231 Lake Dr. Newark, Delaware 19702 USA Tel: (302) 451-7500 Fax: (302) 451-7501 Doc. ID#: SM329WI-03

wire size is 12 AWG (4 mm2). The maximum

wire size is 8 AWG (10 mm2). For modules

that are certified up to 1000V, use TUV

approved 4.0mm2solar cable.

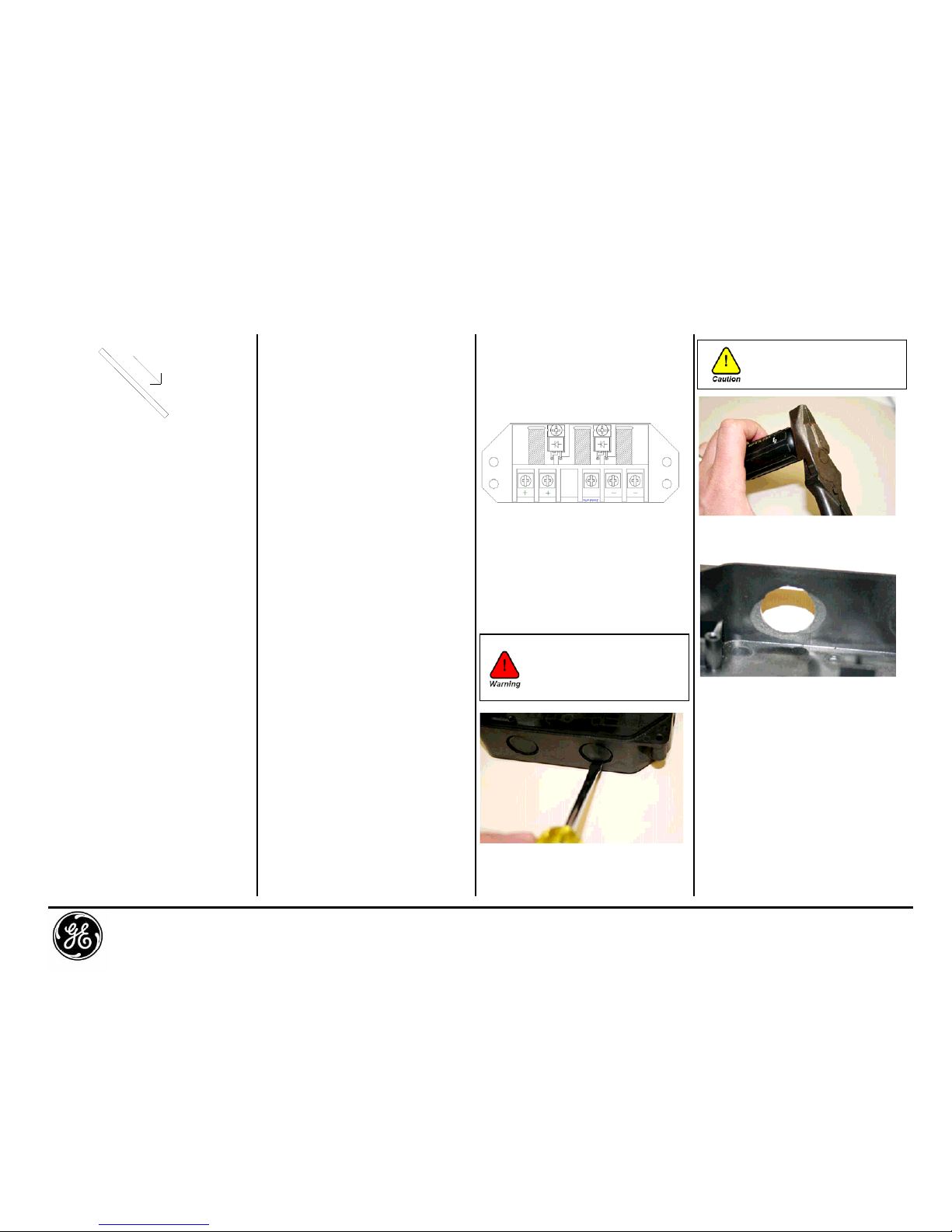

Junction box with Multi-Contact or Solarlok

Leads - When using optional Multi-Contact

(MC) or Solarlok (MS) connectors, there are no

user serviceable parts in the junction boxes.

Do not open the junction box or change inter-

module wiring, as all wiring connections are

performed in the factory. The MC or MS

connectors cannot be opened under load.

Modules may be connected and

disconnected when current is not flowing

through the connector, under open circuit

voltage conditions. Always observe proper

precautions when connecting or

disconnecting modules exposed to light since

hazardous voltage may be present.

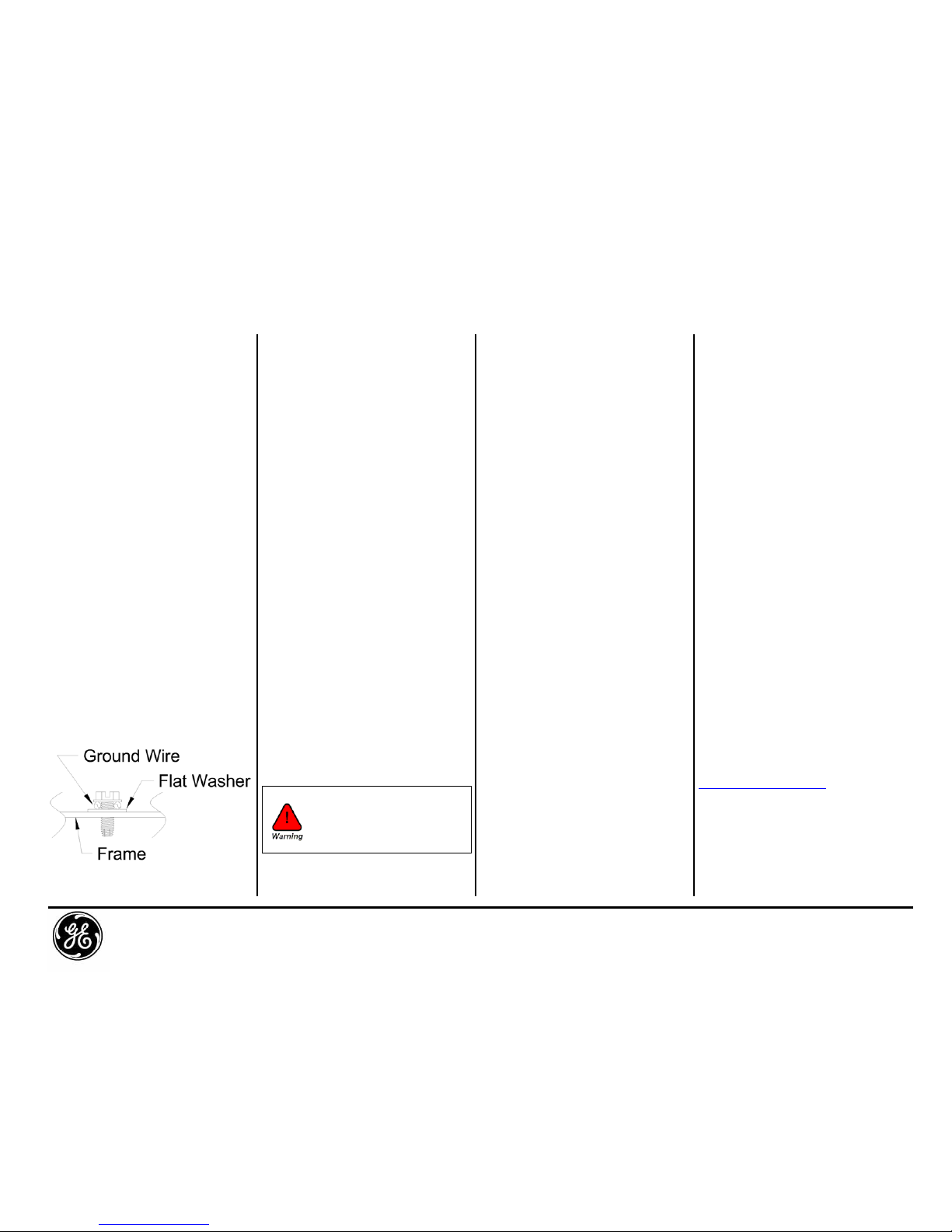

Grounding- Size and earth the equipment

grounding conductor in accordance with

local requirements or the NEC. Attach the

equipment grounding conductor to the

module frame using the hole and hardware

provided. Note that a stainless steel flat

washer is used between the ground wire and

the module frame (see picture below). This

washer is used to avoid corrosion due to

dissimilar metals. Tighten the screw securely .

For optional methods of grounding a solar

module refer to GE Energy Document

“Optional Ground Methods”.

Bypass Diodes- Bypass diodes are pre-

assembled in each GE Energy module.

Typically modules are supplied with a 12 or 18

Amp diode. Do not remove these diodes.

Blocking Diodes and Charge Controllers-

Blocking diodes can prevent the solar module

from discharging the battery at night. GE

Energy modules do not include blocking

diodes. It is recommended that a charge

controller be used to prevent the batteries

from being overcharged and discharged at

night.

Cleaning

Over the life of a solar module, it is common

for dust and dirt particles to accumulate on

the surface of the module. This build up

can reduce the performance of the module as

well as contribute to the growth of moss and

molds. Normally, the build up of dust

particles will be washed away by periodic

rainfall, but in some instances mosses and

molds may appear. If significant moss or

mold growth appears on the module surface

cleaning may be required. To ensure

maximum solar module performance, GE

recommends cleaning the module surface

with a sodium percarbonate solution, similar

to the household-cleaning product

Oxiclean™.

Mixing the sodium percarbonate solution -

Sodium percarbonate is a dry white powder

that can be mixed with warm water to create

an environment-friendly oxidizing agent. The

mixture of sodium percarbonate and warm

water effectively breaks down organic matter.

Do NOT use bleach to clean solar modules, as

it is hazardous to the environment. To create

the cleaning solution, mix 1/2 cup of dry

sodium percarbonate with a gallon of warm

water (100-120° F). The mixture will retain its

cleaning power for 5 to 6 hours.

System preparation and safety precautions-

Cleaning should only be completed by the

system installer or someone with equivalent

fall protection safety training. If you are going

up onto the roof to clean the modules, ensure

that the proper amount of fall protection is

being worn. Follow all warnings at the end of

this technical bulletin.

Applying the cleaning solution to the

modules - Apply the cleaning mixture to the

modules with a clean lawn sprayer. The

sprayer should have a large enough chamber

to hold the entire warm water / sodium

percarbonate solution, it should not be a hose

end sprayer. Once the cleaning mixture has

been applied, let the solution stand on the

modules between 20 and 30 minutes. If

necessary, scrub the module surface to

remove any remaining particles. Thoroughly

rinse the module surface to remove the

cleaning solution. Key points:

• This procedure should only be completed by

the system installer or someone with

equivalent fall protection safety training.

• Fall protection should be worn at all times

while cleaning any modules on a roof-

mounted system.

• Do not drop, allow objects to fall on, stand

or step on solar modules. Do not walk, lean,

sit or rest heavy objects on solar panels.

• Solar modules have a protective glass front.

Broken solar module glass is an electrical

safety hazard (electric shock and fire). These

modules cannot be repaired and must be

replaced immediately. If you have a broken

module turn your system off. If your solar

module is broken do not clean.

• Do not touch the solar modules or the

mounting structures with your bare hands

during the cleaning process. When these

surfaces are exposed to sunlight they can

become extremely hot. Protective gloves

should be worn when touching the system

components.

• Sharp edges may exist on the components.

Protective gloves should be worn while

cleaning the solar array system.

• Exposing the anodized aluminum frame to

the sodium percarbonate cleaning solution

for longer than 10 hours may cause surface

staining on the aluminum.

• The sodium percarbonate cleaning solution

attacks organic matter and should be kept

from directly contacting plants. In the event

the cleaning solution comes in direct contact

with plants that you intend to keep,

thoroughly rinse the plant leaves to remove

the solution.

Performance

Refer to the attached spreadsheet for

performance information. Detailed product

information can be found on the GE Solar

website at:

www.gepower.com/solar

Electric Shock and Burn Hazard

Do not attempt to clean a module with a

broken glass cover or a perforated

backsheet. Such a module can present a

serious shock hazard.