Table of Contents Section-Page

Table of Contents WMdoc032619 iii

SECTION 1 LUBEMIZER INSTALLATION 1-1

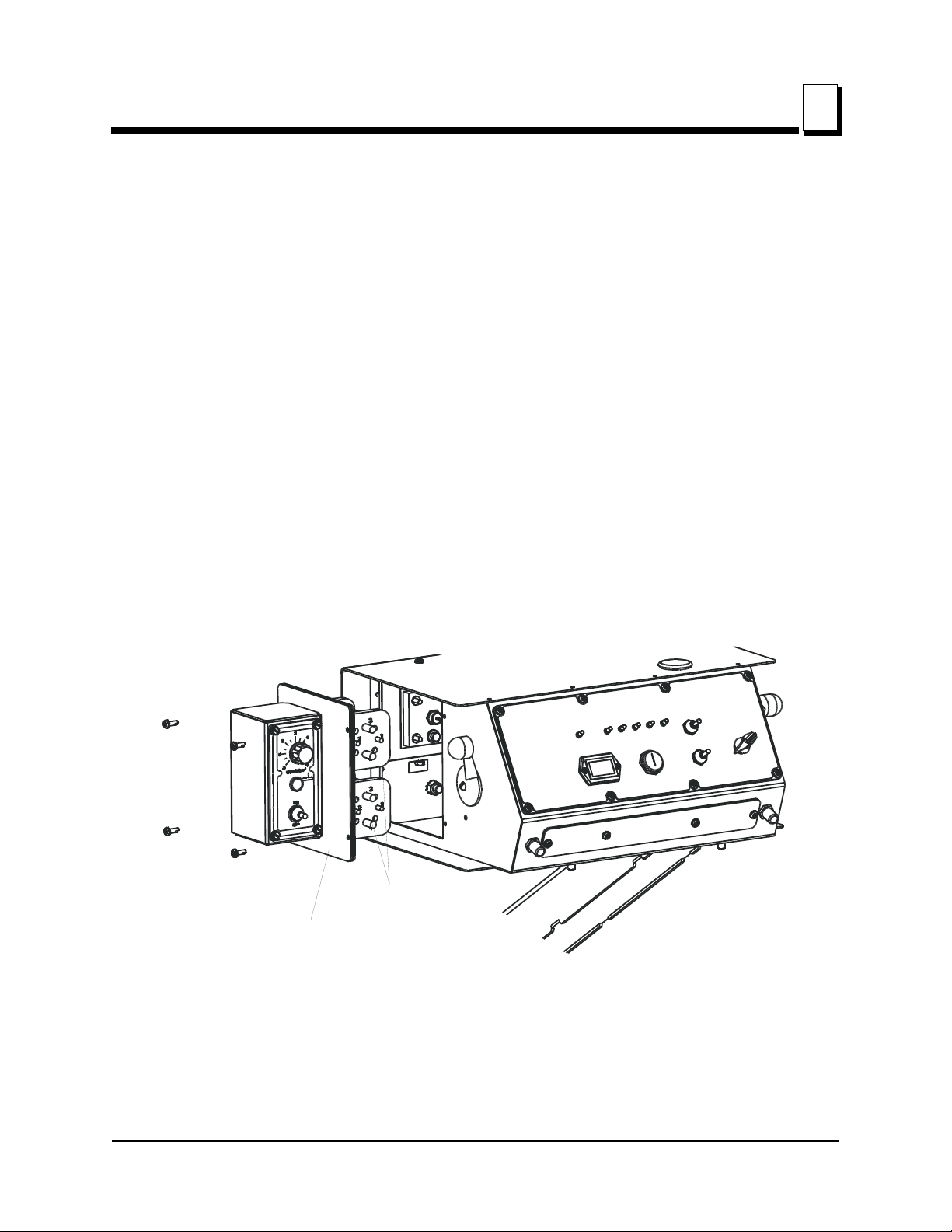

1.1 Control Box Installation .........................................................................1-1

1.2 Control Box Wiring................................................................................1-3

LT30 Super Rev. G9.00+

LT40 Super Rev. H1.00+

LT30HD/40HD Super Rev. H4.00+

LX450 Rev. A1.00+

1.3 Control Box Wiring................................................................................1-4

LT30 Super Rev. F7.00 - G8.00

LT40 Super Rev. F8.00 - G9.00

LT30HD/40HD Super Rev. G1.00 - H3.00

1.4 Control Box Wiring................................................................................1-6

LT30 Rev. F7.00+

LT40 Rev. F8.00+

LT30HD/40HD Rev. G1.00+

1.5 Pump Installation And Wiring (All LT30/LT40 Sawmills)...................1-9

1.6 Pump Installation And Wiring (LX450 Sawmills)...............................1-13

1.7 Water Lube Bottle Conversion and Hose Line Installation (All LT30/LT40 Sawmills)

1-15

1.8 Hose Line Installation (LX450 Sawmills)............................................1-17

1.9 Finishing Steps .....................................................................................1-19

SECTION 2 OPERATION 2-1

2.1 The LubeMizer System ..........................................................................2-1

2.2 Lube Additives .......................................................................................2-3

SECTION 3 MAINTENANCE 3-1

SECTION 4 REPLACEMENT PARTS 4-1

4.1 Pump Assembly (LMS-HP/LMS-A)......................................................4-1

4.2 Pump Assembly (LMS-LX) ...................................................................4-3

4.3 Filter Assembly (LMS-HP/LMS-A).......................................................4-4

4.4 Filter Assembly (LMS-LX)....................................................................4-5

4.5 Blade Guide Block Assembly (LMS-A Only) .......................................4-6

LMS-A Rev. A.01+

4.6 Blade Guide Block Assembly ................................................................4-7

LMS-A Rev. A.00

4.7 Control Box Assembly ...........................................................................4-8

LMS-A Rev A.00+

LMS-RA Rev. E.00+

LMS-LX Rev A.00+

SECTION 5 ELECTRICAL INFORMATION 5-1

5.1 Electrical Components............................................................................5-1