: January, 2010 P/N: E06-091 (Rev 0) Page: 7

2.1.3 EPC SPECIFICATIONS

Part Number: E10-0066

Input Power: 18 to 30 VDC; 300mA

Max. Noise Ripple: 500mV peak at 24 VDC

Fuse: 2A Mini Automotive Type

Lower Limit for Input Power

Shut-down: 16 VDC

Power Consumption: 275mA in Normal State

300mA in Trouble State

200mA in Alarm State

Terminal Block Capacity: 1.5 to 0.14 mm2(16 to 28 AWG)

Input Circuits:

4-20mA: Two detection circuits with maximum resistance of 30 Ω. Minimum 2x 0.5mm2(20 AWG)

twisted shielded pair cable with drain wire.

If the 4-20mA pressure detectors are placed in a hazardous atmosphere a Fike approved

transmitter power supply shall be used on each detection circuit.

Switch Closure: One detection circuit, 24 VDC at 0.10A with a maximum resistance of 30 Ω. Minimum 2 x

0.5 mm2(20 AWG) twisted shielded pair cable with drain wire, class A or class B wiring.

Supervisory Input: One switch closure 24 VDC at 0.10A with a maximum resistance of 30 Ω. Minimum 2 x 0.5

mm2(20 AWG) twisted shielded pair cable with drain wire, class B wiring.

Disable Input: One switch closure 24 VDC at 0.10A with a maximum resistance of 30 Ω. Minimum 2 x 0.5

mm2(20 AWG) twisted shielded pair cable with drain wire, class B wiring.

Series Firing Output Circuit: Voltage and current rating 50 VDC, 3.5A. Maximum loop resistance including actuator(s) is

10 Ω. Each actuator is typically 0.7 Ω. Minimum wire size 2 x 0.75 mm2(18 AWG).

Maximum number of actuators: Six (6).

iCAUTION

Do not measure the resistance of the actuator(s) with a meter. The

meter may provide a current that will activate the actuator.

Relay Output: One SPDT Form C for Trouble; One SPDT Form C for Alarm.

Both rated DC operation: 2 amps @ 30VDC (pf=0.35)

AC operation: 0.5 amps @ 250VAC (pf=0.35)

Fire Bus: Wire specification Alpha wire or RE-Y2Y or Belden 9841, maximum resistance of 50 Ω,

inductance L=100uH, capacitance C=0.02uF, maximum length 1,000 ft (300 m) total.

Status Bus: Wire specification Alpha wire or RE-Y2Y or Belden 9841, maximum resistance of 50 Ω,

inductance L=100uH, capacitance C=0.02uF, maximum length 1,000 ft (300 m) total.

Temperature Rating: -18°C to 60°C (0°F to 140°F). If EPC is located inside auxiliary housing, maximum

temperature is 43.3°C (110°F).

Humidity: 80% relative, maximum (non-condensing).

Size: 200 m L x 130 mm H x 60 mm D (7.7” L x 5.2” H x 2.3” D).

Weight: 0.68 kg (1.5 lbs.).

System Pressure Tolerance: 0.9% of transducer span, 600 mbar (8.7 psi), using the Ceramic pressure transducer, P/N

29945022-S, and EPC, P/N E10-0066, i.e. 5 mbar (0.08 psi).

Hazardous Area: The EPC is not rated for hazardous atmospheres. The EPC must be located in an auxiliary

housing that is rated for the hazardous atmosphere in which it is located.

For FM installations the EPC must be located in a non-hazardous atmosphere.

To maintain the systems ATEX Approval the housing shall be an ATEX approved housing

supplied by Fike.

Current Firmware Version: Can be verified using EPWorksSoftware.

EPACO USER’S MANUAL

Page: 8 P/N E06-091 (Rev 0) Release Date: January, 2010

2.2 POWER SUPPLY UNIT

The Power Supply Unit (PSU) is the primary power source for

the EPACOsystem. The PSU can operate with AC power

using selected transformers with 100V, 120V, or 240V 50/60Hz

input (ordered separately).

The PSU has six (6) separate fused 24 VDC, 1 amp power

output circuits capable of powering up to four EPCs in addition to

an Annunciator Module (AM) and four (4) Relay Card Modules

(RC8). Each output is protected with a 2 Amp fuse and

supervised for high and low voltage. Power to the Annunciator

Module can not be shut off; all other power circuits can be shut

off for service on the various system components.

The PSU has the flexibility of containing its own battery backup

supply or the customer has the option of supplying a backup

power source. The PSU has an imbedded power shutdown

procedure in the event of AC power failure, which prevents the

backup batteries from being completely depleted. The PSU may

be eliminated if battery backed, uninterrupted 24VDC, 2 amps

power can be provided by others.

The PSU is equipped with an internal cooling fan that is supervised for normal operation.

2.2.1 OPERATION

Startup

Upon startup, the AC power is measured for a normal level. If the AC power is too high or too low, the PSU is

held until a normal level is reached. The AC LED is updated accordingly. Once normal AC power is verified,

the output voltage is measured. Output voltage must be within normal boundaries to enable the PSU to

continue.

The PSU then detects if batteries are connected with an appropriate voltage level for battery backup

operation. When the battery level is found normal or low, the battery charging circuit is enabled. In cases

where the back-up battery voltage exceeds 29.5 VDC, the charging circuit is switched off and the battery will

not be switched in line with the output power.

The five switch-able output circuits are measured (while in the OFF state) through a supervision circuit to

determine the load connected to the lines. In case the load is too high, the corresponding output is left

disabled. If the load is found to be appropriate, the output circuit is switched ON to power up the connected

devices. The output lines are routinely measured for high loads or excessive voltages. The normal output

voltage must be between 18VDC and 30VDC.

The complete startup sequence typically is completed within 10 seconds; otherwise a problem has occurred

and should be resolved prior restarting the PSU

Normal Operation

After the startup sequence, normal operation is entered. During this operation, the AC and DC power LED’s

are both Green; the output voltage and trouble LED’s are OFF. This operation can only be stopped in case of

total shutdown of the PSU or when a PC is connected and PC mode becomes active. In this mode of

operation, AC power, output voltage, charge power, output lines and battery are continuously measured.

Upon meeting these systems’ parameters, the LED’s are updated and history is created. When the

parameters are not met, the trouble relay de-energizes and the trouble LED is lit.

EPACO USER’S MANUAL

Release Date: January, 2010 P/N: E06-091 (Rev 0) Page: 9

2.2.2 PSU DIAGNOSTICS

The PSU is equipped with four (4) diagnostic LEDs. The following table identifies how the LEDs will operate

in response to expected system events.

Status 25VAC Output Voltage 24VDC Battery Trouble

Normal Status GREEN GREEN GREEN OFF

Normal AC Power GREEN n/a n/a n/a

No AC Power OFF n/a n/a ON

Low AC Power RED n/a n/a ON

High AC Power RED BLINK n/a n/a ON

Normal Battery Power n/a n/a GREEN n/a

No Battery n/a n/a OFF ON

Battery off n/a n/a RED ON

Battery Shutdown n/a n/a RED ON

Battery Low n/a n/a GREEN BLINK ON

Battery High n/a n/a RED BLINK ON

Normal Charge Power n/a n/a n/a n/a

Charger Power Fail n/a n/a RED ON

Normal Output Power n/a GREEN n/a n/a

Low Output Power n/a GREEN BLINK n/a ON

High Output Power n/a RED n/a ON

Fan Trouble n/a n/a n/a BLINK

Ground Fault n/a n/a n/a ON

LNote: Trouble Relay is energized when Trouble LED is OFF, except when Trouble LED is blinking.

LNote: LED status for items marked “n/a” are not critical to defining that operation status.

EPACO USER’S MANUAL

Page: 10 P/N E06-091 (Rev 0) Release Date: January, 2010

2.2.3 PSU SPECIFICATIONS

PSU Part Number: E10-0067

Transformer Part Number: 02-10644 120/240VAC; 02-10879 100VAC

Transformer Input Power: 100/120/240VAC -15/+10% 50/60Hz , 2A maximum load

Power Consumption: Calculated with EPWorks™ Software

Input Terminal Block Capacity:

Output Terminal Block Capacity 3.3 to 0.14 mm2(12 to 28 AWG)

1.5 to 0.14 mm2(16 to 28 AWG)

Input Power: 24VAC at 0.043A no load; 13.0A max load, fused with 15A mini automotive blade type.

LNote: Transformer shall be mounted within 3 meters (10 feet) of PSU using

minimum 2.08mm2(14AWG) cabling.

Battery Back-up: 75 AH sealed lead-acid, fused at 15A mini automotive blade type

LNote: Size of sealed, lead-acid batteries required will depend on the number and

type of modules used. The designer shall perform a Power Calculation using the

EPWorksTM software or Annex A. Batteries shall be mounted within 3 meters (10

feet) of PSU using minimum 2.08 mm2(14AWG) cabling. Batteries require a

VENTED enclosure.

LNote: When replacing batteries use the same size, type and number. Proper

disposal of old batteries is required; refer to local codes.

PSU Output Power: 24VDC at 1A per output circuit fused with 2A mini automotive blade type. Total output

current from all output circuits 5 Amp max. for CSA approval.

PSU Relay Output: One SPDT Form C for Trouble

Rated DC operation: 2 amps @ 30VDC (pf=.35)

AC operation: 0.5 amps @ 250VAC (pf=.35)

Status Bus: Belden 9841 or RE-Y2Y cabling recommended. Maximum resistance: R=50 ohms,

inductance L=100uH, capacitance C=0.02uF, maximum length 300 m (1,000 ft) total.

Temperature Rating: -20°C to 60°C (0°F to 140°F)

Humidity: 80% relative, maximum (non-condensing)

Size: 210 mm L x 130 mm H x 70 mm D (8.2” L x 5.2” H x 2.9” D)

Weight: 1 kg (2 lbs.)

Hazardous Area: The PSU is not rated for hazardous atmospheres.

For FM or ATEX installations the PSU must be located in a non-hazardous atmosphere.

Current Firmware Version: Can be verified using EPWorks™ Software.

EPACO USER’S MANUAL

Release Date: January, 2010 P/N: E06-091 (Rev 0) Page: 11

2.2.4 PSU VOLTAGE CHART

MINIMUM TYPICAL MAXIMUM

AC Power Input

100V Transformer 85V 100V 110V

120V Transformer 102V 120V 132V

240V Transformer 204V 240V 264V

25VAC (P3) 21V 25V 30V

Battery Charge Power

Charge, P4 (V) 24V 27.6V 29V

Battery Backup

Battery Range 18V 27V 29.5V

Low Battery Trouble 24V

Battery Shut-down 18V

Battery Disconnect 17V

Output Power (single out)

Out (V) 18V 24V 30V

Out (A) 1A 2A

Output Power Overall 6A

EPACO USER’S MANUAL

Page: 12 P/N E06-091 (Rev 0) Release Date: January, 2010

2.3 ANNUNCIATOR MODULE

The Annunciator Module (AM) is the primary system status

indication point for the EPACOsystem. It provides a single

point for retrieving history as well as system status information

for all EPACOmodules attached to the remote bus. This

module is typically installed in an area removed from the process

environment such as a control room that is constantly attended.

The AM is powered with 24VDC from the PSU. A single AM can

be connected to the power supply. The AM is capable of

communicating on the Status Bus for exchanging status

information and remote control of the outputs.

The AM is equipped with two push buttons that allows you to

access the various menus and three seven segment LEDs for

identification of the system status within the menus.

The AM is the customer interface for the EPACO system. The

following tasks are accomplished by the AM:

Monitors all EPC’s, RC8’s and PSU connected to the Status

Bus and displays general status

Provides a central location for history response

Provides central location to connect computer and monitor

history for entire EPACO system

Communicates system status via trouble relay for user

interface

Real time pressure reading of the EPC’s CEREx pressure

transducers

2.3.1 OPERATION

There are six operating modes that the AM utilizes:

Status

History

Pressure Reading

EPC Enable/Disable

PSU Output On/Off

Bus Status

During normal operating conditions, the Annunciator Module will default into the Status mode. A complete

listing of all of the operating modes available on the Annunciator Module is provided on the following page for

your reference.

EPACO USER’S MANUAL

Release Date: January, 2010 P/N: E06-091 (Rev 0) Page: 13

ANNUNCIATOR MODULE OPERATING MODES

Main Menu

Status History Detector Controller Power

Supply

BUS

STATUS

Status

Left Button (-): scrolls to next module

Right Button (+): scrolls to previous module

Annunciator Module

0 0 1 Normal Status Bus

0 0 2 Module Trouble on Status Bus

0 0 3 EP System on Status Bus Activated

0 0 4 Communication Failure on Status Bus

005PCMode

Explosion Protection Controller (EPC) X = EPC 1 to 4

X - - No EPC or EPC Shutdown

X 0 1 Normal Operation Mode

X 0 2 Trouble on one of the Input Circuits

X 0 3 Pressure Warning Level Exceeded

X 0 4 Trouble on one of the Output Circuits

X 0 5 Trouble on the Fire Bus

X 0 6 Predischarge Condition Satisfied

X 0 7 Supervisory Input Active

X 0 8 EPC has Activated Releasing Outputs

X 0 9 EPC has been Disabled

X 1 0 Failure during Arming

Relay Card (RC8) X = RC8 5 to 8

XYYY=Relaystatus

Refer to Appendix A for relay card status codes.

Power Supply Unit (PSU)

9 - - No PSU or No Communications

9 0 1 Normal Operation

9 0 2 Fan Trouble

9 0 3 Ground Fault Trouble

9 0 4 Battery or Charge Trouble

905 ACTrouble

9 0 6 Battery Backup being Utilized

9 0 7 Output Trouble

9 0 8 Outputs Disabled

9 0 9 Shutdown Mode

Navigation

Display current Operating Mode:

Momentarily press both switches

Menu Mode:

Press and hold both switches for 5 seconds

Left Button (-): Scroll menu options

Right Button (+): Select desired option

Menu Mode Timeout: 20 seconds of inactivity

History

Displays 40 most recent events

Refer to Appendix B for listing of History Codes

Left Button (-): scrolls to older events

Right Button (+): scrolls to newer events

Pressing both buttons moves to the top of the file

Three lines across top of LEDs indicates Top of File (most recent)

Three lines across bottom of LEDs indicates Bottom of File

Pressure Detector

X X = Pressure Reading in Hex

Left Button (-): scrolls backward

Right Button (+): scrolls forward

1 X X EPC #1, Detection Circuit #1

2 X X EPC #1, Detection Circuit #2

3 X X EPC #2, Detection Circuit #1

4 X X EPC #2, Detection Circuit #2

5 X X EPC #3, Detection Circuit #1

6 X X EPC #3, Detection Circuit #2

7 X X EPC #4, Detection Circuit #1

8 X X EPC #4, Detection Circuit #2

6 2 -1.00 psig (-69 mbarg)

7 F 0.00 psig (0 mbarg)

8 D 0.49 psig (33 mbarg)

9 4 0.72 psig (50 mbarg)

9 C 0.99 psig (68 mbarg)

Refer to Appendix C for additional values.

Enabled/On Disabled/Off

Explosion Protection Controller (EPC) X X = Enabled/Disabled

Left Button (-): scroll EPC selection

Right Button (+): toggle EPC state

1XXEPC#1

2XXEPC#2

3XXEPC#3

4XXEPC#4

Power Supply Unit (PSU) X X = On/Off

Left Button (-): scroll PSU device selection

Right Button (+): toggle PSU state

1 X X Output #1

2 X X Output #2

3 X X Output #3

4 X X Output #4

5 X X Output #5

Bus Status

Used for engineering diagnostics.

Call Fike for support.

EPACO USER’S MANUAL

Page: 14 P/N E06-091 (Rev 0) Release Date: January, 2010

2.3.2 AM SPECIFICATIONS

Part Number: E10-0068

Input Power: 18 to 30 VDC; 300mA

Max. Noise Ripple: 500mV peak at 24 VDC

Fuse: 2A Mini Automotive Type

Lower Limit for Input Power

Shut-down: 16 VDC

Power Consumption: 130mA in Normal State

Terminal Block Capacity: 1.5 to 0.14 mm2(16 to 28 AWG)

Relay Output: One SPDT Form C for Trouble; One SPDT Form C for Alarm.

Both rated: DC operation: 2 amps @ 30VDC (pf=0.35)

AC operation: 0.5 amps @ 250VAC (pf=0.35)

Status Bus: Wire specification Alpha wire or RE-Y2Y or Belden 9841, maximum resistance of 50 Ω,

inductance L=100uH, capacitance C=0.02uF, maximum length 300 m (1,000 ft) total.

Remote Bus: Wire specification Alpha wire or RE-Y2Y or Belden 9841, maximum resistance of 50 Ω,

inductance L=100uH, capacitance C=0.02uF, maximum length 300 m (1,000 ft) total.

Temperature Rating: -18°C to 60°C (0°F to 140°F). If AM is not located inside auxiliary housing, maximum

temperature is 43.3°C (110°F).

Humidity: 80% relative, maximum (non-condensing).

Size: 120 mm L x 130 mm H x 60 mm D (4.8” L x 5.2” H x 2.3” D).

Weight: 0.5 kg (1 lbs.).

Hazardous Area: The AM is not rated for hazardous atmospheres.

For FM or ATEX installations the AM must be located in a non-hazardous atmosphere.

Current Firmware Version: Can be verified using EPWorks™ Software.

EPACO USER’S MANUAL

Release Date: January, 2010 P/N: E06-091 (Rev 0) Page: 15

2.4 RELAY CARD MODULE

The Relay Card Module (RC8) provides the user with a block of

eight (8) fully programmable Form “C” relays. DIP switches are

provided for configuring the relay’s operation. These relays

facilitate process shutdowns or other actions in response to

conditions recognized by the EPACOsystem. Each relay is

equipped with a green LED to provide visual indication of the

relay state.

The RC8 is powered with 24VDC from the PSU. Up to four (4)

RC8s can be connected in parallel to the power supply. The

RC8 is capable of communicating on the Status Bus for

exchanging status information and remote control of the outputs.

A history of the relay states is captured in the Annunciator

Module

2.4.1 OPERATION

The RC8 is a fully programmable module. System configuration can be performed with DIP switches on

these modules or by way of a DB9 serial port connection to a PC using EPWorks™ Software. RC8

addressing is done using the two ADD (address) DIP switches. The four MODE DIP switches are used for

programming specific relay configurations. Expanded programming may be created via PC with Fike's

EPWorks™ Software.

The RC8 is a process interface for the EPACO system. The following tasks are accomplished by the RC8:

Communicates system status via relays for user interface

Direct shut downs, slow downs, and remote notifications of system trouble and alarm conditions

Remote location of interface, separate from the hazard zone

The RC8 operation can be classified into two main states of operation: Normal and Trouble / Alarm.

2.4.2 RC8 LED DIAGNOSTICS

Condition Power LED Status Bus LED Relay LED(s) based on

Configuration

Initial power up [first 15 seconds] on off all off

Normal Sate

(No troubles or alarms)

on on all on

Invalid configuration on fast pulse all off

Trouble or Alarm on on corresponding off (1)

(1) Relay follows LED condition.

EPACO USER’S MANUAL

Page: 16 P/N E06-091 (Rev 0) Release Date: January, 2010

2.4.4 RC8 SPECIFICATIONS

Part Number: E10-0069

Input Power: 18 to 30 VDC; 300 mA

Max. Noise Ripple: 500 mV peak at 24 VDC

Fuse: 2A Mini Automotive Type

Lower Limit for Input Power

Shut-down: 16 VDC

Power Consumption: 300 mA in Normal State

Terminal Block Capacity: 1.5 to 0.14 mm216 to 28 AWG (16 to 28 AWG)

Relay Output: Eight SPDT Form C.

Each rated DC operation: 2 amps @ 30VDC (pf=0.35)

AC operation: 0.5 amps @ 250VAC (pf=0.35)

Status Bus: Wire specification Alpha wire or RE-Y2Y or Belden 9841, maximum resistance of 50 Ω,

inductance L=100uH, capacitance C=0.02uF, maximum length 300 m (1,000 ft) total.

Temperature Rating: -18°C to 60°C (0°F to 140°F). If EPC is not located inside auxiliary housing, maximum

temperature is 43.3°C 110°F (110°F).

Humidity: 80% relative, maximum (non-condensing).

Size: 120mm L x 125mm H x 54mm D (4.8” L x 4.9” H x 2.1” D).

Weight: 0.5 kg (1 lb.).

Hazardous Area: The RC8 is not rated for hazardous atmospheres.

For FM or ATEX installations the RC8 must be located in a non-hazardous atmosphere.

Current Firmware Version: Can be verified using EPWorksSoftware.

Table of contents

Other Fike Control System manuals

Fike

Fike Cheetah Xi User manual

Fike

Fike CyberCat 1016 User manual

Fike

Fike FIK-CZ-6 User manual

Fike

Fike Cheetah Xi User guide

Fike

Fike 55-042 User manual

Fike

Fike CyberCat 50 10-070 Manual

Fike

Fike CyberCat 1016 Owner's manual

Fike

Fike 10-071 User manual

Fike

Fike CyberCat 1016 Manual

Fike

Fike 10-2539 Owner's manual