– 3 –

Airflow ....................................................................................................................................................................................23

Air Duct Assembly ............................................................................................................................................................42

Belt Switch ...........................................................................................................................................................................34

Blower Housing..................................................................................................................................................................34

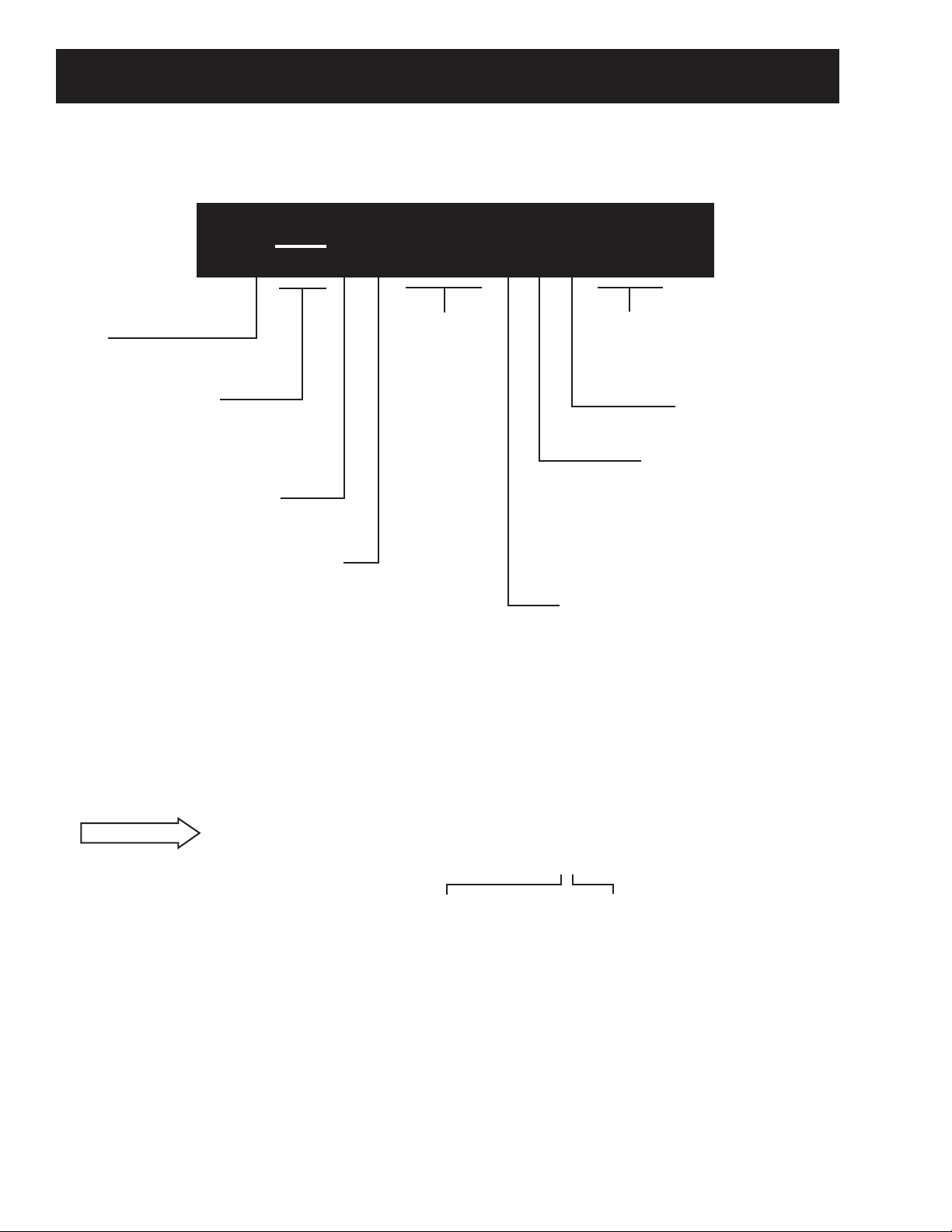

Component Locator Views...........................................................................................................................................24

Control Board Assembly ...............................................................................................................................................44

Control Panel ......................................................................................................................................................................28

Control Features...............................................................................................................................................................6

Cycle Options......................................................................................................................................................................9

Door Switch .........................................................................................................................................................................42

Drive Belt............................................................................................................................................................................... 29

Drum....................................................................................................................................................................................... 30

Drum Shaft Bearing.........................................................................................................................................................31

Drum Slide Assembly......................................................................................................................................................41

Dryer Components ..........................................................................................................................................................28

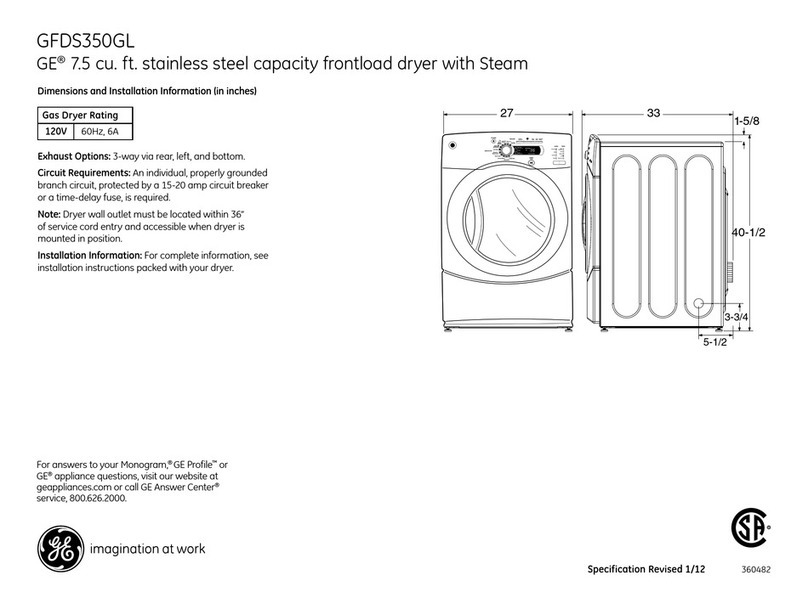

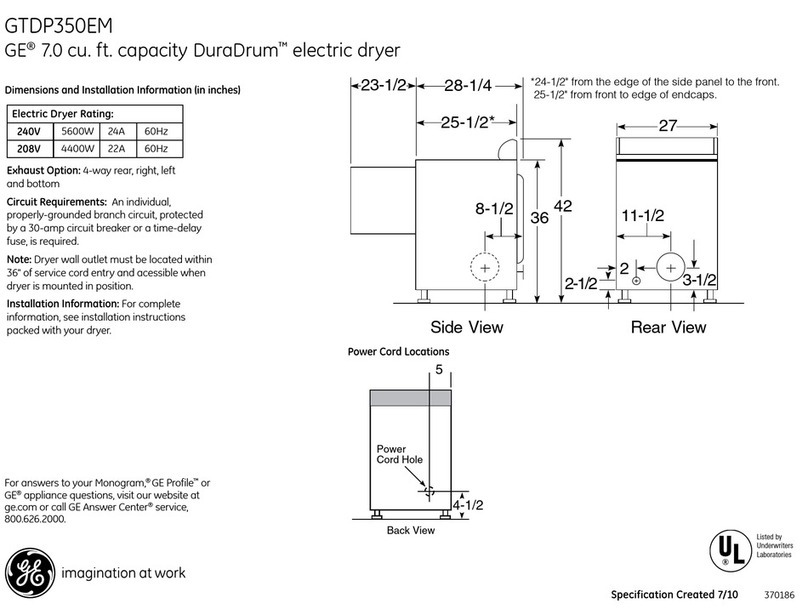

Dryer Features...................................................................................................................................................................11

Error Codes .......................................................................................................................................................................... 47

Flame Detector ..................................................................................................................................................................37

Front Panel...........................................................................................................................................................................29

Gas Valve .............................................................................................................................................................................35

Gas Valve Coil Assembly ...............................................................................................................................................36

Heater Assembly...............................................................................................................................................................35

High Limit Thermostat....................................................................................................................................................40

Idler Assembly....................................................................................................................................................................31

Ignitor.....................................................................................................................................................................................37

Ignitor Circuit Operation................................................................................................................................................38

Inlet Control Thermistor.................................................................................................................................................39

Inlet Safety Thermostat.................................................................................................................................................39

Introduction.........................................................................................................................................................................5

LP Conversion.....................................................................................................................................................................36

Moisture Sensor ................................................................................................................................................................43

Motor and Blower Wheel Assembly......................................................................................................................... 32

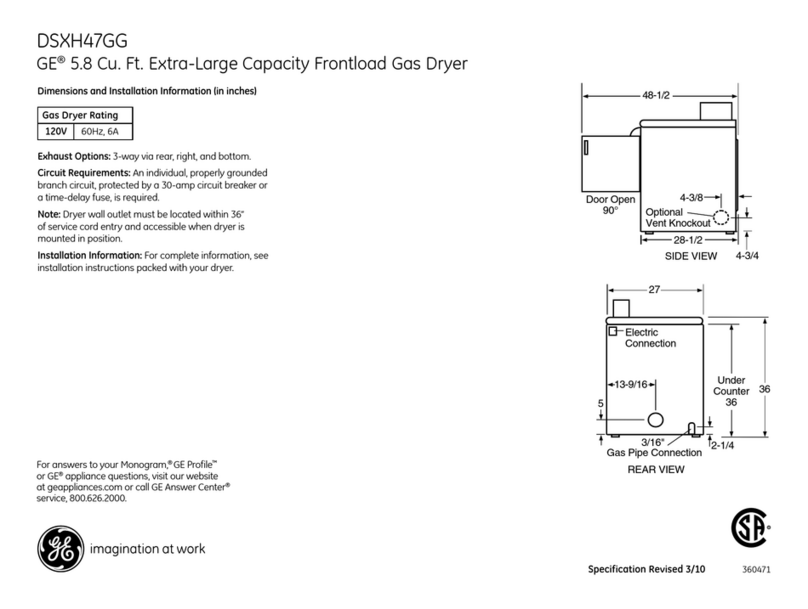

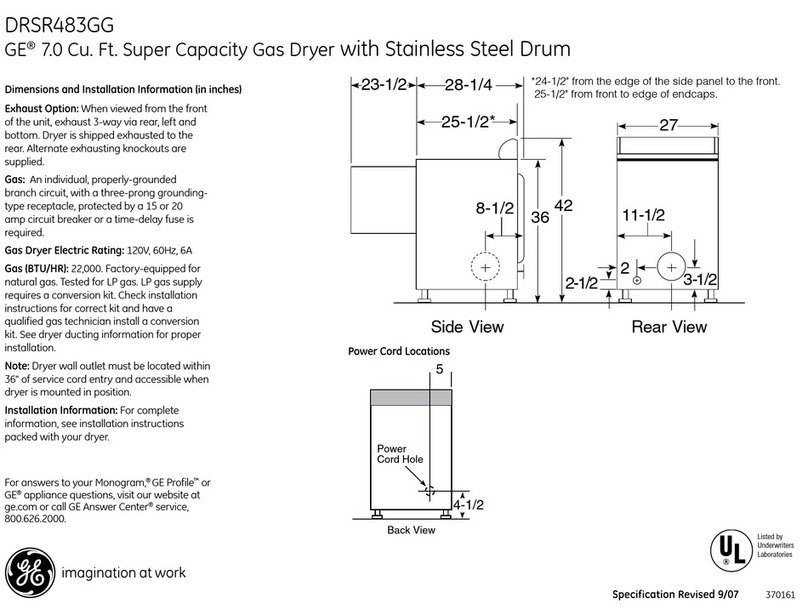

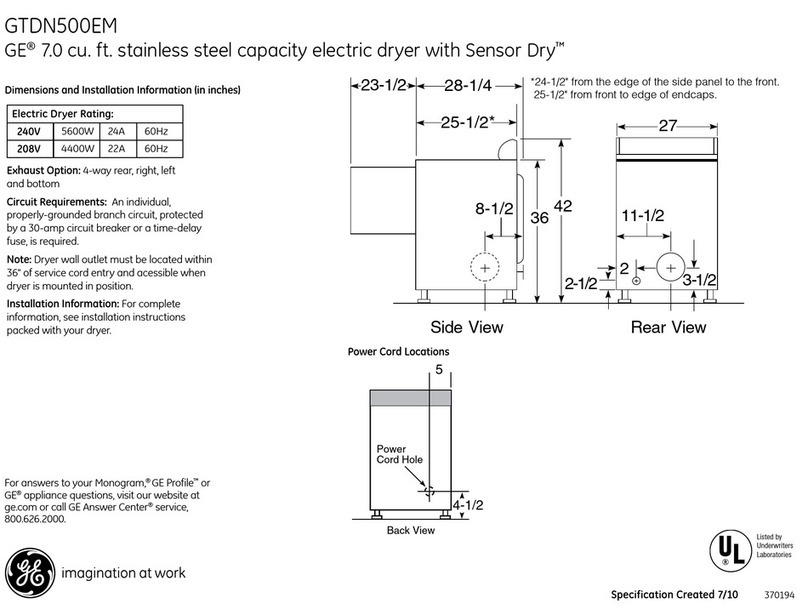

Nomenclature ....................................................................................................................................................................4

Operation Overview.........................................................................................................................................................22

Outlet Control Backup Thermostat........................................................................................................................... 41

Outlet Control Thermistor .............................................................................................................................................40

Pedestal Installation (Washer and Dryer)..............................................................................................................16

Power Board........................................................................................................................................................................43

Reversing the Door Swing ............................................................................................................................................12

Schematics and Wiring Diagrams............................................................................................................................48

Service Test Mode.............................................................................................................................................................45

Stacking Instructions ......................................................................................................................................................19

Top Panel ..............................................................................................................................................................................28

Warranty ..............................................................................................................................................................................50

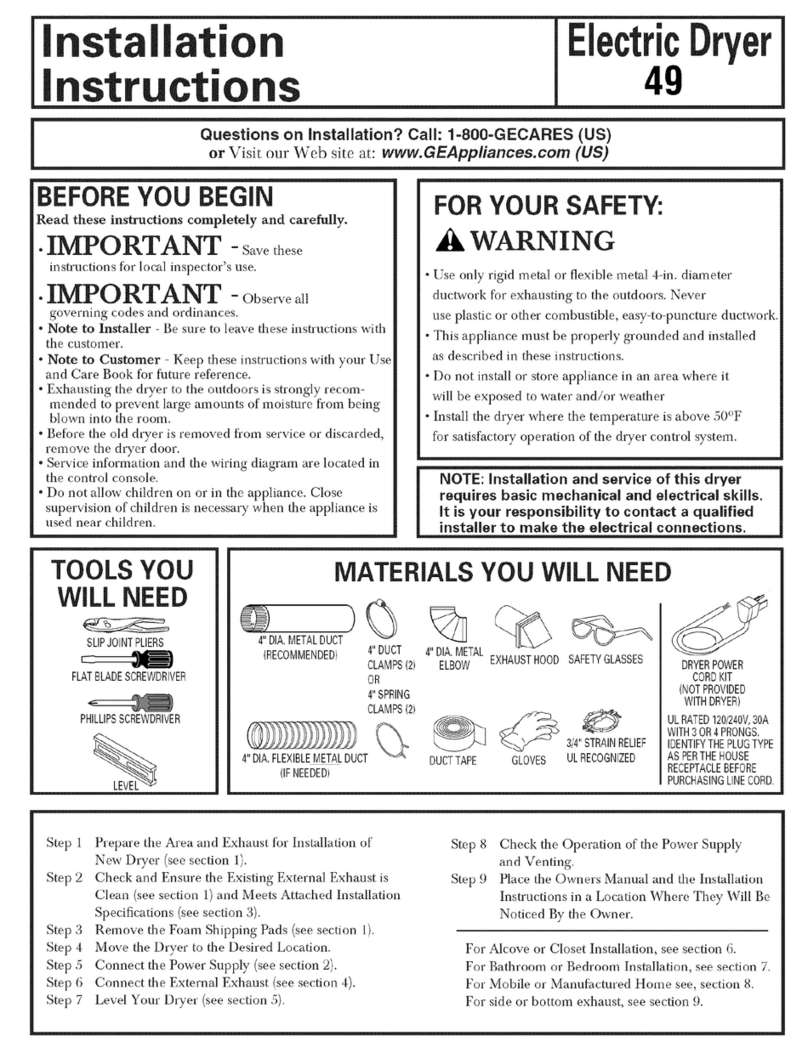

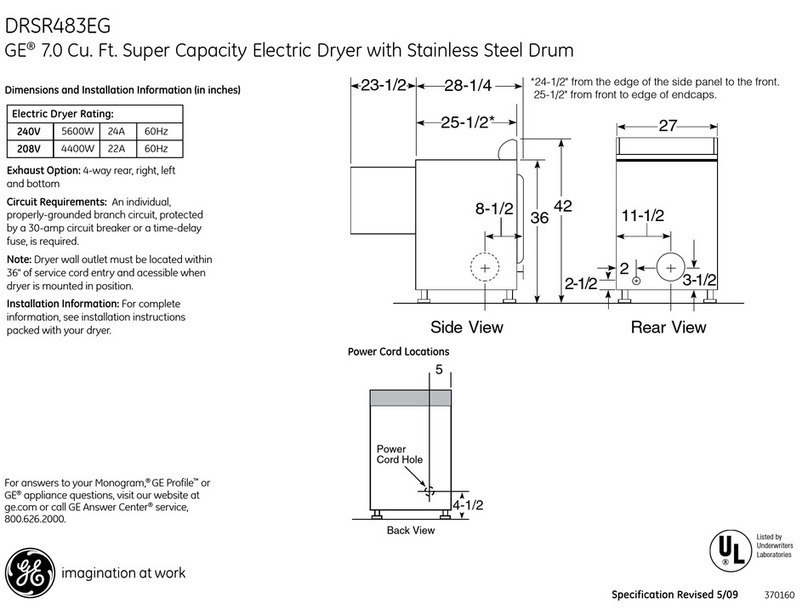

Table of Contents