6 FP400 Series Installation Manual

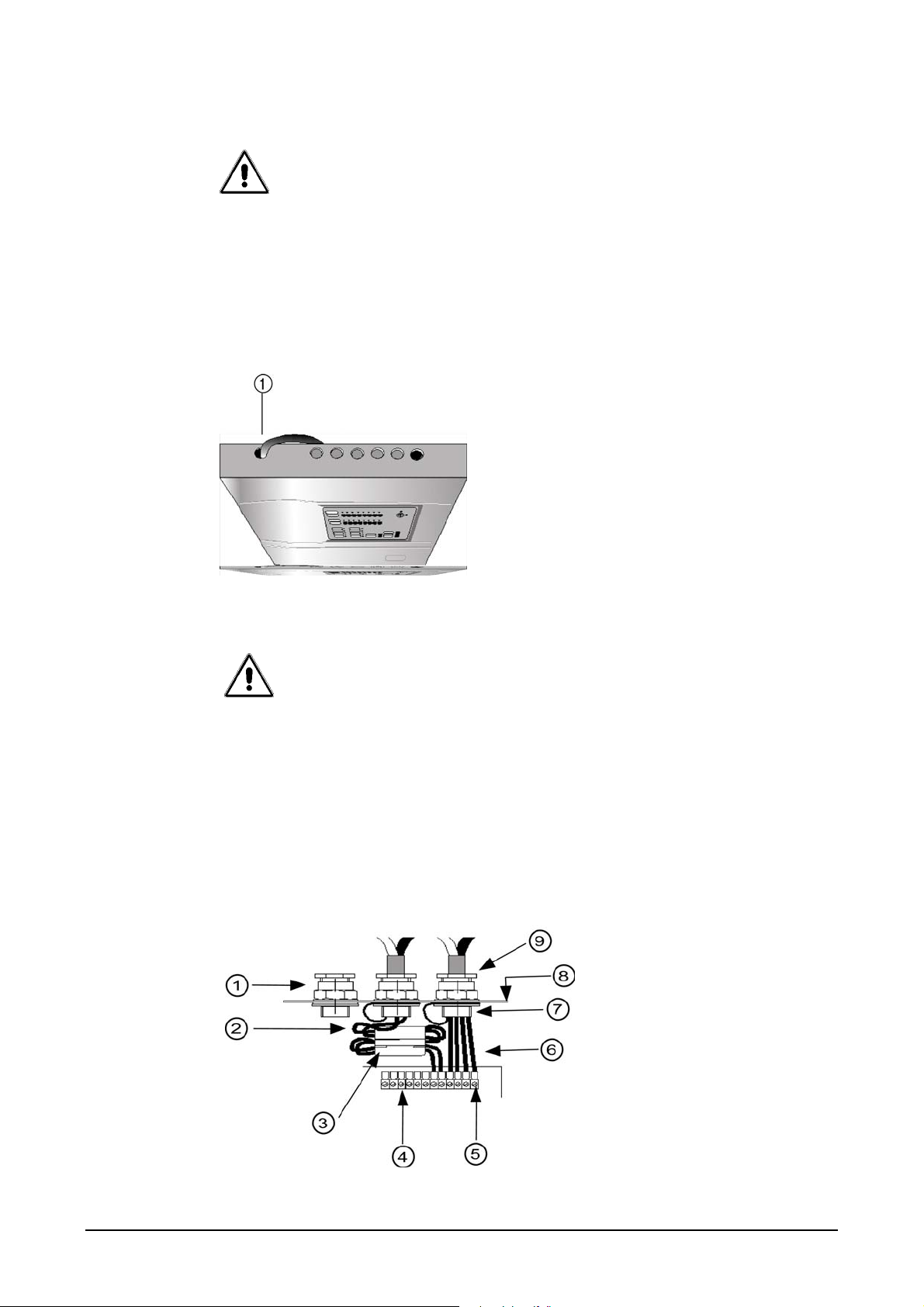

1. Mains connector (110 VAC / 230

VAC)

2. Zones connectors (from 2 to 4, or 8,

12 or 16, depending on fire panel

model)

3. Output connectors: Auxiliary 24 VDC,

Fire and Fault Relays and Sounders

4. 24V Resetable Output - 0.1 A fuse

5. Sounder output #1 - 0.3 A fuse

6. Auxiliary 24 VDC Output - 0.3 A fuse

7. Sounder output #2 - 0.3 A fuse

8. Configuration DIP switch

9. 5 A battery fuse

10.Transformer connector

11.Front panel connector

12.Master module output connector

13.24 V battery connector

Independent of the number of zones, all FP400 panels have the following common

functionality:

Enable / Disable per zone.

Test per zone.

Activation / Silencing of sounders.

Programming of sounder delays.

Supervision of main power, batteries and outputs.

Differentiation of manual call point and/or detector alarm signal within the same zone.

Remote reset optional operating mode.

Active end-of-line optional operating mode.

Relay master modules (optional)

Sounder master modules (optional)

1.4.1 Inputs/Outputs

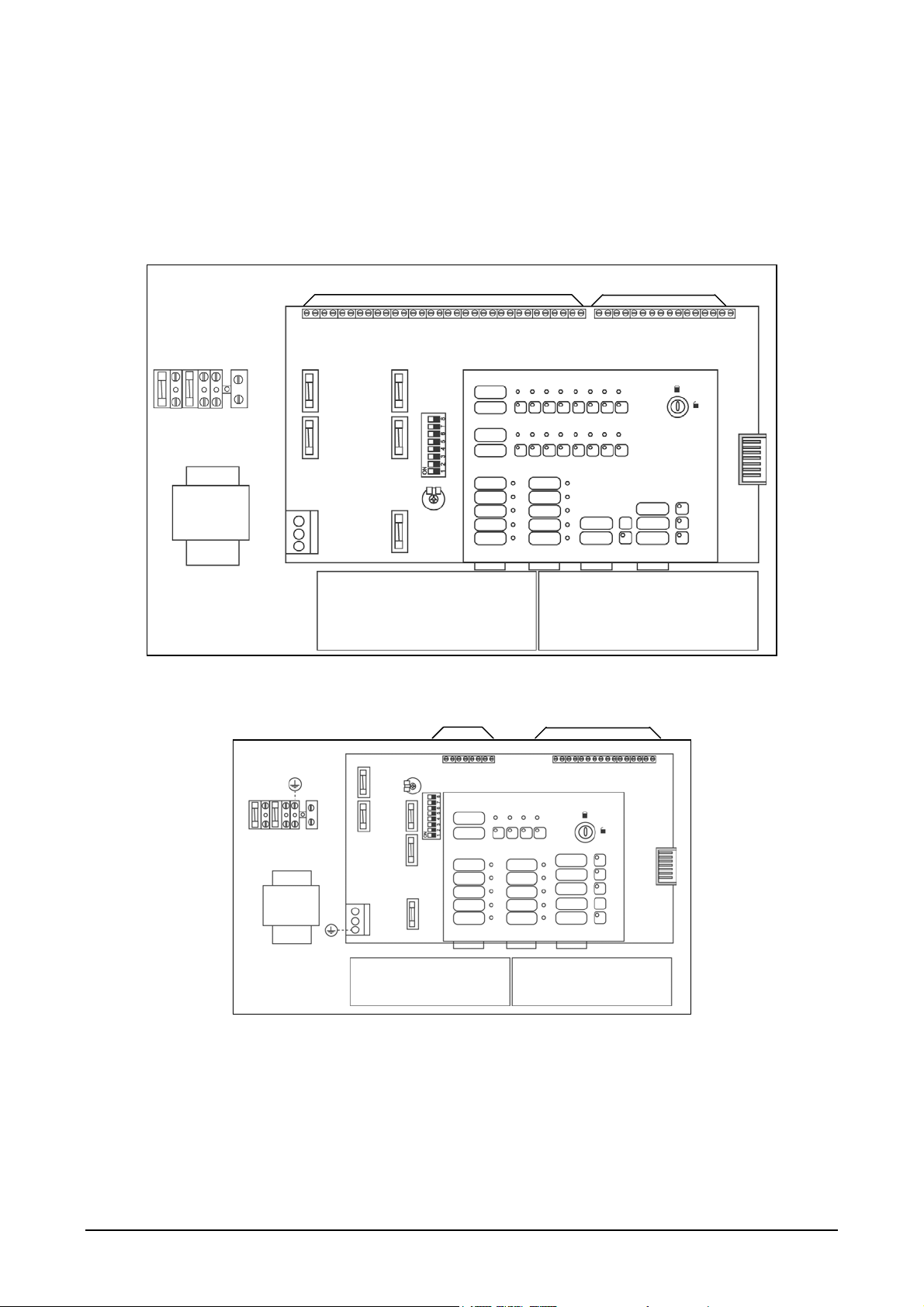

Figure 3: Inputs/outputs of FP400 fire panels

1. Zones input

2. Class change input.

3. Auxiliary 24 VDC output.

4. General alarm and fault relay (potential

free)

5. 24 VDC resetable output.

6. Two supervised 24 VDC sounder

outputs, with programmable delay.

1

23

4

5

6

+

+ + ++ +

++

+