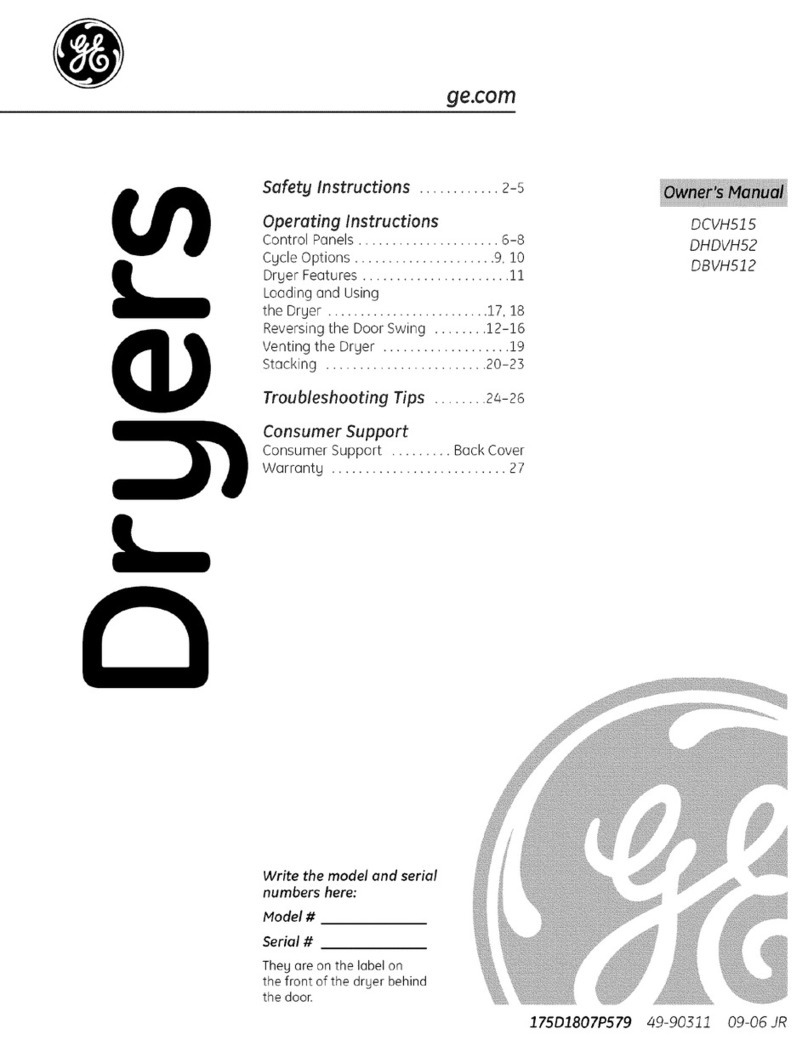

Section 1----- General Information Page 4

Section 2----- Multi-Unit Installation Page 9

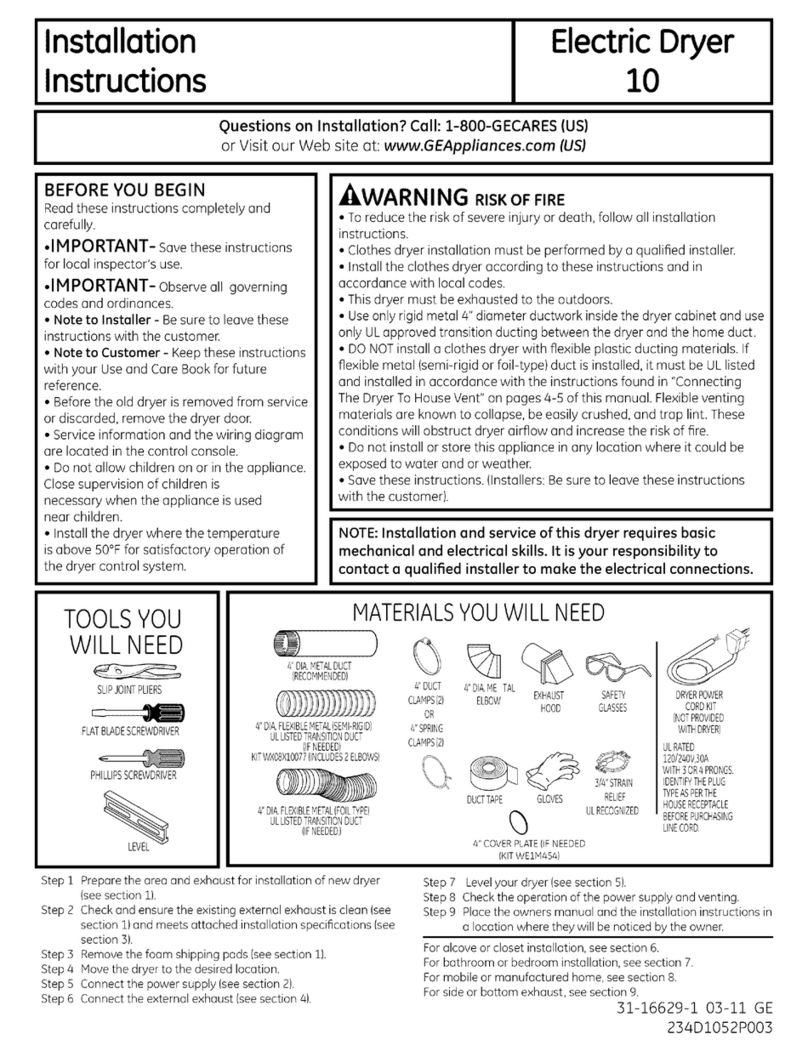

THERE IS A NEED FOR

ACCURATE INFORMATION

The variety of floor plans and laundry

locations, coupled with an increasing

number of building codes and

restrictions, indicates a need to advise

planners well in advance of installation

about exhaust requirements and other

pertinent information. This is especially

true in multi-family construction.

Failure to comply with the

manufacturer’s recommendations when

installing a washer and dryer can void

warranty provisions, cause local

authorities to refuse to grant a certificate

of occupancy, or may even result in legal

liability should the user experience

personal or property damage as a result

of the installation.

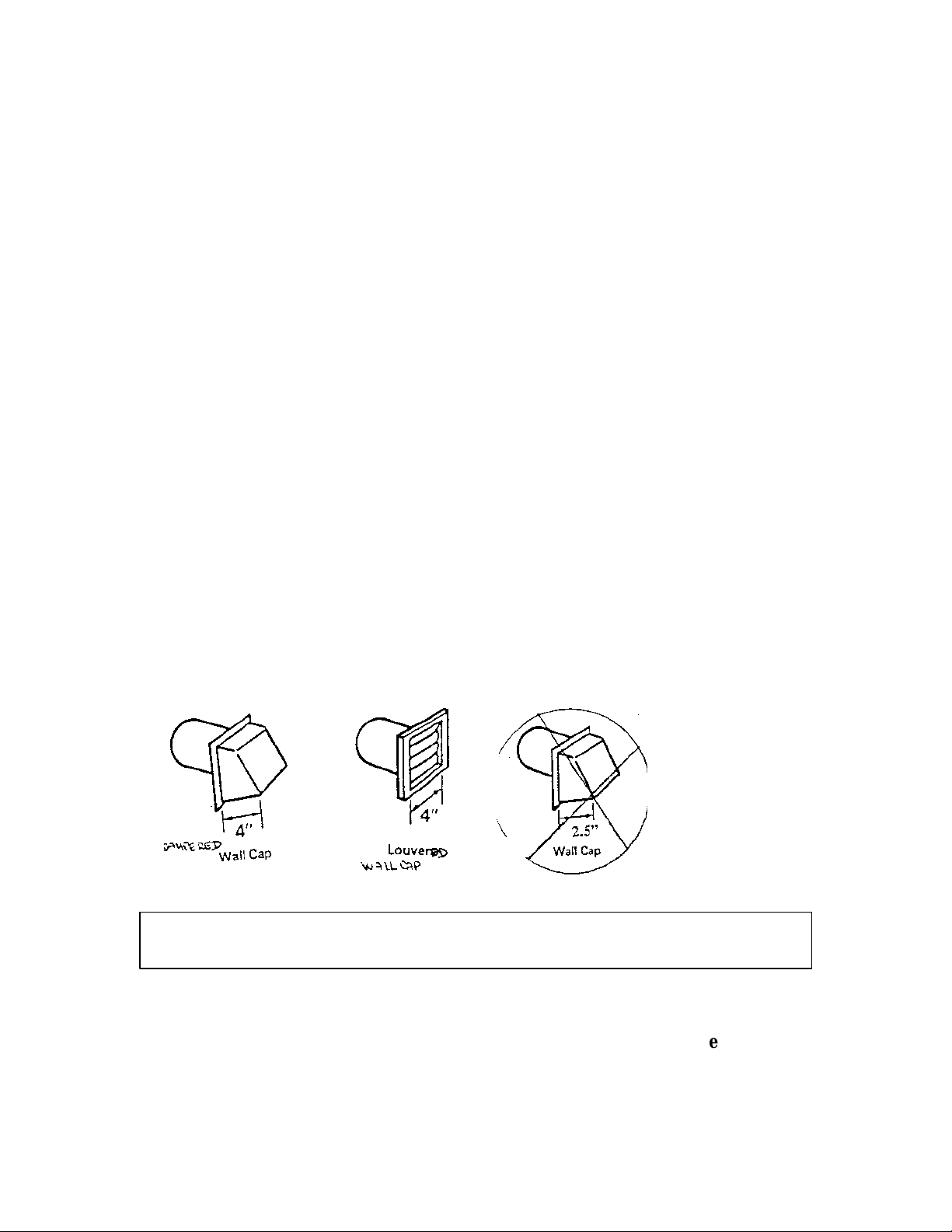

GOOD PRACTICE IN

EXHAUSTING DRYERS

An inadequate or improperly installed

dryer exhaust system will, at the very

least, result in a loss of drying

performance and an excess energy

consumption.

All dryers must be exhausted to the

outdoors. When the dryer is in operation,

the warm humid air passes thorough the

dryer lint filter where the lint is

collected. Fine particles of lint will pass

through the lint screen and will be

pushed through the exhaust duct to the

outdoors. If outdoors exhausting is not

provided, this lint and moist air will be

exhausted into the room. This condition

could create undesirable effects

including:

•Aggravating allergic conditions

•Sweating of cold water pipes,

windows and walls

•Rusting of metal

•Peeling of paint

•Loosening of wall paper

The indoor exhausting also affects dryer

performance, since it re-circulates highly

humid air from the room. It usually

results in longer drying times.

Index