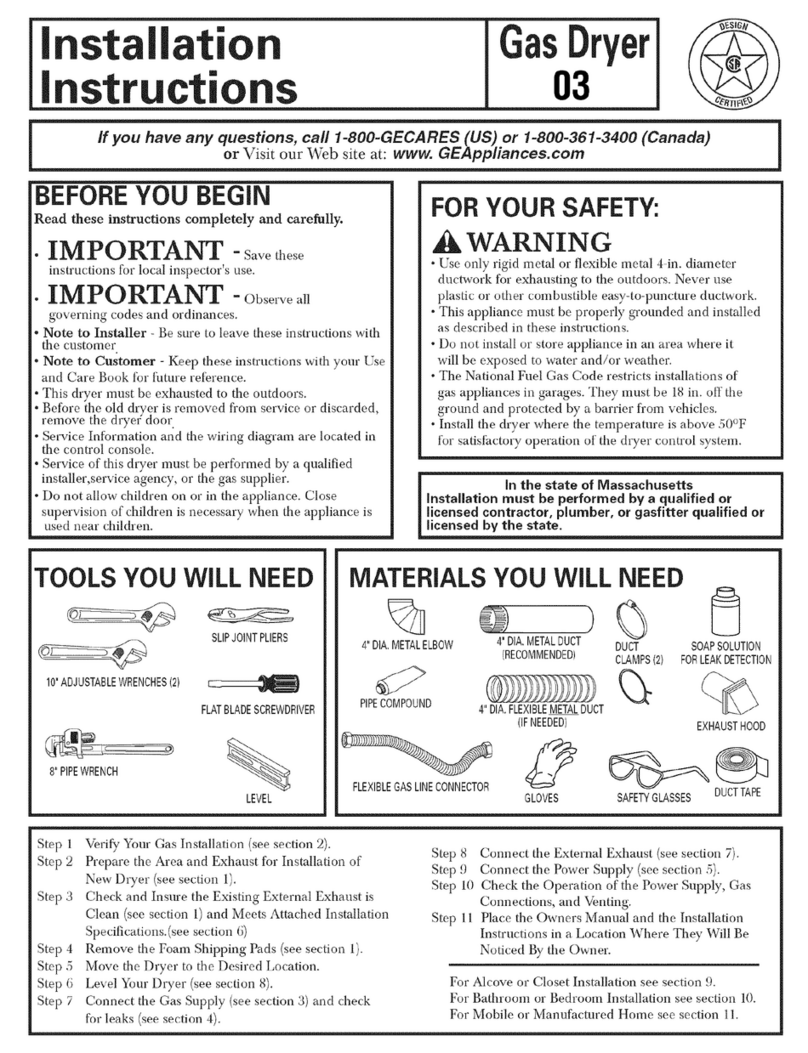

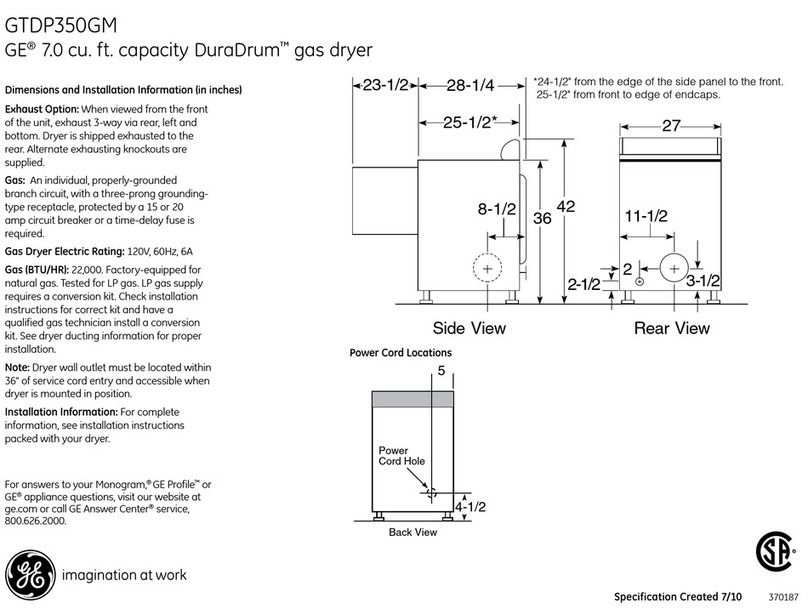

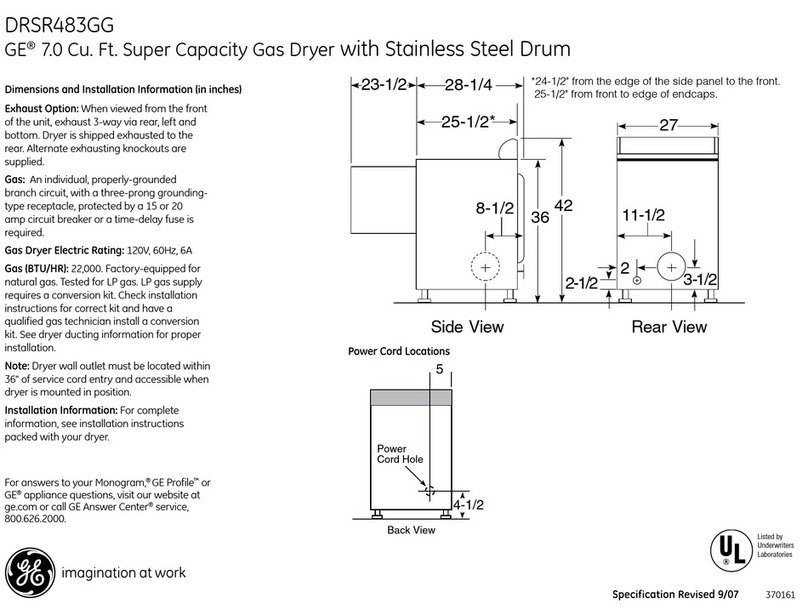

Installation

EXHAUST SYSTEM CHECK LiST(cont.)

SEPARATIONOF TURNS

For best performance, separate all turns by at least 4 ft. of

straight duct, including distance between last turn and exhaust

hood.

TURNSOTHERTHAN90°

, One turn of 450or less may be ignored.

, Two a50turns should be treated as one 90°turn.

, Eachturn over450should be treated usone 900turn.

SEALINGOFJOINTS

, Alljoints should be tight to avoid leaks.Themale end of each

section of duct must point away from the dryer.

, The duct shall not be assembled with screws or other

fastening means that extend into the duct and catch lint.

, Ductjoints can be made air and moisture-tight by wrapping

the overlappedjoints with duct tape.

, Horizontal runs should slope down toward the outdoors 1/4

inchper foot.

INSULATION

Duct work that runs through an unheated area or is near air

conditioning should be insulated to reduce condensation and

lint build-up.

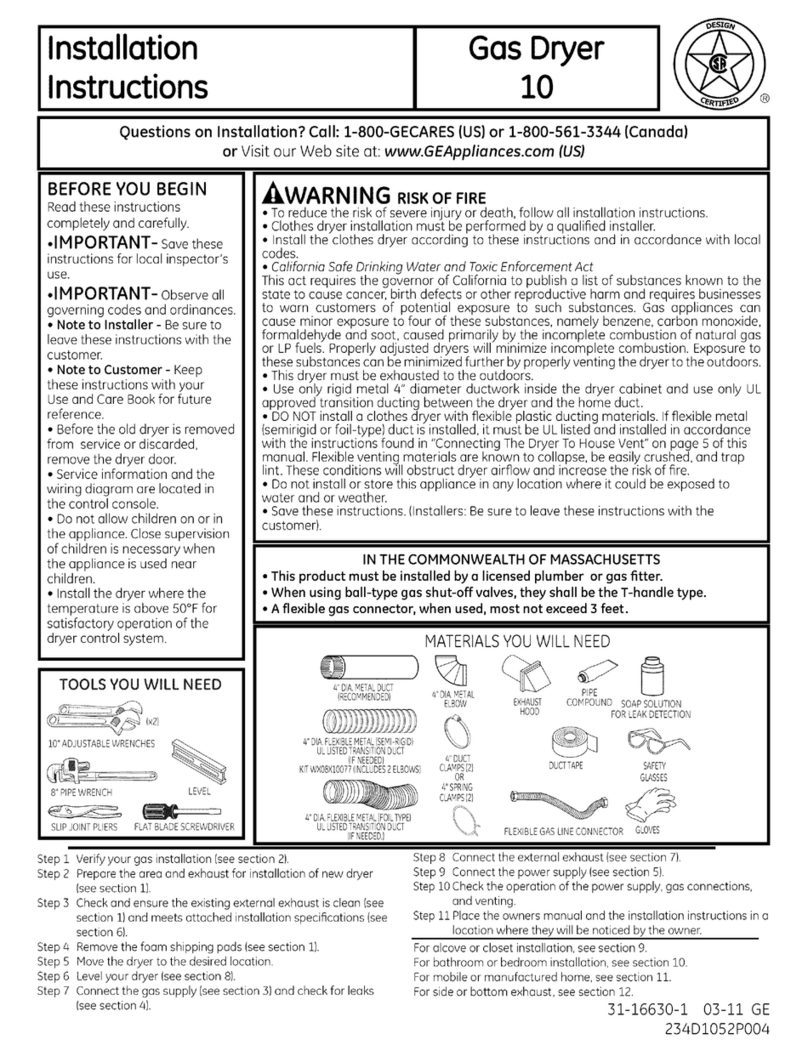

[-4-]EXHAUST CONNECTION

WARNING -TOREDUCETHERiSK

OF FiRE OR PERSONAL iNJURY:

,This clothesdryer must be exhaustedto the outdoors.

, Useonly#' rigid metal ducting for the home exhaustduct.

, Use only a" rigid metal or UL-listedflexible metal (semi-

rigid or foil-type) duct to connect the dryer to the home

exhaust duct. It must be installed in accordance with

the instructions found in "Connecting the Dryerto House

Vent"on pagesa-5 of this manual.

, Do not terminate exhaust in a chimney, a wall, a ceiling,

gas vent, crawl space,attic, under an enclosedfloor, or in

anyother concealed spaceofa building.Theaccumulated

lint could create a potential fire hazard.

, Never terminate the exhaust into a common duct with a

kitchen exhaust system.A combination of greaseand lint

creates a potential fire hazard.

, Do not use duct longer than specified in the exhaust

length table. Longer ducts can accumulate lint, creating

a potential fire hazard.

, Never install a screen inor overthe exhaust duct. Thiswill

cause lint to accumulate, creating a potential fire hazard.

,Do not assemble ductwork with any fasteners that

extend into the duct. These fasteners can accumulate

lint, creating a potential fire hazard.

, Do not obstruct incoming or exhausted air.

, Provide an access for inspection and cleaning of the

exhaust system, especially at turns and joints. Exhaust

system shall be inspected and cleaned at least once a

year.

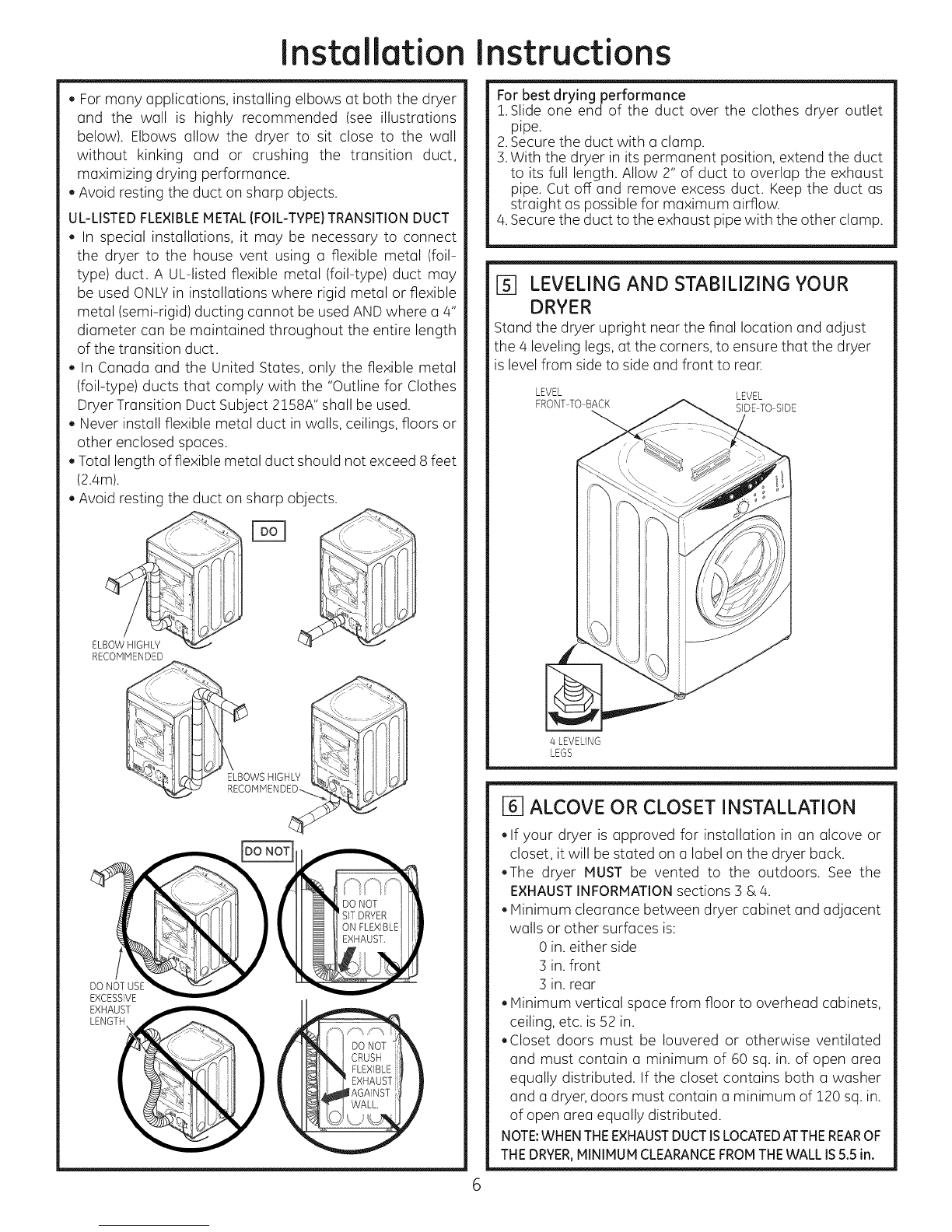

There are multiple installation options.

Select the most appropriate method for

your installation situation.

nstructions

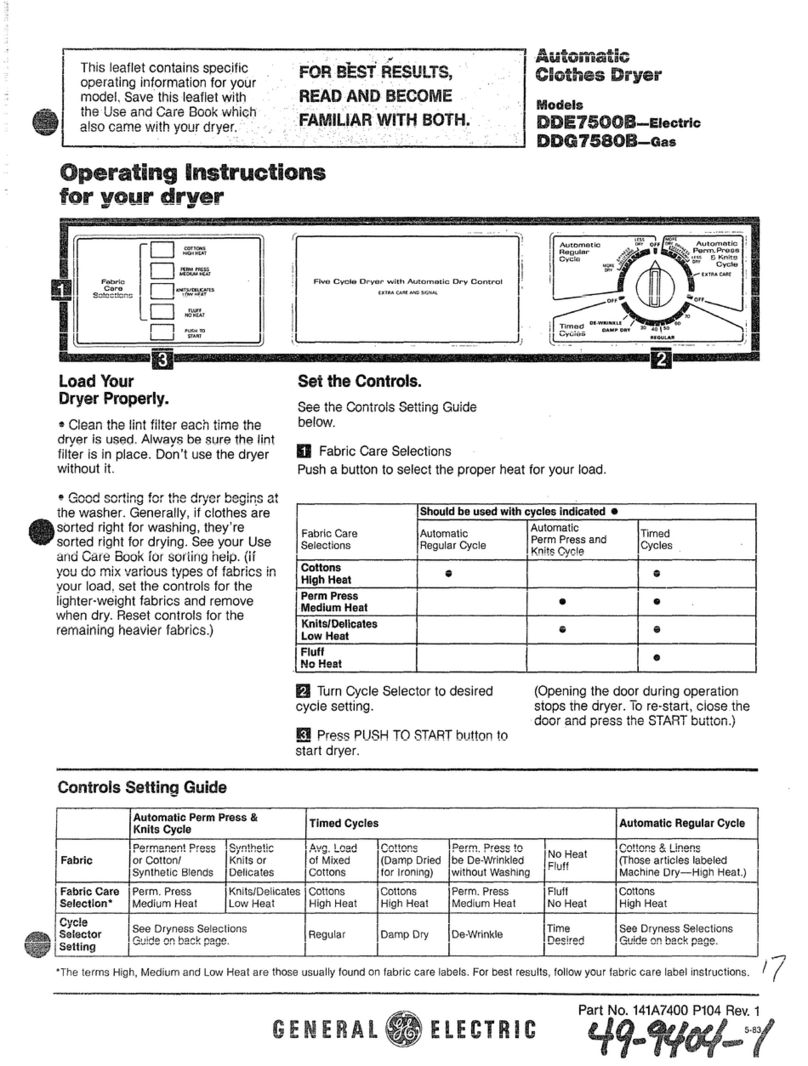

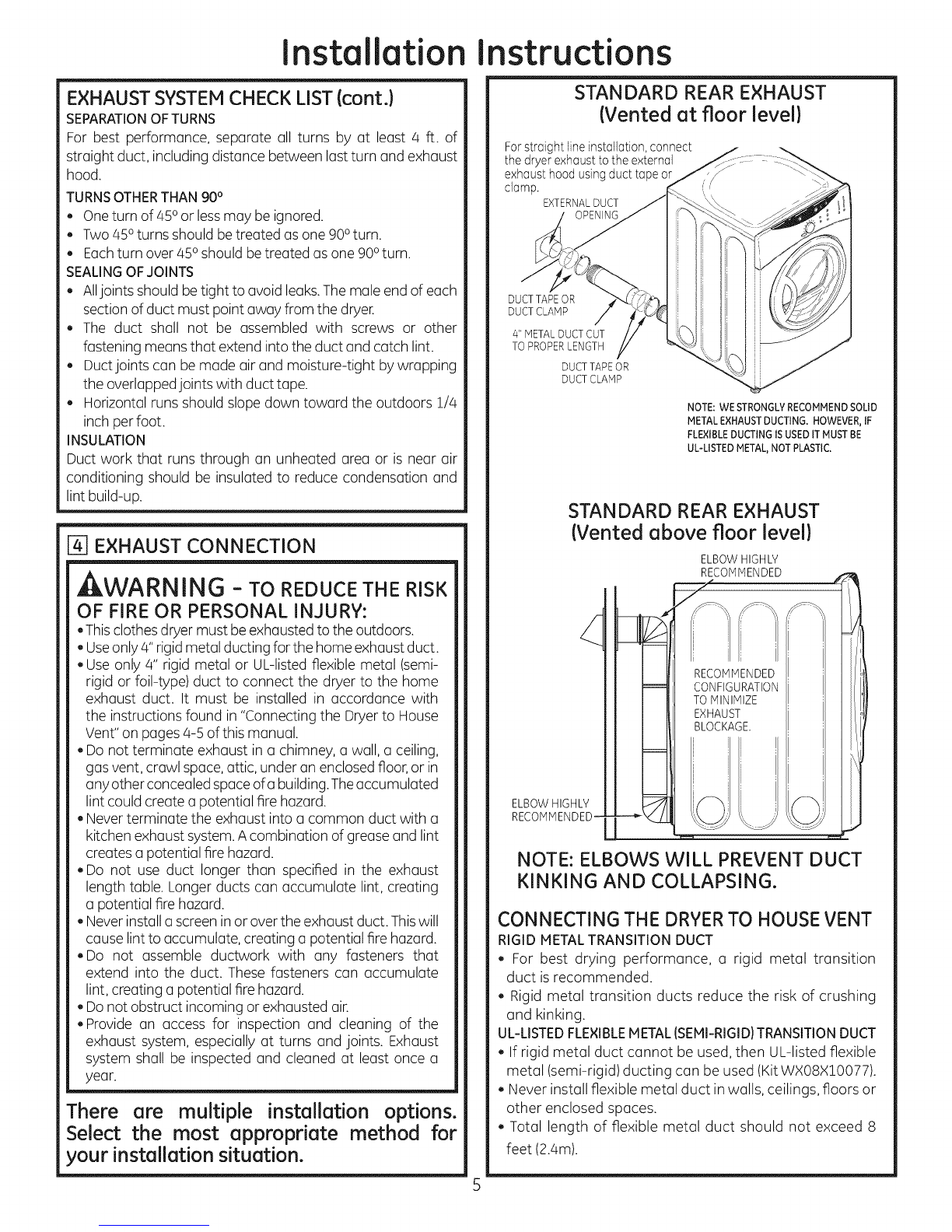

STANDARD REAR EXHAUST

(Vented atfloorlevel)

For straight line installation, connect

the dryer exhaust to the external

exhaust hood using duct tape or

clamp. EXTERNALDUCT

DUCT TAPEOR

DUCT CLAMP

4" METALDUCT CUT

TO PROPERLENGTH

DUCTTAPE OR

DUCTCLAMP

NOTE: WE STRONGLY RECOMMEND SOLID

METAL EXHAUST DUCTING. HOWEVER, IF

FLEXIBLEDUCTING ISUSED ITMUST BE

UL-LISTEDMETAL,NOT PLASTIC.

STANDARD REAR EXHAUST

(Vented above floorlevel)

ELBOWHIGHLY

RECOMMENDED-

ELBOWHIGHLY

RE_I If!

TOMINIMIZE _!1

EXHAUST: I,_,!i

BLOCKAGE. I I_l

i i I I i

NOTE: ELBOWS WILL PREVENT DUCT

KINKING AND COLLAPSING.

CONNECTING THE DRYERTO HOUSE VENT

RIGID METALTRANSITION DUCT

, For best drying performance, a rigid metal transition

duct isrecommended.

, Rigid metal transition ducts reduce the risk of crushing

and kinking.

UL-LISTEDFLEXIBLEMETAL (SEMI-RIGID}TRANSITIONDUCT

, If rigid metal duct cannot be used, then UL-listed flexible

metal (semi-rigid)ducting can be used (KitWXO8X10077).

, Never install flexible metal duct in walls, ceilings, floors or

other enclosed spaces.

, Total length of flexible metal duct should not exceed 8

feet (2.4m).