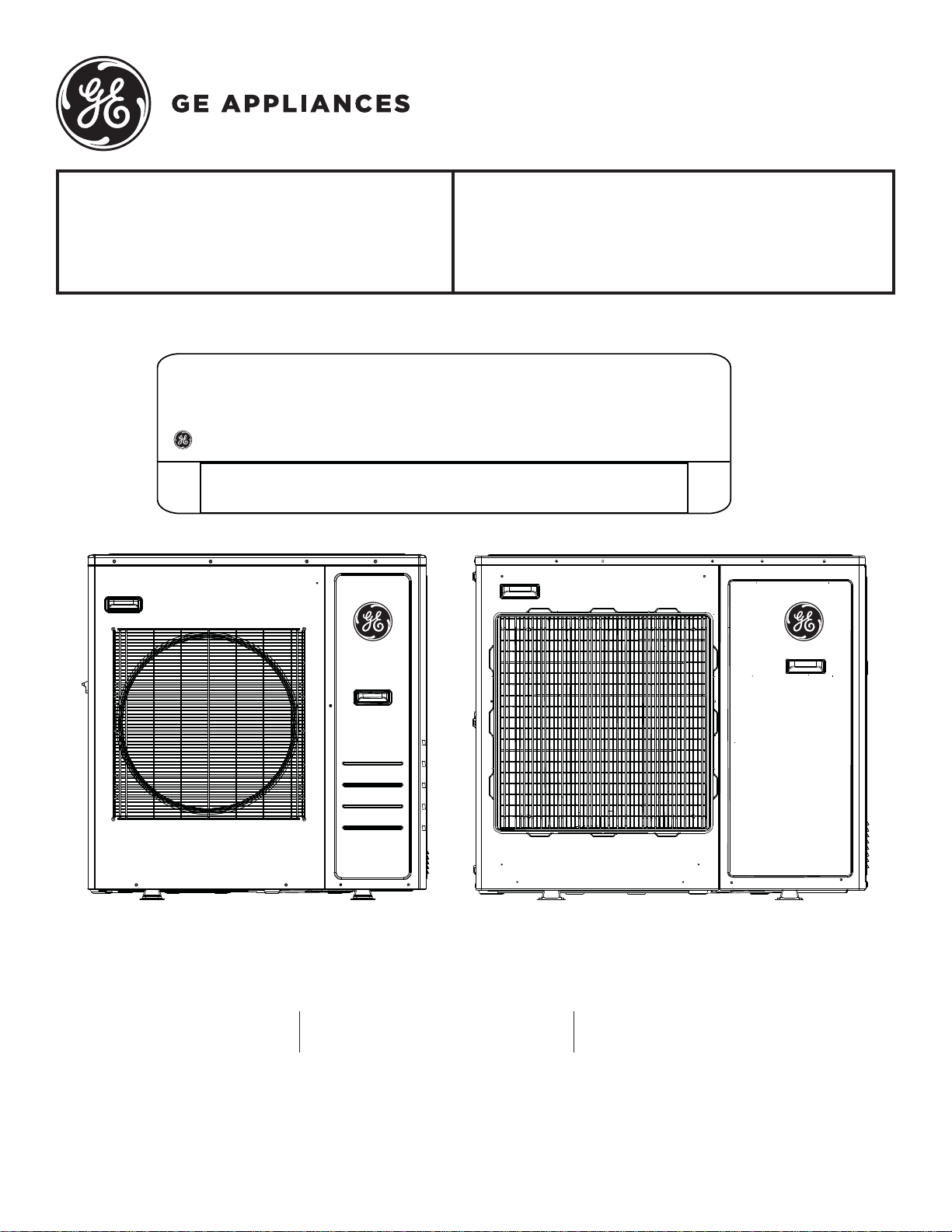

431-5000560 Rev. 5

WARNING For your safety, the information in this manual must be followed to minimize the risk of fire,

electric shock, or personal injury.

• Use this equipment only for its intended purpose as

described in this manual.

• This heat pump must be properly installed in

accordance with these instructions before it is used.

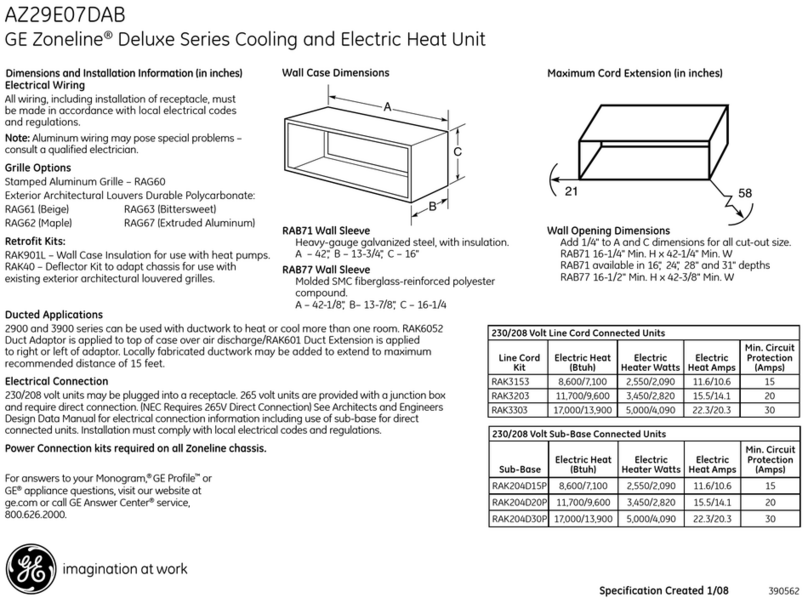

• All wiring should be rated for the amperage value listed

on the rating plate. Use only copper wiring.

• All electrical work must be completed by a qualified

electrician and completed in accordance with local and

national building codes.

• Any servicing must be performed by a qualified

individual.

• All heat pumps contain refrigerants, which under federal

law must be removed prior to product disposal. If you

are getting rid of an old product with refrigerants, check

with the company handling disposal.

• These R-410A heat pumps systems require that

contractors and technicians use tools, equipment and

safety standards approved for use with this refrigerant.

DO NOT use equipment certified for R22 refrigerant

only.

WARNING RISK OF ELECTRIC SHOCK. Could cause injury or death.

• An adequate ground is essential before connecting the

power supply.

• Disconnect all connected electric power supplies before

servicing.

• Repair or replace immediately all electrical wiring that

has become frayed or otherwise damaged. Do not use

wiring that shows cracks or abrasion damage along its

length or at either end.

WARNING

This heat pump system is not intended for use by

persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a

person responsible for their safety. Children should be

supervised to ensure that they do not play with the heat

pump system.

To avoid danger of suffocation, keep the plastic bag or

thin film used as the packaging material away from young

children.

Be sure not to allow foreign materials (oil, water,

etc) entering the refrigerant piping. Seal the ends of

refrigerant piping before storage.

For installation purposes, be sure to use the parts

supplied by the manufacturer or other prescribed parts.

The use of non-prescribed parts can cause serious

accidents such as the unit falling, water leakage, electric

shock, or fire.

The rated power supply of this product is 208/230

VAC/60hz/1PH. Verify the voltage is within 187~253 range

before turning the equipment on.

Supply power to the heat pump should be from a

dedicated circuit that meets branch circuit ampacity

requirements.

Use a special branch circuit breaker and receptacle

matched to the power circuit capacity of the heat pump.

(Install in accordance with local technical standard for

electrical equipment.)

Do not extend the power cord.

Perform wiring work in accordance with standards so that

the heat pump can be operated safely and positively.

Install a leakage special branch circuit breaker in

accordance with the related laws and regulations and

electric company standards.

WARNING

RISK OF FIRE. Could cause injury or death.

•

Do not store or use combustible materials, gasoline or other flammable vapors or liquids in the vicinity of this or any

other appliance.

For any service which requires entry into the

refrigerant sealed system, Federal regulations

require that the work is performed by a technician

having a Class II or Universal certification.

Important Safety Information