Gazi XEF463-207V User guide

1

Montaža in servis gostinske opreme Tibor Gazi s.p.

Obrtniška cesta 2, PE Spodnja Slivnica 101a

SI1290 Grosuplje, Slovenija, EU

T: +386 (0)1 787 20 22 | F: +386 (0)1 786 47 79

Instructions for maintenance and use

Product

Electrical deep fryer with rotated heater

Models:

600 TOP

XEF463-207V

XEF463-112V

700

700 TOP

Built in

XEF479-207V/EF-478-207V

XEF473-207V/EF-473-207V

BEF47-207V

XEF479-112V/EF-478-112V

XEF473-112V/EF-473-112V

BEF47-112V

XEF679-212V/EF-678-212V

XEF673-212V/EF-673-212V

BEF67-212V

XEF779-212V/EF-778-212V

XEF773-212V/EF-773-212 V

XEF879-212V/EF-878-212V

XEF873-212V/EF-873-212V

BEF87-212V

XEF479-117V/EF-478-117V

BEF47-117V

XEF779-217V/EF-778-217V

XEF879-217V)/EF-878-217V

BEF87-217V

XEF479-122V/EF-478-122V

XEF879-222V/EF-878-222V

900 TOP

XEF493-112V/EF-493-112V

XEF893-212V/EF-893-212V

900

XEF499-117V/EF-498-117V

XEF899-217V/EF-898-217V

XEF499-122V/EF-498-122V

XEF899-122V/EF-898-222V

2

Dear Customer,

In order to be able to use the device properly and to your utmost satisfaction, you should first become familiar with the

contents of the operating manual.

Using the operating manual

Using the operating manual

These instructions describe the use and maintenance of the device.

If you have any questions concerning this operating manual, please contact us. Instructions are provided with

each device and must always be available to the user or maintenance personnel, if necessary.

If the operating manual is damaged or lost, you should immediately obtain a new one.

This manual provides information on the state of the art, which are valid at the time of shipment.

In the course of further technical developments, we reserve the right to change the structure and data, as well

as the components.

The operating manual should always be at hand for the installer and the maintainer, i.e. for each supervisor or

person responsible for the operation of the product. In case of internal tampering with the device, it is

necessary to carefully observe the regulations regarding the protection at work and the following warning

labels:

- GENERAL DANGER (in the case of carelessness may cause injuries to the person performing the works)

- DANGER ELECTRICITY (the negligence cause an electric shock to the operator intervention)

- ATTENTION (in the case of carelessness may cause damage or faulty operation of the product)

N O T E

This operating manual represents an integral part of the device, therefore

it should be available to the operating personnel at all times.

Consideration should be given to the safety instructions contained

therein.

Warning symbols

These instructions contain warning information against injury or damage to the device.

Always read and follow the safety symbols. The warning instructions are marked in bold and indicated by the

following expressions

Danger! or Attention!

or

Warning!

The warning levels have the following meanings:

Danger:

Disregarding the warning signs could result in death and serious injury to the operator or damage to the

device.

WARNING!

Before using the device, please read

the entire operating manual

3

Warning:

Disregarding the warning signs could result in personal injury or damage to the device.

Safety warnings

The following safety instructions are intended to protect personnel and to ensure long operating life of

the device. The personnel involved in the installation, operation, maintenance and use must be aware

of the safety instructions and work in accordance with them. All work must be carried out by qualified

personnel with the appropriate tools and testing equipment.

Qualified staff

The installation, maintenance and management of devices can only be implemented by qualified

personnel. Qualified personnel include persons who:

have appropriate qualifications and experience

are familiar with the applicable standards and regulations for ensuring safety

know the operation procedures and conditions of the device

Responsibility

If the device is operating in unsuitable ambient conditions or is improperly used (see technical data),

the manufacturer shall not be able to accept responsibility for its proper functioning.

If any defects should occur, please contact us and provide us with the following information:

type (name)

serial number

defects

total operating time

environmental conditions

application (how to use)

Address and phone numbers of customer service and technical assistance:

TIBOR GAZI s.p.

Obrtniška cesta 2

1290 GROSUPLJE

Tel: +386 1 787 20 22

Fax: +386 1 786 47 79

Declaration of Conformity

The devices comply with the requirements of all relevant European directives (see. CE declaration):

- Rules on electrical equipment designed for use within certain voltage limits

(Official Gazette of RS, no. 27/2004, 17/2011, 71/2011)

LVD Directive 2006/95/EC

- Regulations on Electromagnetic Compatibility

(Official Gazette of RS, no. 84/2001, 32/2002, 132/2006)

EMC Directive 2004/108/EC

In order to be able to use the device properly and to your utmost satisfaction, you should first become

familiar with the

contents of the operating manual.

Using the operating manual

4

1. Description, technical data and the intended use of the device

1.1 Use

The devices are designed to prepare food for catering and should not be used for other purposes!

Individual options of use are described in the following chapters of this operating manual.

Cases devices containing various electrical equipment to be installed in their interior and protected

against external influences. Switching devices are protected against access by water or dust into the

interior closet, access to live parts, contact with live parts and any moving parts.

Improper use

The device is designed only for the purposes mentioned in the manual. It is necessary to take into

account its purpose when using it, as it should not be used for any other purposes, as stated in the

instructions

Any other use shall be considered as contrary to regulations. The manufacturer is not liable for

damages resulting from improper use of the device. The entire risk is the liability of the user.

The intended use also includes compliance with the guidelines determined by the manufacturer

regarding the management and maintenance.

The appliance should only be used and maintained by persons who have read the operating instructions

and were informed in particular on possible risks arising from the use of the device.

1.2 Operating (environmental) conditions

Max. ambient temperature under normal conditions of use is + 40°C, while the average temperature

within 24 hours should not exceed + 35°C. The minimum permissible ambient temperature is -5°C.

Altitude of the installation site should not exceed 2,000 m. For electronic equipment, which is used above

1,000 m, it is necessary to consider the reduction of dielectric strength and the conditions of air cooling.

•

1.3 Technical data

Identification data of the manufacturer and the serial numbers

All data for the physical identification of the device are located on the rating plate and must not be

changed. When reporting defects you should always include information about the identification number

situated therein.

Rating plate is in accordance with EC regulations, containing the information for identification, which

should be identifiable both by the producer and the user.

The manufacturer provides maintenance services for the supplied equipment. However, as a

precautionary measure, it is recommended to carefully observe the existing instructions, in order to avoid

many inconveniences just by carrying out small, very simple interventions.

In every case, the buyer can refer directly to the manufacturer.

Rating plate

Rating plate with basic information and a label marking the power supply, to which the appliance is

connected, are mounted in a visible place on the outside of the housing!

5

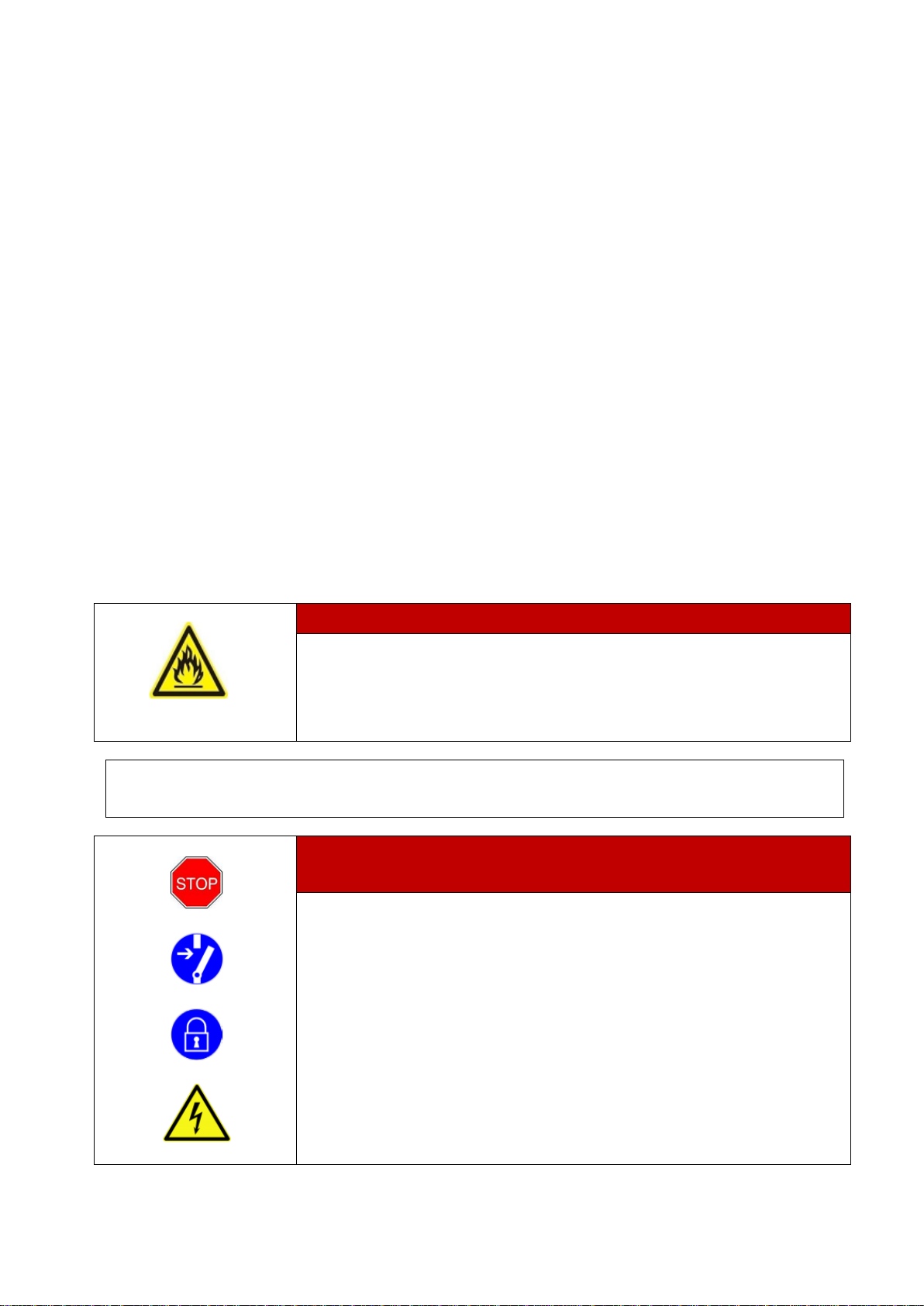

2. Safety information, warnings

When connected in a correct way and if complying with the instructions for use, these devices are not

dangerous; electrical components contained therein are protected from access of water or dust inside the

machine, against access to parts under voltage, or contact with parts under voltage.

Important warnings!

Persons with reduced physical, sensory and

mental abilities or with insufficient knowledge

and experience can use this device only if they

have received adequate instructions concerning

the safe use and if they understand the dangers

associated with the use of the appliance.

• WARNING: The appliance and some

accessible parts of the appliance are very hot

during operation. Be careful not to touch the

heating elements.

• WARNING: Risk of fire: Do not store any

objects on the surface of the hob.

• After use, turn the fryer off with the relevant

control elements.

In any operation switch turn switches of all

cooking zones off and remove the fuse or switch

off the main fuse so that the appliance

completely disconnected from the electrical

network.

• CLEANING! Do not use hot steam devices or

high-pressure cleaners, as this may result in an

electric shock.

• The appliance is not intended for the

management of external programming hours or

special monitoring system.

• The appliance may only be connected by the

manufacturer or an authorized specialist.

• In the case of non-professional interventions

and repair of the appliance there is a danger of

serious bodily injury and damage to the

appliance. Repairs can be carried out only by

the manufacturer or an authorized specialist.

• Do not use the device for any other purpose,

for example; for space heating.

• On or in device do not store flammable,

explosive and temperature non-resistant

objects (paper, wiping cloth, plastic bags,

cleaning agents, and various sprays), whereas

using the device could cause a fire.

• The device is placed directly on the floor

without the use of any kind of trays.

!WARNING: The user shall assume all responsibility for any damages resulting from

improper use.

ELECTRICAL CONNECTION MUST BE CARRIED OUT BY A QUALIFIED PERSON!

PRIOR TO INSTALLING OR ANY INTERVENTION INSIDE THE DEVICE IT IS

ABSOLUTELY NECESSARY TO READ THE INSTRUCTIONS FOR USE AND

INSTALLATION!

IT IS FORBIDDEN TO PLACE ANY OBJECTS ON OR INTO THE DEVICE!

CONNECTION IS NEEDED EXECUTED WITHOUT POWER!

6

SAFETY INSTRUCTIONS

Negligence or disregard of rules and warnings may cause damage to people, equipment and

environment. This can lead to various mechanical or chemical accidents, as well as to the release of

hazardous and noxious substances (gas).

The staff intended for the implementation and maintenance of works (installation, assembly, connection to

the gas network) must be qualified and trained to work with such devices. Supervision and coordination

should only be implemented by a qualified person able to solve problems and instruct the relevant

maintenance services. In case of major issues, you can directly contact the device manufacturer.

Possible hazards

Observe the safety systems and safety instructions described in this operating manual!

W A R N I N G

The buyer must prevent unauthorized persons from accessing the area

where the device is installed (except for the operating and maintenance

staff).

D A N G E R

When equipping, or carrying out maintenance and repair work,

watch out for hazards caused by electric shock.

3. Instructions for installation, connection and operation (use)

INSTALATION OF THE APPLIANCE

•Prior to the installation at the corresponding desired location remove the protective film on the surface

of the appliance, preferably with a detergent for Cr / Ni steels and cleaned surface well wiped with a

dry cloth.

•The appliance should be positioned in a well ventilated area, if possible under the kitchen hood.

•The appliances should be placed in a horizontal position (control with adjustable legs) and in an

ergonomic height of approximately 900 mm.

•Depending on the type the appliances can stand alone or in a kitchen block, in row with other

appliances.

•If there is electrical wiring, appliances must have a ground terminal and must be grounded.

OPEN ACCESS TO THE DEVICE MUST BE ENABLED IN CASE OF EMERGENCY

SHUTDOWN AND MAINTENANCE

INTERVENTION IN THE EQUIPMENT SHOULD BE NOTED THAT STATIC

DISCHARGE MAY DAMAGE ELECTRONIC COMPONENTS!

7

! WARNING:

When installing the device, check the squareness (straight line), to avoid any mechanical damage and

irregular load (bending).

When installing the appliance in the proximity of walls, partitions, kitchen furniture, decorative coverings

etc., these should be made of non-combustible material. If this requirement is not fulfilled, they must be

coated with non-combustible insulating material.

Compliance with regulations on fire protection must be ensured.

CONNECTING THE APPLIANCE

Connecting the device to the mains must be carried out according to applicable laws and regulations.

Warning!

Appliance can be connected only by an authorized qualified person in accordance with applicable

laws, regulations, and recommendations of the indication written on the label and with due regard

for safety measures regarding leakage current.

Electrical fryter is connected to the mains via a fixed connection to the earth terminal.

Installation and connection must be made so that the built-in and connected device is not possible to

access the live wires parts without the use of tools.

A fuse in the permanent electrical installation must be provided for the proper amperage (see table).

We recommend installation of switch in the permanent electrical installation, which separates all poles

from the mains with a 3 mm distance between the open contacts. Connection point for potential

equalization coupled with a conductor that has a cross-section of 10 mm2.

Instructions for the first connection and operation

•Connecting the appliances must be performed by a qualified person in accordance with

regulations. After connecting and installing the components must pass the control test connected circuits

and consumers to ensure the safe and proper operation.

PROTECTION AGAINST OVER-VOLTAGE

Protection against over-voltage is performed using grounding.

8

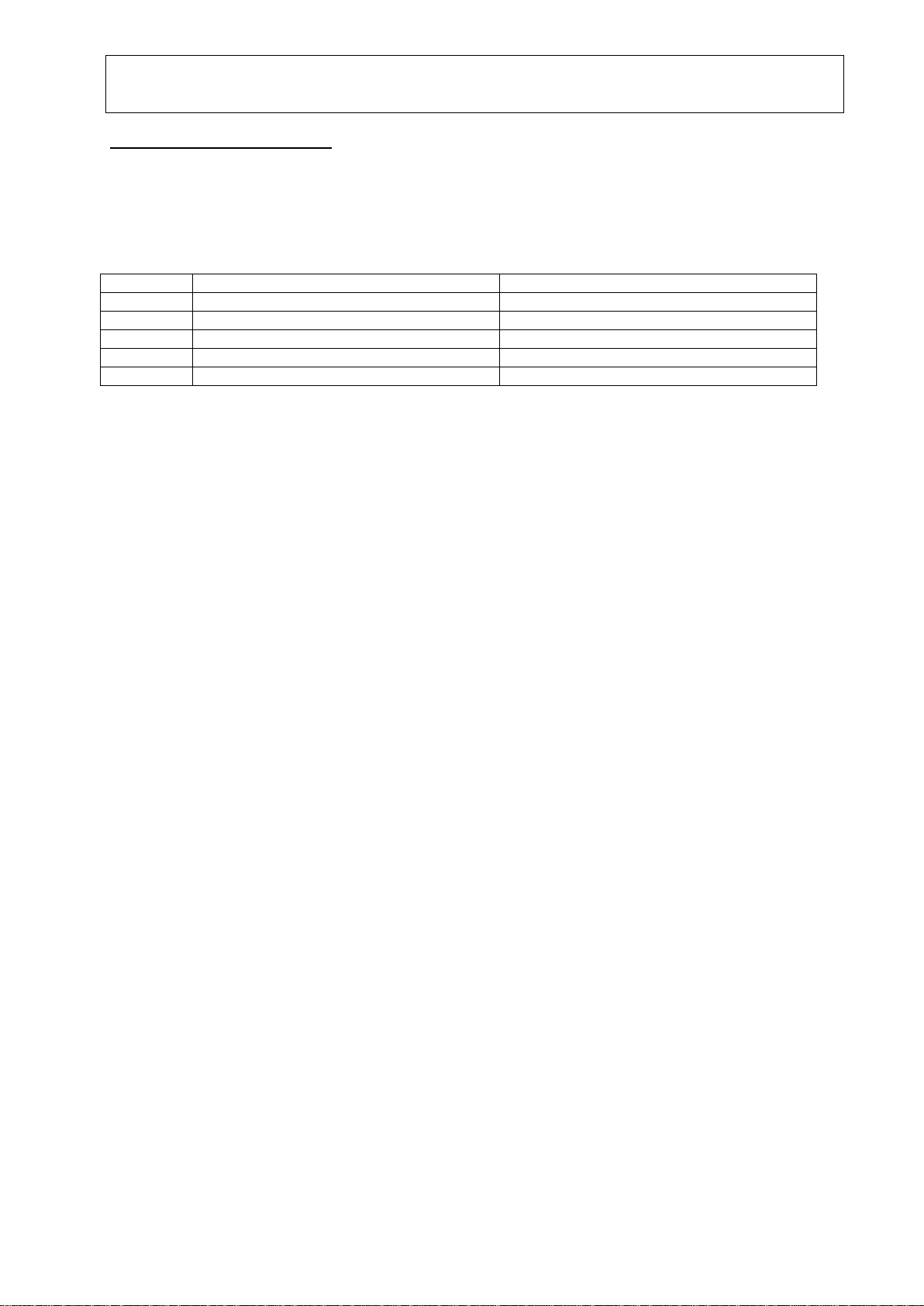

Models information:

Model/Art

Dimension

Capacity

Kapazität

Power

Leistung

Current / Strom

600 TOP

XEF463-207V

400x600x270/340

2x7

L

9,6 kW

400 V

3L N PE

50

Hz

15,0 A

XEF463-112V

400x600x270/340

12

L

9,6 kW

400 V

3L N PE

50

Hz

15,0 A

700 TOP

XEF473-207V/EF-473-207V

400x700x270/340

2x7

L

9,6 kW

400 V

3L N PE

50

Hz

15,0 A

XEF473-112V/EF-473-112V

400x700x270/340

12

L

9,6 kW

400 V

3L N PE

50

Hz

15,0 A

XEF673-212V/EF-673-212V

600x700x270/340

2x12

L

19,2 kW

400 V

3L N PE

50

Hz

29,0 A

XEF773-212V/EF-773-212 V

700x700x270/340

2x12

L

19,2 kW

400 V

3L N PE

50

Hz

29,0 A

XEF873-212V/EF-873-212V

800x700x270/340

2x12

L

19,2 kW

400 V

3L N PE

50

Hz

29,0 A

700

XEF479-207V/EF-478-207V

400x700x900/875

2x7

L

9,6 kW

400 V

3L N PE

50

Hz

15,0 A

XEF479-112V/EF-478-112V

400x700x900/875

12

L

9,6 kW

400 V

3L N PE

50

Hz

15,0 A

XEF679-212V/EF-678-212V

600x700x900/875

2x12

L

19,2 kW

400 V

3L N PE

50

Hz

29,0 A

XEF779-212V/EF-778-212V

700x700x900/875

2x12

L

19,2 kW

400 V

3L N PE

50

Hz

29,0 A

XEF879-212V/EF-878-212V

800x700x900/875

2x12

L

19,2 kW

400 V

3L N PE

50

Hz

29,0 A

XEF479-117V/EF-478-117V

400x700x900/875

17

L

13,8 kW

400 V

3L N PE

50

Hz

21,0 A

XEF779-217V/EF-778-217V

700x700x900/875

2x17

L

27,6 kW

400 V

3L N PE

50

Hz

41,0 A

XEF879-217V)/EF-878-217V

800x700x900/875

2x17

L

27,6 kW

400 V

3L N PE

50

Hz

41,0 A

XEF479-122V/EF-478-122V

400x700x900/875

22

L

13,8 kW

400 V

3L N PE

50

Hz

21,0 A

XEF879-222V/EF-878-222V

800x700x900/875

2x22

L

27,6 kW

400 V

3L N PE

50

Hz

41,0 A

900 TOP

XEF493-112V/EF-493-112V

400x900x900/875

12

L

9,6 kW

400 V

3L N PE

50

Hz

15,0 A

XEF893-212V/EF-893-212V

800x900x900/875

2x12

L

19,2 kW

400 V

3L N PE

50

Hz

29,0 A

900

XEF499-112V/EF-498-112V

400x900x900/875

12

L

9,6 kW

400 V

3L N PE

50

Hz

15,0 A

XEF899-212V/EF-898-212V

800x900x900/875

2x12

L

19,2 kW

400 V

3L N PE

50

Hz

29,0 A

XEF499-117V/EF-498-117V

400x900x900/875

17

L

13,8 kW

400 V

3L N PE

50

Hz

21,0 A

XEF899-214V/EF-898-217V

800x900x900/875

2x17

L

27,6 kW

400 V

3L N PE

50

Hz

41,0 A

XEF499-122V/EF-498-122V

400x900x900/875

22

L

13,8 kW

400 V

3L N PE

50

Hz

21,0 A

XEF899-122V/EF-898-222V

800x900x900/875

2x22

L

27,6 kW

400 V

3L N PE

50

Hz

41,0 A

Built in

BEF47-207V

400x700

2x7

L

9,6 kW

400 V

3L N PE

50

Hz

15,0 A

BEF47-112V

400x700

12

L

9,6 kW

400 V

3L N PE

50

Hz

15,0 A

BEF67-212V

600x700

2x12

L

19,2 kW

400 V

3L N PE

50

Hz

29,0 A

BEF87-212V

800x700

2x12

L

19,2 kW

400 V

3L N PE

50

Hz

29,0 A

BEF47-117V

400x700

17

L

13,8 kW

400 V

3L N PE

50

Hz

21,0 A

BEF87-217V

800x700

2x17

L

27,6 kW

400 V

3L N PE

50

Hz

41,0 A

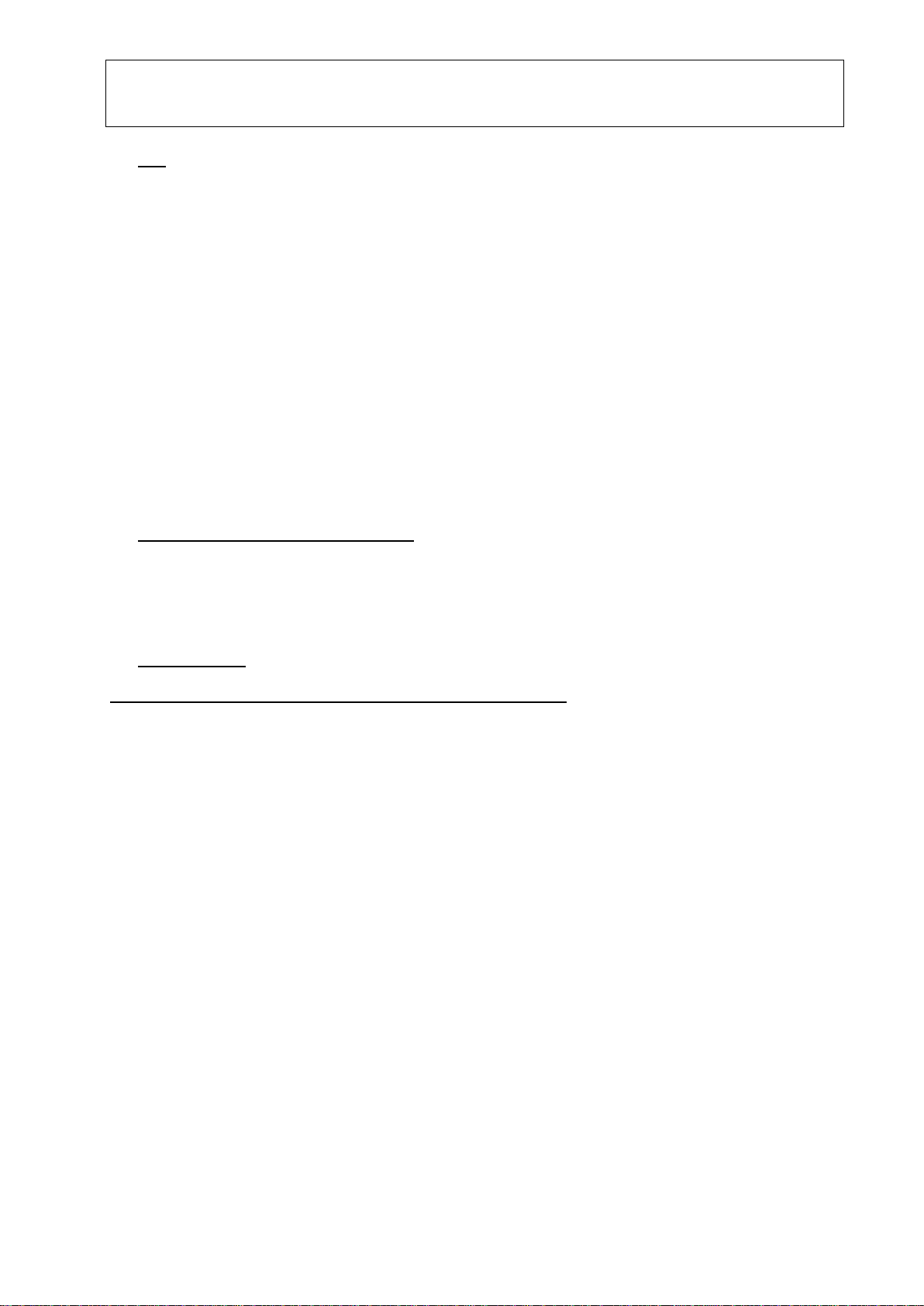

SCHEME OF CONNECTION

A-PE, electricity

L1

Black

L2

Brown

L3

Grey

N

Blue

PE

Yellow/Green

9

A-PE electricity connection A-PE electricity connection (serie 700 and 900)

(serie 600 TOP, 700 TOP, 900 TOP)

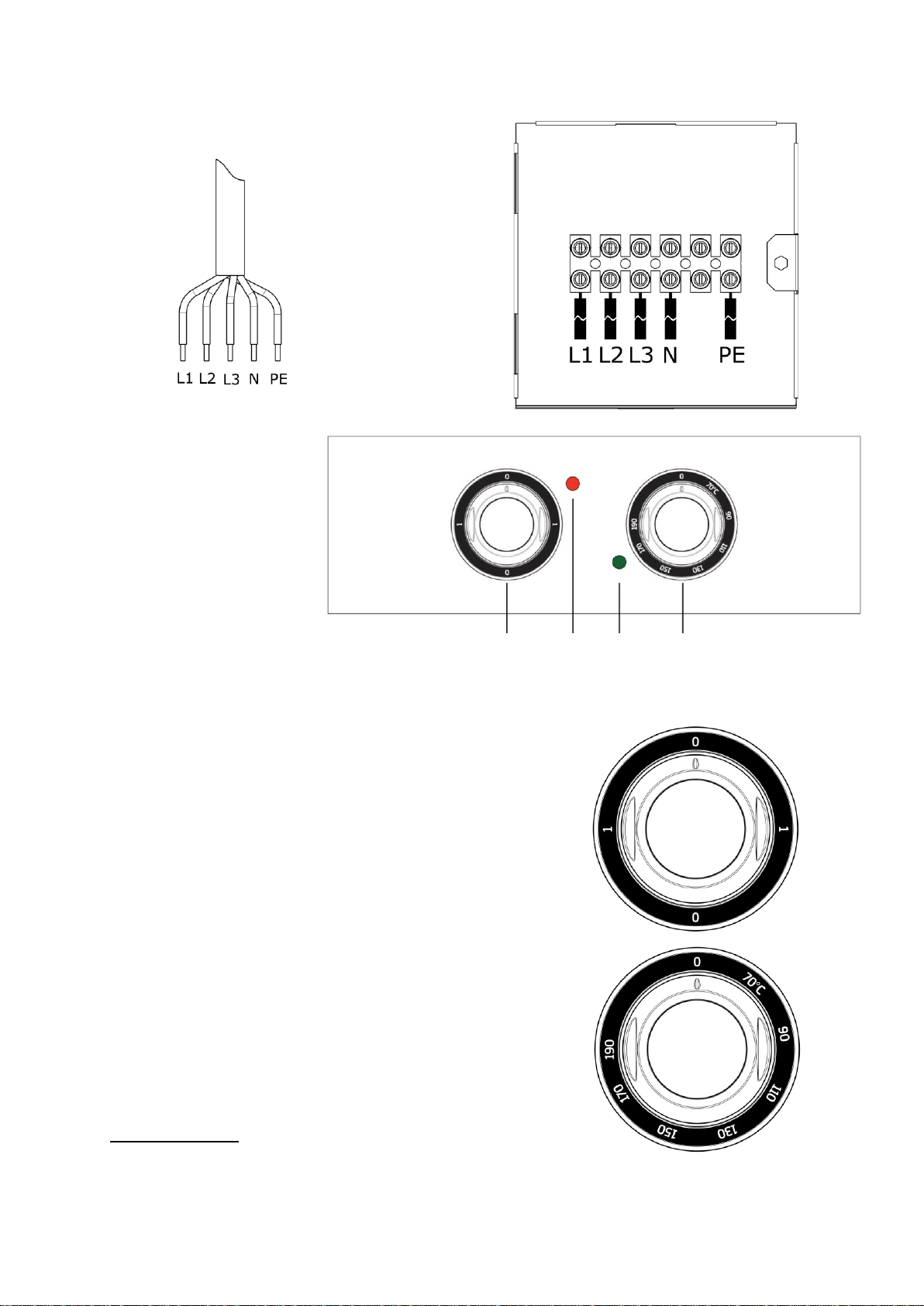

ELEMENTS ON THE CONTROL PANEL

A –Main switch knob

B –Main switch signal light

C –Thermostat signai light

D –Thermostat knob

A B C D

Main switch

0 - Main switc is turned OFF

1 - Main switc is turned ON

Thermostat knob

0 -the thermostat is turned off

70°C -initial (min) temperature cooking

190°C -final (max) temperature cooking

Start of operation

Oil drain valve must be closed. In the sink pour the appropriate amount of oil (see table).

10

Appliance is switched on by pressing the main switch from position ˝0˝ to position ˝1˝. The oil temperature

and set with the button of the thermostat in a clockwise direction at a temperature range of 70 to 190 ° C.

By turning the thermostat turns the signal light that signals activate or deactivate the electric tubular

heaters and burning only in the case of electric tube heaters are turned on. When the oil temperature

reaches the set value, the thermostat senses through the sink the appliance is switched off electricity

tubular heaters, which signals the indication light. When the oil in the tank to cool below the set value

(insert food into the pool), the thermostat senses through it detects and switches the electric heater pipe,

which allows light signals the thermostat so that it lights up.

The heated oil slowly insert basket with dry (dried) food to minimize oil boil and expand. When food is

cooked, lift the basket above the sink, you attach the adapter installed in the cabinet heaters and wait for

food to be dried and the oil to drain into the pool unit and then take the food out of the basket.

Warning!

Not TURN ON the appliance if the pool is no oil or fat, as this could damage the appliance.

Use only the oil that can be heated up to 200 ° C.

As the quality of the oil quality oil with reusable worse, we recommend daily oil drain through the drain

valve of the appliance and filtering polluted oil. Then out of the pool removed the remains of food and

clean electric heaters.

The use of old oil, which is highly prone to turbulent boiling and has reduced flashpoint, is a great danger

that the oil burns and cause a fire in the kitchen.

Fire-fighting equipment

D A N G E R

In case of fire we recommend the use of fire extinguishers with CO2or taking

appropriate measures and using the equipment and protection in accordance

with applicable regulations on fire safety.

4. Instructions for maintenance, repair and cleaning

D A N G E R

Before cleaning, maintenance or repair works (only experts) it is mandatory

to follow the procedure of switching off.

1. Turning off the Power

2. For maintenance and repairs, make sure the power is off;

Failure to observe the resulting risk of injury and danger of life for the staff!

11

Works can only be carried out by qualified and authorized persons

Before starting work it is necessary to switch turn switches of all cooking zones off and remove the fuse

or switch off the main fuse so that the appliance

completely disconnected from the electrical network.

In case of repairs only original spare parts may be used

CLEANING AND MAINTENANCE

It is necessary to daily clean the machine using the following procedure:

- Turn the appliance off (position of the thermostat knob and the main switch - off) and allow to cool

- Drain the oil from the basin of the appliance and wipe the backing thoroughly with a dry cloth or paper

towel (heavy grease stains removed by pouring a little hot water with detergent to clean the tank and thus

achieve maximum hygiene)

- For easier cleaning of the appliance rotate heaters when they are cold to the top position, so you have

easier access to the bottom of the pool.

- Care should be taken that the appliance before reuse thoroughly dry

Warning!

Whenever purified appliance and lift-rotate the cold electrical pipe heaters button should be main

switch in position off.

Electrical deep-frying should not be cleaned with a water jet or high-pressure cleaning machine!

When cleaning electric deep fat fryers should not be used mushrooms wire, wire brushes or other

sharp objects.

Do not salt dishes in the deep fryer, because salt causes foaming and adversely affect the quality of

oil.

Maintainers must have adequate training;

- Carry out routine checks, and all checks specified in the instructions for use;

- For all repairs required to keep proper records.

PROCEEDING IN CASE OF FAULT ON THE APPLIANCE

In case you notice any abnormal operation of fryers or malfunction, switch off the machine so that the

main switch and the thermostat knob to position 0. For this, call the manufacturer or an authorized

customer service.

Troubleshooting within the warranty period is implemented by the manufacturer or its authorized service,

while maintenance and repairs outside the warranty period is carried out according to agreement with the

customer.

Devices must be cleaned and inspected regularly and inappropriate parts should be replaced if

necessary.

Instructions for repairs and maintenance

•all works be carried out only by qualified and authorized person;

•before starting work it is necessary to turn off the power supply and the device shall be marked

with appropriate warning sign;

•all work is carried out in accordance with the manufacturer's instructions and original spare parts;

12

•troubleshooting within the warranty period is implemented by the manufacturer or its authorized

service, while maintenance and repairs outside the warranty period is carried out according to

agreement with the customer.

•Devices must be cleaned and inspected regularly and inappropriate parts should be replaced if

necessary.

WARNING!

Warnings for maintenance works:

•All disassembled components need to be protected during the implementation of works inside the

device.

•During operation it is prohibited to remove the protecting parts from the device.

•In case of gas leaks from the system it is required to implement the intervention in a way that

does not threaten human health and has no harmful influence on the environment.

•Electrical connections and maintenance must be carried out according to the standards and

legislation, including regulations on safety at work.

Warnings for operators, maintenance and installation workers:

•Installation, repair and maintenance works must be carried out, whenever the appliance does not

operate according to exactly determined instructions.

•After completing repair and maintenance works or other interventions in the machine the parts

designated for protection and safety need to be reattached to the original locations in order to be

able to perform their function.

•Restarting the device is performed by the same procedure as the initial start-up.

•Changes and modifications to the machine are permitted with the written consent of the

manufacturer, when using original parts. In all other cases of alterations, repair or maintenance

works manufacturer shall not be liable for the faulty operation of the device.

•Also, the manufacturer does not bear any responsibility for the operation of the device in case of

non-compliance with the manufacturer's instructions, and when the device is operated contrary to

the working conditions and characteristics determined by the manufacturer.

W A R N I N G

Maintenace, cleaning and repairs can only be carried out by professionals.

Professionals

Persons who due to their technical training, knowledge and experience, as well as knowledge of relevant

standards, are able to assess the extent and type of necessary works, and their associated hazards.

To ensure interference-free operation of the device it is necessary to regularly clean and maintain the

equipment.

N O T E

Maintenance and cleaning of certain components of the device or additional

parts is described in the documentation of the producer.

!

13

D A N G E R

When equipping, or carrying out maintenance and repair work, watch out

for hazards caused by electric shock.

Maintenance of the device

In the case of maintenance, observe the following guidelines:

•Never clean with compressed air, you should only use vacuum. Use appropriate tools (vacuum

cleaner).

•After maintenance, perform visual inspection.

W A R N I N G

Maintenance, cleaning and repairs can only be carried out:

• By specialists

• When the device is switched off and secured against switching on

• With personal protective equipment and appropriate clothing

5. Instructions for transport and storage

N O T E

Transport can only be carried out by qualified personnel in accordance with

local conditions.

Staff should be fully trained in the field of transport.

The device is to be transported to the place of installation with adequate special vehicles and installed at

the appropriate location by using forklifts or cranes.

W A R N I N G

The machine can tip over during transport. Pay attention to its center of

gravity. Before transportation secure it with ropes or other means.

In determining the necessary space for transportation it is necessary to take

account of a possible tilt of the device (the height of the components).

The lifting device must be capable of carrying the weight of each item; the operator shall be responsible

for the operating of the lifting device.

Installation and assembly should be carried out according to the plans of the layout.

Observe the appropriate weight.

N O T E

The device can be moved manually or in other manner (forklift, crane…)!

Before moving the device needs to be adequately protected!

Devices should be transported wrapped in foil or cardboard packaging and, where appropriate, need to

be protected against mechanical damage. If necessary, they should be installed on pallets.

The permissible temperature range during transport and storage is between -25 ° C and + 55 ° C, while

for short periods of time, not exceeding 24 hours, temperatures of up to + 70 ° C are allowed.

WARNING: Devices should not be placed on surfaces with doors or carrying equipment!

14

6. List of spare parts

If possible, the elements should be replaced with original or functionallyequivalent spare parts.

7. Completed tests, the results of measurements

The devices have undergone all the necessary tests required by current standards listed in the

Declaration of Conformity. Records of testing and implemented measurements are included in the

technical file.

8. Decommission

After the end of its life span it is necessary to remove the device or parts of the device from use.

Disused parts should be deposited at a landfill for industrial waste in accordance with applicable rules:

-Directive on the management of waste electrical and electronic equipment (WEEE)

(Official Gazette of RS, no. 107/2006)

Directive 2012/19/EU on waste electrical and electronic equipment (WEEE)

- Regulation on the restriction of the use of certain hazardous substances in electrical and

electronic equipment (RoHS)

(Official Gazette of RS, no. 102/2012)

- Regulation amending the regulation on the restriction of the use of certain hazardous

substances in electrical and electronic equipment

(Official Gazette of RS, no. 20/2014)

Directive 2011/65/EU on the restriction of the use of certain hazardous substances in electrical

and electronic equipment

Environmentally-harmful components and parts, which were installed inside the device, should be

disposed of at specially designed sites.

When present on a device or its packaging, the

symbol shown above indicates that such a

product maynot be treated as normal waste. It

should be disposed of at the appropriate collection

point for the recycling of electrical and electronic

equipment. The correct method of disposal of the

product will help prevent potential negative

consequences for the environment and human

health, which could otherwise be caused by

inappropriate waste handling. For more

information about recycling of this product, please

contact your local city office, household waste

disposal service or the retailer where you bought

the machine.

9. Obligations of the manufacturer –Warranty terms & conditions

The manufacturer shall undertake to eliminate all errors and defects during the warranty period, which is

agreed with the customer, whereas the warranty for the installed equipment is determined by the

manufacturer of the said equipment.

During the warranty period, the manufacturer shall eliminate the defects, which are not caused by force

majeure, improper intervention or improper use.

15

10. CE Declaration of Conformity

EC –Declaration of Conformity

CE (EC) Declaration of Conformity ensures the safety of the device / equipment, and confirms that it was

properly inspected and tested, thus meeting all the requirements specified in the applicable standards,

directives and regulations. CE Declaration of Conformity is included in the attachment.

Acknowledgement of having been acquainted with the instructions

By signing I confirm that I am acquainted with the instructions and fully agree with them!

Surname and first name

Signature

1

2

3

4

5

This manual suits for next models

49

Table of contents