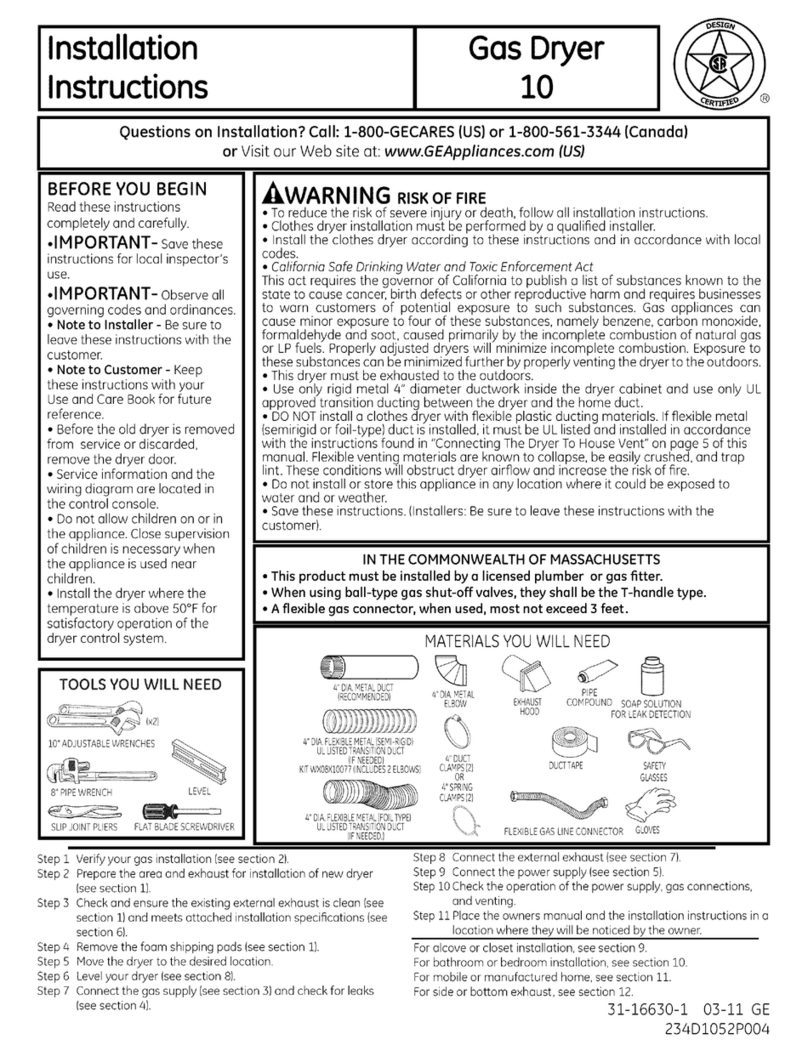

Installation

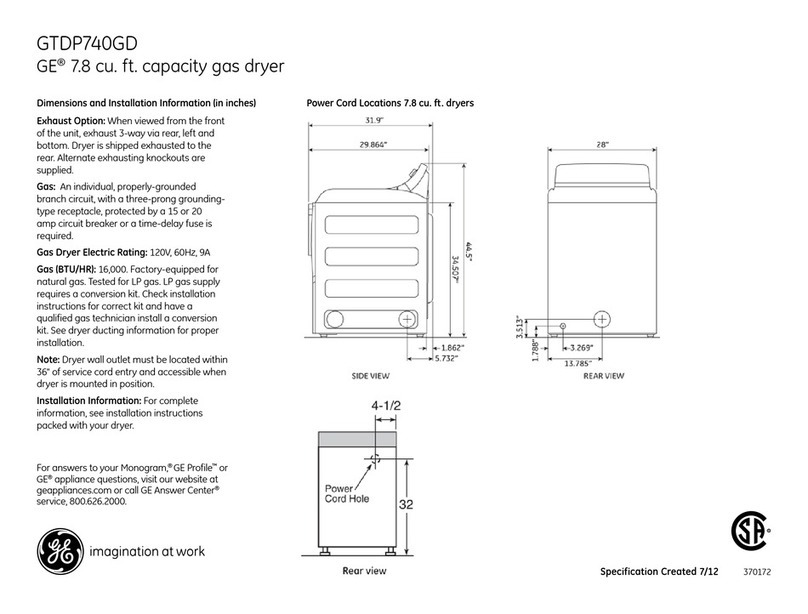

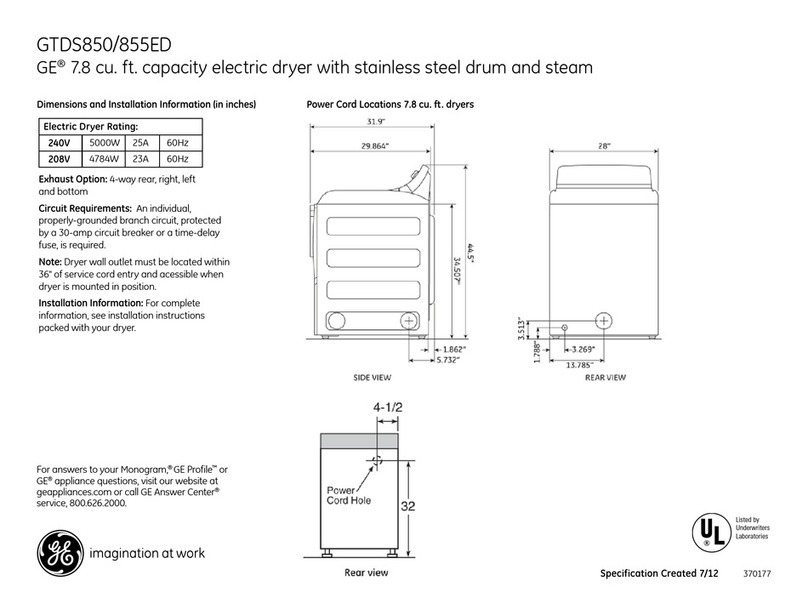

Instructions Gas

Dryer

Questions on Installation? Call: 1-800-GECARES (US)

or Visit our Web site at: www.GEAppliances.com (US)

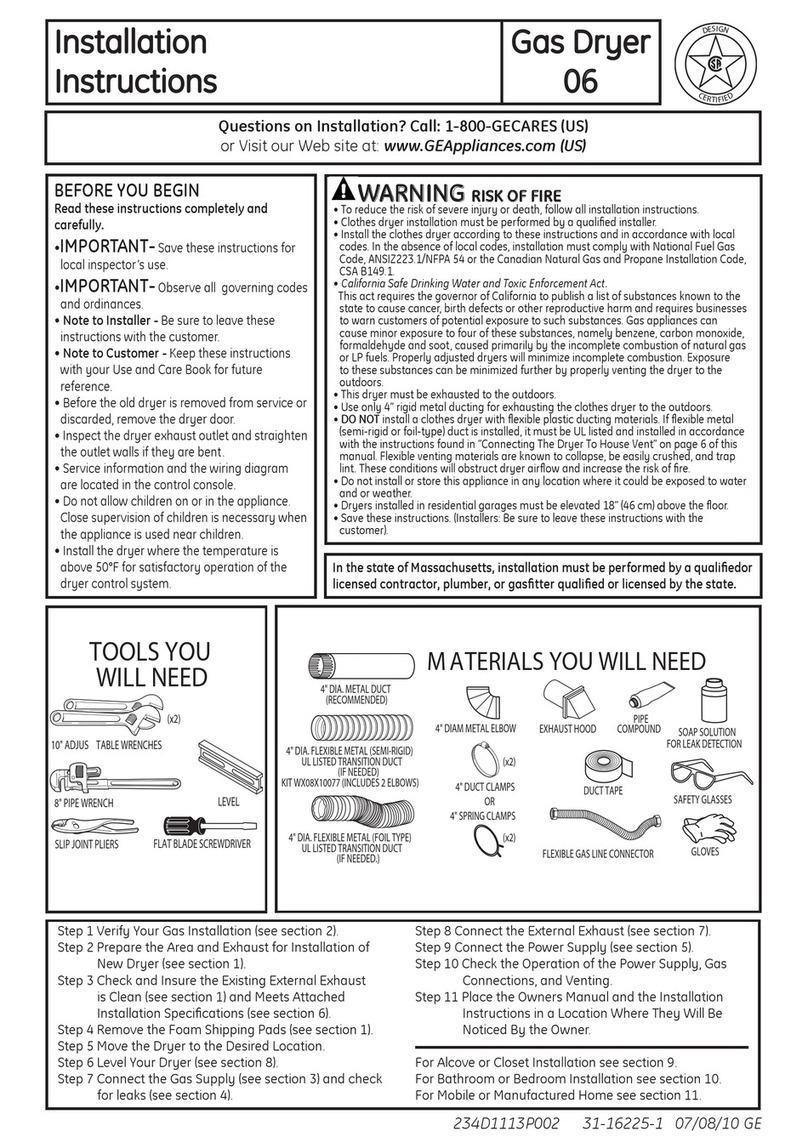

5Tore/.",#-%) -0re#($/,3),."

)&&)1&&#(-.&&.#)(#(-.,/.#)(-

5(-.&&."&)."-,3,),#(!.)."-e

#(-.,/.#)(-(#(),(1#."&)&)-

5California Safe Drinking Water and Toxic Enforcement Act

"#-.re+/#,-."!)0,(),) &# ),(#.)*/&#-"&#-.) -/-.(-%()1(.)."

-...)/-(,#,." .-),).",repr)/.#0",'(re+/#,-/-#(---

.) 1,( /-.)',- ) *).(.#& 2*)-/, .) -/" -/-.(- - **&#(- (

/-'#(),2*)-/re.) )/,) ."--/-.(-('&3(4(,)(')()2#

),'&"3(-))./-*,#',#&33."#()'*&.)'/-.#)() (./,&!-

), /&-Pr)*,&3$/-.,3,-1#&&'#(#'#4#()'*&.)'/-.#)(2*)-/,.)

."--/-.(-('#(#'#4 /,.",3pr)*,&30(.#(!.",3,.).")/.)),-

5"#-,3,'/-.2"/-..).")/.)),-

5-)(&3,#!#'.&6#'.,/.1),%#(-#.",3,#(.(/-)(&3

**,)0.,(-#.#)(/.#(!.1(.",3,(."")'/.

5#(-.&&&)."-,3,1#." &2#&*&-.#/.#(!'.,#&- &2#&'.&

-'#,#!#), )#&.3*/.#-#(-.&&#.'/-.&#-.(#(-.&&#(),(

1#."."#(-.,/.#)(- )/(#(“Connecting The Dryer To House Vent”)(*!-) ."#-

'(/&&2#&0(.#(!'.,#&-,%()1(.))&&*--#&3,/-"(.,*&#(.

"-)(#.#)(-1#&&)-.,/.,3,#, &)1(#(,-.",#-%) #,

5)().#(-.&&),-.),."#-**&#(#((3&).#)(1",#.)/&2*)-.)1.r

(),1.",

5),/.",#-%) -0,#($/,3),." )&&)1&&#(-.&&.#)(#(-.,/.#)(-

50."-#(-.,/.#)(-(Installers: Be sure to leave these instructions with the customer).

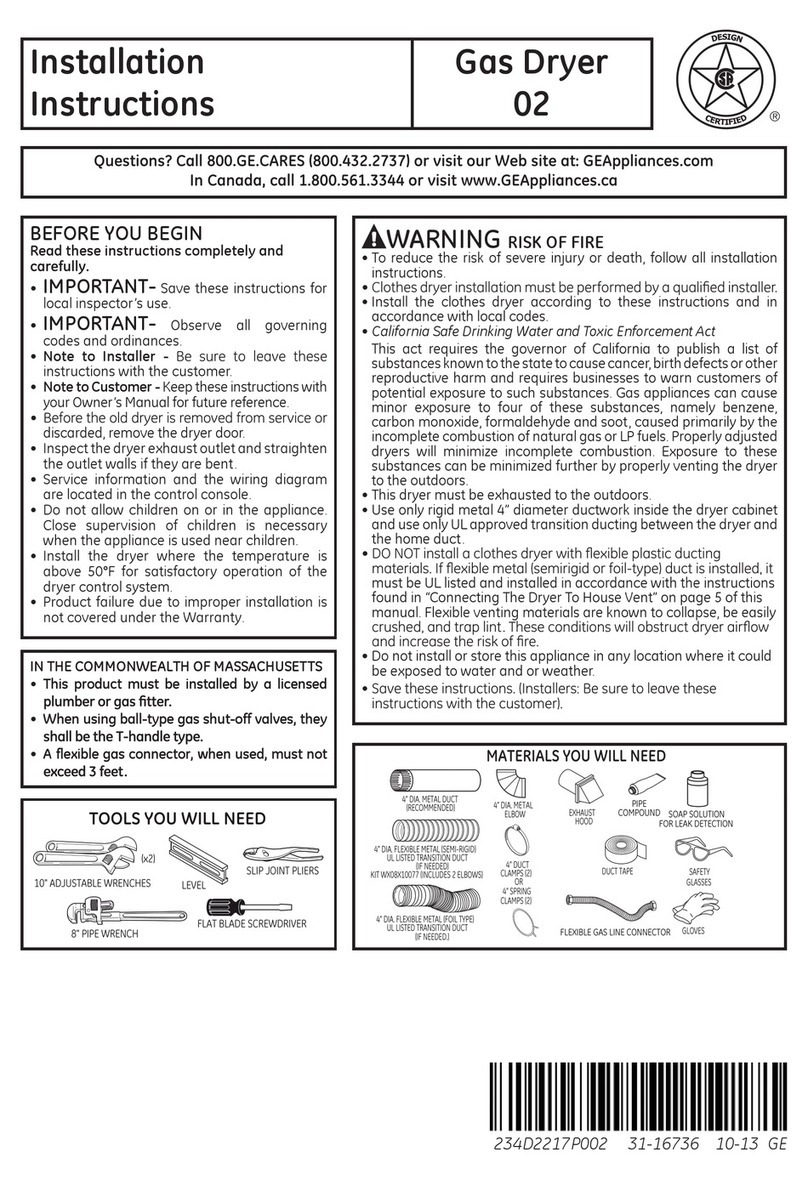

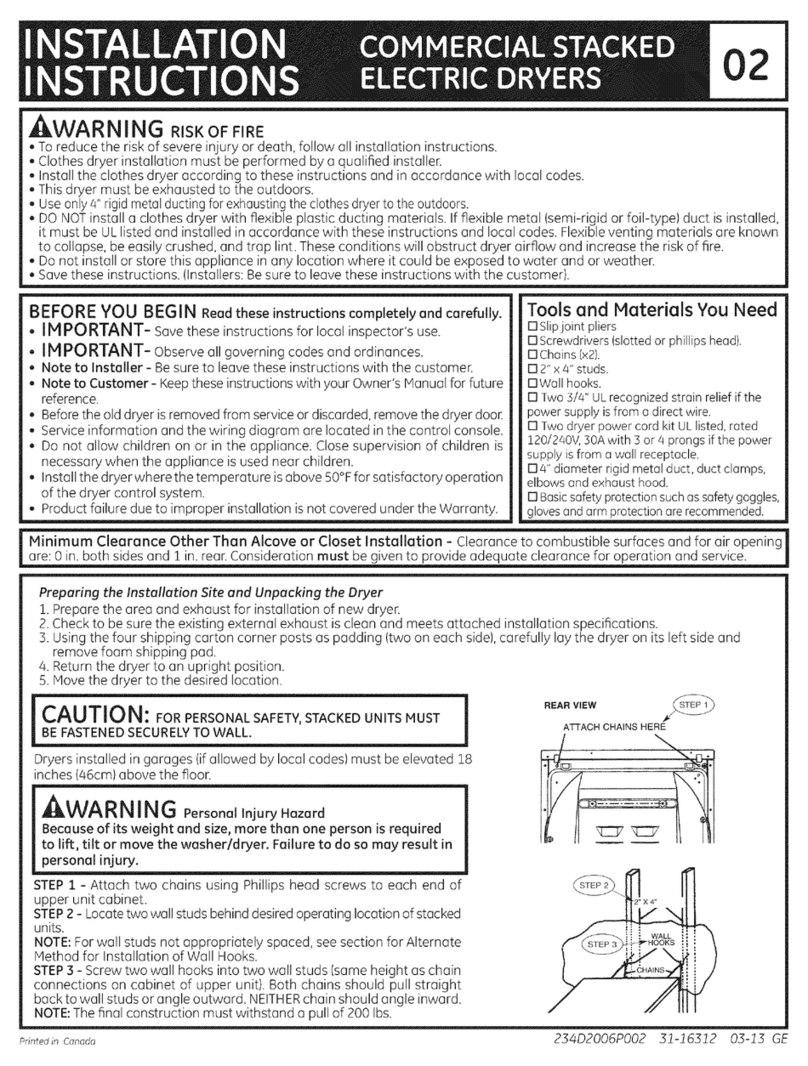

BEFORE YOU BEGIN

."-#(-.,/.#)(-

)'*&.&3(, /&&3

5

IMPORTANT-0."-

#(-.,/.#)(- ),&)&#(-*.),-/-

5IMPORTANT--,0&&

!)0,(#(!)-(),#((-

5Note to Installer --/re.)

&0."-#(-.,/.#)(-1#."."

/-.)',

5Note to Customer -*

."-#(-.,/.#)(-1#."3)/,Use

& Care Book ), /./,, ,(

5 ),.")&,3,#-,')0

,)'-,0#),#-,

re')0.",3,)),

5,0##( ),'.#)((."

1#,#(!#!,',&).#(

.")(.,)&)(-)&

5)().&&)1"#&,()(),#(

."**&#(&)--/*,0#-#)(

) "#&,(#-(--,31"(."

**&#(#-/-(,"#&,(

5(-.&&.",3,1"re."

.'*,./re#-)07 ),

-.#- .),3)*,.#)() ."

,3,)(.,)&-3-.'

234D1753P002 Rev. 3 31-16699

Fire Hazard

WARNING

This is the safety alert symbol. This symbol alerts you to

potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and the word

´'$1*(5µ´:$51,1*µRU´&$87,21µ7KHVHZRUGVDUHGH¿QHGDV

Indicates a hazardous

situation which, if not

avoided, will result in death

or serious injury.

Indicates a hazardous

situation which, if not

avoided, could result in

death or serious injury.

Indicates a hazardous

situation which, if not

avoided, could result in

minor or moderate injury.

DANGE

CAUTION

WARNING

In the state of Massachusetts:

Installation must be performed by a qualified or licensed contractor,

plumber or gasfitter qualified or licensed by the state.

NOTE: Installation and service of this dryer requires basic mechanical and

HOHFWULFDOVNLOOV,WLV\RXUUHVSRQVLELOLW\WRFRQWDFWDTXDOL¿HGLQVWDOOHUWR

make the electrical connections.

No washer can completely remove oil.

DO NOT dry anything that has ever had any type of oil

on it (including cooking oils).

Items containing foam, rubber or plastic must be dried

on a clothesline or by using an Air Dry cycle.

)DLOXUHWRIROORZWKLVLQVWUXFWLRQVFDQUHVXOWRQGHDWKRU¿UH

Plug into a grounded 3 prong outlet.

DO NOT remove ground prong.

DO NOT use an adapter.

DO NOT use an extension cord.

)DLOXUHWRGRVRFDQUHVXOWLQGHDWK¿UHRUHOHFWULFDOVKRFN

.HHSÀDPPDEOHPDWHULDOVDQGYDSRUVVXFKDV

gasoline, away from dryer.

3ODFHGU\HUDWOHDVWLQFKHVFPDERYHWKHÀRRU

for a garage installation.

)DLOXUHWRGRVRFDQUHVXOWLQGHDWKH[SORVLRQRU¿UH.

Fire Hazard

WARNING

DO NOT allow children on or in the appliance. Close

supervision of children is necessary when the appliance

is used near children.