GCAN GCAN-IO-8000 User manual

GCAN-IO-8000

CANopen bus coupler

User manual

Document version: V3.25 (2019/03/20)

2

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

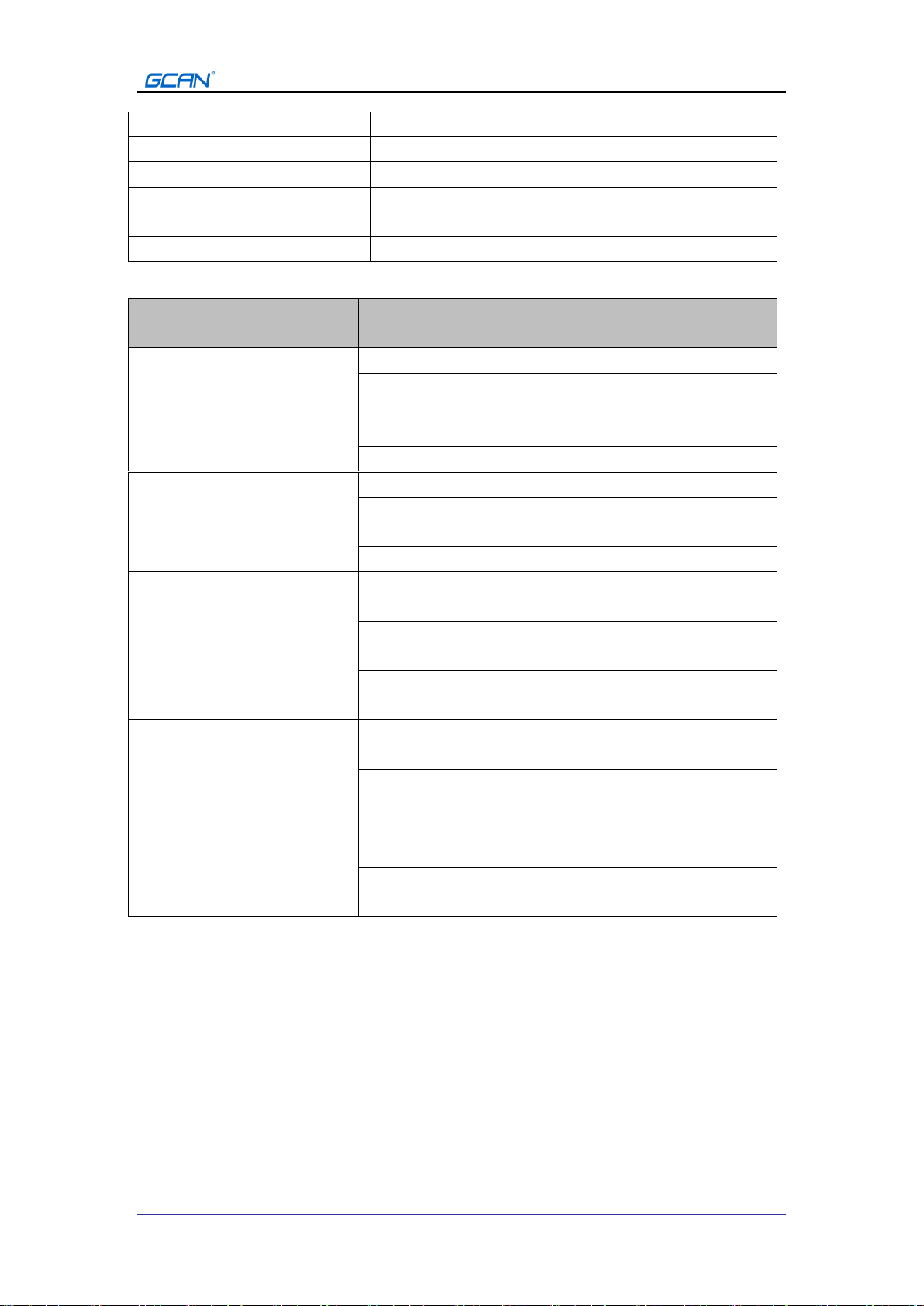

revise history

Version

Date

The reason

V1.00

2015/10/16

Create document

V2.01

2015/12/20

Correct equipment working parameters

V3.01

2017/11/22

Add some parameters

V3.02

2018/01/22

Add communication protocol section

V3.03

2018/03/22

Correct equipment working parameters

V3.25

2019/3/20

Modify selection table

3

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

catalog

1. Function introduction.................................................................................................4

1.1 Functional Overview........................................................................................4

1.2 Performance characteristics .............................................................................4

1.3 Typical applications .........................................................................................5

2. Equipment installation and use..................................................................................5

2.1 Module appearance and dimensions................................................................5

Figure 2.1 Appearance of GCAN-IO-8000 CANopen bus coupler.......................5

2.1 Module fixing...................................................................................................5

2.2 Wiring method .................................................................................................7

2.3 System status indicator..................................................................................9

3. Communication connection.....................................................................................11

3.1 Serial port connection....................................................................................11

3.2 CAN connection.............................................................................................11

Table 3.1 Baud rate and maximum bus length reference table............................12

3.3 CAN bus termination resistance ....................................................................12

3.4 Setting of CAN baud rate and node number..................................................12

4. Communication protocol .........................................................................................15

4.1 NMT command..............................................................................................15

Figure 4.3 NMT command monitoring interface.................................................17

4.2 Equipped with GC-1008 module...................................................................17

4.3 Equipped with GC-2008 module...................................................................18

4.4 Equipped with GC-3804 module...................................................................19

4.5 Equipped with multiple sets of modules at the same time.......................20

5. Technical specifications ...........................................................................................23

6. GC series module selection table.............................................................................24

Appendix A: CAN2.0A protocol frame format............................................................26

Appendix B: Introduction to CANopen Protocol ........................................................27

B.1 Explanation of related terms and writing rules .............................................27

B.2 Predefined CAN identifier ............................................................................28

.......................................................................29

B.4 CANopen communication.............................................................................29

B.5 CANopen network configuration..................................................................34

Sales and Service .........................................................................................................35

4

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

1. Function introduction

1.1 Functional Overview

GCAN-IO-8000 CANopen bus coupler can be used to connect CAN bus system and

distributed bus terminal modules. These terminal modules can be expanded in a

modular manner. A complete node consists of a bus coupler, 1-32 any number of

terminal modules and a terminal terminal module. Adopt GCAN-IO-8000 bus coupler,

through GC-bus expansion technology, can establish I/O connection very

conveniently, can connect up to 32 input/output terminal modules.

GCAN-IO-8000 CANopen bus coupler adopts CAN bus protocol that conforms to

ISO 11898 standard. The GCAN-IO-8000 bus coupler not only supports all types of

CANopen communication, but can also be easily applied to manufacturer-specific

CAN bus environments. In addition, the firmware can be upgraded through the

configuration interface.

GCAN-IO-8000 bus coupler can connect all bus terminal modules. As far as the user

is concerned, the processing of analog input/output signals is no different from the

processing of other types of signals. The information in the process image area of the

controller is displayed in byte array format.According to different models, the analog

bus terminal module register contains the temperature range, gain value and linearized

characteristic curve.

GCAN-IO-8000 bus coupler supports automatic configuration, you do not need to set

parameters on the PC. The CANopen baud rate of the GCAN-IO-8000 bus coupler

can be configured via the RS-232 interface.

1.2 Performance characteristics

CANopen baud rate supports 1000k, 500k, 250k, 125k, 100k, 50k, 10k;

PDO mode supports synchronization, loop, event-driven, and polling;

The number of bus terminal modules is 32;

Send 12 PDO (CANopen), receive 12 PDO (CANopen);

The configuration mode is automatic configuration;

The CAN bus interface is an open 4-pin terminal;

The power supply adopts 24V DC (-15%/+20%);

The input current is 70mA+ (total GC-bus current), the maximum is 2.5A;

Starting current: about 2.5 times the continuous current;

Power supply: Max 24V DC/Max 10A;

The electrical isolation is 1500 Vrms;

Working temperature range: -40℃~+85℃;

Dimensions: length 100mm * width 69mm * height 48mm.

5

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

1.3 Typical applications

Connect with the distributed bus terminal module to form a complete control node;

Perform data collection and data transmission with CANopen protocol.

2. Equipment installation and use

This chapter will explain in detail the installation method, wiring method, the

meaning of the indicator light and the meaning of the interface of GCAN-IO-8000

CANopen bus coupler.

2.1 Module appearance and dimensions

The appearance of GCAN-IO-8000 is shown in Figure 2.1. GCAN-IO-8000

CANopen bus coupler includes 2 communication interfaces, 1 controller

programming interface, 1 group controller power interface, 2 groups I/O power

interface, 2 groups shielded wire interface. Among them, the communication interface

includes a CAN bus interface and an RS232 interface.

Figure 2.1 Appearance of GCAN-IO-8000 CANopen bus coupler

2.1 Module fixing

The installation method of GCAN-IO-8000 CANopen bus coupler is shown in figure

2.2, you need to use a flat screwdriver for auxiliary installation.

6

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

Figure 2.2 GCAN-IO-8000 module installation

Figure 2.3 GCAN-IO-8000 module self-locking mechanism

Please install the GCAN-IO-8000 CANopen bus coupler on the guide rail as shown in

Figure 2.3 until the latch snaps and makes a “click” sound. GCAN-IO-8000 CANopen

bus coupler has a self-locking mechanism, which can effectively prevent the device

from falling. As shown in Figure 2.3, you can release the self-locking mechanism by

pulling out the orange label.

GCAN-IO-8000 CANopen bus coupler can connect up to 32 distributed bus terminal

modules. When inserting the bus terminal module, be sure to follow the groove and

insert it on the right side of the existing module in sequence until the latch snaps and

makes a “click” sound. At the far right end of the entire node, you need to install a

terminal module. The terminal can guarantee the data transmission and power supply

of GC-Bus.

When you assemble the nodes correctly, there will be no obvious gaps between the

7

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

terminal modules. If the modules are not assembled correctly, the entire node will not

operate normally.

2.2 Wiring method

As shown in Figure 2.4, use a flat-blade screwdriver to insert into the square hole,

press the upper edge of the metal sheet in the square hole, and press firmly in the

direction of the round hole. Then insert the cable into the circular hole. After plugging

in, pull out the screwdriver, and the cable can be firmly locked in the circular hole

.

Figure 2.4 Wiring of GCAN-IO-8000 module power supply

8

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

Figure 2.5 GCAN-IO-8000 module power terminal block

The power terminal block of GCAN-IO-8000 CANopen bus coupler is shown in

Figure 2.5. The GCAN-IO-8000 CANopen bus coupler contains 8 terminals, and the

corresponding serial numbers and meanings of each terminal are shown in Table 2.1.

Please note that between terminal 3 and terminal 4, between terminal 5 and terminal 6,

and between terminal 7 and terminal 8 are connected inside the module.

Terminal

Serial number

meaning

24V

1

Power 24V input

0V

2

Power GND

+

3

IO power supply is positive

+

4

IO power supply is positive

-

5

IO power negative

-

6

IO power negative

PE

7

shield

PE

8

shield

Table 2.1 Definition of GCAN-IO-8000 module power terminal

9

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

Figure 2.6 GCAN-IO-8000 module CAN bus terminal block

The CAN bus terminal block of GCAN-IO-8000 CANopen bus coupler is shown in

Figure 2.6. The CAN bus terminal block of GCAN-IO-8000 contains 4 terminals, and

the corresponding serial number and meaning of each terminal are shown in Table 2.2.

Terminal

Serial number

meaning

CAN-H

1

CANopen high

PE

2

Shielded wire

CAN-L

3

CANopen low

CAN-G

4

CANopen ground

Table 2.2 Definition of CAN bus terminal of GCAN-IO-8000 module

Figure 2.7 GCAN-IO-8000 module RS-232 interface definition

The definition of RS-232 interface of GCAN-IO-8000 CANopen bus coupler is

shown in Figure 2.7. GCAN-IO-8000's RS-232 interface only defines three signal

lines, namely RXD, TXD and GND.

2.3 System status indicator

GCAN-IO-8000 CANopen bus coupler has two sets of status indicators. The left area

contains 6 circular status indicators, and the right area contains 2 small power

indicators. The specific indication function of the indicator light is shown in Table 2.3.

When the indicator lights are in different states, the state of the GCAN-IO-8000

module is shown in Table 2.4.

Indicator light

colour

Indication status

PWR

green

Power indicator

SYS

green

System instructions

10

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

RUN

green

Operating instructions

ERR

green

Error indication

IO RUN

green

Internal bus operation instructions

IO ERR

green

Internal bus error indication

Position 1 on the right

green

Power indicator

Position 3 on the right

green

Internal bus power indication

Table 2.3 GCAN-IO-8000 module indicator

Indicator light

status

Indication status

PWR

Always on

Power supply is normal

not bright

Abnormal power supply

SYS

flicker

The device is initialized and enters

the working state

not bright

Device initialization failed

RUN

flicker

The device is operating normally

not bright

Device operation stopped

ERR

Always on

system error

not bright

No errors in the system

IO RUN

flicker

The internal bus is operating

normally

not bright

Internal bus stop

IO ERR

Always on

Internal bus operation error

not bright

No error occurred during internal

bus operation

Position 1 on the right

Always on

Normal power supply on the

terminal side

not bright

Abnormal power supply on the

terminal side

Position 3 on the right

Always on

The internal bus power supply of

the terminal is normal

not bright

Abnormal internal bus power

supply of the terminal

Table 2.4 GCAN-IO-8000 module indicator status

11

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

3. Communication connection

3.1 Serial port connection

GCAN-IO-8000 CANopen bus coupler uses standard serial port level (RS232:

±3~15V), so the module can be directly connected to devices with RS232 interface.

The baud rate of the RS232 interface of the GCAN-IO-8000 CANopen bus coupler

cannot be modified and is fixed at 19200bps.

3.2 CAN connection

GCAN-IO-8000 module is connected to the CAN bus as described in 2.2. Connect

CAN_H to CAN_H and CAN_L to CAN_L to establish communication.

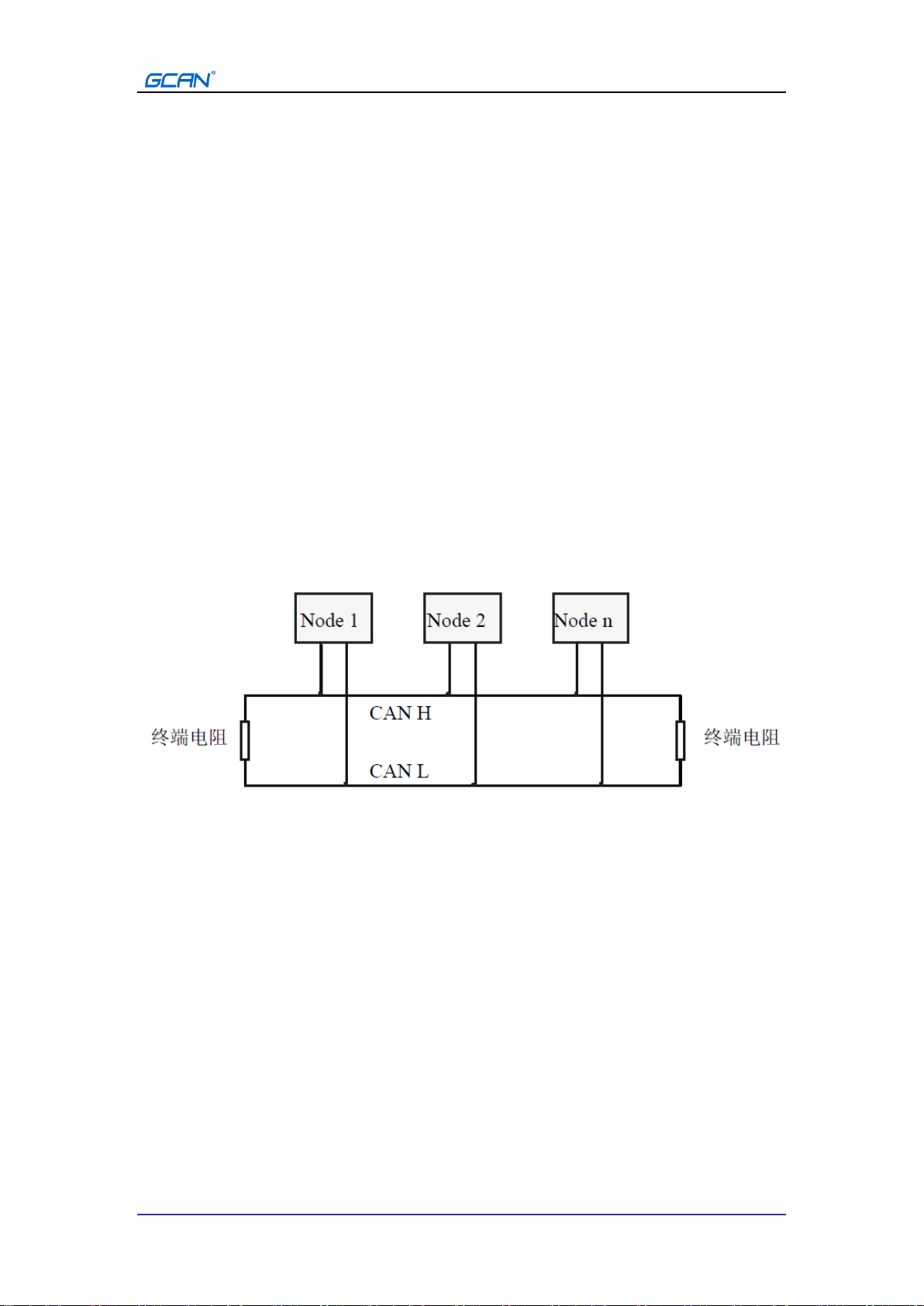

The CAN-bus network adopts a straight-line topology structure, and the two furthest

terminals of the bus need to install 120Ω terminal resistance; if the number of nodes is

greater than 2, the intermediate nodes do not need to install 120Ω terminal resistance.

For branch connections, the length should not exceed 3 meters. The connection of

CAN-bus bus is shown in Figure 3.1.

Figure 3.1 Topology of CAN-bus network

Please note: CAN-bus cable can use ordinary twisted pair and shielded twisted

pair. The theoretical maximum communication distance mainly depends on the

bus baud rate. For the relationship between the maximum bus length and baud

rate, see Table 3.1. If the communication distance exceeds 1km, the

cross-sectional area of the line should be greater than Φ1.0mm2, the specific

specifications should be determined according to the distance, and the

conventional is to increase appropriately as the distance increases.

12

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

Baud rate

Bus length

1 Mbit/s

40m

500 kbit/s

110m

250 kbit/s

240m

125 kbit/s

500m

50 kbit/s

1.3km

20 kbit/s

3.3km

10 kbit/s

6.6km

5 kbit/s

13km

Table 3.1 Baud rate and maximum bus length reference table

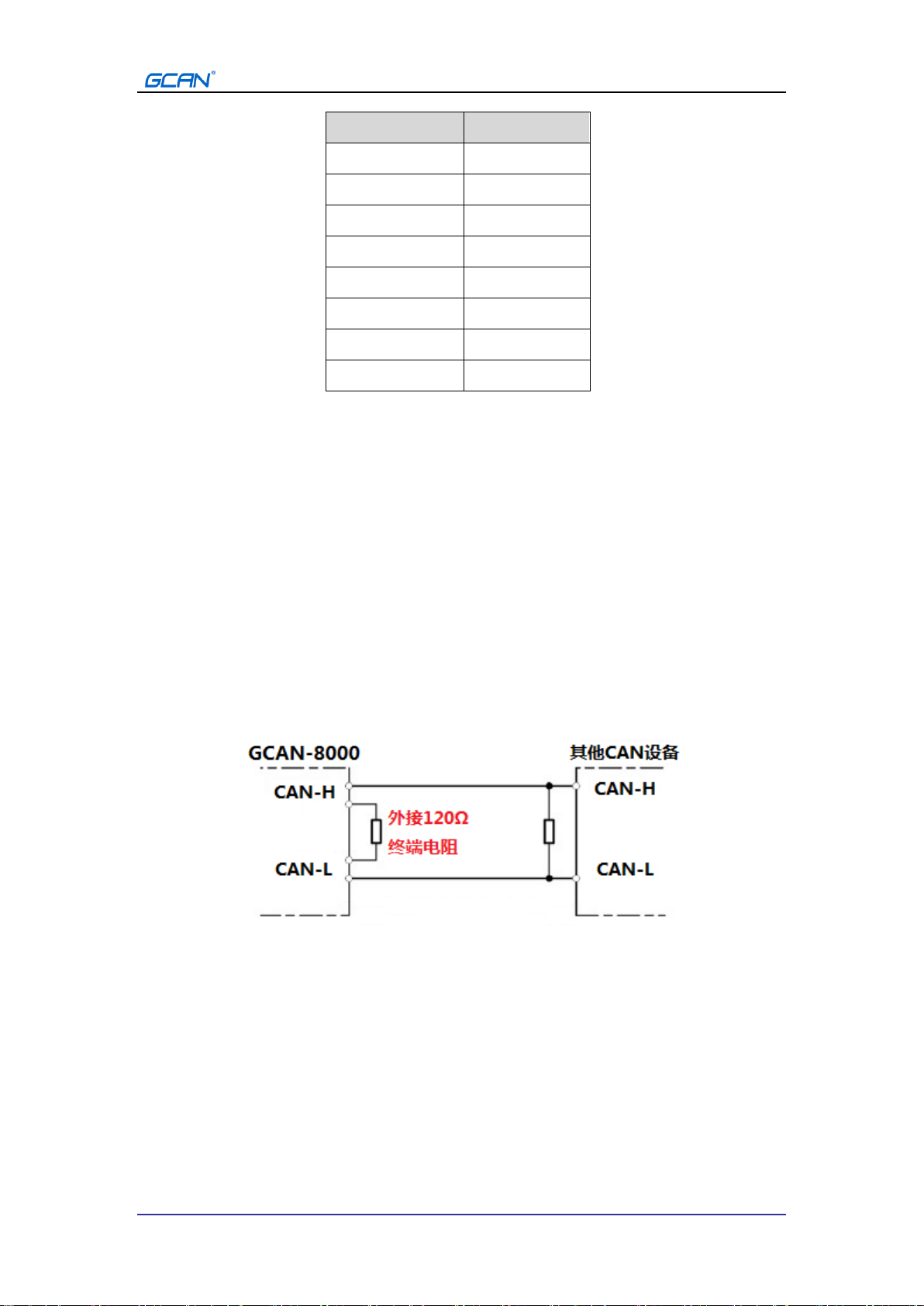

3.3 CAN bus termination resistance

In order to enhance the reliability of CAN communication and eliminate CAN bus

terminal signal reflection interference, the two farthest endpoints of the CAN bus

network usually need to add terminal matching resistors, as shown in Figure 3.2. The

value of the termination matching resistance is determined by the characteristic

impedance of the transmission cable. For example, the characteristic impedance of the

twisted pair is 120Ω, then the two endpoints on the bus should also integrate 120Ω

termination resistors. If other nodes on the network use different transceivers, the

termination resistance must be calculated separately.

Figure 3.2 GCAN-IO-8000 connected with other CAN node devices

Please note: The 120Ω termination resistor is not integrated inside the

GCAN-IO-8000 module. If the number of nodes is greater than 2, the

intermediate node does not need to install a 120Ω termination resistor. When

needed, connect CAN_H and CAN_L at both ends of the resistor, as shown in

Figure 3.2.

3.4 Setting of CAN baud rate and node number

You can modify the CAN bus communication baud rate of the GCAN-IO-8000

module through the RS232 interface. The specific process is as follows: first establish

13

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

a serial port connection, the baud rate is 19200bps, the data bit and stop bit are

configured as none, 8, 1, send a "help" command or "?" command through the RS232

interface, and then the RS232 interface will return to the configuration information.

Please note that when sending the command, please add a carriage return at the

end or select the "send new line" of the software. For display and transmission,

please do not select "hexadecimal display" or "hexadecimal transmission". You can

send "setbaud=500000" to modify the baud rate of the GCAN-IO-8000 module to

500kbps. At the same time, you can send "getbaud" to get the CAN baud rate of the

machine, and the unit of the reply value is bps. The detailed baud rate correspondence

is shown in Table 3.2. The settings when sending the request command are shown in

Figure 3.3.

Figure 3.3 Settings when sending a request command

baud setting value

Corresponding baud rate

(kbps)

setbaud=1000000

1000

setbaud=500000

500

setbaud=250000

250

setbaud=125000

125

setbaud=100000

100

setbaud=50000

50

setbaud=10000

10

Table 3.2 Baud setting value and baud rate comparison table

The method of setting and obtaining the CANopen node ID is similar to the baud rate.

14

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

You can modify the CAN bus node number of the GCAN-IO-8000 module through

the RS232 interface. You can send "setid=3" to modify the CANopen node ID of

GCAN-IO-8000 module to 3. At the same time, you can send "getid" to get the

CANopen node ID of this machine. The node number can be set arbitrarily within

1-127.

15

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

4. Communication protocol

GCAN-IO-8000 implements CANopen communication protocol and is a CANopen

slave device. The GCAN-IO-8000 module uses PDO (Process Data Object) to collect

or output digital signals.

When equipped with GC-3804 or GC-1008 module, GCAN-IO-8000 will send out

TPDO data, typical frame ID such as 0x181, 0x281, etc. When equipped with

GC-2008 module, GCAN-IO-8000 will receive RPDO data, typical frame ID such as

0x203, 0x303, etc.

In this chapter, Guangcheng Technology USBCAN-II Pro module and ECANTools

software can be used to receive and send CAN bus data. The CANopen master station

function provided with the software can help debug the CANopen slave station, which

is very convenient and practical.

Using the USBCAN bus analyzer of Guangcheng Technology can simulate the CAN

bus communication device and conduct the communication test of the

GCAN-IO-8000 module. The USBCAN bus analyzer is an intuitive CAN bus

debugging and analysis tool. Using this device can monitor and simulate CAN data

transmission and reception through a computer. It is an essential tool for engineers

engaged in the CAN bus industry. You are welcome to purchase through the contact

information on the last page of this manual.

4.1 NMT command

The GCAN-IO-8000 module meets the standard CANopen Cia301 protocol and is a

standard CANopen slave device. After GCAN-IO-8000 is started, it will actively

send a frame command to the master station, the frame ID is 0x700+Node ID,

and the frame data is 0x7F.

For example: Set the Node ID of GCAN-IO-8000 to 1 through the DIP switch, then

USBCAN-II Pro as the master device can receive a start command, the frame ID is

0x701, and the frame data is 0x7F. As shown in Figure 4.1, using ECANTools

software can receive this data.

Frame

ID

(HEX)

DLC

Frame data (HEX)

701

1

7F

--

--

--

--

--

--

--

16

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

Figure 4.1 Start command monitoring interface

The GCAN-IO-8000 module receives the operation command issued by the

master station, the frame ID is 0x000, the DLC is 2, the first byte of the frame

data is the command symbol, and the second byte is the node number (00 is all

nodes) .

For example: The node ID of GCAN-IO-8000 is 1, and the command GCAN-IO-8000

is to enter the operation state (01), then the NMT command frame ID is 0x000, and

the frame data is 0x01,0x01. This command can also be issued by the

CANopenMaster plug-in of the ECANTools software. For detailed instructions of

NMT, please refer to Appendix B.4 CANopen Communication.

Frame

ID

(HEX)

DLC

Frame data (HEX)

000

2

Comman

d

Node address

01

01

--

--

--

--

--

--

17

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

Figure 4.2 NMT command sending interface

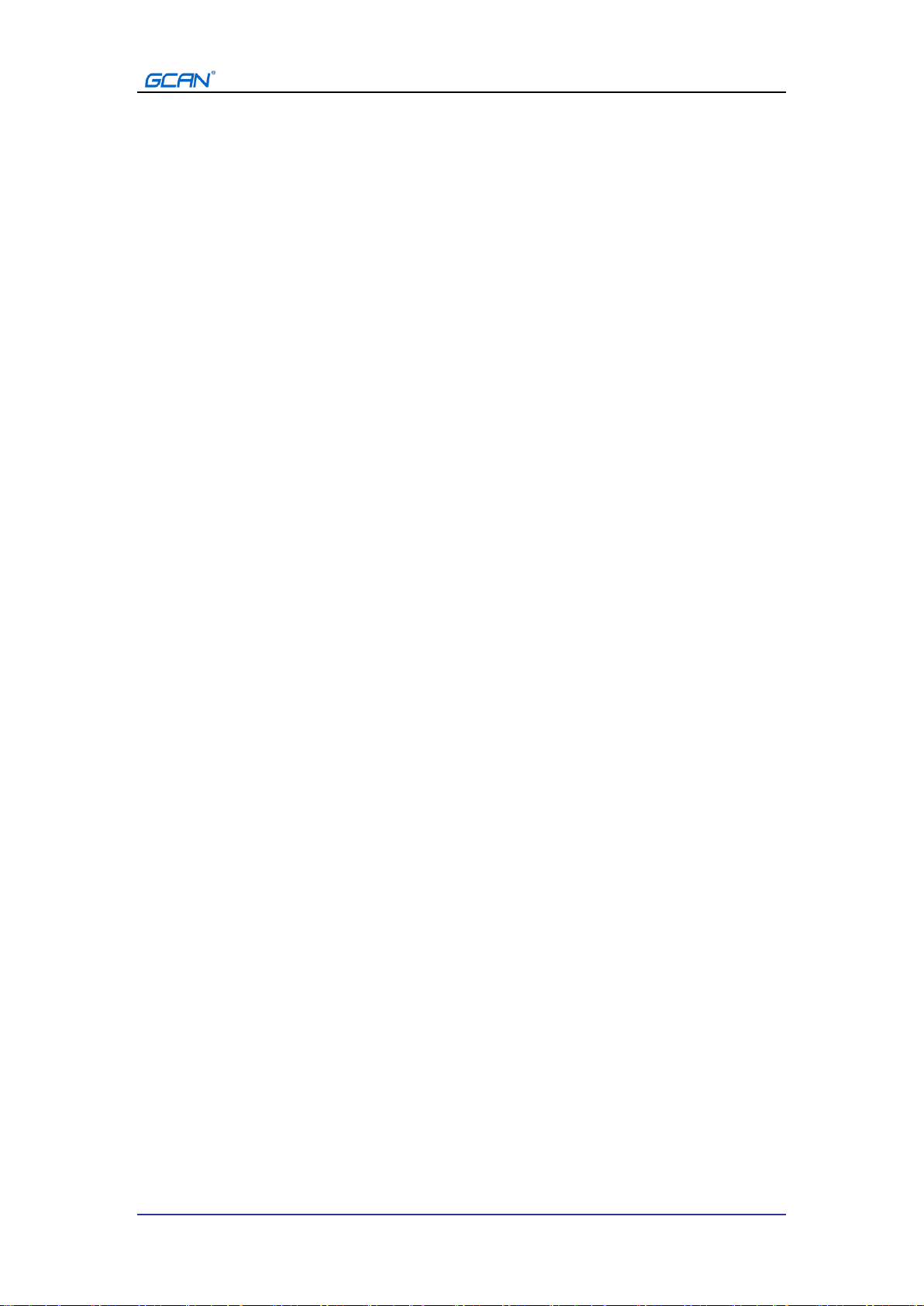

Use the ECANTools software to command GCAN-IO-8000 to enter the operation

state: ①fill the slave node number into the text box behind the ID, ②click the add

slave button, ③open the + sign on the left of the node, and click " NMT", ④

Select "Start Remote Node" (default) and click the "NMT" button below. As shown in

Figure 4.3, the NMT command can be viewed in the ECANTools monitoring interface

after sending.

After receiving the NMT command, GCAN-IO-8000 will start broadcasting PDO data

and issue a heartbeat command with frame ID 0x701 and frame data 0x05, indicating

that GCAN-IO-8000 has entered the operating state.

Figure 4.3 NMT command monitoring interface

4.2 Equipped with GC-1008 module

The state of the digital input is represented by a byte, channel 8 is in the high bit, and

channel 1 is in the low bit.

For example, the node number of the GCAN-IO-8000 module is set to 1. The state of

18

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

channel 8 and channel 4 is 1, and the other states are all 0, then the DI status data

displayed on one end of the CAN bus is 88. The frame ID sent is 0x181, the data

length (DLC) is 8, the frame data is 0x88, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00.

Please note that when only one GCAN-1008 module is inserted, only the first byte in

the frame data is valid. The following table lists two common DI states and their

corresponding state data.

DI status

Number

of

channels

8

7

6

5

4

3

2

1

status

1

0

0

0

1

0

0

0

Data

displayed

on the

CAN bus

88

DI status

Number

of

channels

8

7

6

5

4

3

2

1

status

0

1

0

1

1

0

1

0

Data

displayed

on the

CAN bus

5A

When only one GCAN-1008 module is inserted, the TPDO data frame ID issued by

the GCAN-IO-8000 module is 0x180+node ID (Node ID), the data length is 8, and the

first byte of the frame data is the digital input status of the module .

4.3 Equipped with GC-2008 module

The state of the digital output is represented by a byte, channel 8 is in the high bit, and

channel 1 is in the low bit.

For example, the node number of the GCAN-IO-8000 module is set to 1. Need to set

the state of channel 8 and channel 4 to 1, and set all other states to 0, then the CAN

19

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

bus DO status data to be sent is 88. The frame ID to be sent to GCAN-IO-8000 is

0x201, the data length (DLC) is 8, and the frame data is 0x88, 0x00, 0x00, 0x00, 0x00,

0x00, 0x00, 0x00. Please note that only the first byte in the frame data is valid. The

following table lists two common DO states and their corresponding state data.

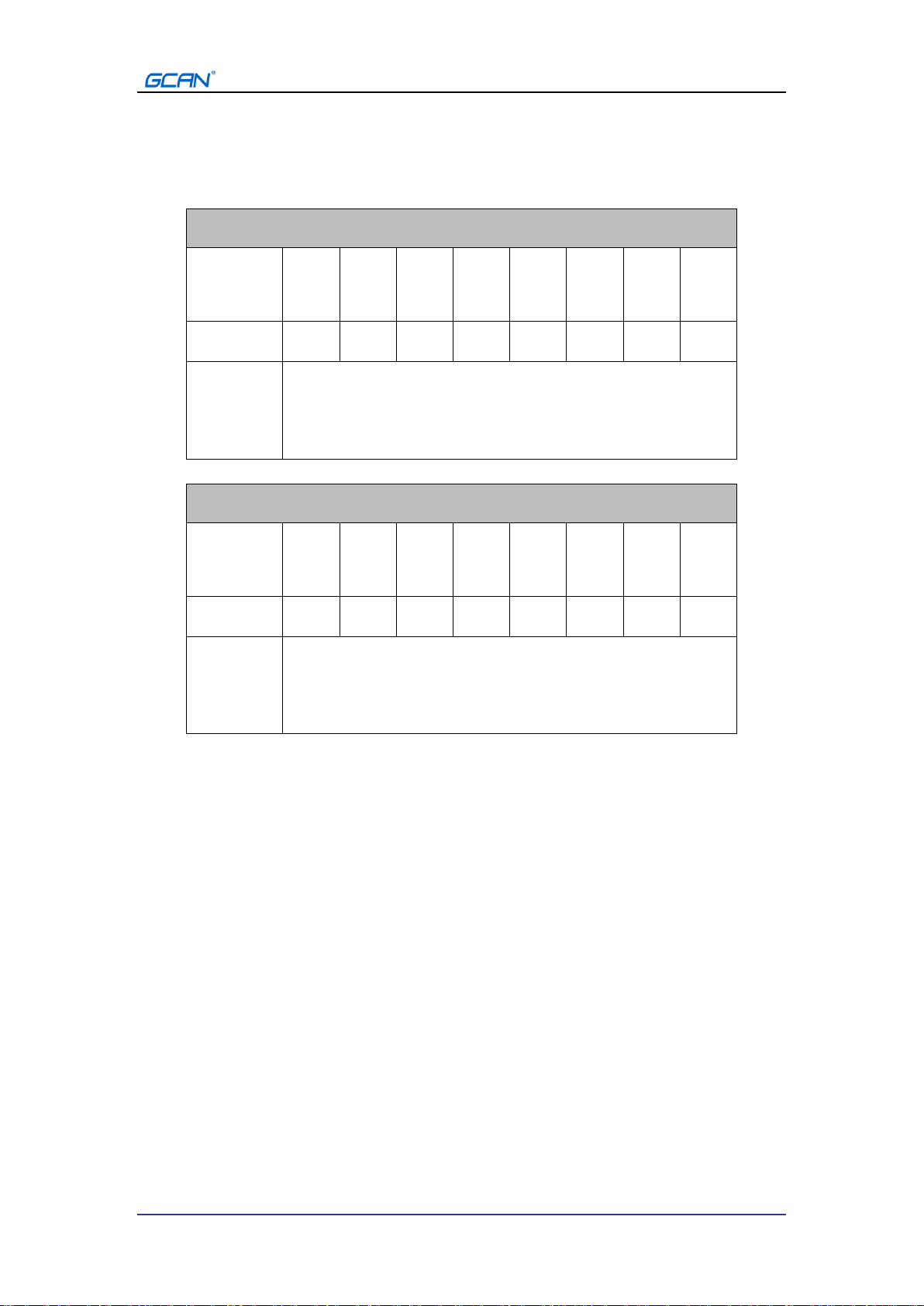

DO status

Number

of

channels

8

7

6

5

4

3

2

1

status

1

0

0

0

1

0

0

0

Data

displayed

on the

CAN bus

88

DO 状态

Number

of

channels

8

7

6

5

4

3

2

1

status

0

1

0

1

1

0

1

0

Data

displayed

on the

CAN bus

5A

When receiving the RPDO data, the GCAN-IO-8000 module needs to ensure that the

frame ID is 0x200 + node ID (Node ID), the data length is 8, and the first byte of the

frame data is the digital output status that needs to be set.

4.4 Equipped with GC-3804 module

The temperature status of each channel is represented by two bytes, and the four

channels have a total of eight bytes.

Among them, the two bytes representing the temperature status, the first byte is the

low bit, the data of the byte needs to be converted to decimal and multiplied by 0.1;

the second byte is the high bit, the data of the byte needs to be converted Multiply by

25.6 after decimal. Finally, the two values are added together to obtain the final

temperature value in degrees Celsius.

For example, the node number of the GCAN-IO-8000 module is set to 1. The

temperatures of the four channels are 25.6 degrees, 25.5 degrees, 20 degrees, and 30

degrees, respectively. The frame ID sent is 0x181, the data length (DLC) is 8, the

frame data is 0x00, 0x01, 0xFF, 0x00, 0xC8, 0x00, 0x2C, 0x01. The following table

lists two possible CAN data and their corresponding temperature values.

20

Shenyang Guangcheng Technology Co., Ltd. CANopen bus coupler—GCAN-IO-8000

Product data sheet Shenyang Guangcheng Technology CO.LTD.

Correspondence between GC-3804 temperature and CAN data

Data

displayed on

the CAN

bus

Low byte C8

High byte 00

coefficient

200(0xC8)x0.1

0(0x00)x25.6

Temperatur

e value

20℃

Correspondence between GC-3804 temperature and CAN data

Data

displayed on

the CAN

bus

Low byte 2C

High byte 01

coefficient

44(0x2C)x0.1

1(0x01)x25.6

Temperatur

e value

30℃

When the GCAN-IO-8000 module sends out TPDO data, the frame ID is 0x180+node

ID (Node ID), and the data length is 8. If PT100 is not connected, the CAN data of the

corresponding channel will be displayed as FF 7F.

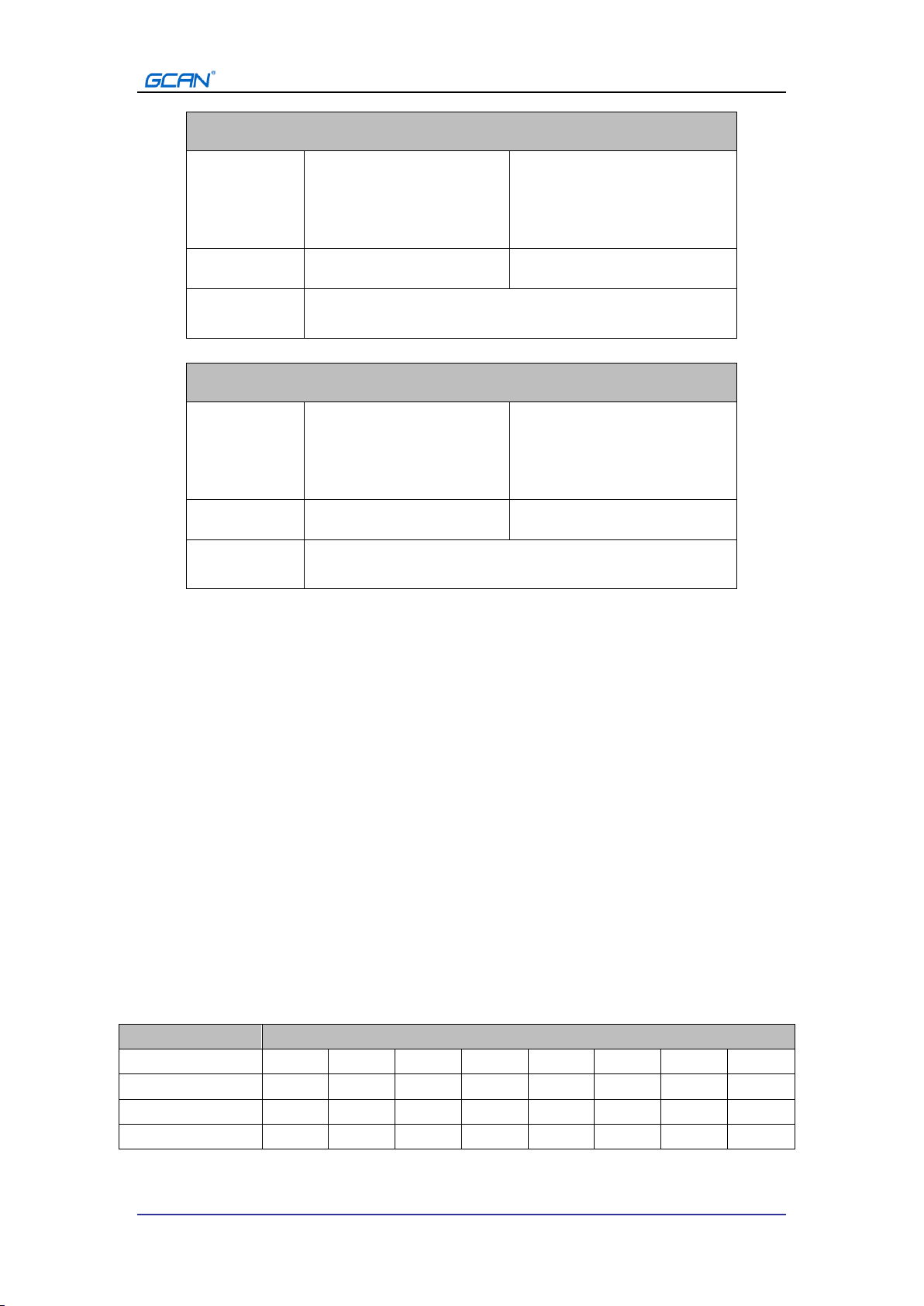

4.5 Equipped with multiple sets of modules at the same

time

If GCAN-IO-8000 is equipped with multiple sets of GC-1008 modules at the same

time, then we will number them according to their distance from GCAN-IO-8000

from near to far, and the nearest one is No. 1. The TPDO data sent by the

GCAN-IO-8000 coupler will be sent according to the following table. For example,

when the GCAN-IO-8000 node number is 3 and it is equipped with 9 GC-1008

modules at the same time, you will receive two sets of data with frame IDs 0x183 and

0x283. Among them, the eight data bytes with the frame ID of 0x183 correspond to

the GC-1008 module No. 1-8 in turn; the one data byte with the frame ID of 0x283

corresponds to the GC-1008 module No. 9.

Table 4.1 Correspondence between multiple sets of GC-1008 modules and CAN data

Frame ID

Frame data

0x180+Node ID

1

2

3

4

5

6

7

8

0x280+Node ID

9

10

11

12

13

14

15

16

0x380+Node ID

17

18

19

20

21

22

23

24

0x480+Node ID

25

26

27

28

29

30

31

32

Other manuals for GCAN-IO-8000

1

Table of contents

Popular Industrial Equipment manuals by other brands

Ditch Witch

Ditch Witch FX20 Operator's manual

Alfalaval

Alfalaval Toftejorg MultiMidget instruction manual

Burger & Brown

Burger & Brown SMARTFLOW FasTie installation instructions

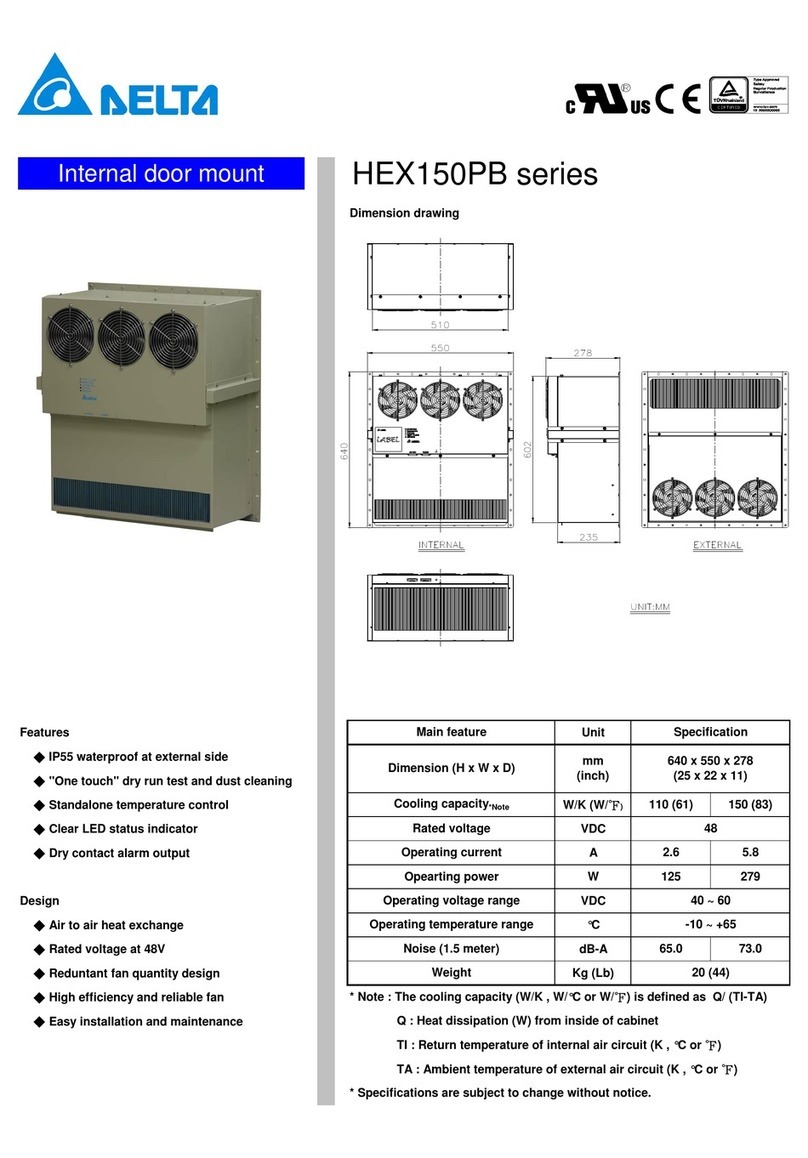

Delta

Delta HEX150PB Series instruction manual

Alfalaval

Alfalaval COMPABLOC CP15 Installation, operation and maintenance manual

woodmizer

woodmizer LubeMizer manual